Process for producing arene through continuous reforming

A process method and aromatics technology, applied in the field of continuous reforming technology to produce aromatics, can solve the problems of high consumption of chemicals, low product yield, and solid waste generation, so as to improve reaction efficiency, reduce investment and operating costs, and improve economic efficiency. benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

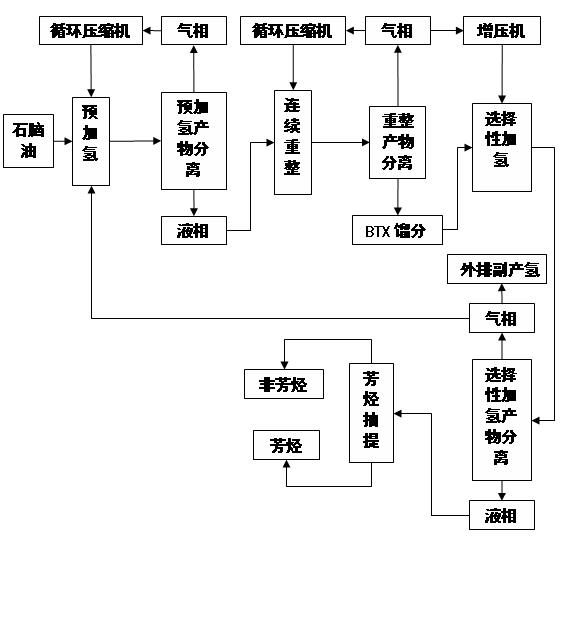

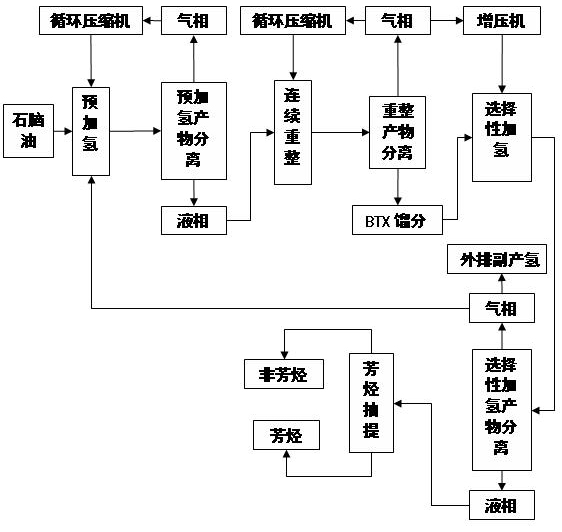

Image

Examples

Embodiment 1~3

[0035] Adopt the method of the present invention, raw material and hydrogen pass through bed I and bed II successively under hydrogenation condition, bed I is the mixed catalyst bed of Mo-Ni type catalyst and Mo-Co type catalyst, bed II is W- Mo-Ni-Co type catalyst.

[0036] Different catalyst ratios can be used to effectively process different types of raw materials, so that the oil produced by hydrogenation meets the requirements of catalytic reforming feed. The specific process conditions and reaction results are shown in Table 3.

[0037] Table 3 Main process conditions and properties of hydrogenated oil in Examples 1-3.

[0038] Example

Embodiment 4

[0040] According to the catalyst compounding scheme in Example 1, different raw materials can be processed at a higher space velocity, and qualified catalytic reforming raw materials can be obtained.

Embodiment 5

[0049] The hydrogenation products of the three raw materials in Example 4 were used for catalytic reforming, and at least part of the paraffins and naphthenes were converted into aromatics. The catalytic reforming is a continuous reforming experimental device. The continuous reforming uses four moving bed reactors and a catalyst regeneration system. The catalytic reforming catalyst is the RC-011 continuous reforming catalyst developed by the Sinopec Petrochemical Research Institute. The four reaction The effective reaction volume of the device is 10:15:25:50. Reaction pressure 0.35MPa, hydrogen oil ratio 700Nm 3 .m -3 , volumetric space velocity 2.0h -1 , the average bed reaction temperature is 508°C, and the reaction results of different raw materials are shown in Table 5.

[0050] Table 5 Experimental results of catalytic reforming of different hydrogenated naphthas.

[0051] raw material

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com