Normal-paraffin isomerization catalyst, preparation method and application thereof

A technology of n-alkane and catalyst, which is applied in the field of n-alkane isomerization catalyst and its preparation, can solve the problems of low activity, low conversion rate and poor stability of isomerization catalyst, and achieve low cost, high conversion rate, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

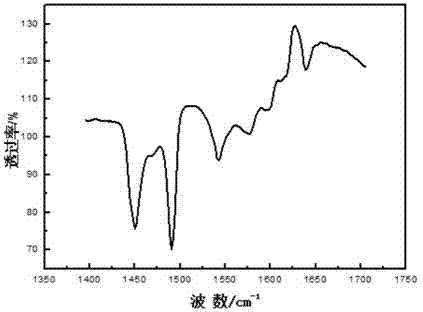

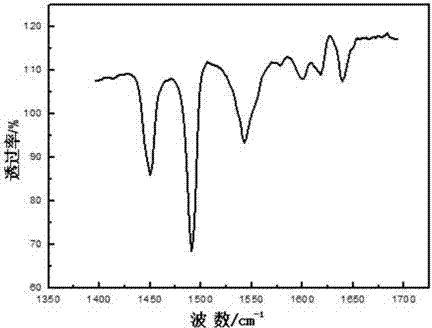

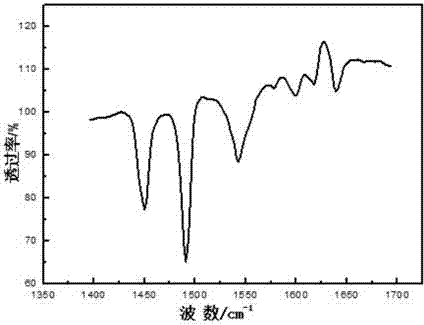

Image

Examples

preparation example Construction

[0029] See attached Figure 5 , a preparation method of n-paraffin isomerization catalyst, comprising the following steps:

[0030] 1) impregnation, in the γ-Al of 80-120 parts by weight 2 o 3 20-30 parts by weight of chloroplatinic acid is impregnated on the carrier, the impregnated product is dried at 100-120°C for 2-5 hours, and then oxidized at 500-700°C for 2-5 hours;

[0031] 2) Reduction, the product obtained in step 1) is subjected to reduction treatment, the reduction temperature is 200-500°C, the reduction time is 2-5h, and the reduction pressure is 1-3MPa;

[0032] 3) Inorganic chlorination, the product obtained in step 2) is subjected to inorganic chlorination, the temperature of the inorganic chlorination is 400-500°C, the chlorination time is 2-8h, and the inorganic chlorination agent is AlCl 3 , AlCl 3 The mass of γ-Al 2 o 3 15-50% of the mass of the carrier;

[0033] 4) Organic chlorination, the product obtained in step 3) is organically chlorinated, the...

Embodiment 1

[0041] Get 20 parts by weight of chloroplatinic acid, impregnate it into γ-Al of 100 parts by weight 2 o 3 On the carrier, γ-Al 2 o 3 The specific surface of the carrier is 200m 2 / g, the pore volume was 0.60mL / g; then, the impregnated product was dried in an oven at 100°C for 2 hours, and then baked in a muffle furnace at 500°C for 5 hours.

[0042] Put the obtained product in a reactor, and use hydrogen for reduction treatment. The reduction temperature is 250°C, the hydrogen pressure is 2MPa, and the reduction time is 2h; The catalyst can be chlorinated.

[0043] AlCl 3 Sublimation gasification, using H 2 As a carrier gas to vaporize AlCl 3 Loaded into the catalyst bed, the chlorination temperature is 500°C, chlorination at normal pressure for 6h, the AlCl used 3 The mass of γ-Al 2 o 3 50% of the mass of the carrier; after chlorination, use H 2 Continue purging for 2h to lower the temperature to 200°C.

[0044] CCl 4 Gasification, using N 2 As a carrier gas to...

Embodiment 2

[0049] Get 30 parts by weight of chloroplatinic acid and impregnate it into 80 parts by weight of γ-Al 2 o 3 On the carrier, γ-Al 2 o 3 The specific surface of the carrier is 220m 2 / g, the pore volume was 0.45mL / g; then, the impregnated product was dried in an oven at 120°C for 5 hours, and then baked in a muffle furnace at 600°C for 2 hours.

[0050] Put the obtained product in a reactor for reduction treatment, the reduction treatment process is gas phase reduction, the reduction gas is hydrogen, the reduction temperature is 500 ° C, the hydrogen pressure is 1 MPa, and the reduction time is 3 hours. The reduced catalyst can be chlorinated deal with.

[0051] AlCl 3 Sublimation gasification, using H 2 As a carrier gas to vaporize AlCl 3 Loaded into the catalyst bed, the chlorination temperature is 400°C, chlorination at normal pressure for 8h, the AlCl used 3 The mass of γ-Al 2 o 3 30% of the mass of the carrier; after chlorination, use H 2 Continue purging for 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com