Preparation method of metal modified Y type molecular sieve

A metal modification, molecular sieve technology, applied in molecular sieve catalysts, chemical instruments and methods, catalytic cracking and other directions, to achieve the effects of improving liquid yield, gasoline yield, and liquefied gas yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

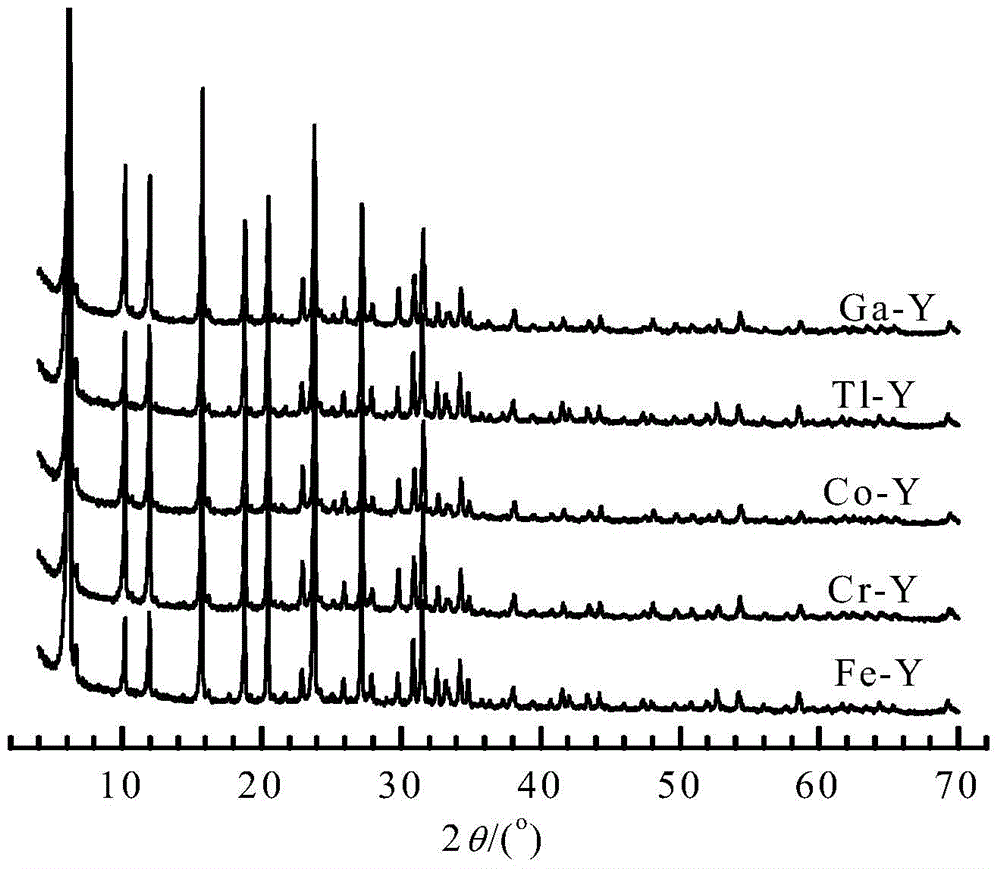

Image

Examples

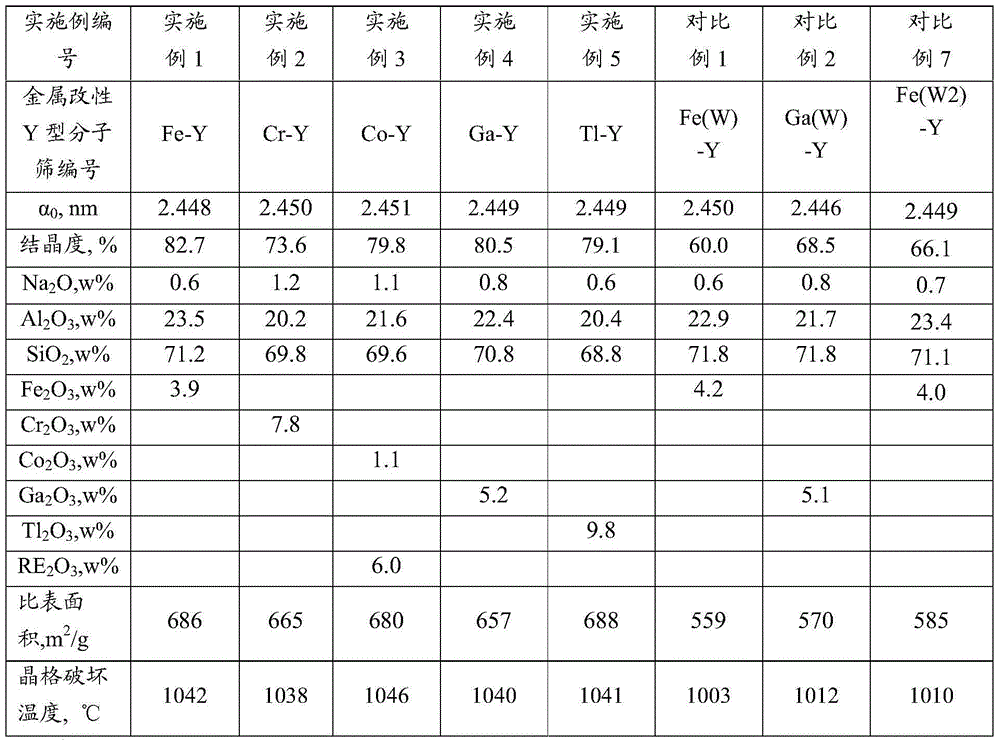

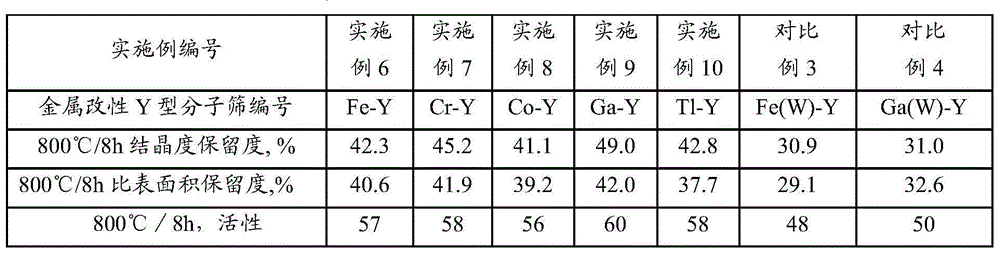

Embodiment 1

[0027] At room temperature, take 150g (dry basis) DASY (0.0) molecular sieve, mix it with 1500ml hydrochloric acid solution with a molar concentration of 1.0mol / L, stir for 30 minutes, filter, wash with 1500ml deionized water, and obtain Y molecular sieve after acid treatment. The sodium oxide content is 0.6% by weight; the Y molecular sieve obtained after the acid treatment is roasted at 300°C for 3 hours to obtain a molecular sieve with a solid content of 97% by weight, which is designated as FZ-1;

[0028] Get 12ml ethanol and add 180ml deionized water, add 5mol / L acetic acid aqueous solution 3ml, adjust solution pH value to 3.7 with 10mol / L ammonium hydroxide aqueous solution, then 30.4g Fe(NO 3 ) 3 9H 2 O was dissolved in the above buffer solution to obtain an impregnating liquid, and the above FZ-1 molecular sieve was mixed with the impregnating liquid evenly, left to stand for 12 hours, dried and roasted at 650°C and 100% water vapor for 2 hours to obtain the present i...

Embodiment 2

[0030] At room temperature, take 200g NaY molecular sieves (dry basis 75% by weight), mix them with 1500ml of hydrochloric acid solution with a molar concentration of 0.5mol / L, stir for 30 minutes, filter, and wash with 1500ml deionized water to obtain NaY molecular sieves after acid treatment. The content of sodium oxide is 1.5% by weight; the obtained NaY molecular sieve after acid treatment is roasted at 300°C for 3 hours to obtain a molecular sieve with a solid content of 96% by weight (water content 4% by weight), which is designated as FZ-2;

[0031] Get 12ml ethanol and add 180ml deionized water, add 5mol / L acetic acid aqueous solution 3ml, adjust solution pH value to 4.5 with 10mol / L ammonia water, obtain buffer solution, 37.6g Cr(NO 3 ) 3 9H 2 O is dissolved in the above buffer solution to obtain an impregnating liquid, and the above molecular sieve FZ-2 is mixed evenly with the impregnating liquid, left to stand for 12 hours, dried and roasted at 500°C and 100% wate...

Embodiment 3

[0033] Take 200g NaY molecular sieve (same as above), beat with 1500g of deionized water, add 45g of ammonium chloride and 33.5ml of RECl 3 solution (the concentration is 270g / L in terms of RE2O3), rare earth salts (in terms of RE 2 o 3 Calculated): ammonium salt: NaY molecular sieve: deionized water with a weight ratio of 0.06:0.3:1:10, adjust the pH value of the slurry to 3.8, heat up to 80°C for 2 hours, filter and rinse with water, and then filter the cake Baking at 600°C and 100% steam for 2 hours. The molecular sieve after roasting is mixed with the sulfuric acid solution 1500ml that the molar concentration is 0.2mol / L, stirs 30 minutes, filters, washes with 1500ml deionized water, obtains the Y molecular sieve after the acid treatment, and its sodium oxide content is 1.2% by weight; The resulting acid-treated Y molecular sieve was calcined at 350°C for 3 hours to obtain a molecular sieve with a solid content of 97% by weight, denoted as FZ-3;

[0034] Get 12ml ethano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com