Method for recovering ethylene and hydrogen from refinery dry gases by combining cold oil absorption and membrane separation

A cold oil absorption and refinery dry gas technology, which is applied in absorption purification/separation, gas mixture processing, hydrogen separation, etc., can solve the problems of low yield, inability to realize refinery dry gas, low purity, etc., and achieve improvement Purity, lower operating costs, less interference effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

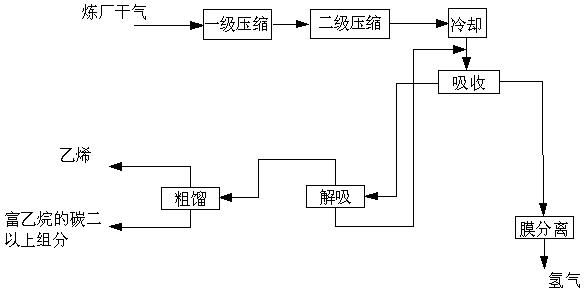

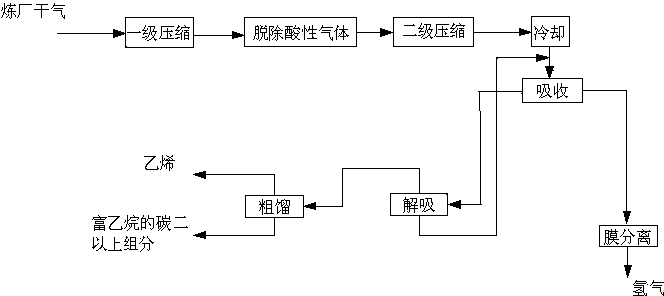

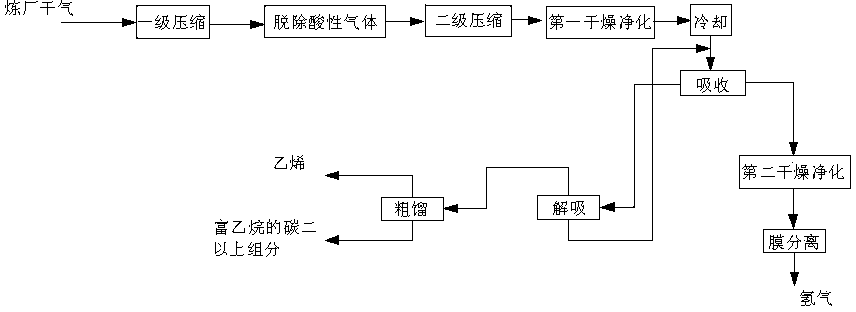

[0033] Such as figure 1 As shown, the method for the refinery dry gas cooling oil absorption, membrane separation and combined recovery of ethylene and hydrogen described in this embodiment comprises the following steps:

[0034] (1) Compression and boosting: the refining process with hydrogen content of 18.5%, ethane content of 14.5%, ethylene content of 16%, methane content of 30%, nitrogen content of 14.5%, carbon dioxide and above components content of 3.5%, acid gas content of 3% After the dry gas (volume ratio) of the plant is compressed by the first stage and the second stage, the pressure is increased to 2.0MPa;

[0035] (2) Cold oil absorption: Cool the refinery dry gas boosted in step (1), and then send it to the absorption tower, the top of the absorption tower discharges non-condensable gas rich in methane, hydrogen and nitrogen, and the bottom of the absorption tower Outflow of absorbed carbon 2 and above components;

[0036] (3) Membrane separation: The non-con...

Embodiment 2

[0041] Such as figure 1 As shown, the method for the refinery dry gas cooling oil absorption, membrane separation and combined recovery of ethylene and hydrogen described in this embodiment comprises the following steps:

[0042] (1) Compression and boosting: the refining process with hydrogen content of 46.5%, ethane content of 12.4%, ethylene content of 6.0%, methane content of 20%, nitrogen content of 9.5%, carbon dioxide and above components content of 2.2%, and acid gas content of 3.2% After the plant dry gas (volume ratio) is compressed by the first stage and the second stage, the pressure is increased to 2.8MPa;

[0043] (2) Cold oil absorption: Cool the refinery dry gas boosted in step (1), and then send it to the absorption tower, the top of the absorption tower discharges non-condensable gas rich in methane, hydrogen and nitrogen, and the bottom of the absorption tower Outflow of absorbed carbon 2 and above components;

[0044] (3) Membrane separation: The non-conden...

Embodiment 3

[0049] Such as figure 1 As shown, the method for the refinery dry gas cooling oil absorption, membrane separation and combined recovery of ethylene and hydrogen described in this embodiment comprises the following steps:

[0050] (1) Compression and boosting: the refining process with hydrogen content of 18.5%, ethane content of 14.5%, ethylene content of 16%, methane content of 30%, nitrogen content of 14.5%, carbon dioxide and above components content of 3.5%, acid gas content of 3% After the plant dry gas (volume ratio) is compressed by the first stage and the second stage, the pressure is increased to 3.6MPa;

[0051] (3) Membrane separation: The non-condensable gas discharged from the top of the absorption tower in step (2) enters the membrane separation system under the condition of 3.6 MPa pressure and normal temperature, and the product hydrogen is obtained on the permeation side of the membrane. The purity of hydrogen is 99%, which is very Permeate returns to step (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com