Sulfur-doped NiFe(CN) 5NO electrolyze water oxygen evolution catalyst by using solvothermal preparing method and application thereof

A solvothermal method and sulfur doping technology, which is applied in the electrolysis process, electrolysis components, electrodes, etc., can solve the problems of rare research reports on metal-organic framework materials, and achieve excellent electrocatalytic activity, good electrochemical stability, and excellent performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] NiFe(CN) 5 Preparation of NO nanoparticles:

[0030] Add an equal volume of Na 2 Fe(CN) 5 NO . 2H 2 O solution was added to Ni(NO 3 ) . 6H 2 O solution, stir evenly, let it stand for 8-12h, preferably 10h, the obtained precipitate is centrifuged, and after washing, vacuum-dry at 60°C for 12h to obtain NiFe(CN) 5 NO nanoparticles, where the Na 2 Fe(CN) 5 NO . 2H 2 O and Ni(NO 3 ) . 6H 2 The mass concentration ratio of O is 1:3.

Embodiment 1

[0032] 154 mg NiFe(CN) 5 Disperse NO in 60 mL of absolute ethanol with a concentration of 2.5 g / L. After the ultrasonic dispersion is uniform, add thiourea to control the concentration of thiourea to 8.2 g / L, continue ultrasonic dispersion, stir evenly, and transfer the mixture to a volume of 100 mL Reactor, at 140 o C for 12 h. After the reaction, cool naturally, the product is centrifuged, and the resulting precipitate is washed and vacuum-dried to obtain the dark green product S-NiFe(CN) 5 NO.

[0033] Weigh 4 mg of the catalyst and ultrasonically disperse it in 1 mL of 98% ethanol, then add 10 μL of 5% Nafion solution, and ultrasonicate for 30 minutes to form a uniform slurry. 5 μL of the catalyst slurry was dropped on a glassy carbon electrode with a diameter of 3 mm, and the oxygen evolution reaction was tested after the electrode was dried.

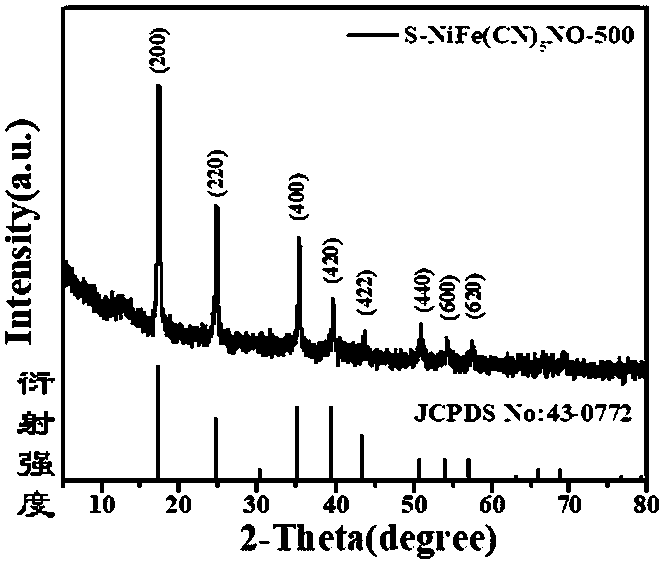

[0034] figure 1 is S-NiFe(CN) 5 XRD pattern of NO. All diffraction peaks are consistent with cubic NiFe(CN) 5 NO . 5H 2...

Embodiment 2

[0041] 154 mg NiFe(CN) 5 Disperse NO in absolute ethanol with a concentration of 2.5 g / L. After ultrasonic dispersion is uniform, add thiourea to control the concentration of thiourea to 4.1 g / L, continue ultrasonic dispersion, stir evenly, and transfer the mixture to a reaction chamber with a capacity of 100 mL. Kettle, at 140 o C for 12 h. After the reaction, cool naturally, the product is centrifuged, and the resulting precipitate is washed and vacuum-dried to obtain the dark green product S-NiFe(CN) 5 NO.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com