Supported type nickel catalyst for producing hydrogen via decomposition of ammonia and preparation method

A catalyst, catalytic reforming technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the secondary pollution of the environment, low hydrogen purity, process flow Long and other problems, to achieve the effect of protecting the environment, less equipment investment, and shortening the process

Inactive Publication Date: 2009-01-28

EAST CHINA UNIV OF SCI & TECH

View PDF1 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0010] The technical problem to be solved by the present invention is to overcome the shortcomings of the existing catalytic hydrogen production process for steam catalytic reforming, such as the relatively long process flow, the low purity of hydrogen produced, and secondary pollution to the environment, and provides Catalyst for catalytic hydrogen production and method for catalytic hydrogen production

Method used

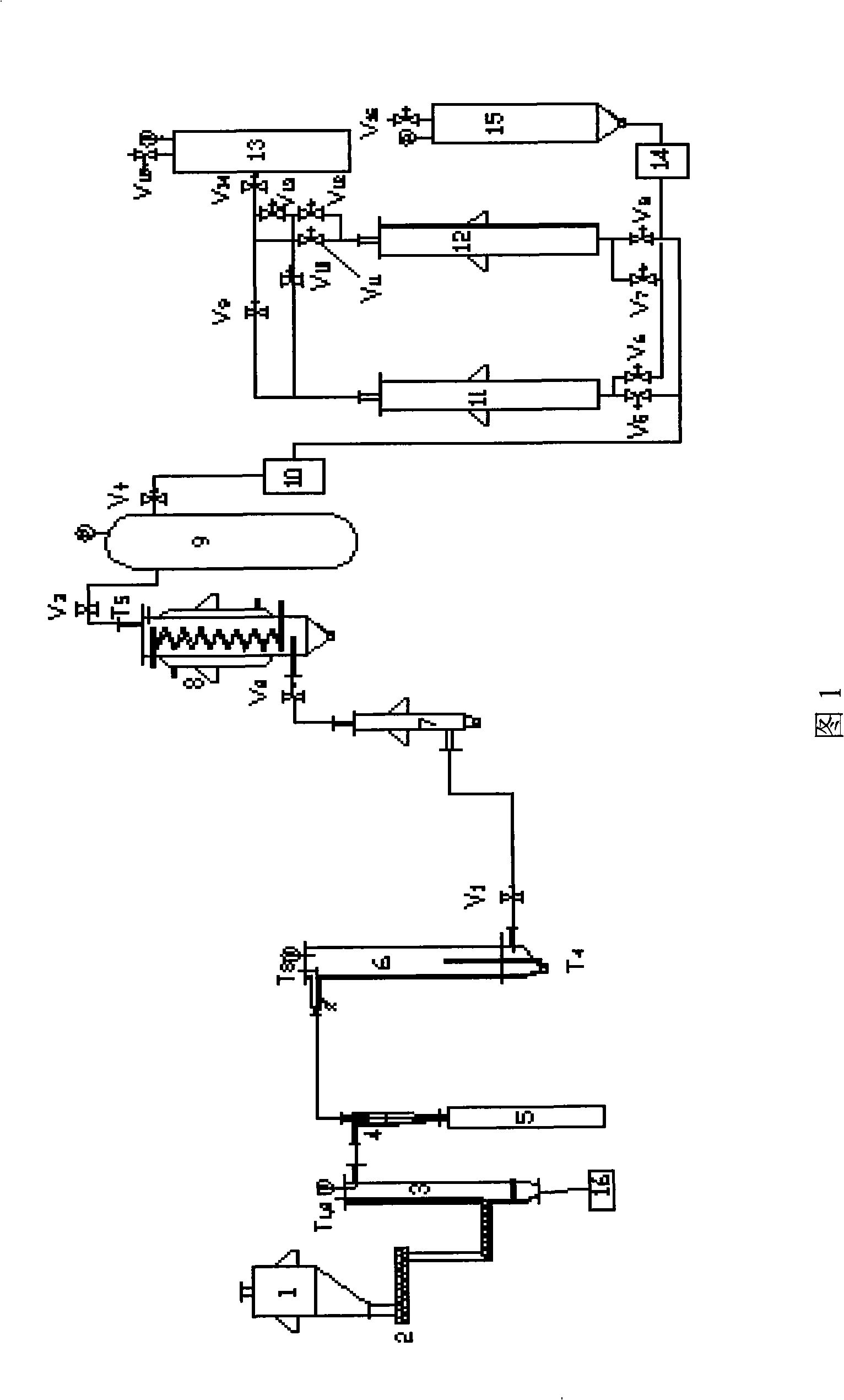

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0056] YWC95

Embodiment 2

[0058] YWC95

Embodiment 3

[0060] YWC95

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to a catalyst applied to catalyst hydrogen generation and a method of the catalyst hydrogen generation. The catalyst comprises industrial catalyst YWC-95 and CaO. The catalyst is used in steam catalytic reforming reaction of the catalyst hydrogen generation, the technical process of the catalyst hydrogen generation is shortened, hydrogen purity and production rate are improved and no secondary pollutant is generated in the production process.

Description

technical field [0001] The invention relates to a catalyst and a method, in particular to a catalyst for catalytic hydrogen production and a method for catalytic hydrogen production. Background technique [0002] Hydrogen energy is generally considered to be the most ideal pollution-free green energy in the new century, but there is no large amount of hydrogen energy in nature itself. The main source of hydrogen energy is obtained from other energy sources through technical means, and steam catalytic reforming It is one of the important process routes. [0003] Searching for catalysts with good catalytic effect, high mechanical strength, low cost and easy availability is the top priority of the steam catalytic reforming process. [0004] Catalysts commonly used in steam catalytic reforming in industry include Cu-based, Cr-Zn-based, and Ni-based catalysts, among which Ni-based catalysts are the most common. Among them, the commercial Z409 naphtha hydrocarbon conversion hydr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01J23/78C01B3/22

Inventor 张尤华颜涌捷张素平许庆利王复辛善志戎欣黄清发

Owner EAST CHINA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com