Catalyst and device for preparing high-purity hydrogen through electrocatalytic water-vapor shift reaction

A technology of water vapor shift and catalyst, applied in the field of energy chemistry, to achieve the effects of mild reaction conditions, good stability, and large hydrogen production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

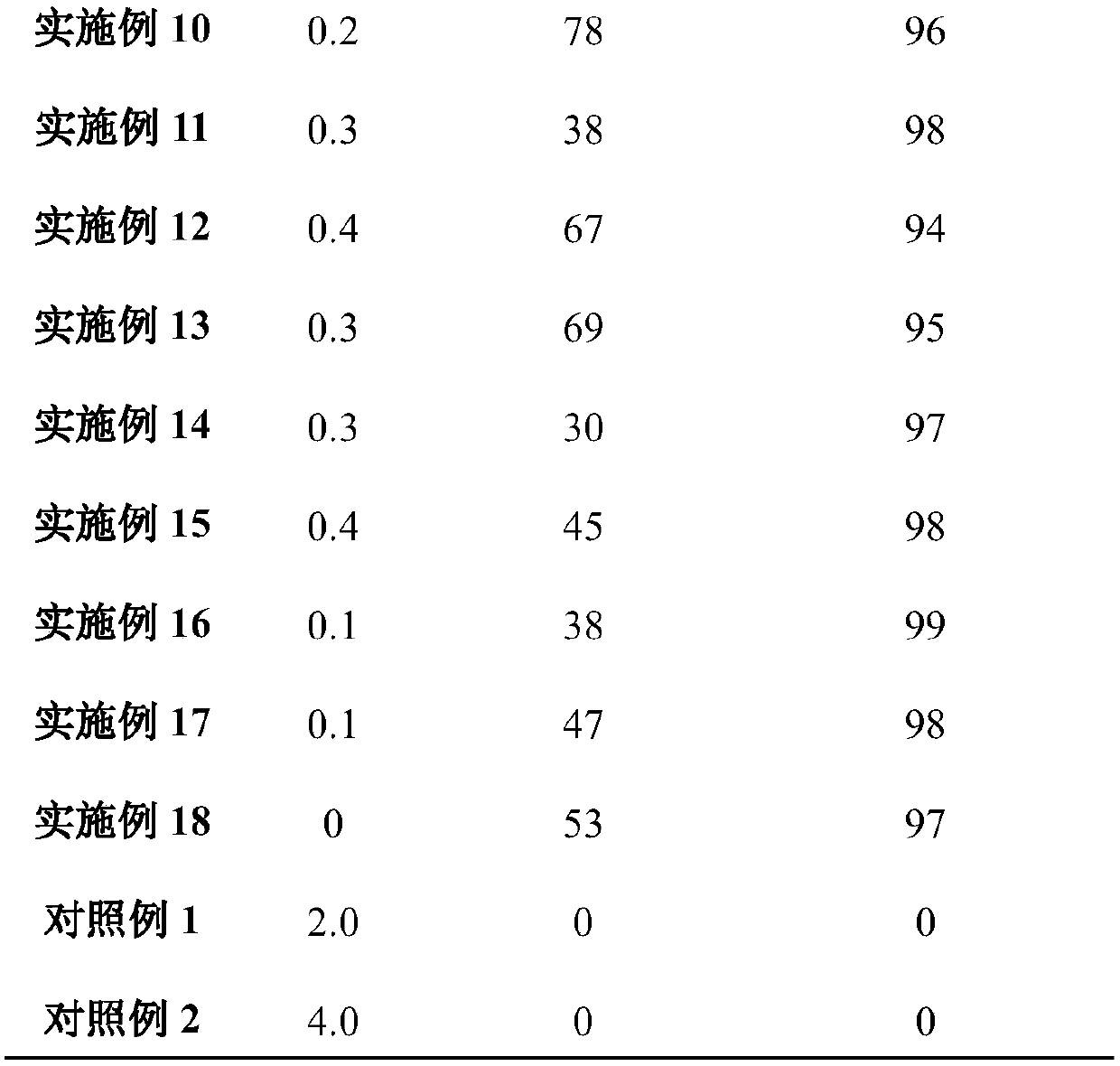

Examples

Embodiment 1

[0019] Dissolve 2 mL of 0.1 M chloroplatinic acid aqueous solution at 25 °C in 100 μL min -1 Add it dropwise to the ethanol and water dispersion containing 100mg graphene at a speed of 30°C, dip and stir until dry to obtain a solid powder; then place the obtained solid powder in a tube furnace, heat up to 400°C, and heat up to 400°C at 50 %H 2 / Ar atmosphere at 60mL min -1 Treat at the flow rate for 4 hours, cool down to 30 °C, switch to 10% O 2 / Ar atmosphere, treated for 12 hours to obtain the metal-supported anode catalyst Pt@graphene.

Embodiment 2

[0021] Dissolve 5 mL of 0.3M chloroauric acid aqueous solution at 50°C in 200 μL min -1 Add dropwise at a speed of 300mg molybdenum carbide to methanol and water dispersion, dip and stir at 50°C until dry to obtain a solid powder; then place the obtained solid powder in a tube furnace, heat up to 300°C, at 80°C %H 2 / Ar atmosphere at 100mL min -1 Treat at the flow rate for 2 hours, cool down to 50 °C, switch to 2% O 2 / Ar atmosphere, and treated for 10 hours, the metal-supported anode catalyst Au@MoC was obtained.

Embodiment 3

[0023] Dissolve 20 mL of 0.01M ferric nitrate aqueous solution at 25°C in 100 μL min -1 Add it dropwise to the ethylene glycol and water dispersion containing 200mg of nitrogen-doped XC-72R, dip and stir at 25°C until dry to obtain a solid powder; then place the obtained solid powder in a tube furnace and heat up to 500°C at 40% H 2 / Ar atmosphere at 50mL min -1Treat at the flow rate for 8 hours, cool down to 25 °C, switch to 1% O 2 / Ar atmosphere, treated for 24 hours to obtain a metal-supported anode catalyst Fe@N-XC-72R.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com