Alloy used for preparing hydrogen gas and method of producing the same

A technology of alloy and hydrogen, which is applied in the field of material preparation and hydrogen preparation, can solve environmental pollution, safety and other problems, and achieve the effects of safe transportation, wide source of raw materials, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The raw materials for the preparation of the above-mentioned alloys are lithium and aluminum, which can be in the form of powder, flakes, granules and strips, or ingots; 1-x Li x Proportioning is carried out to form a mixture, wherein 0.5<x<0.9, so that the mass percentage of lithium is 20%-70%, and the mass percentage of aluminum is 30%-80%. Batching takes place in a vacuum glove box with water content below 90ppm and oxygen content below 100ppm.

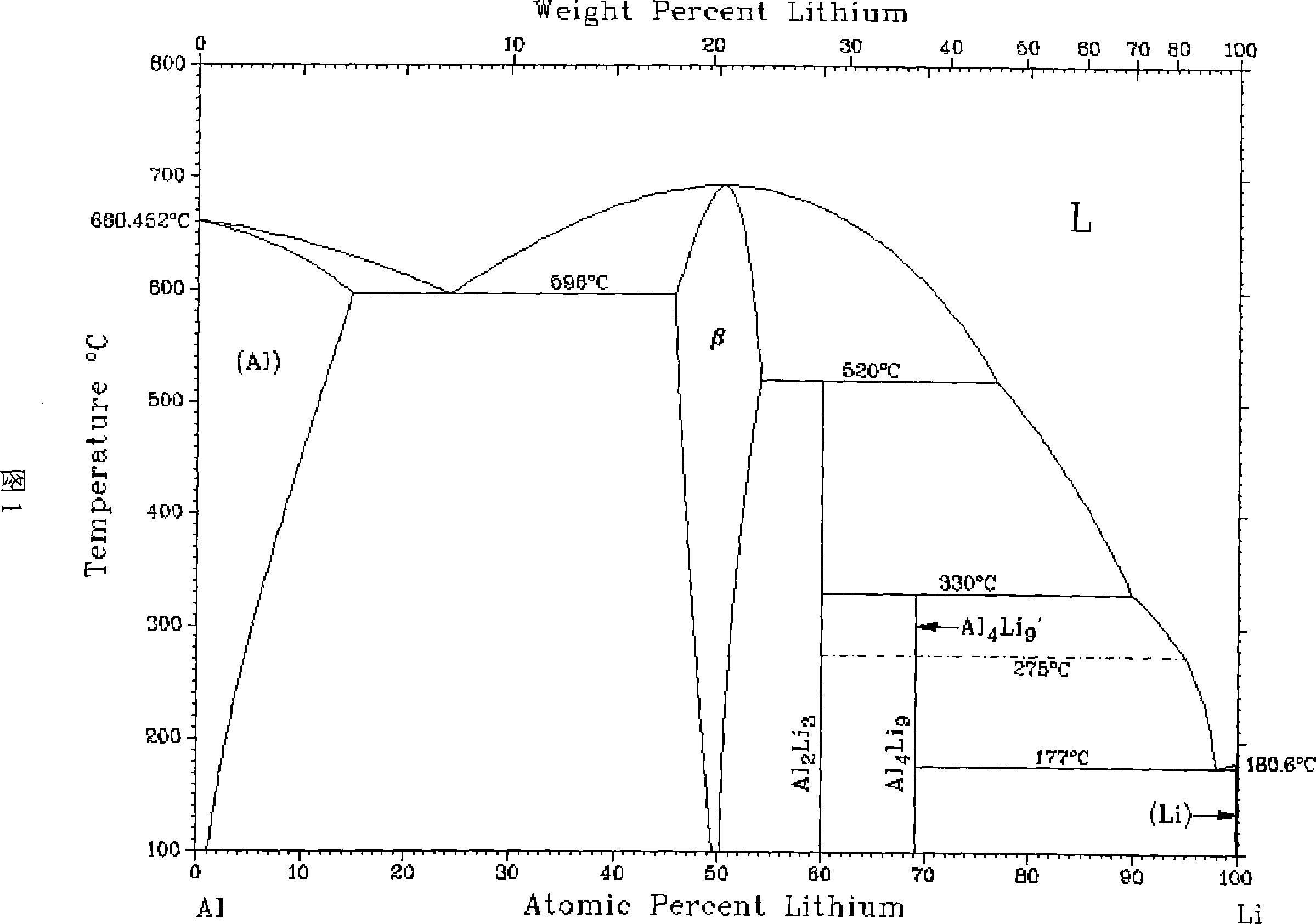

[0035]The above-mentioned alloy is prepared by vacuum smelting method, which is characterized in that the above-mentioned mixed raw materials of lithium and aluminum are smelted under vacuum conditions, and the melting temperature is higher than the melting point of pure aluminum at 680°C. , the specific holding temperature is slightly higher than the liquidus temperature of the Li-Al phase diagram, so that lithium and aluminum can fully react to form β-phase AlLi and triangular rhomboid Al 2 Li 3 and monoclinic Al 4 Li ...

Embodiment 1

[0038] The raw material of lithium metal is commercially available battery grade lithium metal, in the form of flakes Φ25×1mm 3 , with a purity of 99.99%, vacuum-packed in aluminum-plastic bags. Metal aluminum is common aluminum ingot with a purity of 99%. The aluminum ingot is shredded before batching to facilitate weighing and mixing. The raw material ingredients are proportioned according to AlLi to form a mixture, the mass percentage of lithium is 20%, and the mass percentage of aluminum is 80%. The ingredients are operated in a vacuum glove box with dry water and low oxygen content, and the prepared raw materials are sealed in vacuum bags for use.

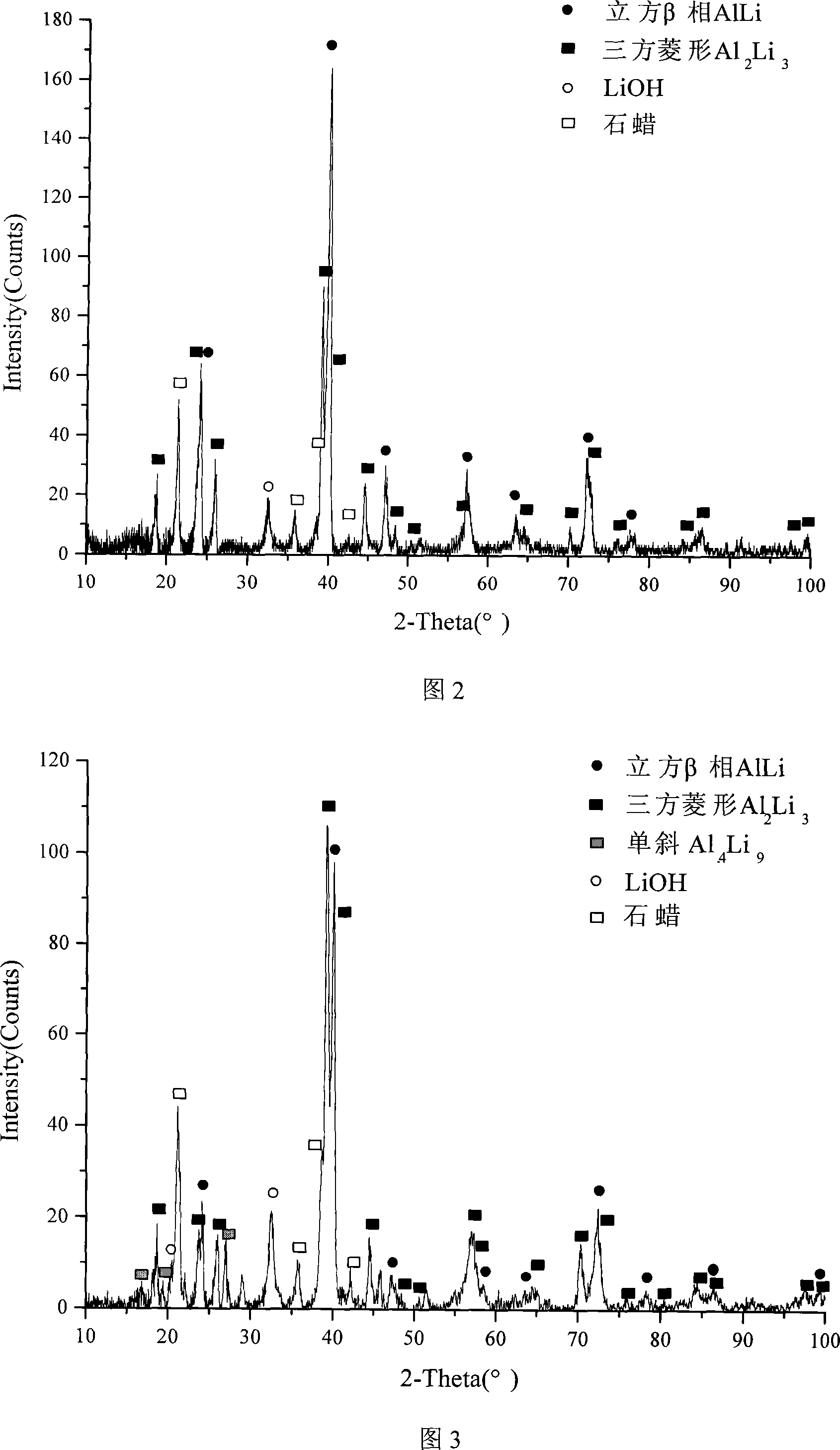

[0039] The above-mentioned mixed raw materials of lithium and aluminum are melted under vacuum conditions, the pressure is 100Pa, and the melting temperature is 700°C. After the melting is complete, the temperature is lowered to 680°C to keep the alloy melt for 20 minutes, so that the lithium and aluminum can fully react and ...

Embodiment 2

[0043] The raw material of lithium metal is commercially available battery grade lithium metal, in the form of flakes Φ25×1mm 3 , with a purity of 99.99%, vacuum-packed in aluminum-plastic bags. Metal aluminum is common aluminum ingot with a purity of 99%. The aluminum ingot is shredded before batching to facilitate weighing and mixing. Raw material ingredients according to Al 2 Li 3 Proportioning is carried out to form a mixture, the mass percentage of metal lithium is 28%, and the mass percentage of metal aluminum is 72%. The ingredients are operated in a vacuum glove box with dry water and low oxygen content, and the prepared raw materials are sealed in vacuum bags for use.

[0044] The above-mentioned mixed raw materials of lithium and aluminum are melted under vacuum conditions, the pressure is 100Pa, and the melting temperature is 700°C. After the melting is complete, the temperature is lowered to 680°C to keep the alloy melt for 20 minutes, so that the lithium and al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com