Method of producing hydrogen energy through physical ball milling of metal powder

A metal powder and hydrogen energy technology, applied in the field of hydrogen production, can solve the problems of high equipment requirements, high alloy material preparation cost and high preparation cost, and achieve the effects of high equipment requirements, low preparation cost and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

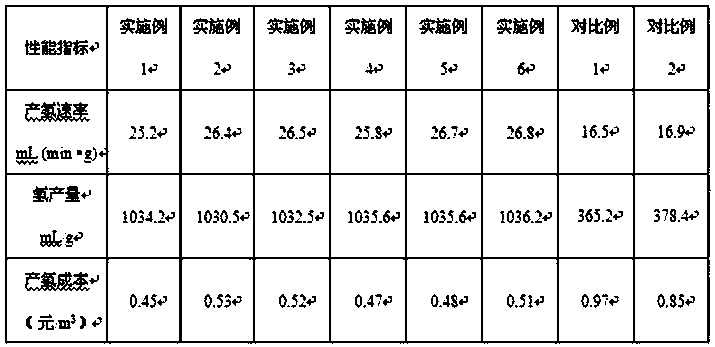

Examples

Embodiment 1

[0029] Put the metal powder in a vacuum ball mill, add a small amount of metal chloride aqueous solution and additives, and carry out wet ball milling under the protection of hydrogen. The oxide layer or the hydroxide formed by the reaction is peeled off by the metal powder under the action of ball milling, exposing more Multiple active sites, thereby increasing the yield and reaction rate of hydrogen production.

[0030] The metal powder is aluminum powder. The metal chloride is aluminum chloride. The mass concentration of the metal chloride aqueous solution is 30%. The additive is copper. The vacuum degree of the vacuum ball mill is 0.001Pa. The balls of the vacuum ball mill are zirconium balls, and the ball-to-material ratio is 2:1. The rotating speed of ball milling is 250r / min, and the ball milling time is 90min. In the wet ball milling system, there are 72 parts by weight of metal powder, 20 parts by weight of metal chloride aqueous solution, and 8 parts by weight o...

Embodiment 2

[0032] Put the metal powder in a vacuum ball mill, add a small amount of metal chloride aqueous solution and additives, and carry out wet ball milling under the protection of hydrogen. The oxide layer or the hydroxide formed by the reaction is peeled off by the metal powder under the action of ball milling, exposing more Multiple active sites, thereby increasing the yield and reaction rate of hydrogen production.

[0033] The metal powder is aluminum powder. The metal chloride is magnesium chloride. The mass concentration of the metal chloride aqueous solution is 40%. The additive is strontium carbonate. The vacuum degree of the vacuum ball mill is 0.1Pa. The balls of the vacuum ball mill are zirconium balls, and the ball-to-material ratio is 2:1. The rotating speed of ball milling is 250r / min, and the ball milling time is 60min. In the wet ball milling system, 82 parts by weight of metal powder, 15 parts by weight of metal chloride aqueous solution, and 3 parts by weight...

Embodiment 3

[0035] Put the metal powder in a vacuum ball mill, add a small amount of metal chloride aqueous solution and additives, and carry out wet ball milling under the protection of hydrogen. The oxide layer or the hydroxide formed by the reaction is peeled off by the metal powder under the action of ball milling, exposing more Multiple active sites, thereby increasing the yield and reaction rate of hydrogen production.

[0036]The metal powder is aluminum powder. The metal chloride is magnesium chloride. The mass concentration of the metal chloride aqueous solution is 32%. The additive is calcium sulfate. The vacuum degree of the vacuum ball mill is 0.01Pa. The balls of the vacuum ball mill are zirconium balls, and the ball-to-material ratio is 2:1. The rotating speed of the ball mill was 280r / min, and the ball milling time was 80min. In the wet ball milling system, 77 parts by weight of metal powder, 15 parts by weight of metal chloride aqueous solution, and 8 parts by weight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com