Combined technique for improving yield of high-octane gasoline by using inferior catalytic cracking diesel

A technology for catalytic cracking of diesel oil and high-octane gasoline, which is applied in the petroleum industry, hydrotreating process, hydrocarbon oil treatment products, etc., and can solve problems such as poor extraction effect, high sulfur and nitrogen content, and large loss of extraction solvent , to achieve the effect of increasing liquid recovery and increasing aromatics content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

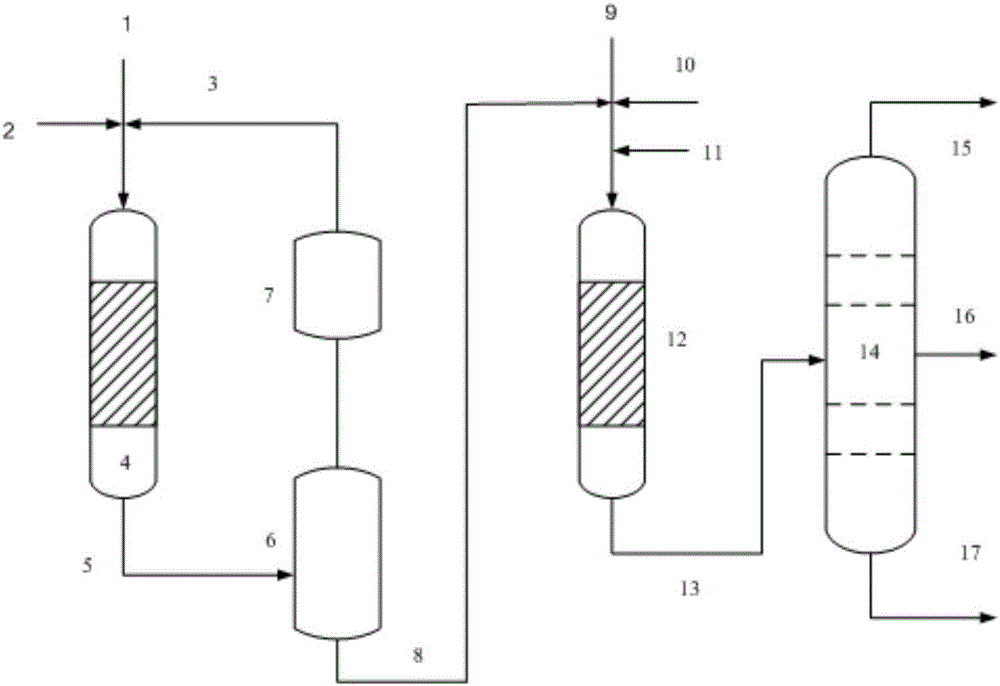

Method used

Image

Examples

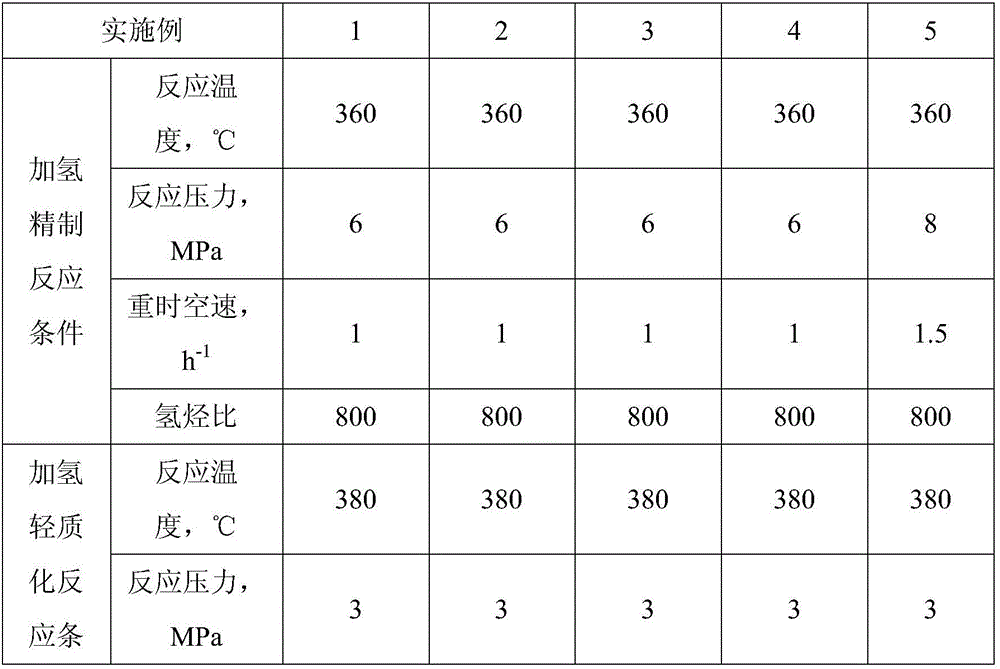

Embodiment 1~4

[0027]Investigation of combined process for increasing production of high-octane gasoline from low-quality catalytic cracking diesel in a fixed-bed reactor. Among them, the hydrofinishing catalyst is prepared according to the preparation method of conventional hydrofinishing preparations, but it is preferably prepared by the method of patent CN104646034A. The refining preparations of Examples 1-4 are prepared by the method of patent CN104646034A, and the lightweight catalyst is anti-sulfur and nitrogen. The noble metal catalyst is prepared by the method of patent CN103551180B. The feed to the reactor is from the top to the bottom, and the composition of the liquid product is analyzed by gas chromatography.

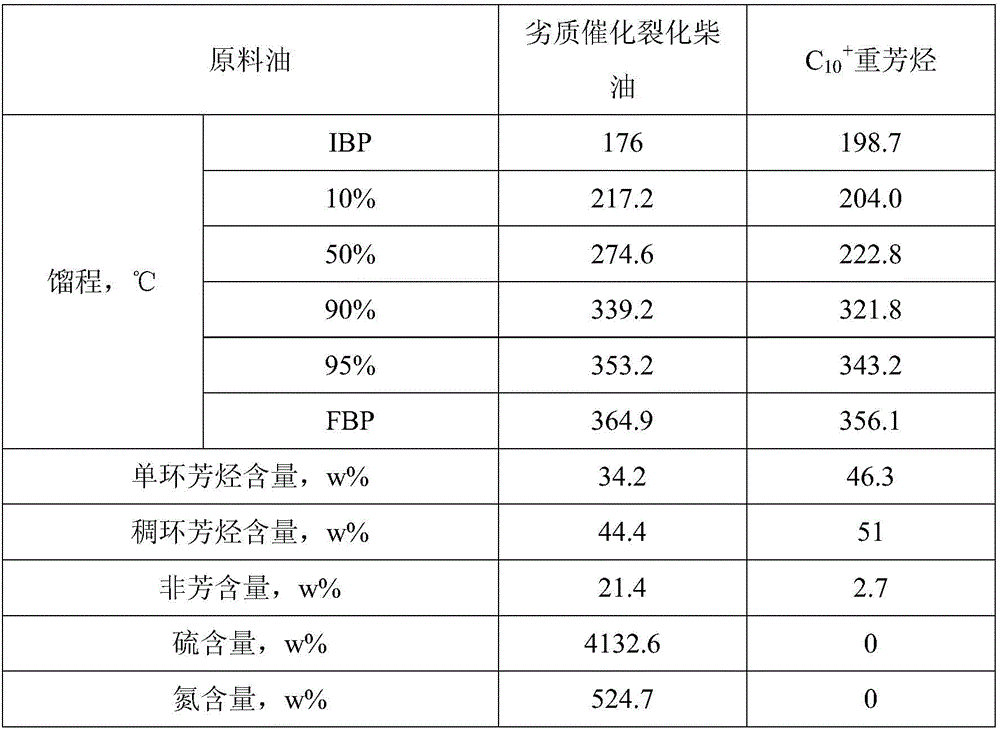

[0028] See Table 1 and Table 2 for the composition and evaluation results of the low-quality catalytic cracking diesel feedstock and heavy aromatic hydrocarbon feedstock used in Examples 1-4, respectively.

[0029] Table 1 Inferior FCC diesel oil and C 10 + Composition ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com