Oil-water separation device with flow guide plate

An oil-water separation device, oil-water separator technology, applied in liquid separation, separation methods, essential oils/spices, etc., can solve the problems of increased oil droplet floating time, disturbance of oil-water mixture, and reduced oil recovery rate, etc. Surface tension, direct impact elimination, easy-to-handle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

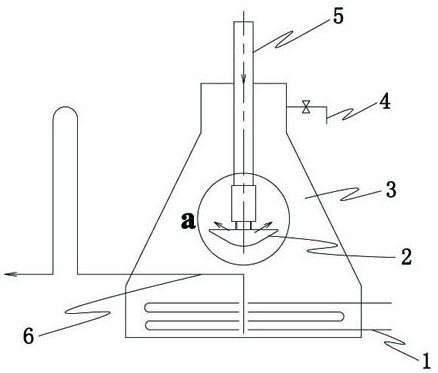

[0017] Below in conjunction with the accompanying drawings, the present invention will be further described by taking steam distillation to extract the volatile oil of natural flower petals as an example.

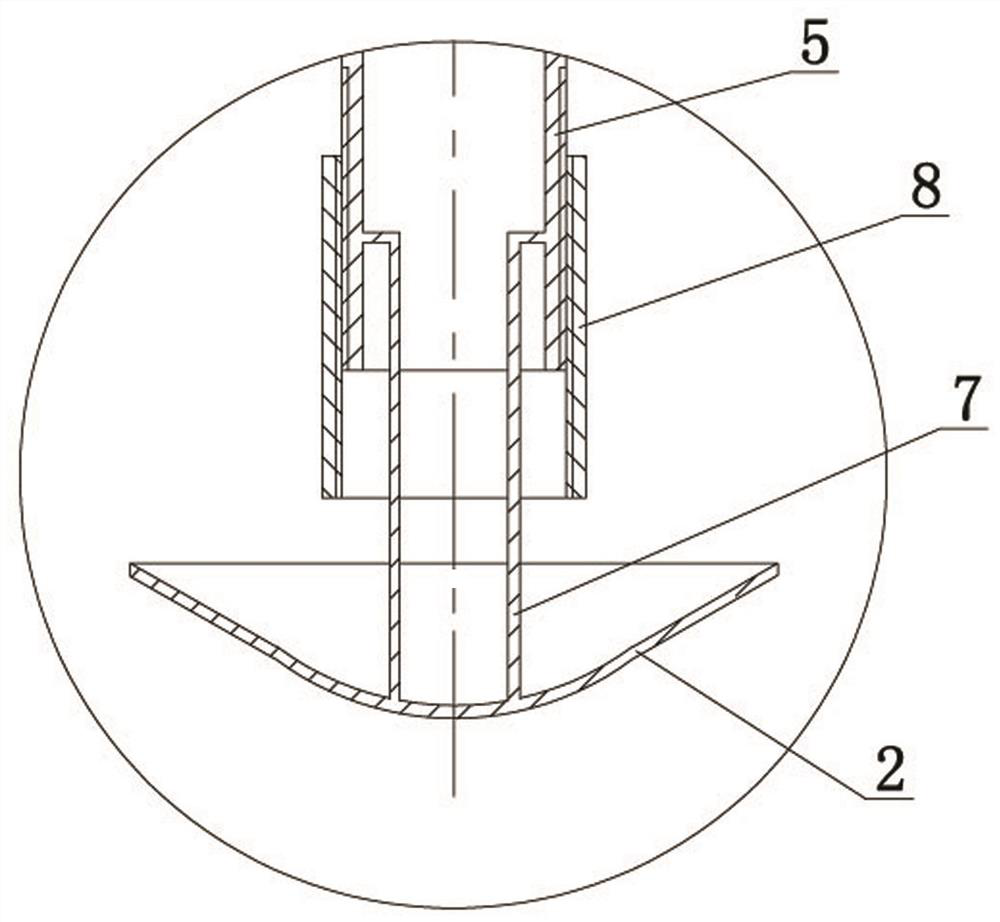

[0018] Such as figure 1 , figure 2 As shown, this oil-water separation device with deflectors includes an oil-water separator 3, the oil-water separator 3 is a conical structure, and the bottom outlet end of the inlet pipe 5 assembled at the top inlet of the oil-water separator 3 is provided with a round Slotted deflector 2, the diameter of the deflector 2 is 1.5 to 3 times the inner diameter of the introduction pipe 5, the deflector 2 is fixedly connected with the inner wall of the introduction pipe 5 by at least three rod-shaped bodies 7, each rod-shaped body 7 The lower end is welded and fixedly connected with the inner wall of the deflector 2, and the three rod-shaped bodies 7 are distributed at 120° on the deflector 2, and a section of adjustment pipe 8 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com