Device and technique of producing liquid ammonia by coke oven gas and methanol relief gas

A methanol degassing and coke oven gas technology, which is applied in the chemical industry, can solve the problems of obsolete equipment, cumbersome process, and low output, and achieve the effect of saving energy and improving the purity of hydrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

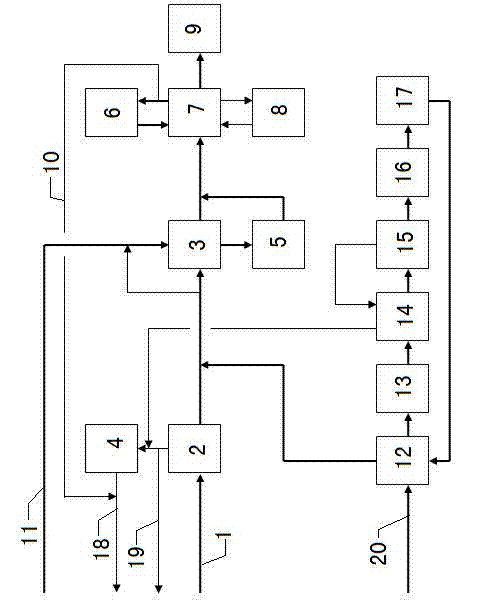

[0018] Such as figure 1 Shown, a kind of equipment that produces liquefied ammonia with coke oven gas, methanol purge gas, comprises methanol purge gas raw material pipeline 1, coke oven gas raw material pipeline 20, nitrogen raw material pipeline 11, described methanol purge gas raw material pipeline 1 is connected to the purge gas hydrogen extraction system 2, the purge gas hydrogen extraction system 2 is connected to the desorption gas compressor 4 and the hydrogen-nitrogen combined compressor 3 through pipelines, and the hydrogen-nitrogen combined compressor 3 is connected to the deoxygenation drying device through pipelines 5. The nitrogen raw material pipeline 11 is connected to the ammonia synthesis system 7, and the ammonia synthesis system 7 is connected to the ammonia synthesis cycle machine 6, the ice machine system 8, and the liquid ammonia spherical tank 9 through pipelines respectively; the coke oven gas raw material pipeline 20 Connected with the combined compre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com