Combined type gas distributor

A gas distributor and compound technology, which is applied in the field of gas phase and gas-liquid two-phase feed distribution equipment, can solve the problems of difficult to achieve uniform distribution of gas, large amount of droplet entrainment, large airflow resistance, etc. The effect of drop, uniform radial distribution and uniform airflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

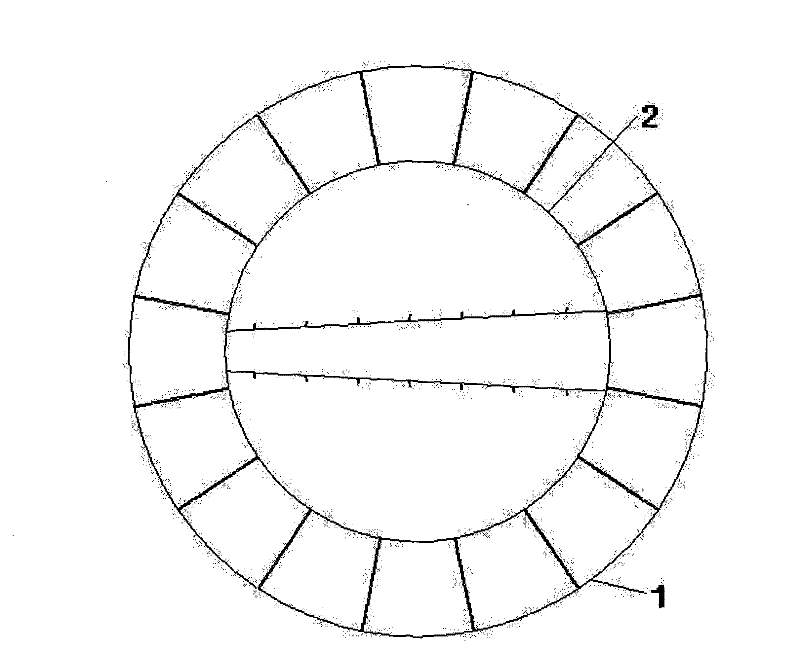

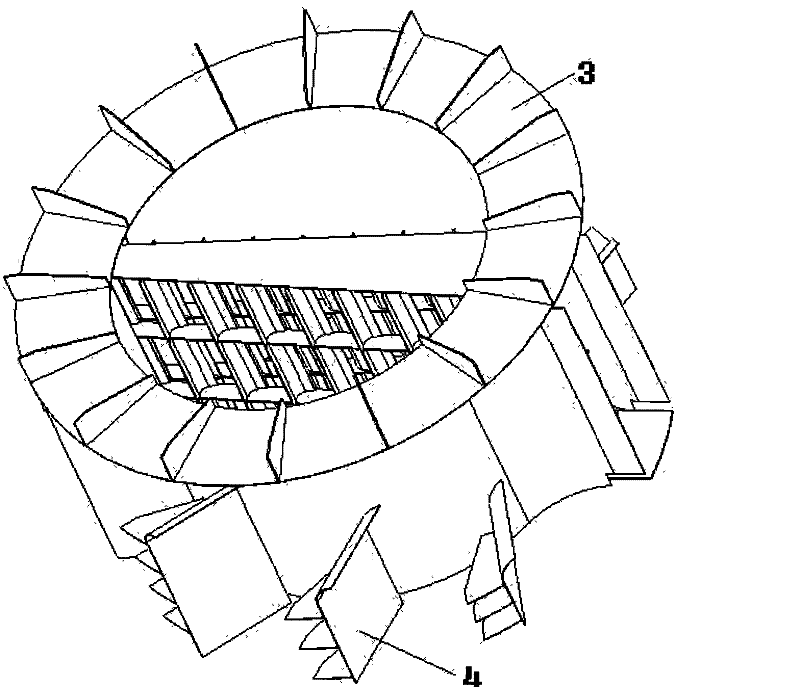

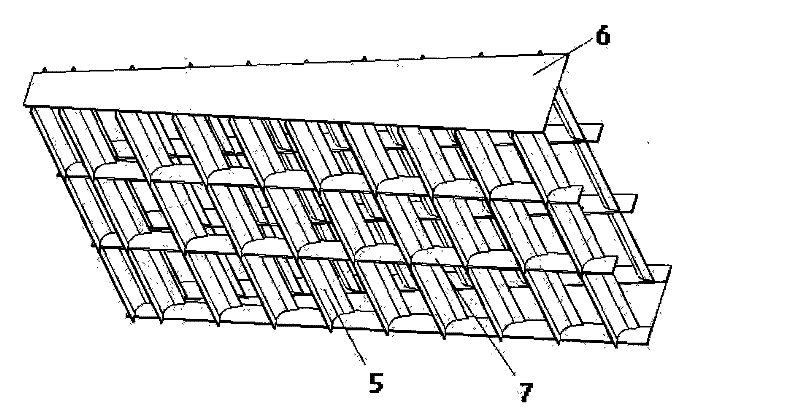

[0024] Such as figure 1 , 2 As shown, the composite gas distributor is composed of an inner cylinder 2, a top ring plate 3, a baffle plate 4, a guide vane 5, upper and lower cover plates 6 and a connecting plate 7. The size of the top ring plate 3 is determined according to the requirements of the tower wall 1 and the inner cylinder 2 . The top ring plate 3 is welded on the tower wall 1 . The inner cylinder 2 is welded to the top ring plate, so that the inner circular surface of the ring plate and the inner cylinder coincide. The double-row vane-type gas distribution device inside the inner cylinder 2 is composed of three layers connected up and down, and the guide vanes 5 in each layer are welded on the connecting plate 7 according to the corresponding positions. The whole three-layer double-row vane-type deflector and the top ring plate 3 are connected with bolts.

[0025] The baffles 4 are welded to the outside of the inner cylinder 2 according to the different position...

Embodiment 2

[0031] The basic structure of the gas distributor is the same as that of Embodiment 1. The difference from Embodiment 1 is that the hydrodynamic calculation is performed according to the specific process parameters, and the length of the baffles 4 is changed. The lengths of the four baffles are 650mm and 950mm respectively. , 1250mm, 1550mm; the internal double-row blade gas distribution structure is a single layer, with a height of 1500mm.

[0032] Process parameters:

[0033] Tower diameter: 8m, tower height: 15m, feed pipe diameter: 1.6m, feed amount: 702.5t / h, feed temperature: 90°C, feed pressure: 80mmH 2 O, feed liquid content: 0

[0034] The gas enters the distributor through the feed port and is divided into two parts, inside and outside. The gas entering the inner cylinder 2 is guided by the guide vanes 5, flows out of the double-row vane distribution device in the radial direction, and then is evenly distributed in the inner cylinder; The flow is diverted, changed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com