Desulphurization sorbent composition

A technology of adsorbent and composition, applied in the direction of refined hydrocarbon oil, petroleum industry, other chemical processes, etc., can solve the problems of gasoline product octane number loss, not enough to achieve deep desulfurization, etc., and achieve high liquid recovery and adsorbent distribution Uniformity and good desulfurization activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The preparation of the adsorbent solid particles used in this embodiment is as follows:

[0052] The main raw materials of the carrier used in this embodiment are as follows:

[0053] C1 # Carrier: 10 kg of pseudo-boehmite (solid content is 64% by weight, industrial product of Shandong Zibo Aluminum Factory, the same below) + 1.0 kg of silica sol (solid content is 25% by weight, produced by Qingdao Lifan Chemical Factory, the same below) +13.1 kilograms of zinc oxide (purity 99.7%, product of Cangzhou Jiewei Chemical Co., Ltd.);

[0054] C2 # Carrier: 4 kilograms of pseudoboehmite+1.0 kilogram of silica sol+6 kilograms of kaolin (solid content is 73% by weight, produced by Suzhou China Clay Company)+10 kilograms of zinc hydroxide (zinc oxide content 71.5%, Peixian Zinc Oxide Factory product);

[0055] C3 # Carrier: 5 kg of pseudo-boehmite+4 kg of kaolin+2 kg of cumulated clay (solid content is 68% by weight, produced by Hubei Zhongxiang)+3.5 kg of zinc sulfate (pur...

Embodiment 1-3

[0065] Examples 1-3 illustrate the composition and preparation method of the adsorbent of the phosphorus-containing modified rare earth zeolite mixture.

[0066] 7.5 kg of nickel chloride produced by Zhangjiagang Huayi Chemical Co., Ltd., and 8.5 kg of metal salt mixtures of cobalt nitrate and nickel nitrate were formulated into aqueous solutions with a metal ion concentration of 1 to 10 mol / L for use.

[0067] Mix nickel chloride aqueous solution with PS1 at room temperature # -C1 # Mix the solid particles, add ammonia water with a concentration of 3mol / L while stirring, keep the pH at 7-10, keep stirring until the precipitation is complete, raise the temperature to 90°C and leave it to age for at least 0.5 hours, filter, and wash the filter cake until there is no acid ion A mixture of nickel hydroxide, P-RE-ZSM5, P-REY and alumina carrier material is prepared, and washed with water until there is no chloride ion. After drying at 100-200°C for at least 2 hours, then roastin...

Embodiment 4-5

[0076] Examples 4-5 illustrate the application of phosphorus-modified rare earth zeolite mixture adsorbents in gasoline desulfurization.

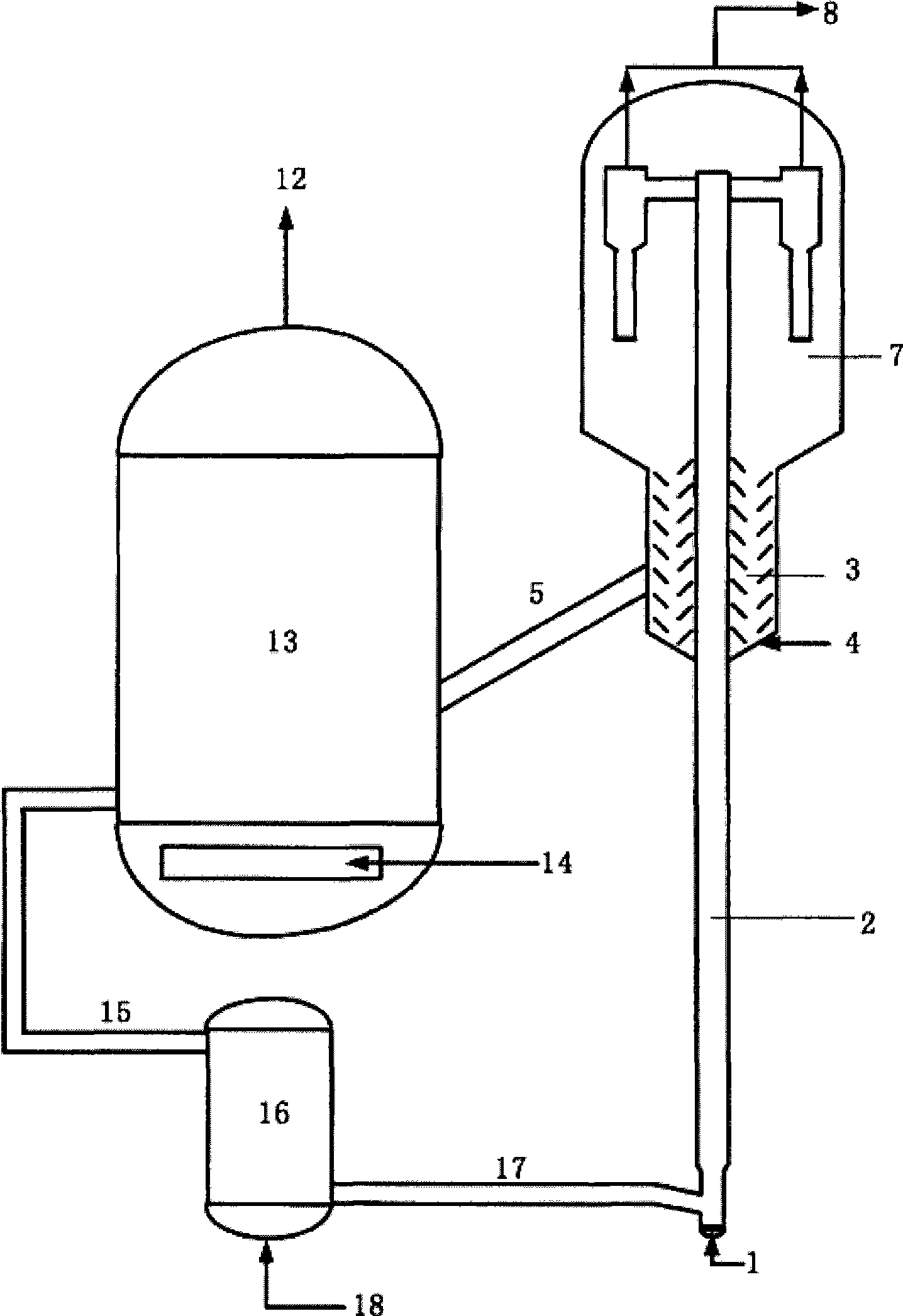

[0077] Using raw gasoline A and B in Table 1 as raw materials, the adsorption and catalytic conversion of raw gasoline raw materials in small fluidized bed reactors were fully contacted with adsorbents PZYS-1 and PZYS-2 respectively. The loading capacity of the adsorbent is 500 grams, and it is reduced for 60 minutes with hydrogen at a temperature of 360° C. and a hydrogen flow rate of 1.5 liters / hour before use. The reaction product, steam and the raw adsorbent mixture are separated in the settler, and the reaction product is separated to obtain gas products and liquid products, while the raw adsorbent is stripped of the hydrocarbon products adsorbed on the raw adsorbent mixture by steam. The stripped adsorbent is regenerated by contacting with heated air, and the regenerated catalyst mixture is recycled after cooling and hydrogen reductio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com