Method of recovering light hydrocarbon from byproduct gas of Fischer-Tropsch synthesis

A by-product gas and Fischer-Tropsch synthesis technology, applied in the chemical industry, can solve problems such as unrealized use value, achieve the effect of simplifying the composition and improving the product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

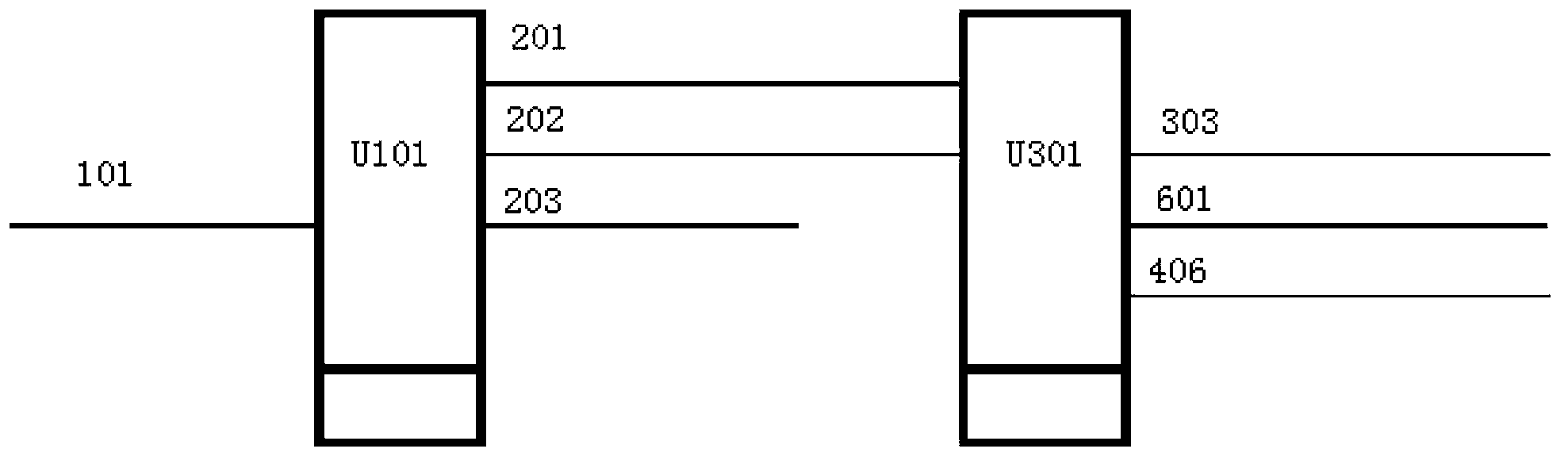

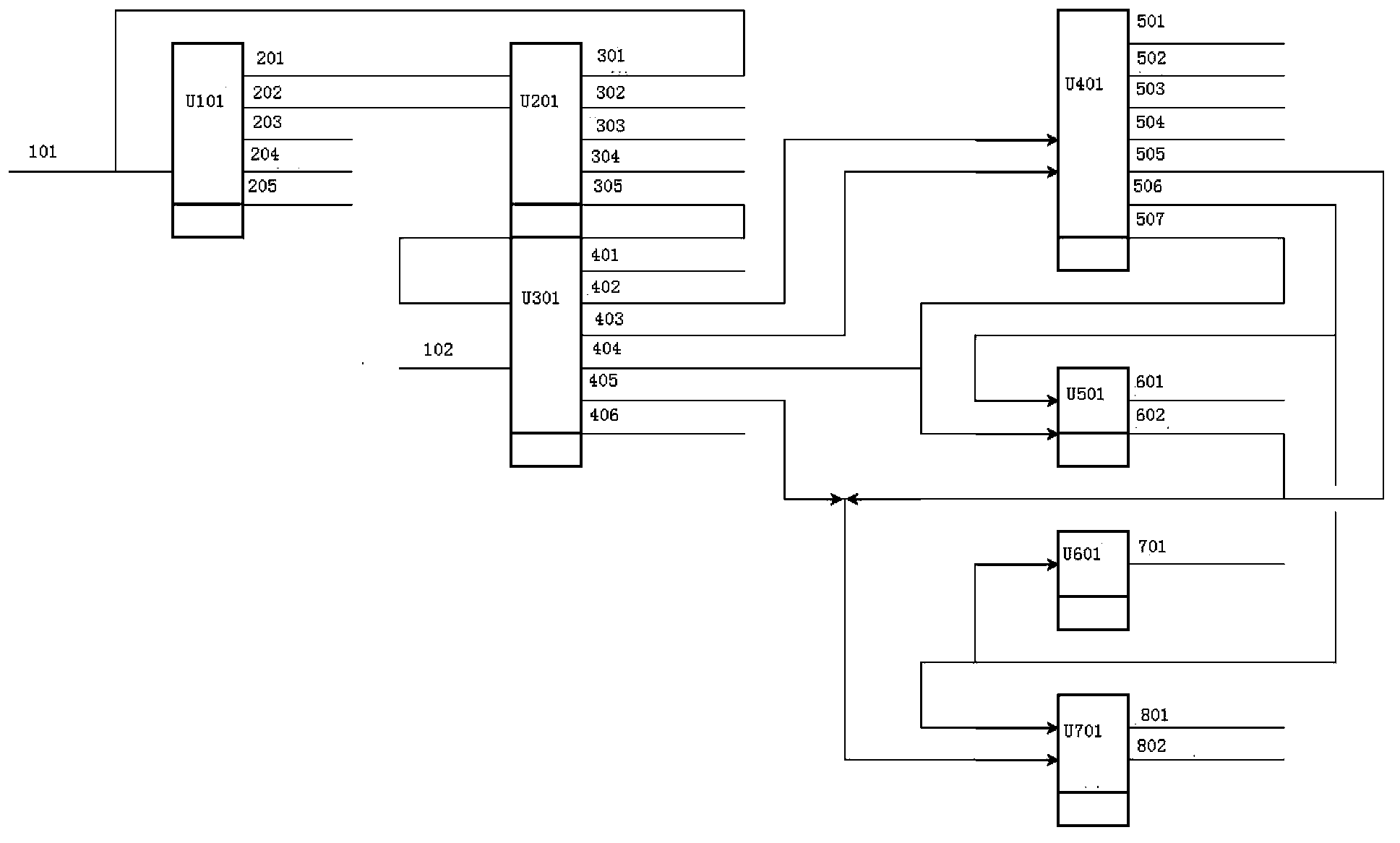

[0051] 1. Fischer-Tropsch synthesis by-product gas treatment

[0052] A by-product gas processing unit U201 is provided to process the by-product gases 201 and 202 from the Fischer-Tropsch unit U101. This unit realizes the removal of N2 and CO in the by-product gas of Fischer-Tropsch synthesis, and separates the decarbonized gas between carbon one and carbon two, and separates it into carbon one material and carbon two stream. The carbon dioxide stream 305 is sent to the light hydrocarbon recovery unit after removing CO2 again through the scrubber installed in this unit. This unit also includes carbon-stream conversion and hydrogen purification.

[0053] The by-product gas of Fischer-Tropsch synthesis is firstly removed by solvent absorption and desorption process to within 1.5-3.0% of CO2, and the gas after decarbonization is roughly divided into carbon-1 stream and carbon-2 stream through adsorption and separation; among them, after decarburization 75-99% of the carbon one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com