Inductive coupling type plasma device

A plasma and inductive coupling technology, applied in the direction of plasma, semiconductor/solid-state device manufacturing, chemical/physical/physicochemical process of energy application, etc., can solve problems such as not very effective, incompatible sensors, small ratio, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

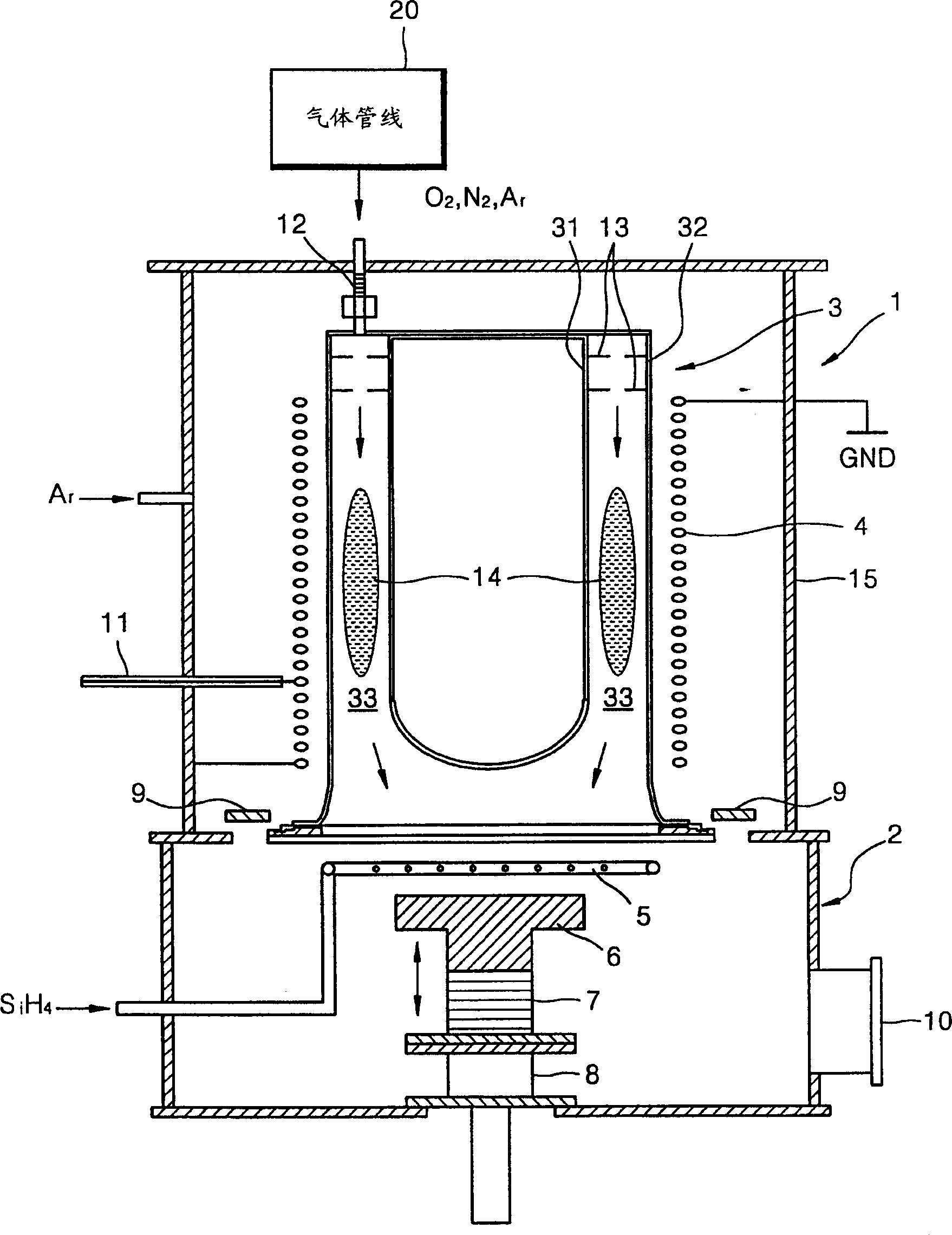

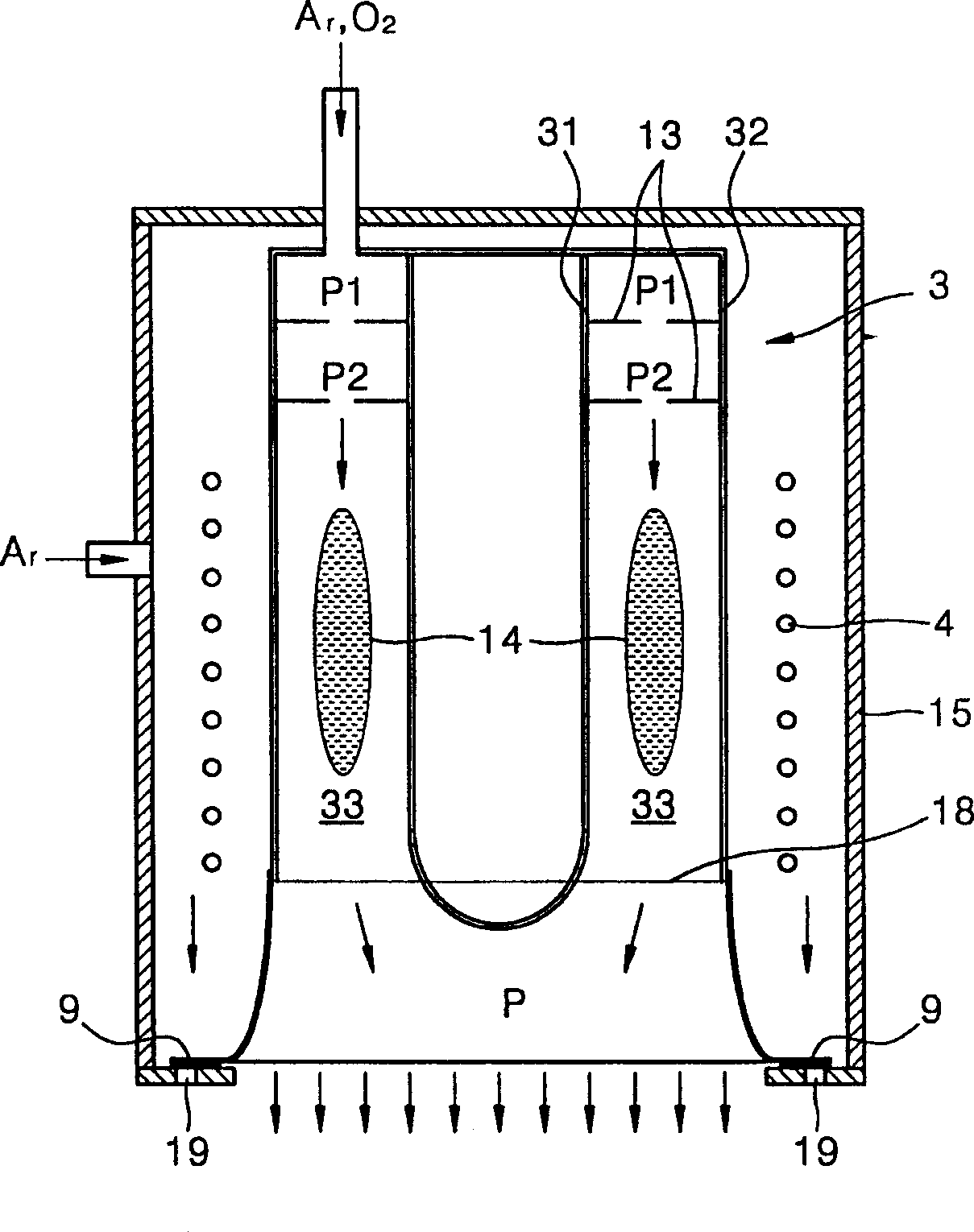

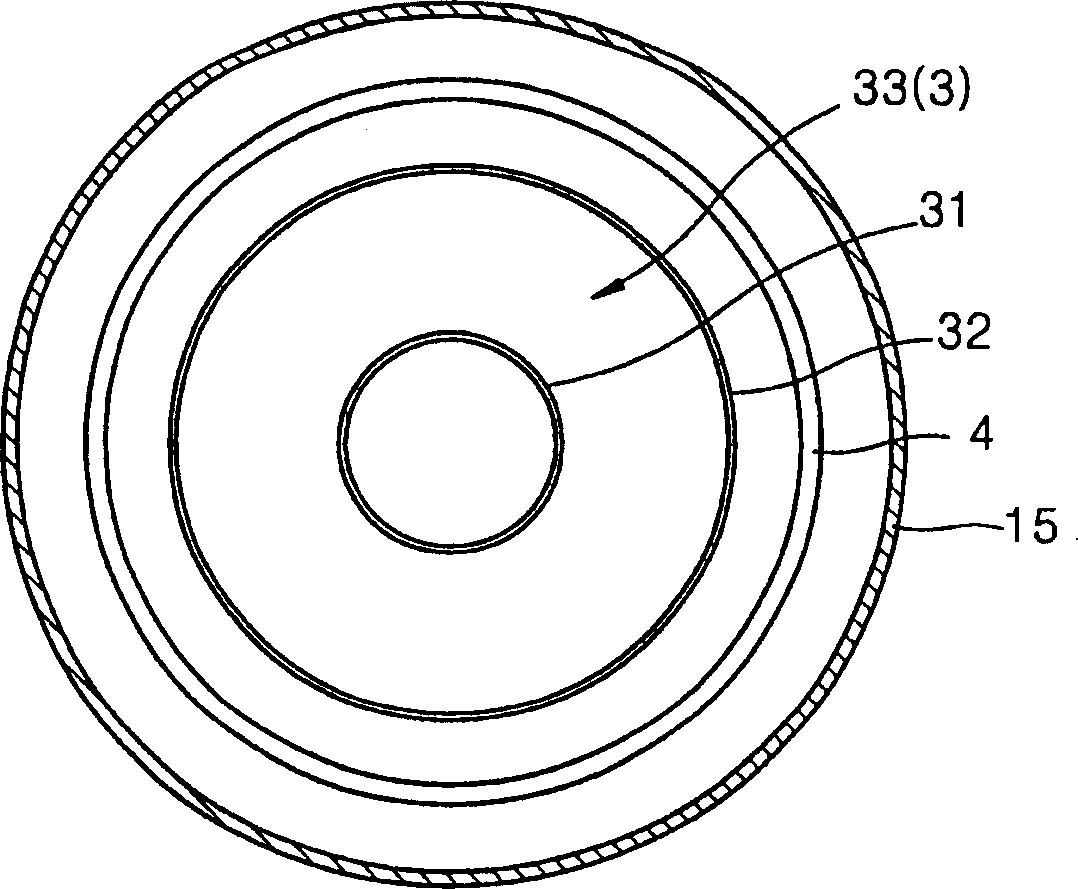

[0026] figure 1 A cross-sectional side view showing a preferred embodiment of an inductively coupled plasma (ICP) apparatus of the present invention. The ICP device includes a top plasma source chamber 1 and a processing chamber 2 .

[0027] A plasma source is arranged inside the top plasma source chamber 1 . The plasma source includes a spiral induction coil 4 and a plasma reactor 3 . The plasma reactor 3 is connected to the supply O by means of a screw cap and a bellows 12 2 , N 2 , Ar and similar gases a gas line 20. The RF energy that excites the plasma in the plasma reactor 3 is fed to one of the turns of the induction coil 4 via an RF cable and an RF feed through (not shown). Both ends of the induction coil 4 are grounded. The entire length of the induction coil 4 is equal to the full wavelength of an RF electromagnetic field. Under these conditions, standing waves of voltage and current are formed in the induction coil 4 . Preferably, the induction coil 4 should...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com