Bubbling tower reactor having damping internal construction member

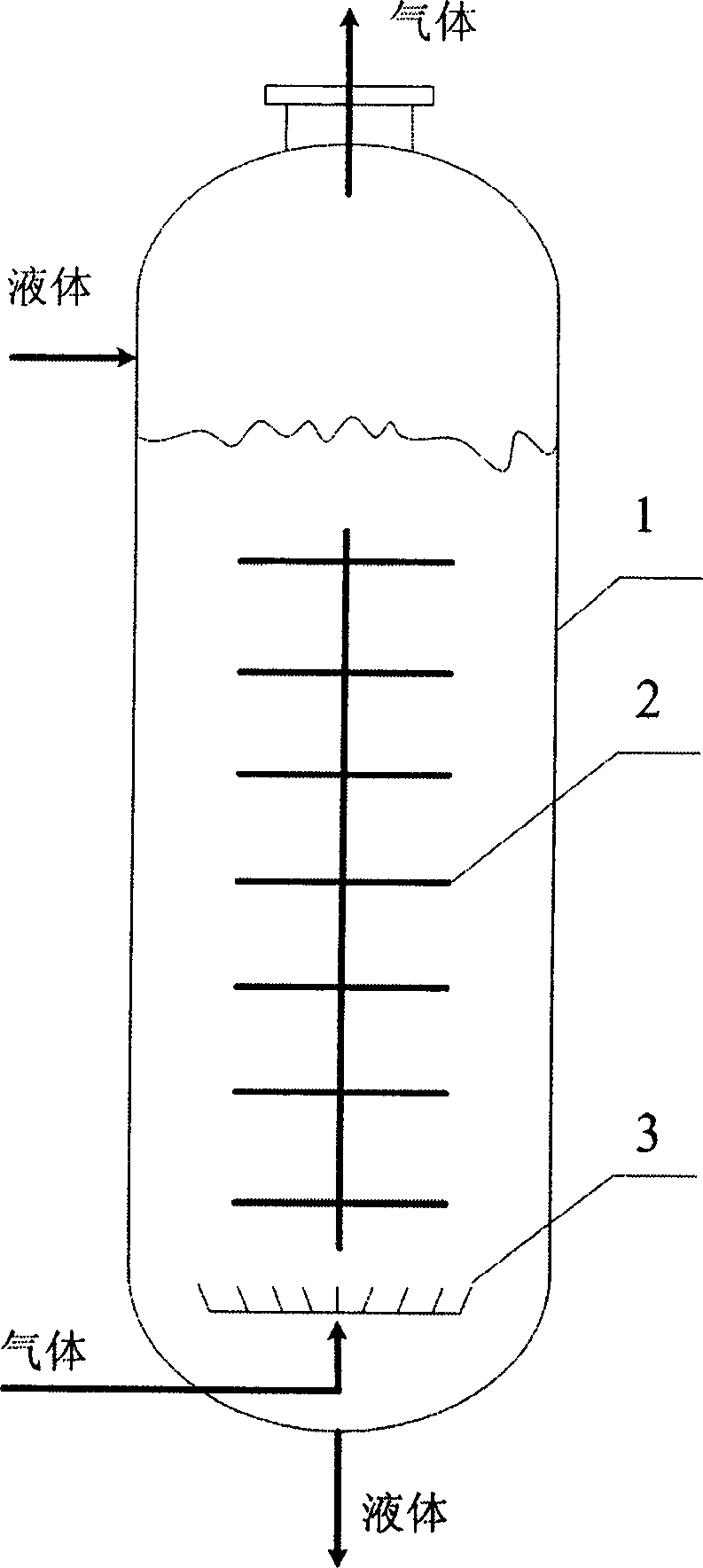

A technology of internal components and reactors, applied in chemical methods, chemical instruments and methods, chemical/physical processes, etc. that make liquids react with gaseous media, can solve problems such as gas short circuits, difficult amplification, and poor gas-liquid contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

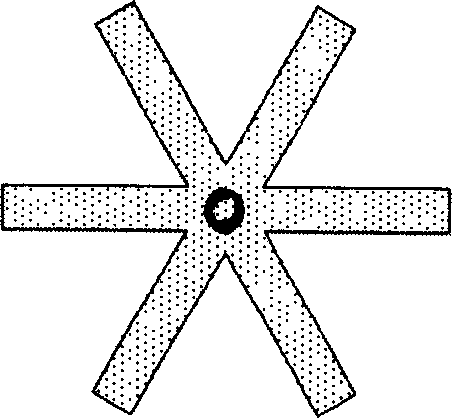

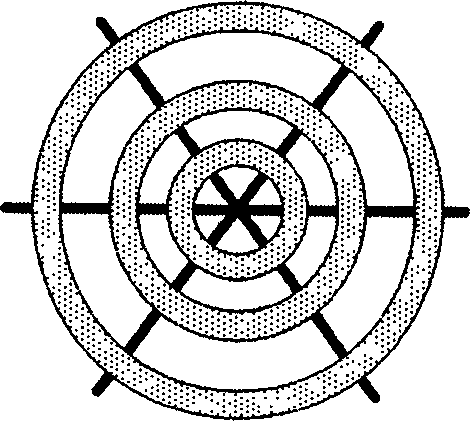

[0018] In the axial central area of the bubble column reactor with a diameter of 500 mm and a height of 4000 mm, a damping member is fixed by a central vertical rod in the reaction area above the gas distributor and below the liquid level of the bubble tower. The damping member has 14 Such as figure 2 The radial damping unit shown has a diameter of 250mm, the distance between adjacent damping units is 200mm, the lowest damping unit is 200mm away from the gas distributor, and the uppermost damping unit is flush with the liquid level. The damping area density is 0.35m 2 / m 3 .

[0019] The experiment was carried out in an air-water system, the liquid level height after bubbling was 3000mm, and the superficial gas velocity was 0.62m / s. At the midpoint between the two damping units at a distance of 2250mm from the distributor, measure the axial velocity at different radial positions, and then compare the radial distribution of the fluid velocity without the damping inner mem...

Embodiment 2

[0022] The experimental conditions are the same as in Example 1, and the gas-liquid mass transfer rate is measured by chemical absorption method, and then the gas-liquid mass transfer coefficient k without damping internals and after installing damping internals is compared l α, the results are shown in Table 1.

[0023] The gas-liquid mass transfer coefficient of the empty tower reactor is 0.41. After adding the damping internal member described in Example 1, the mass transfer coefficient increases to 0.49, and the mass transfer rate increases by 20%. It shows that the disturbance of the damping internal member to the flow field strengthens the fluid turbulence and significantly increases the mass transfer rate.

[0024] Experimental conditions

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com