Patents

Literature

166 results about "Bubble column reactor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

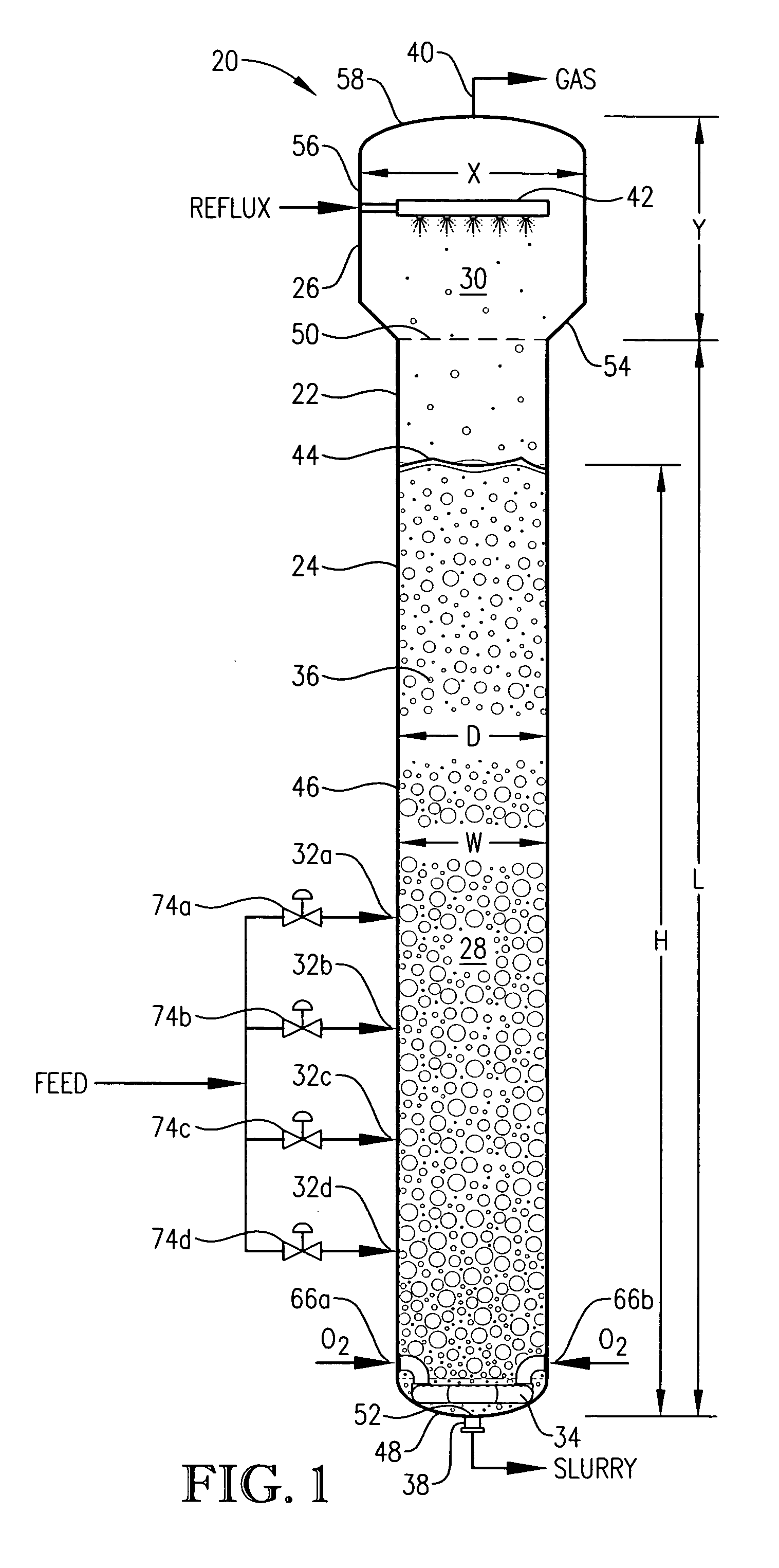

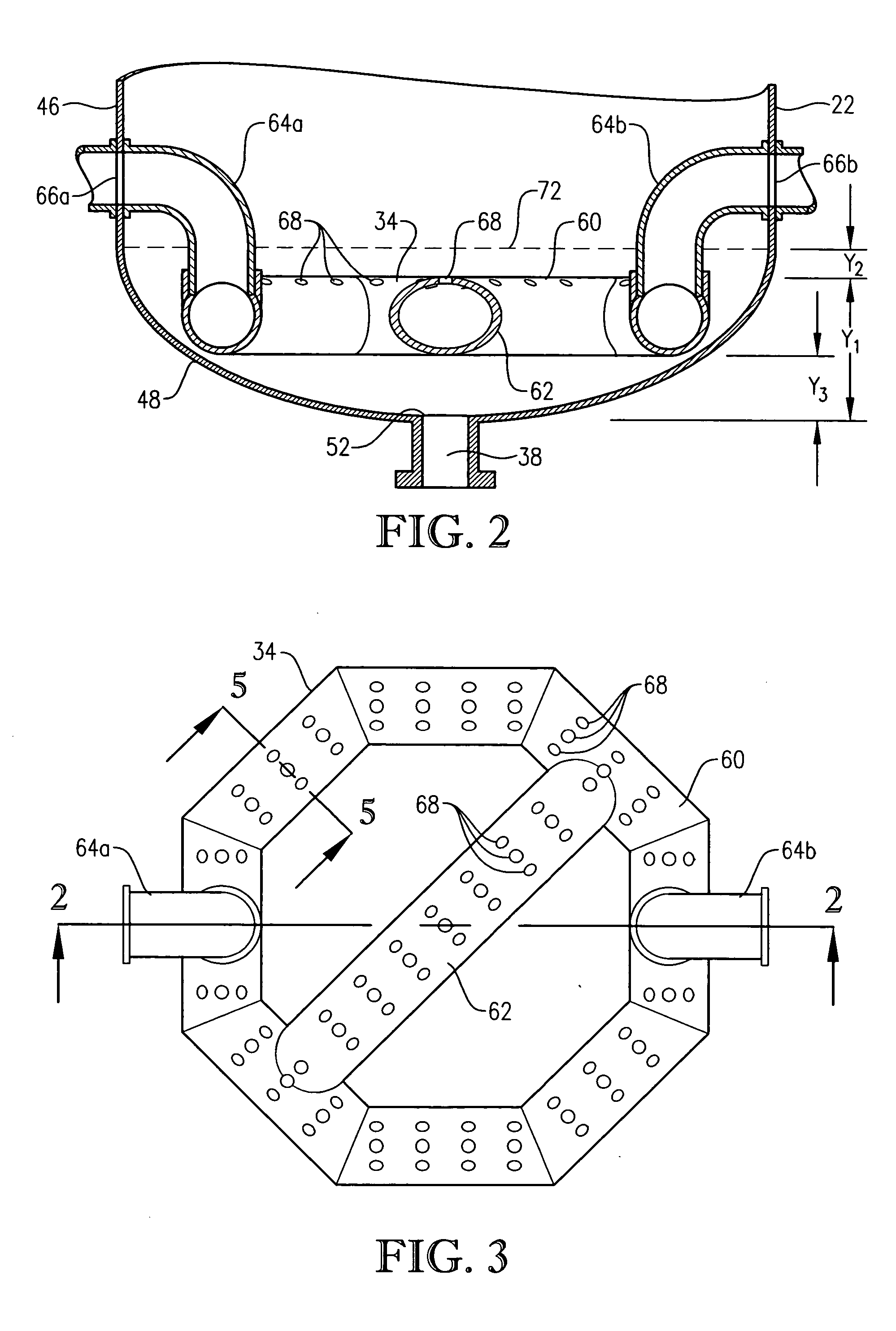

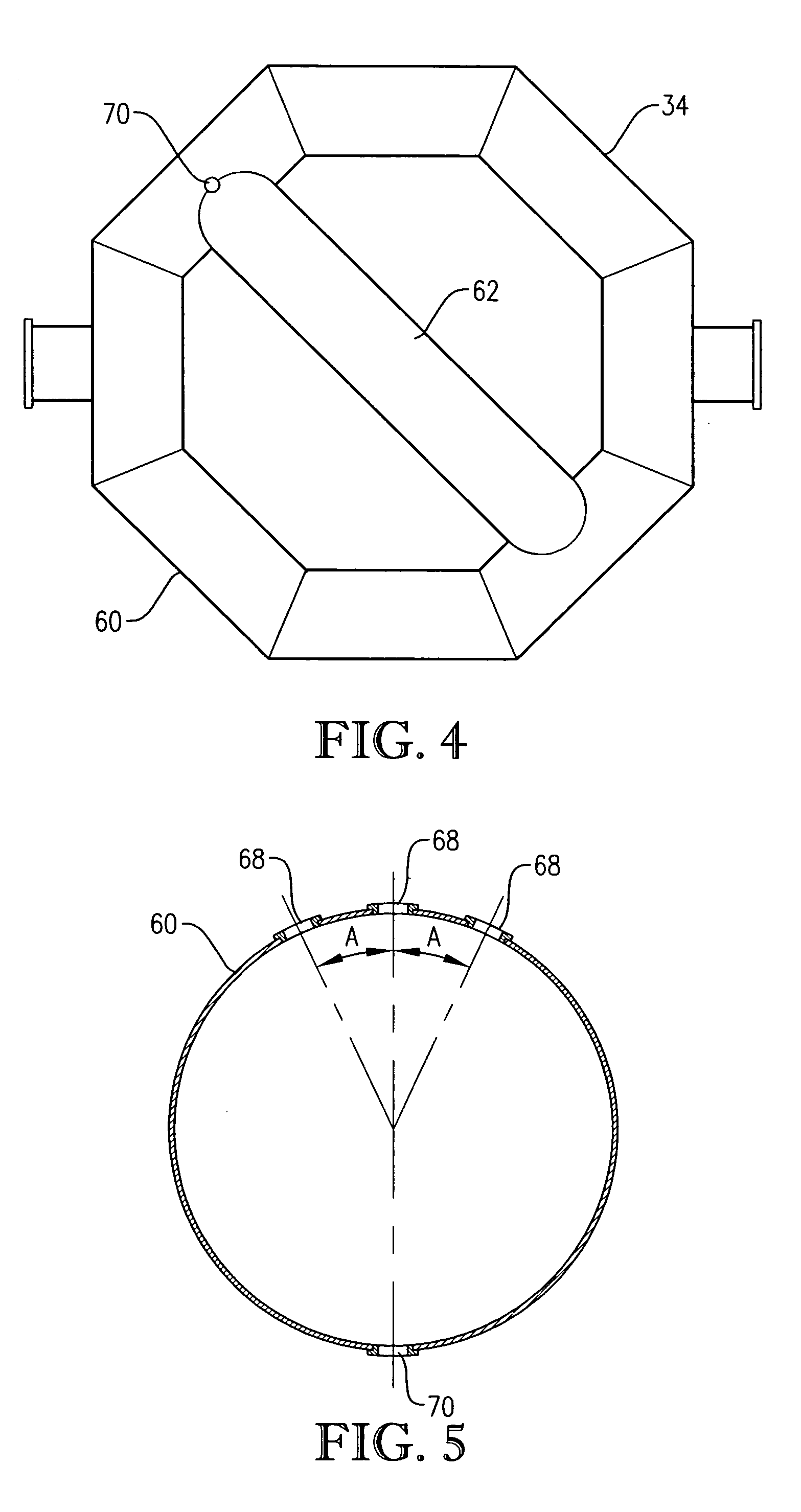

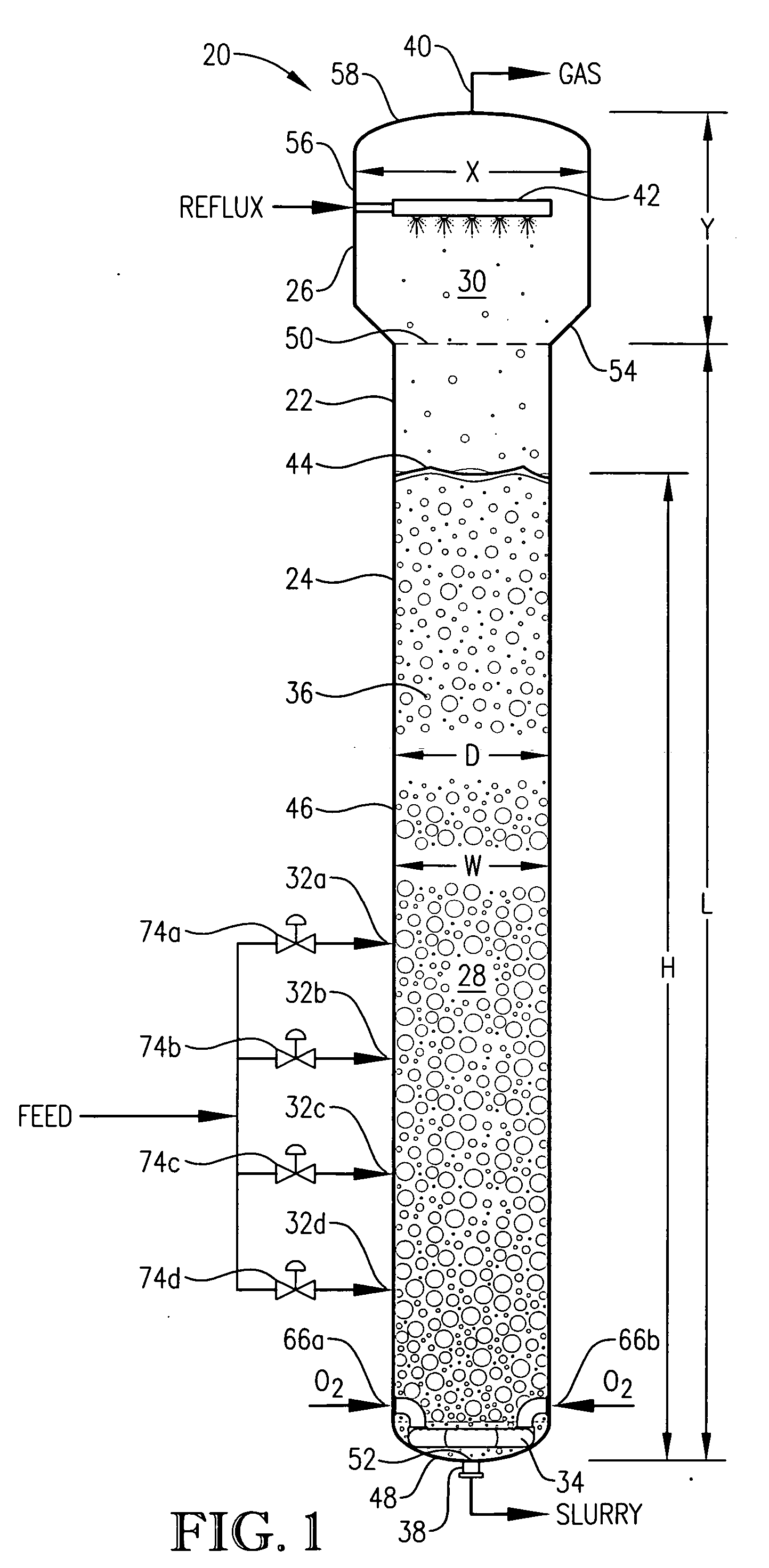

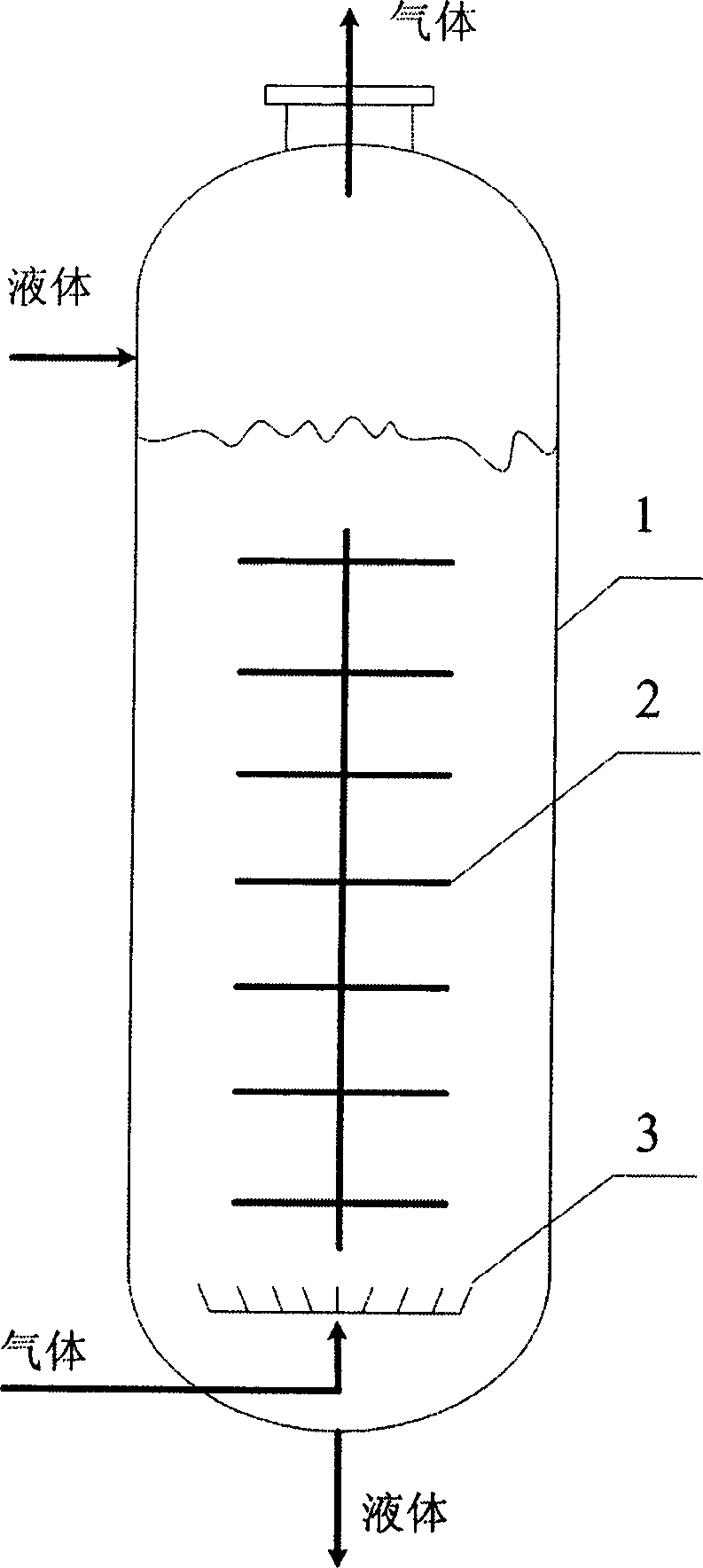

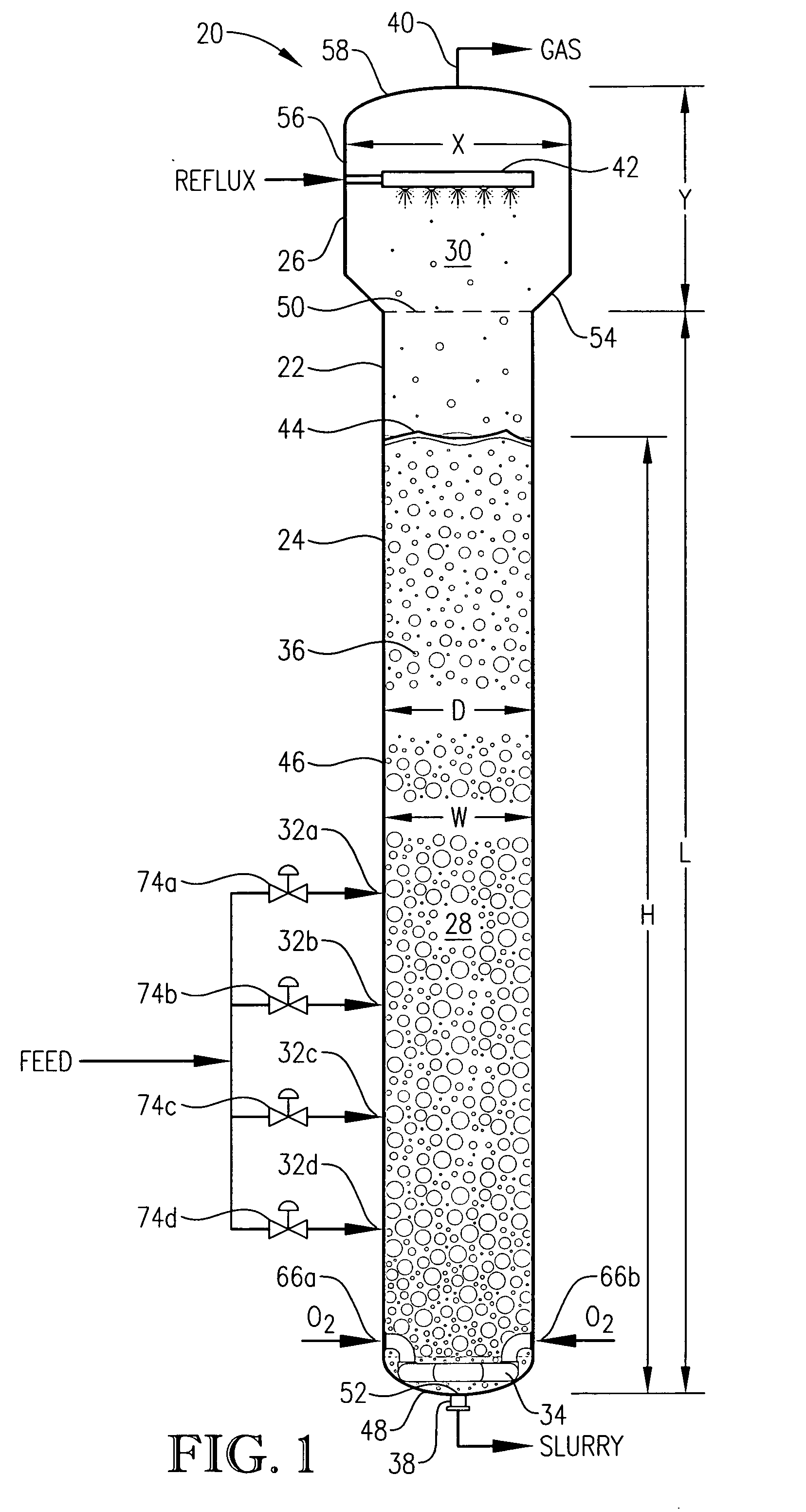

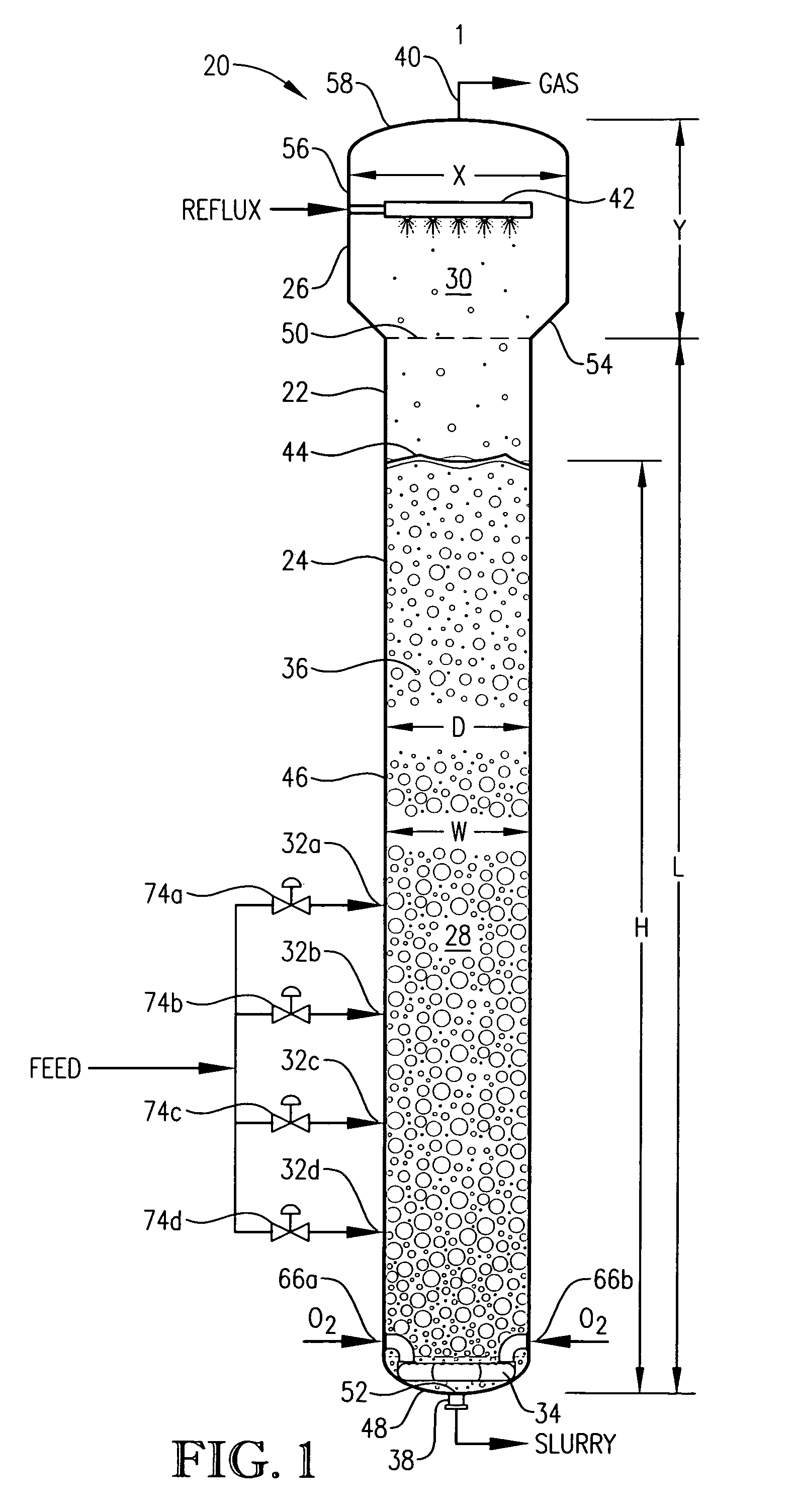

A bubble column reactor is an apparatus used to generate and control gas-liquid chemical reactions. It consists of a vertically-arranged cylindrical column filled with liquid, at the bottom of which gas is inserted.

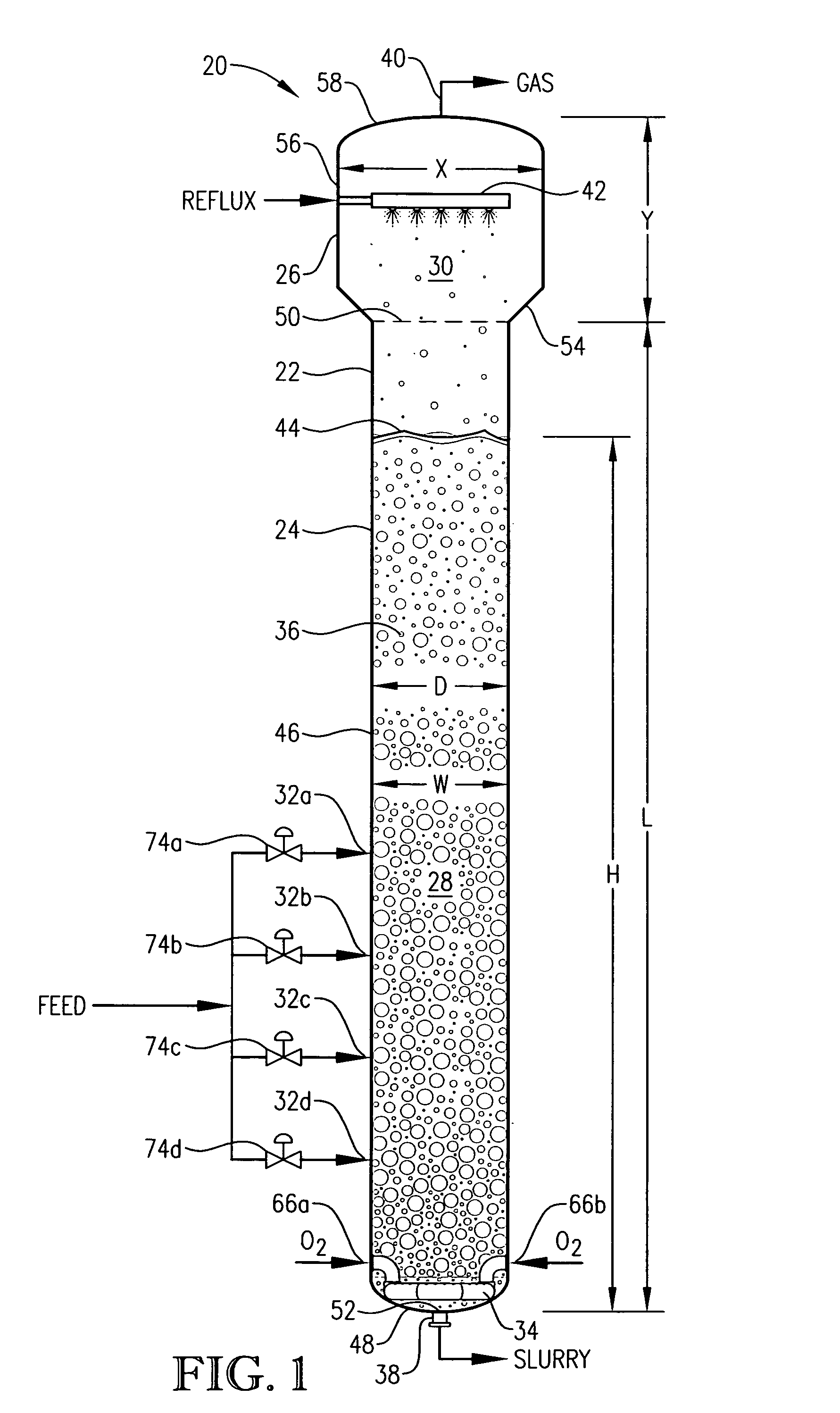

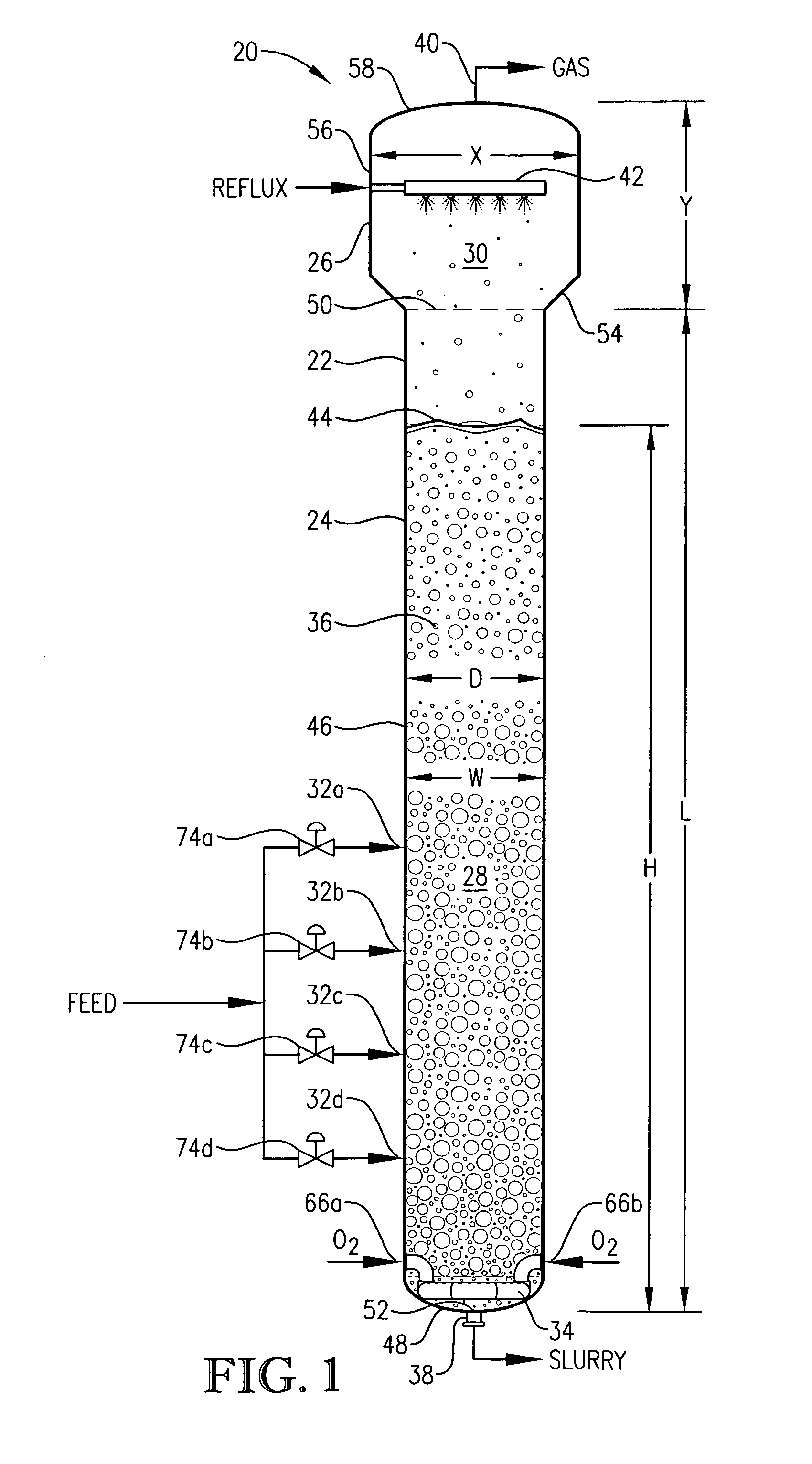

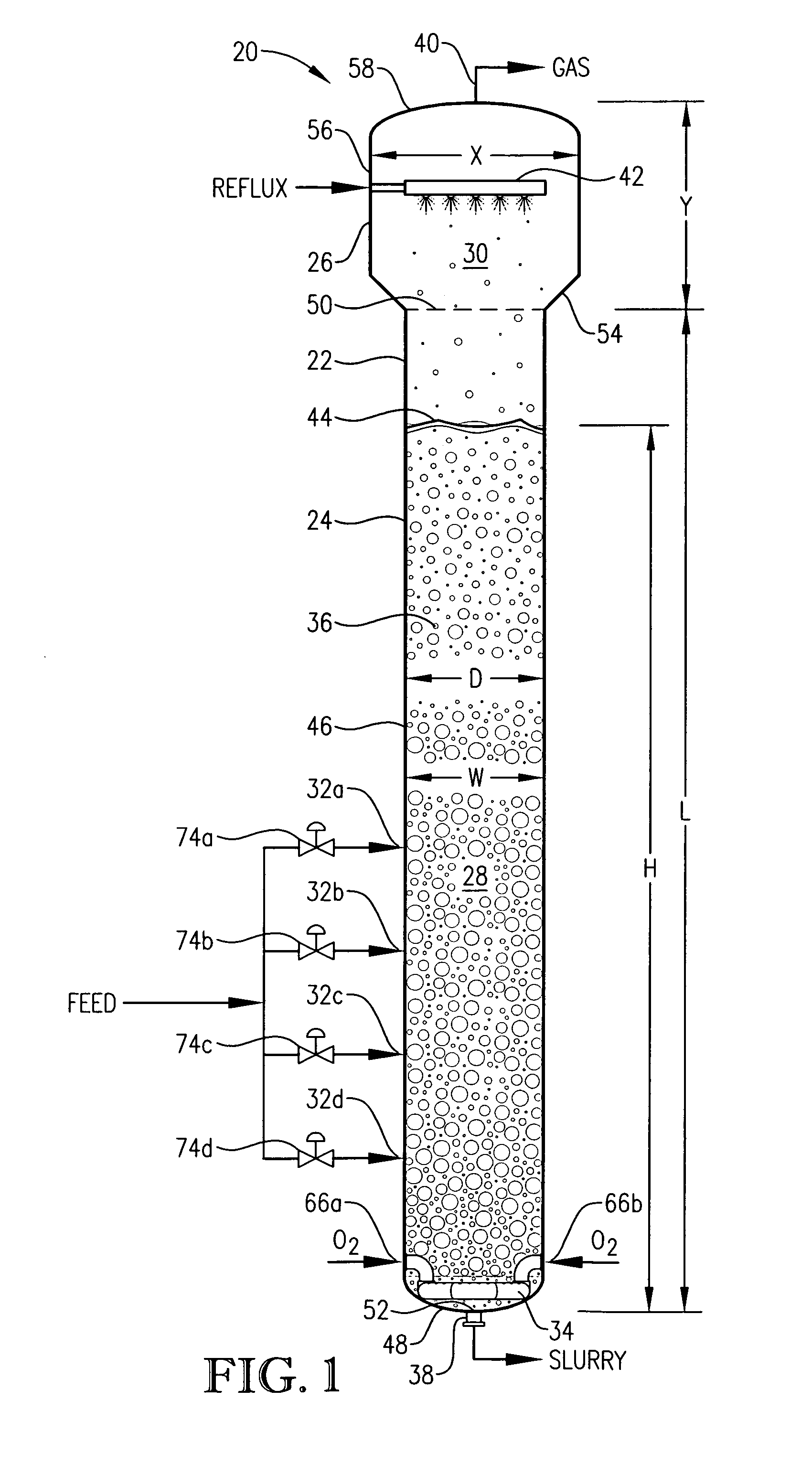

Optimized liquid-phase oxidation

ActiveUS20060047163A1Effective and economicalReduce formationOrganic oxidationOrganic compound preparationOrganic chemistryTerephthalic acid

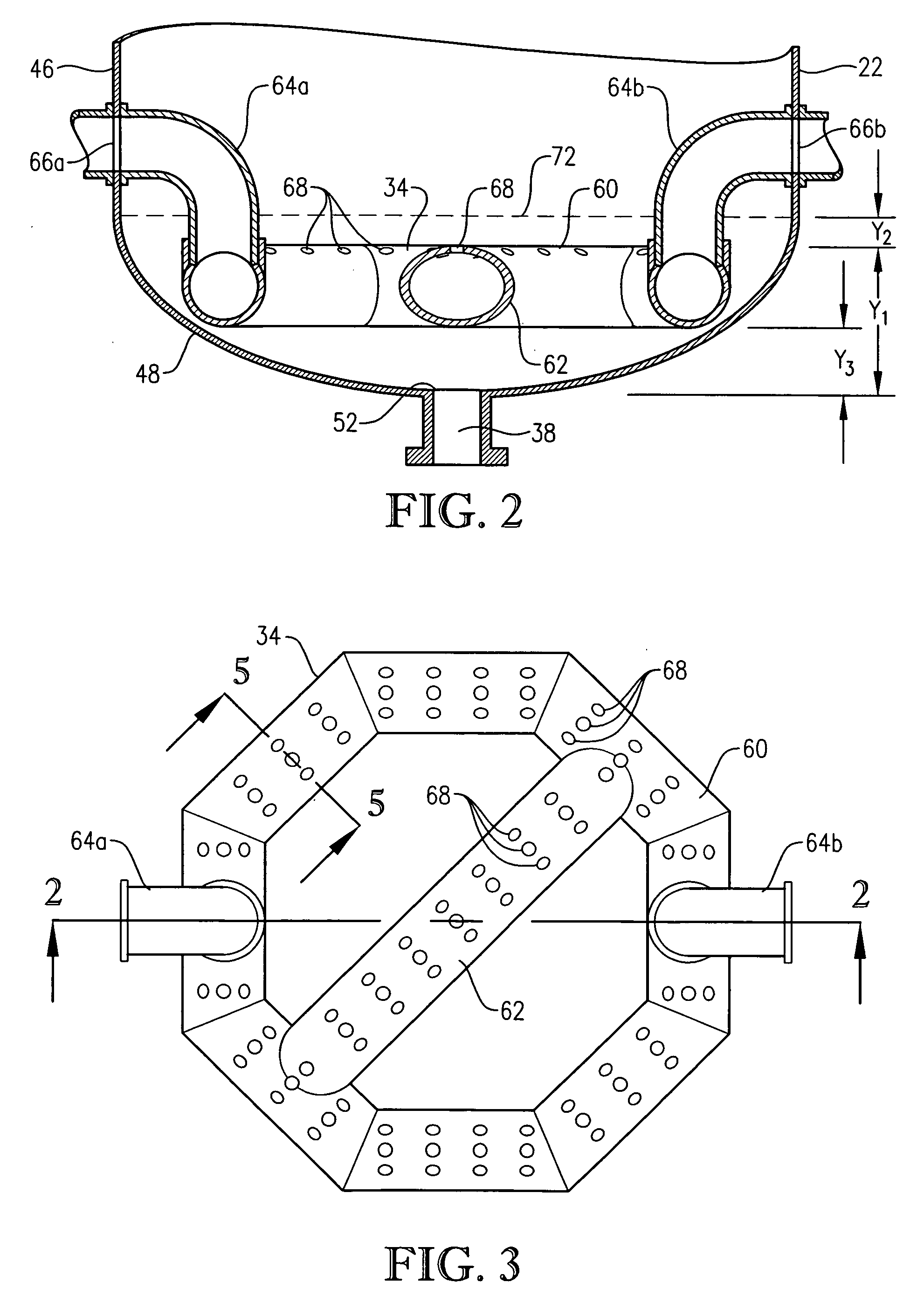

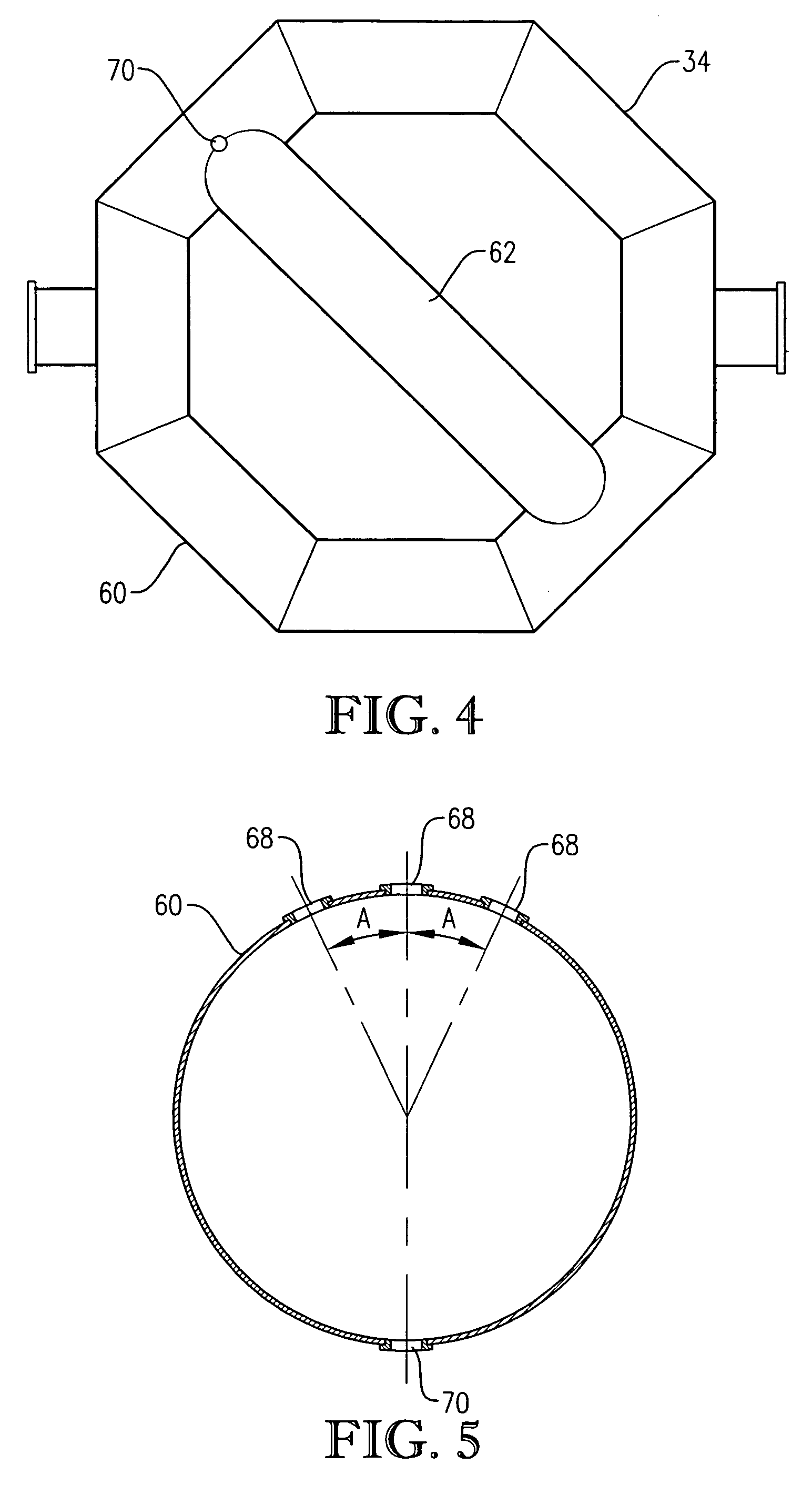

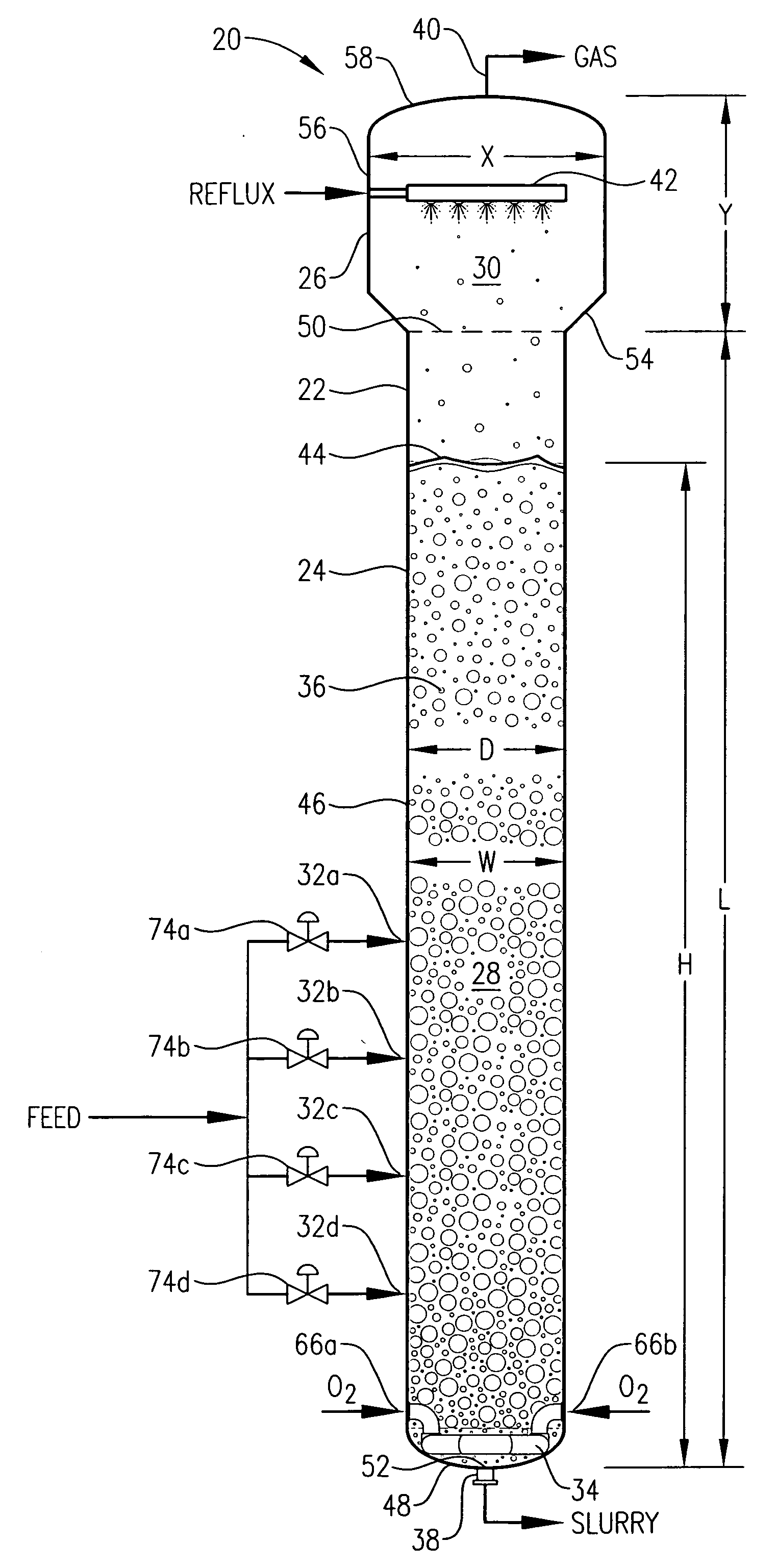

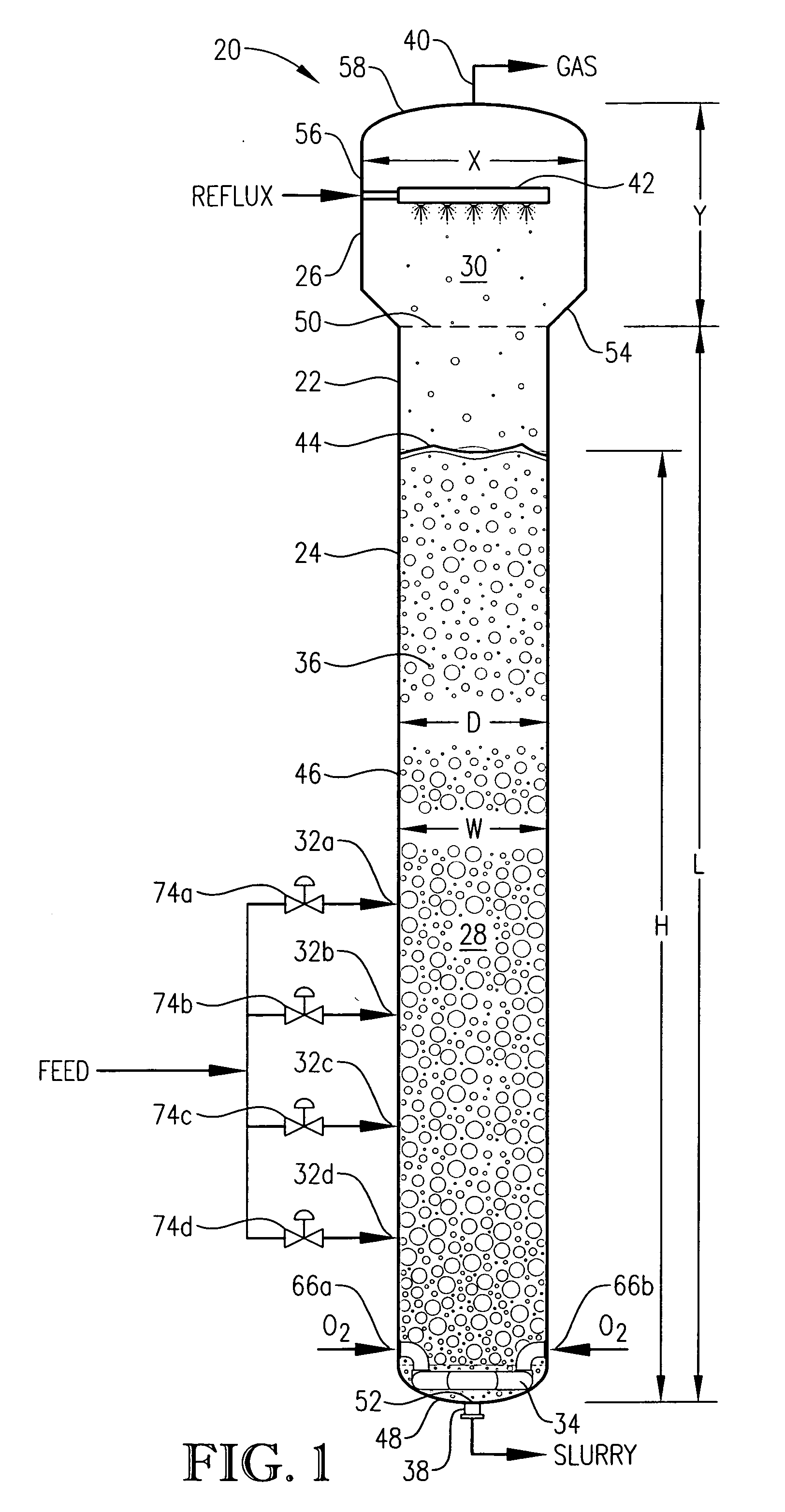

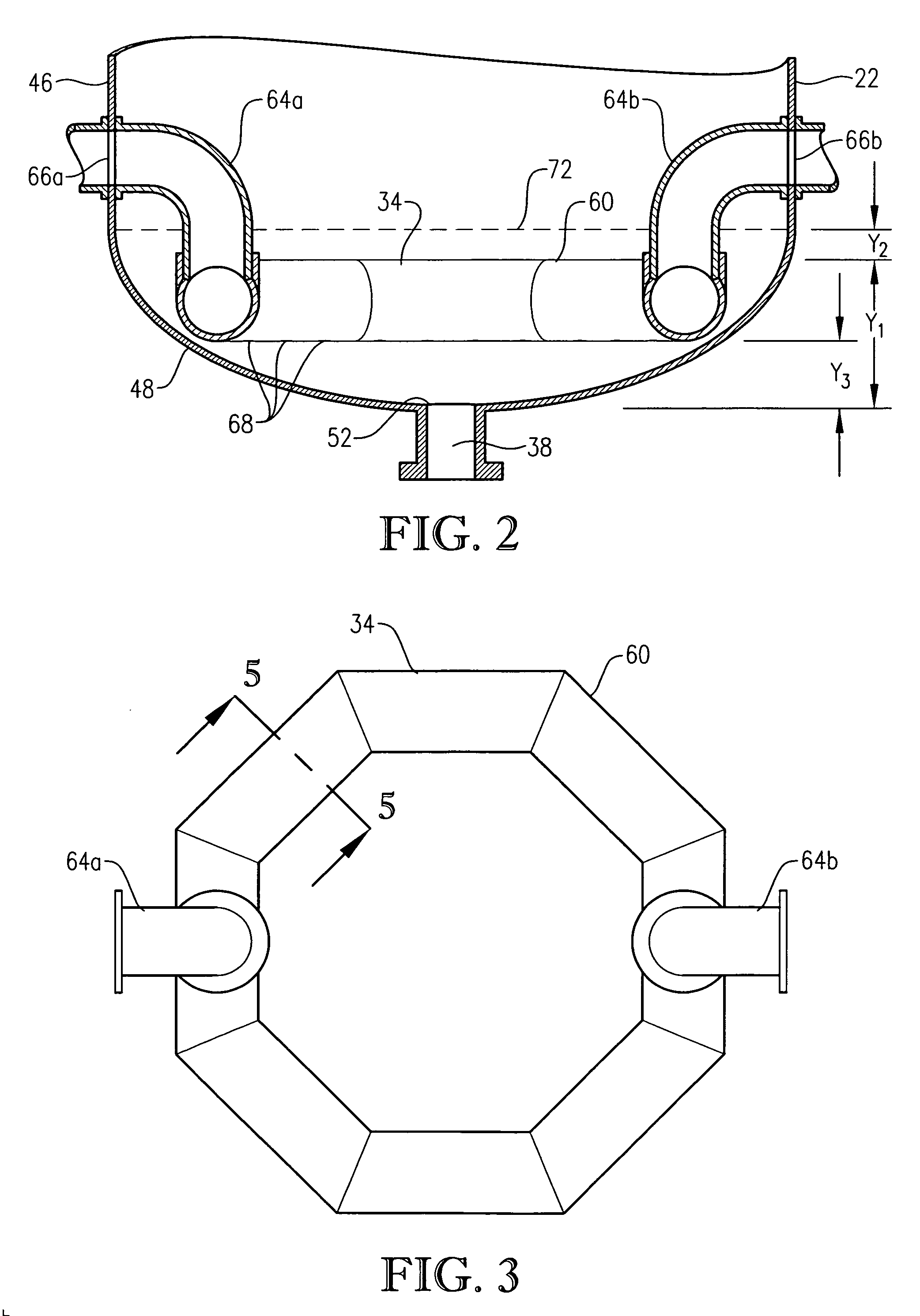

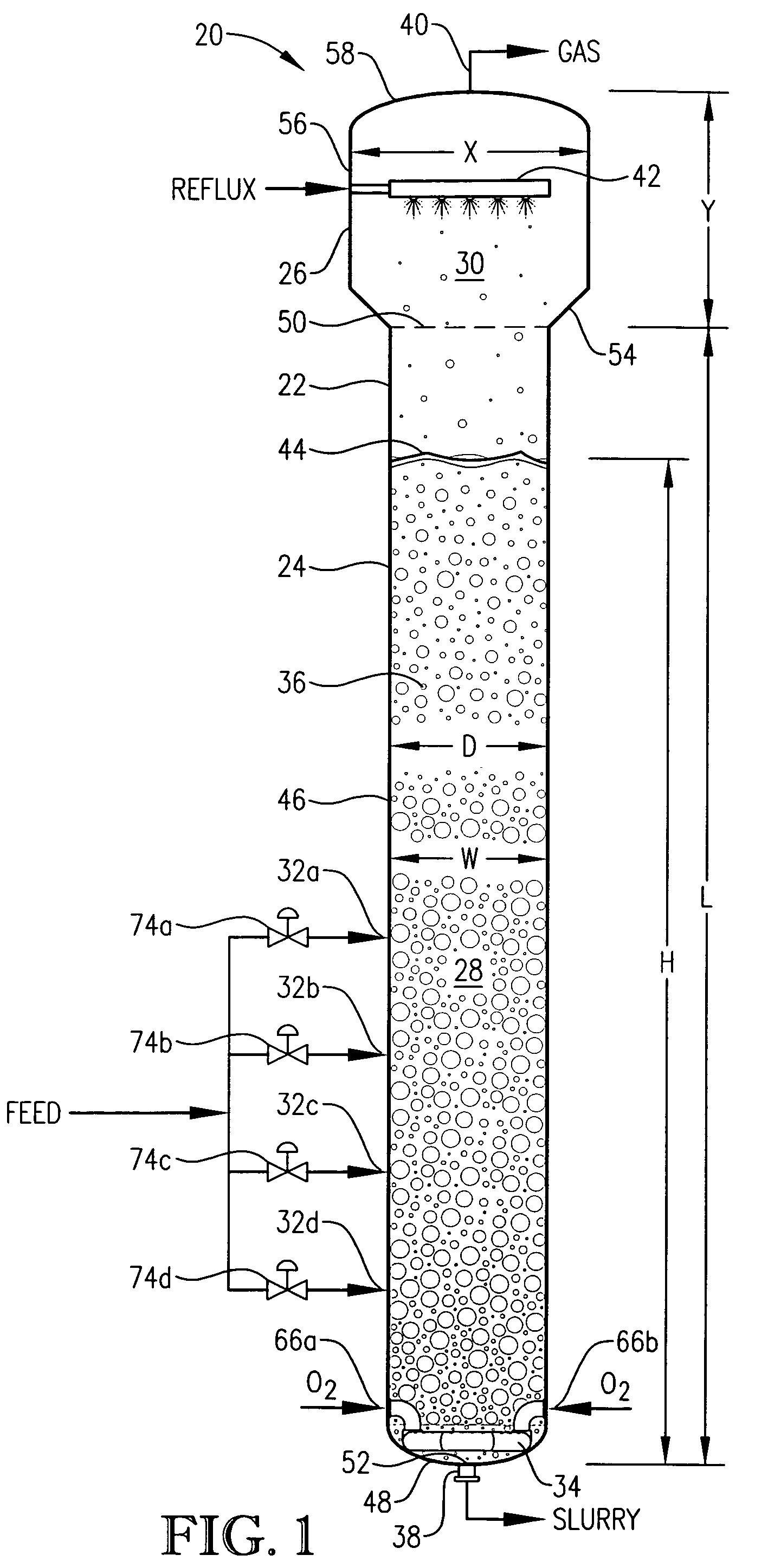

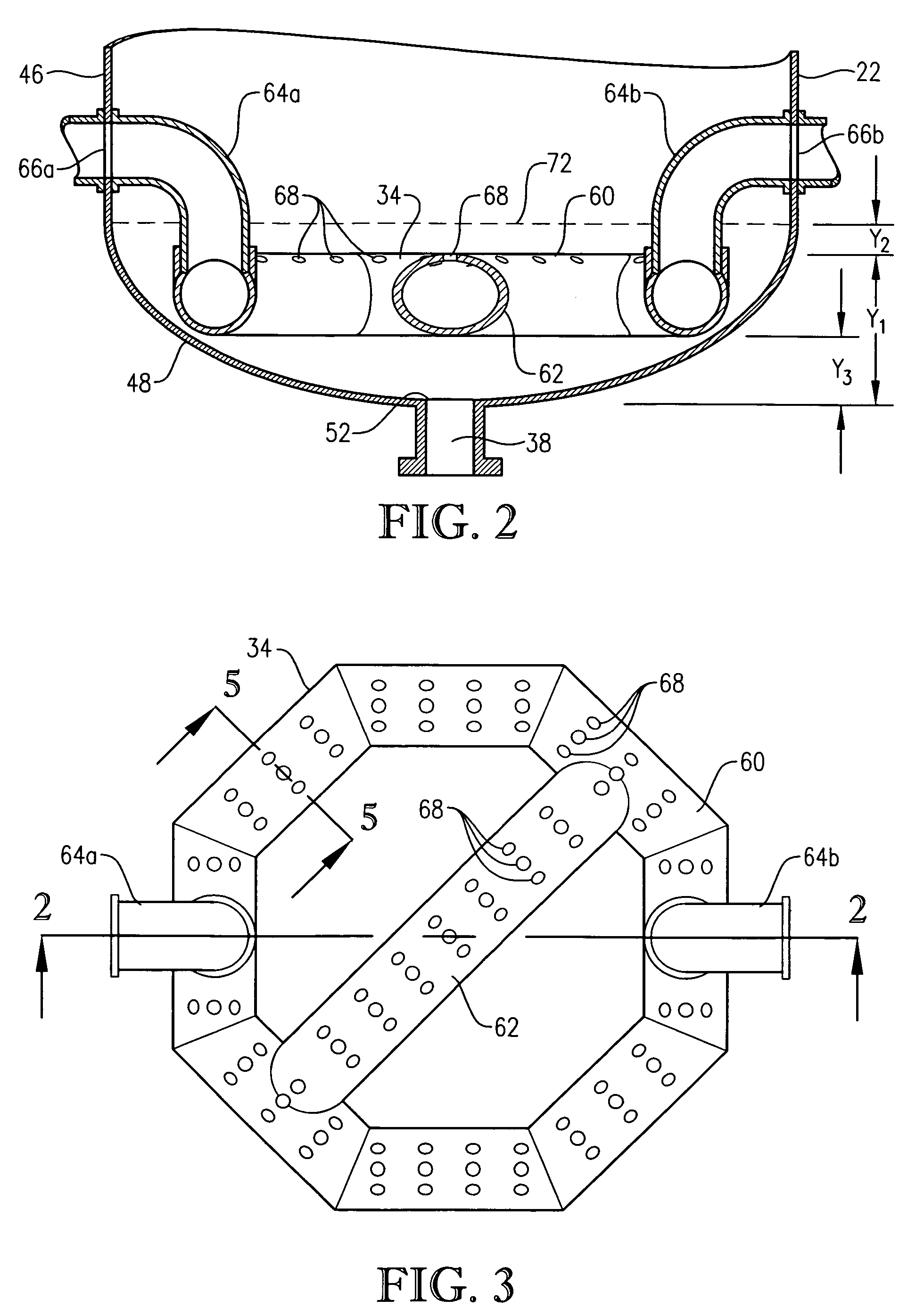

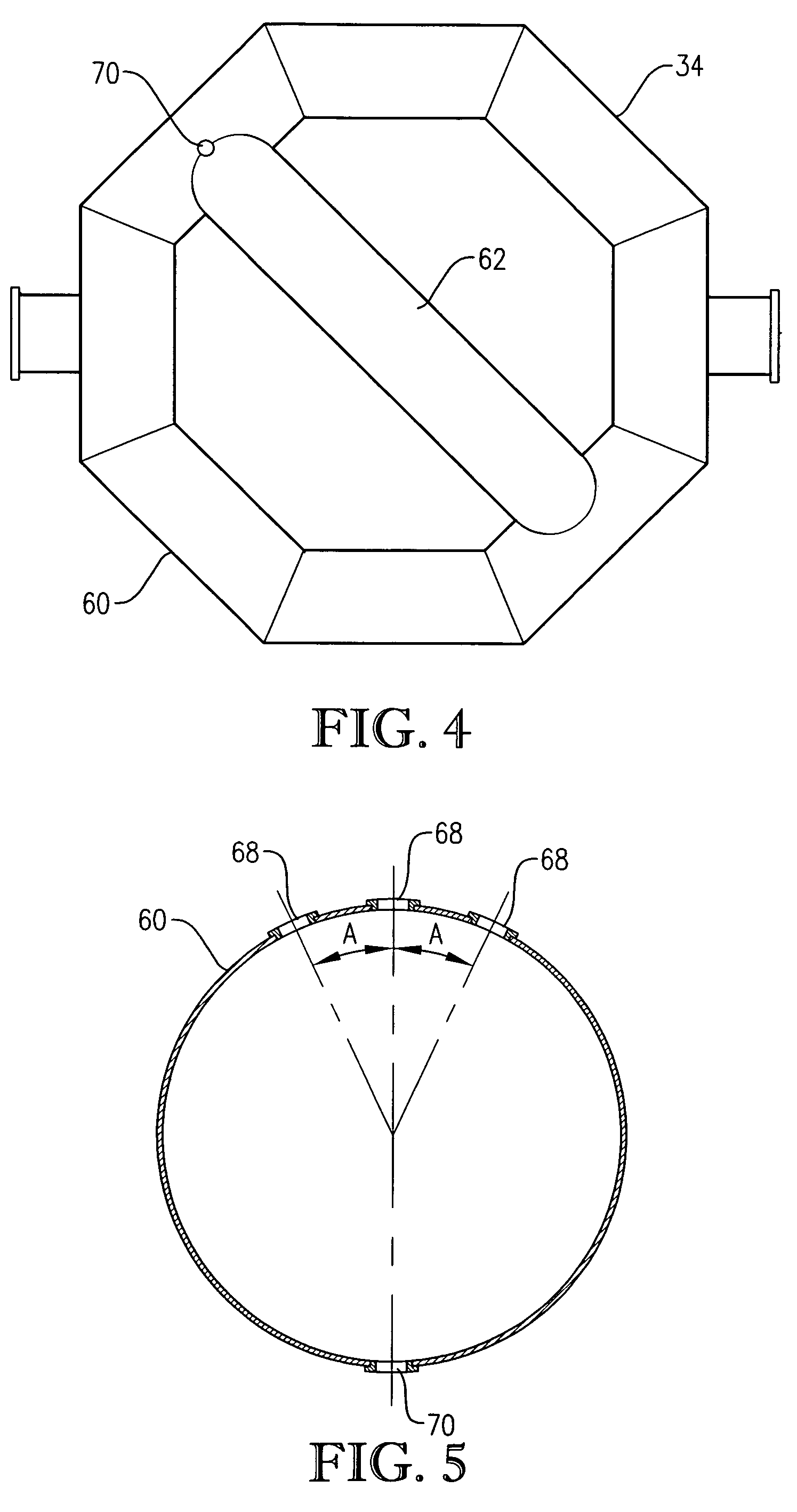

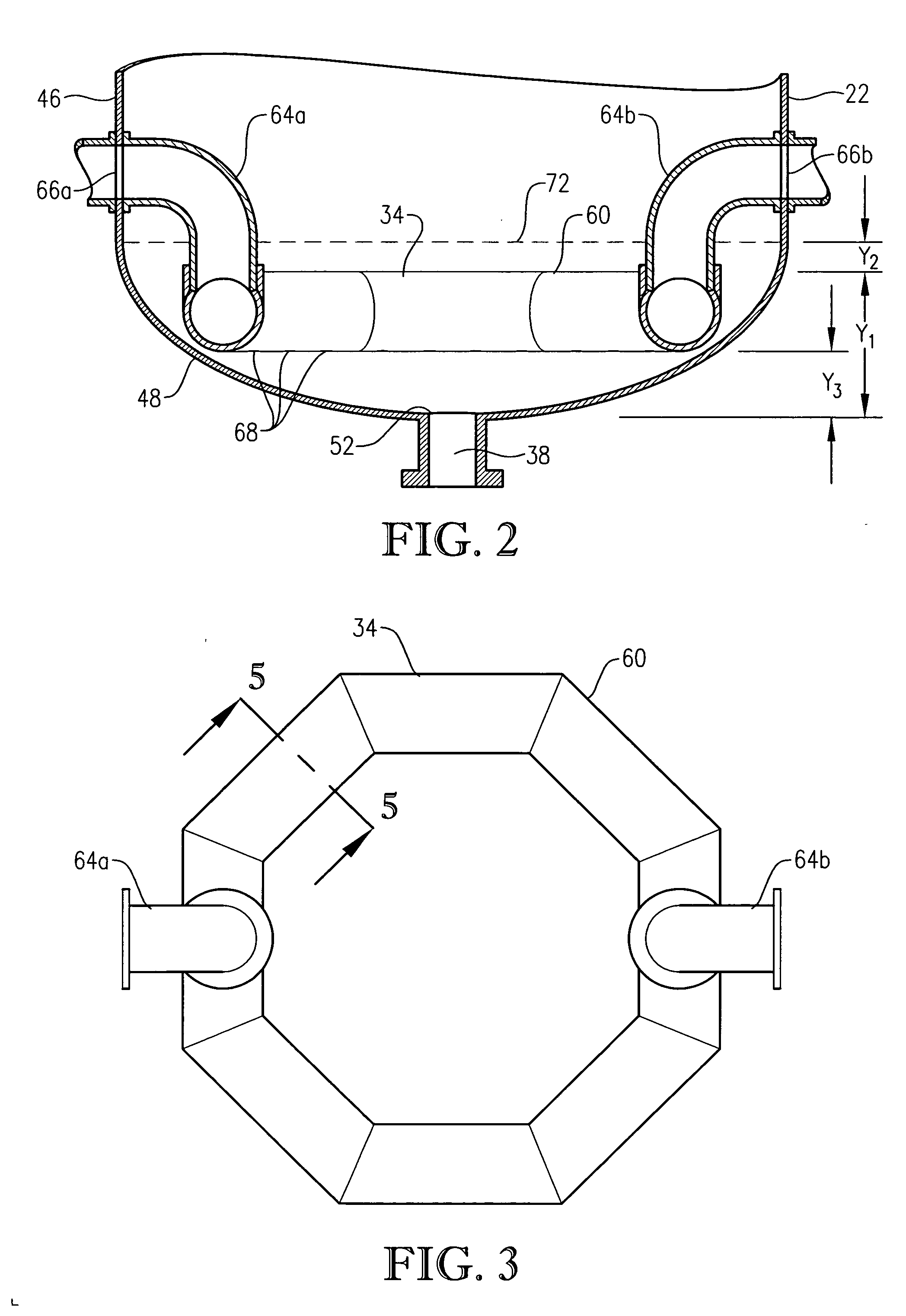

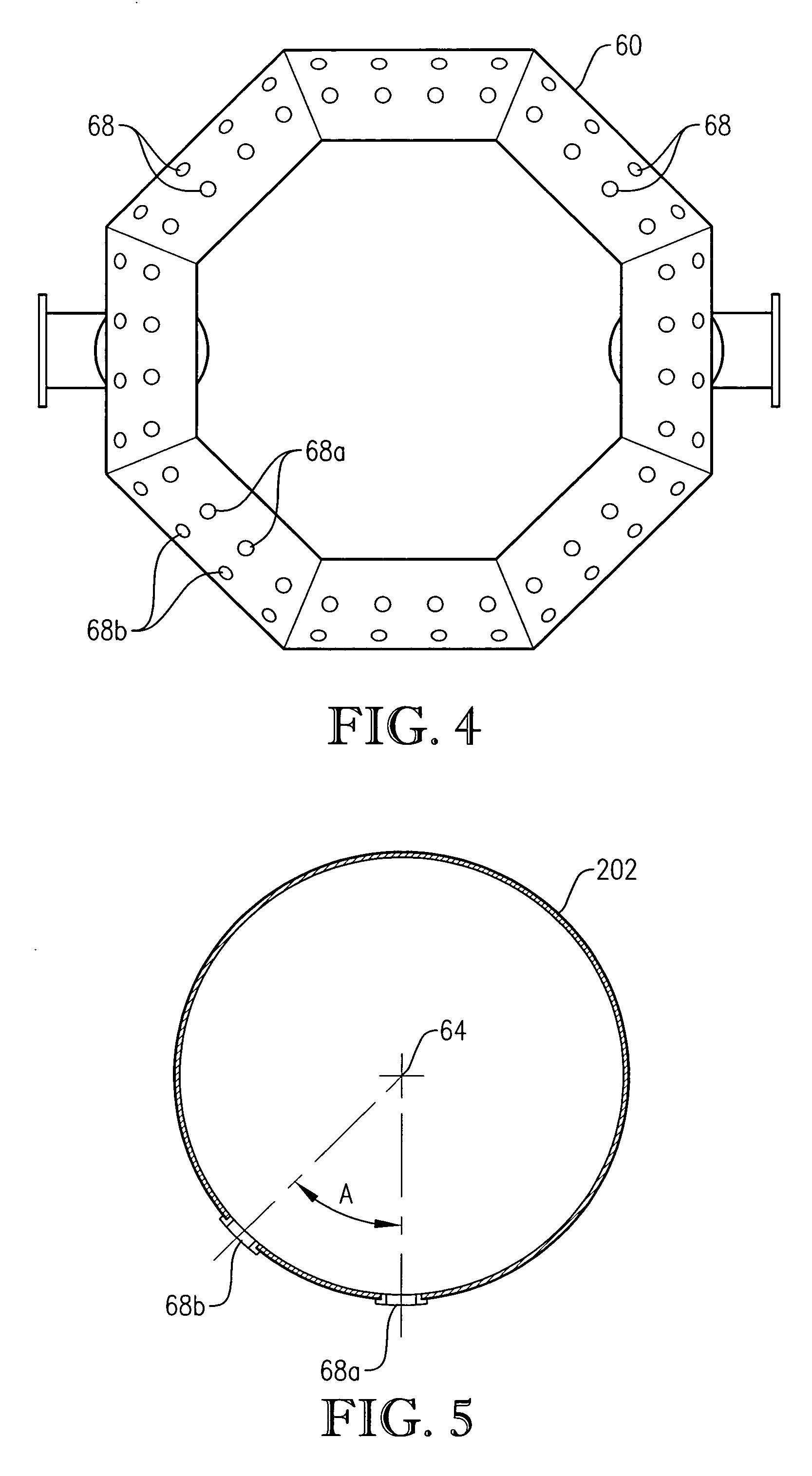

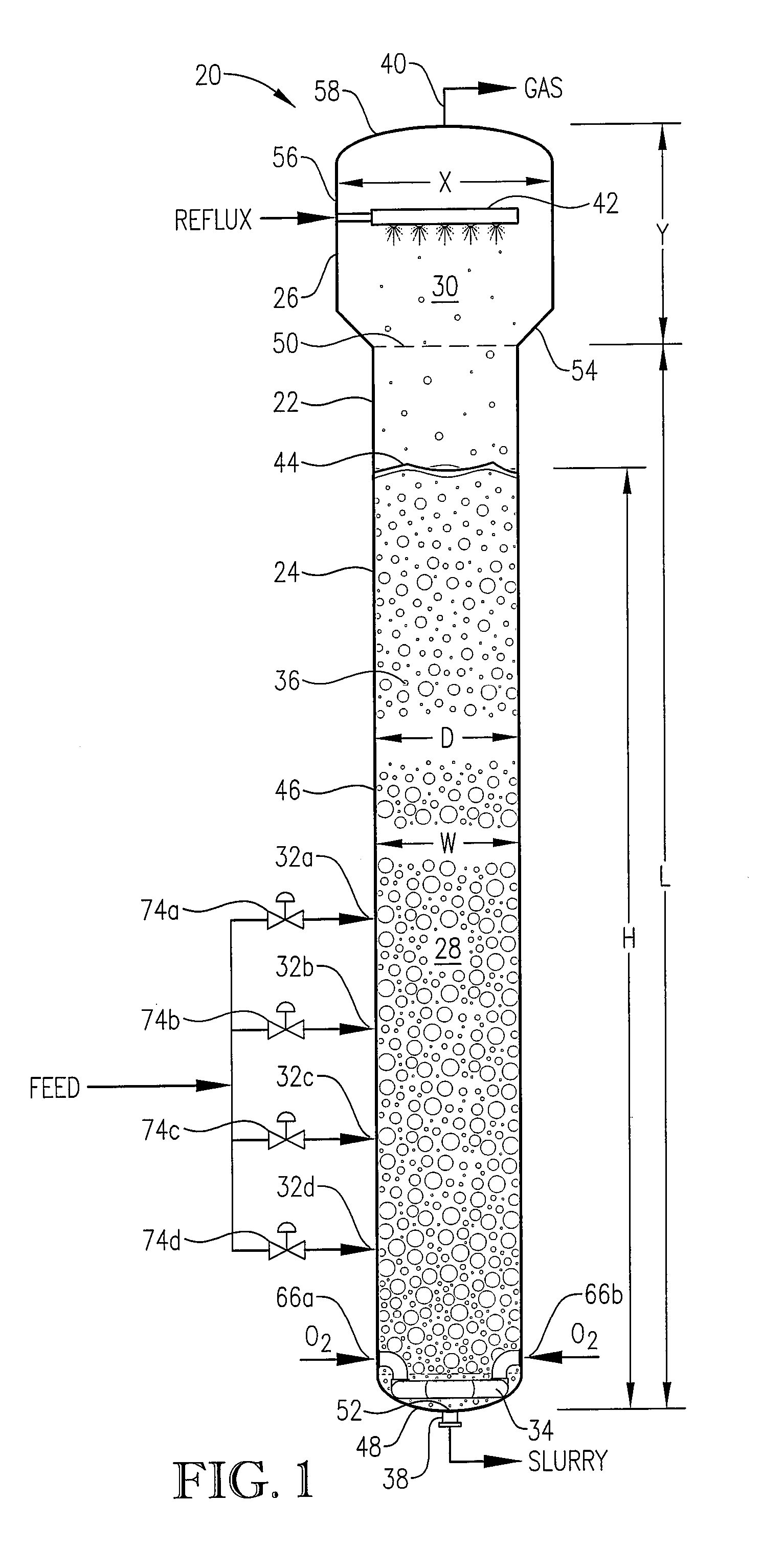

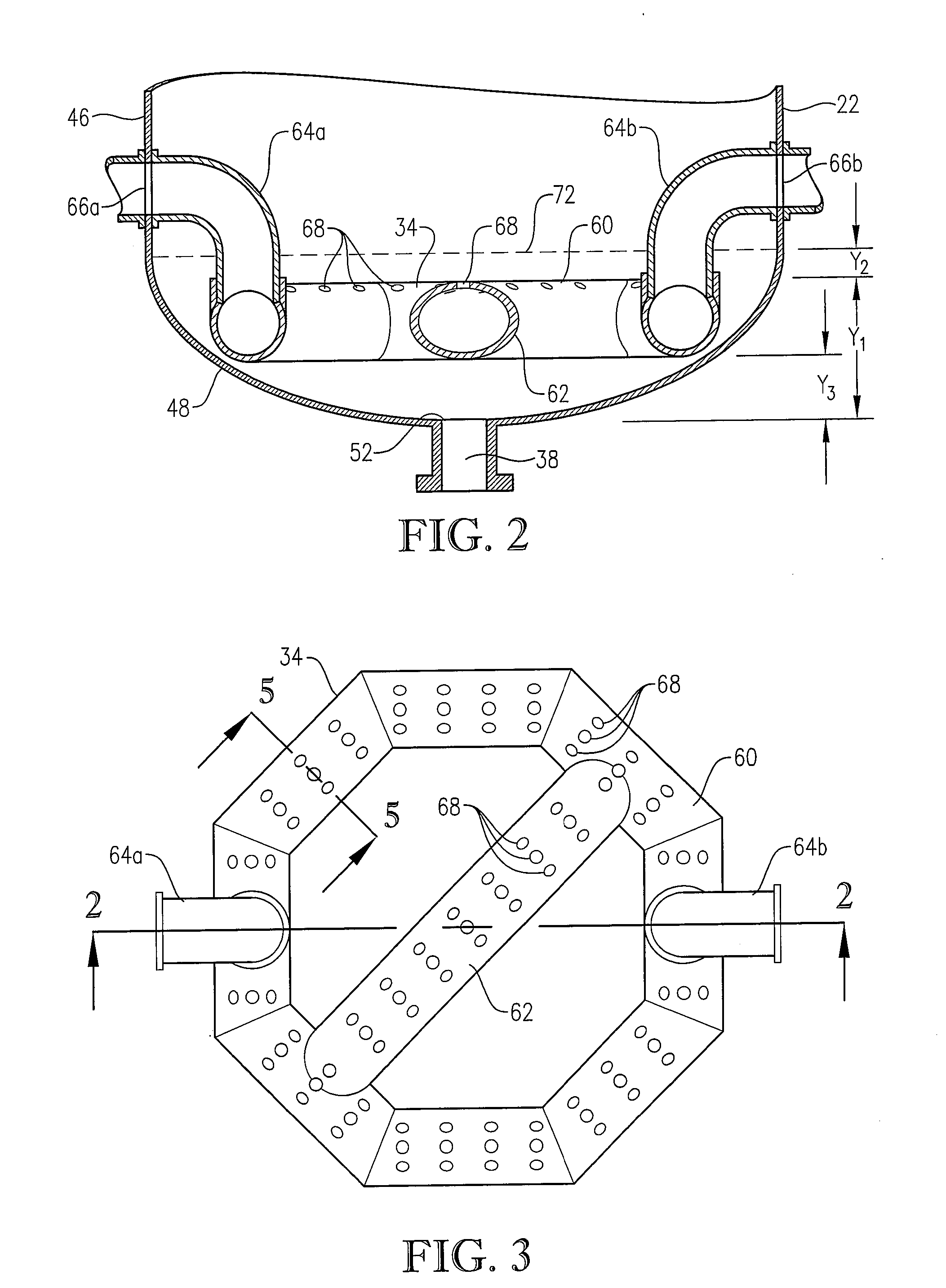

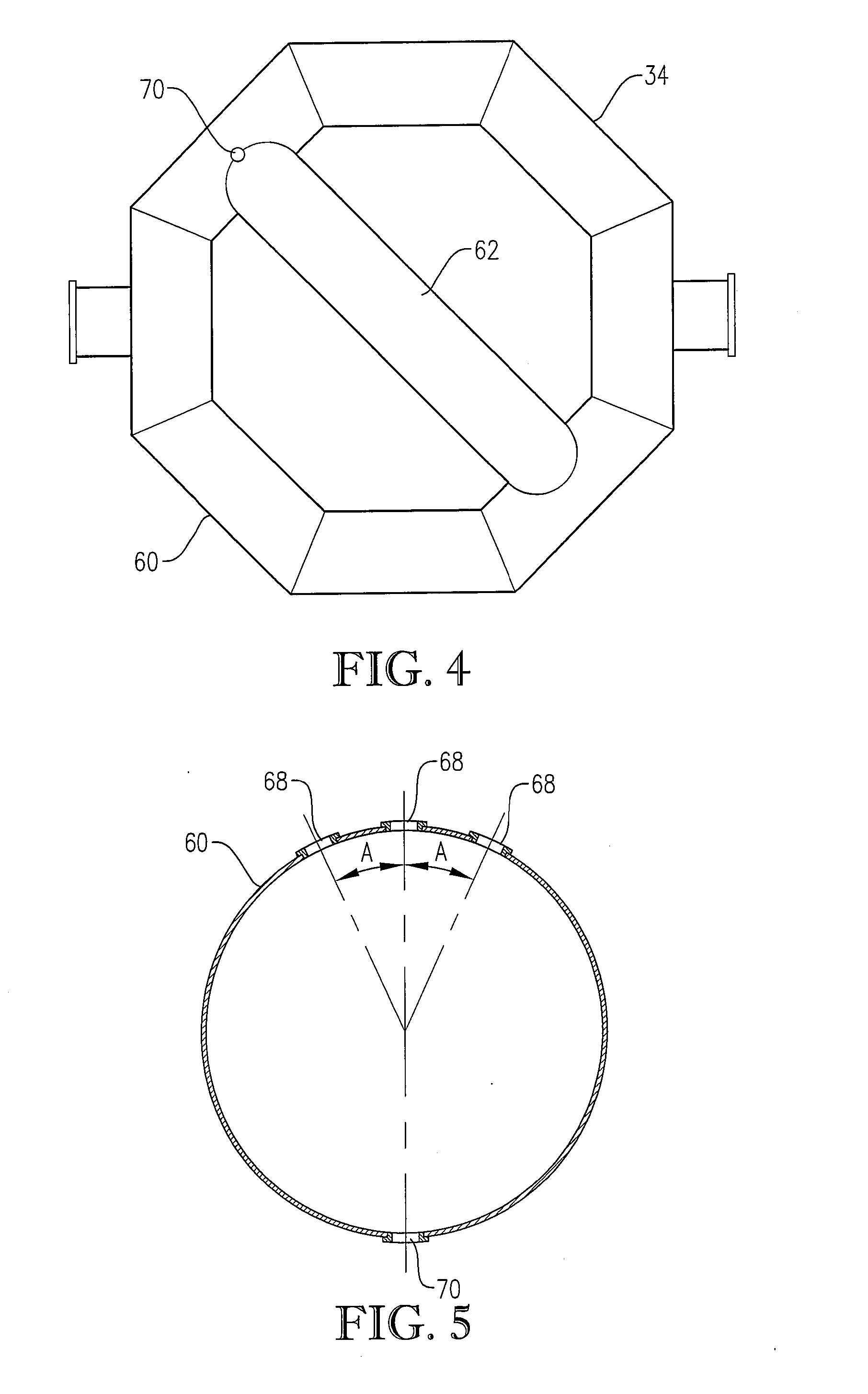

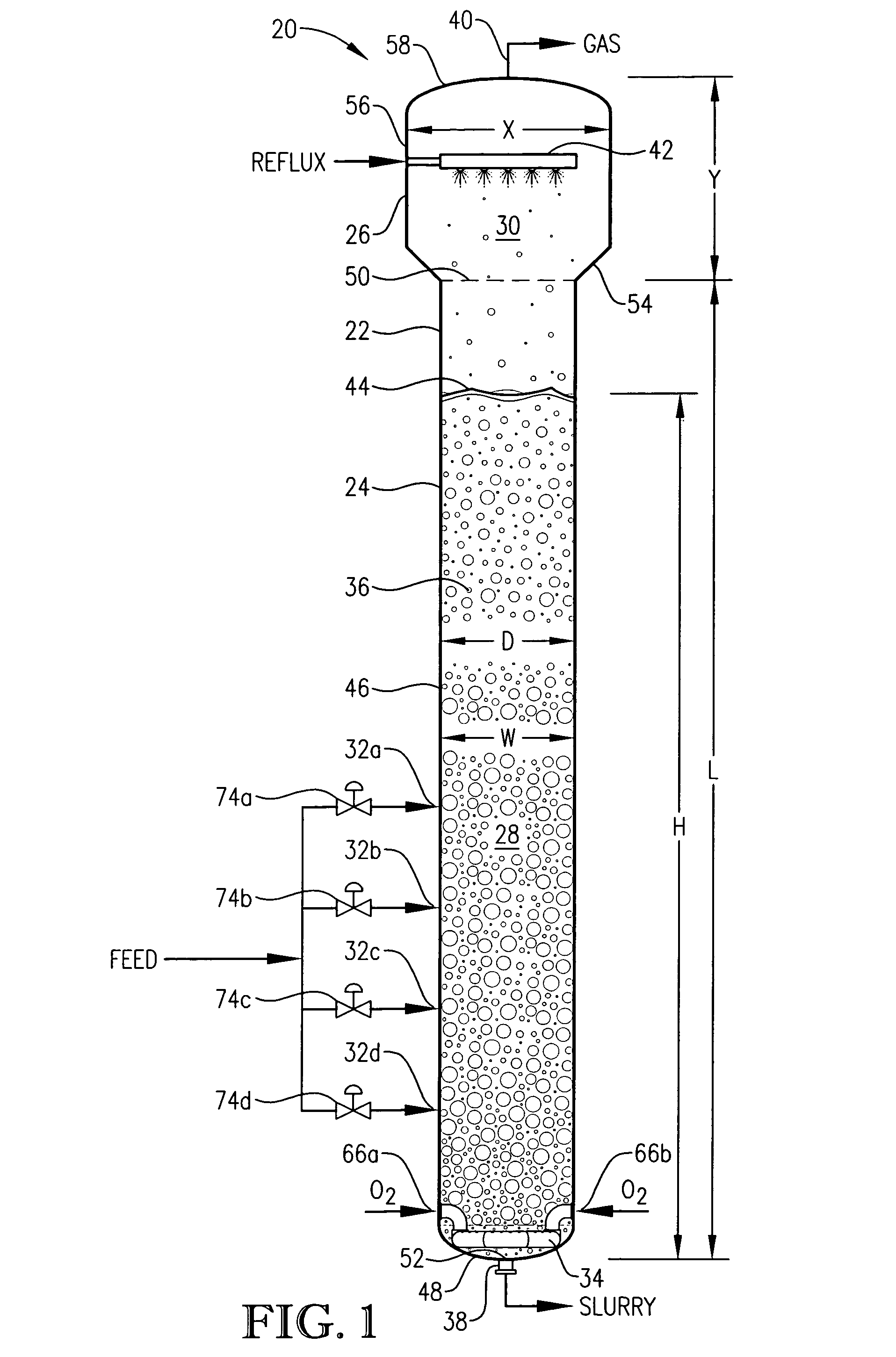

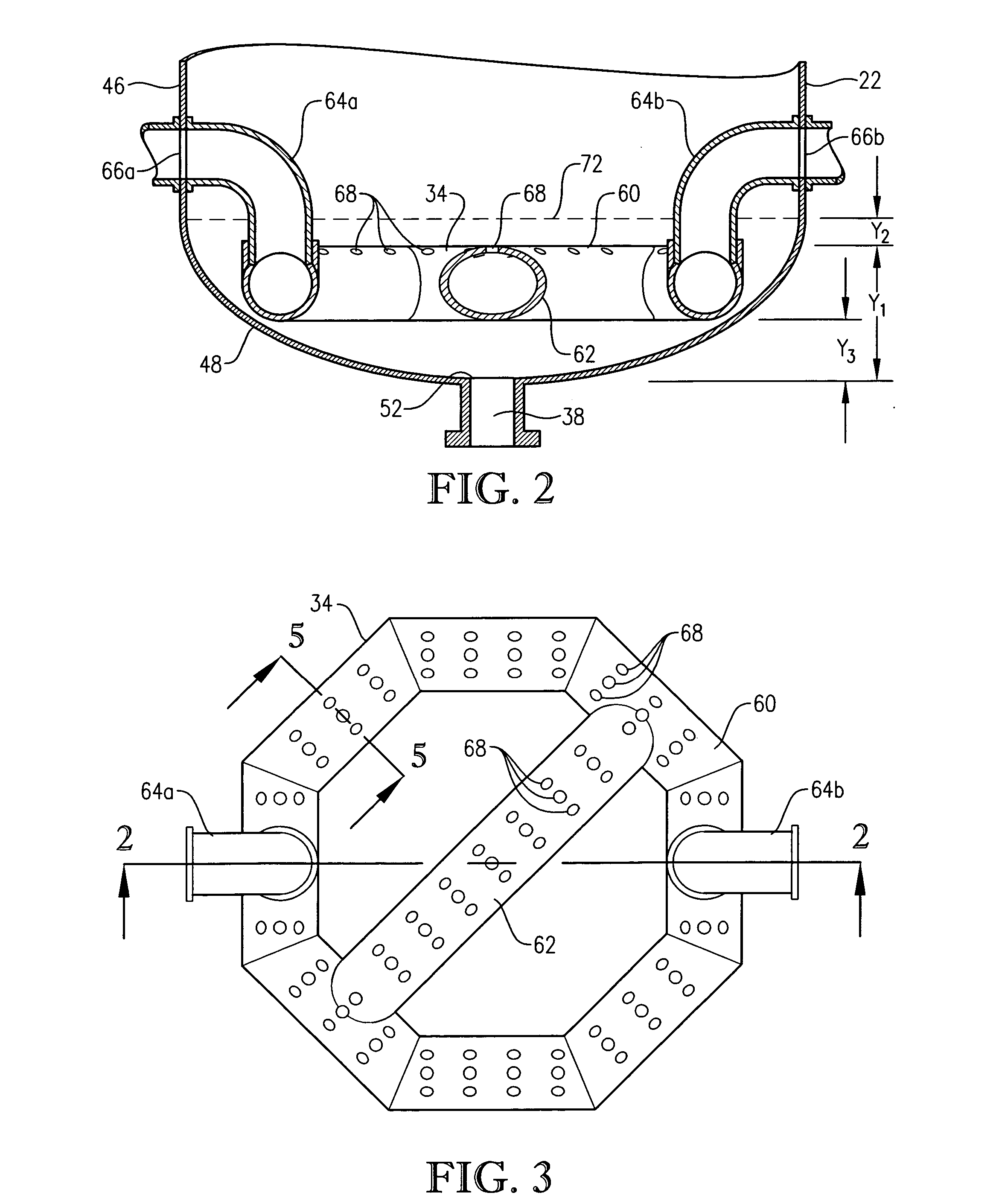

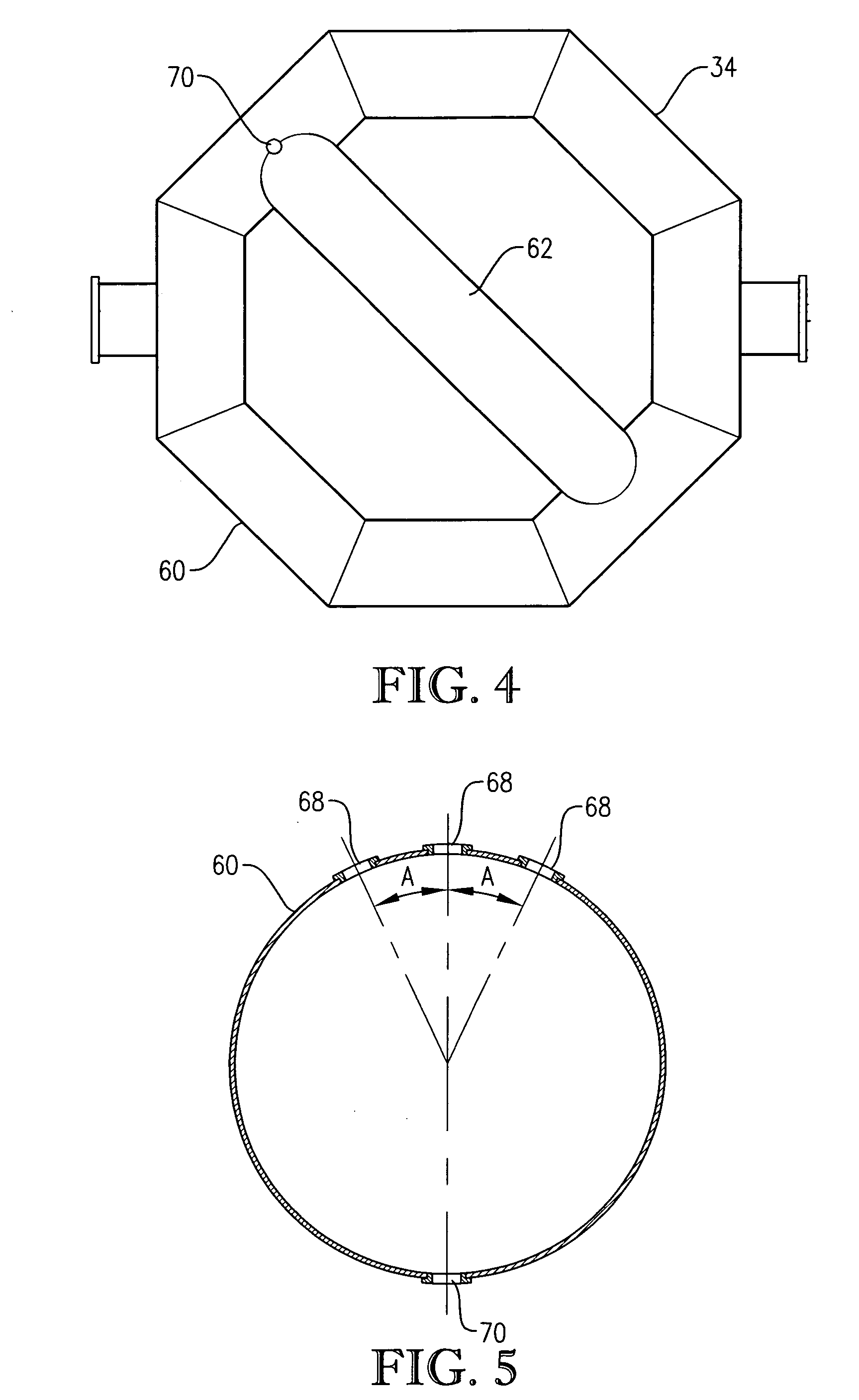

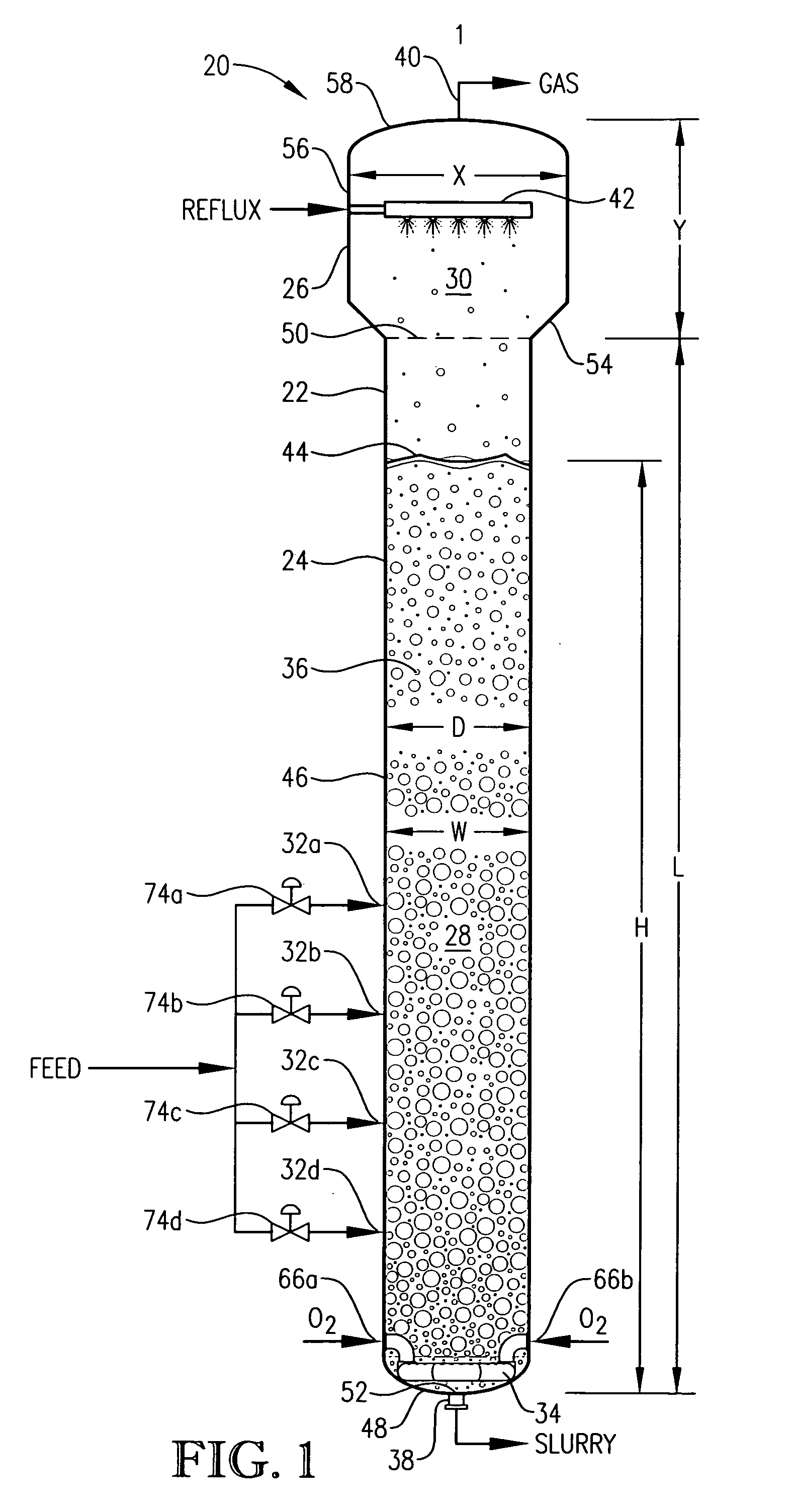

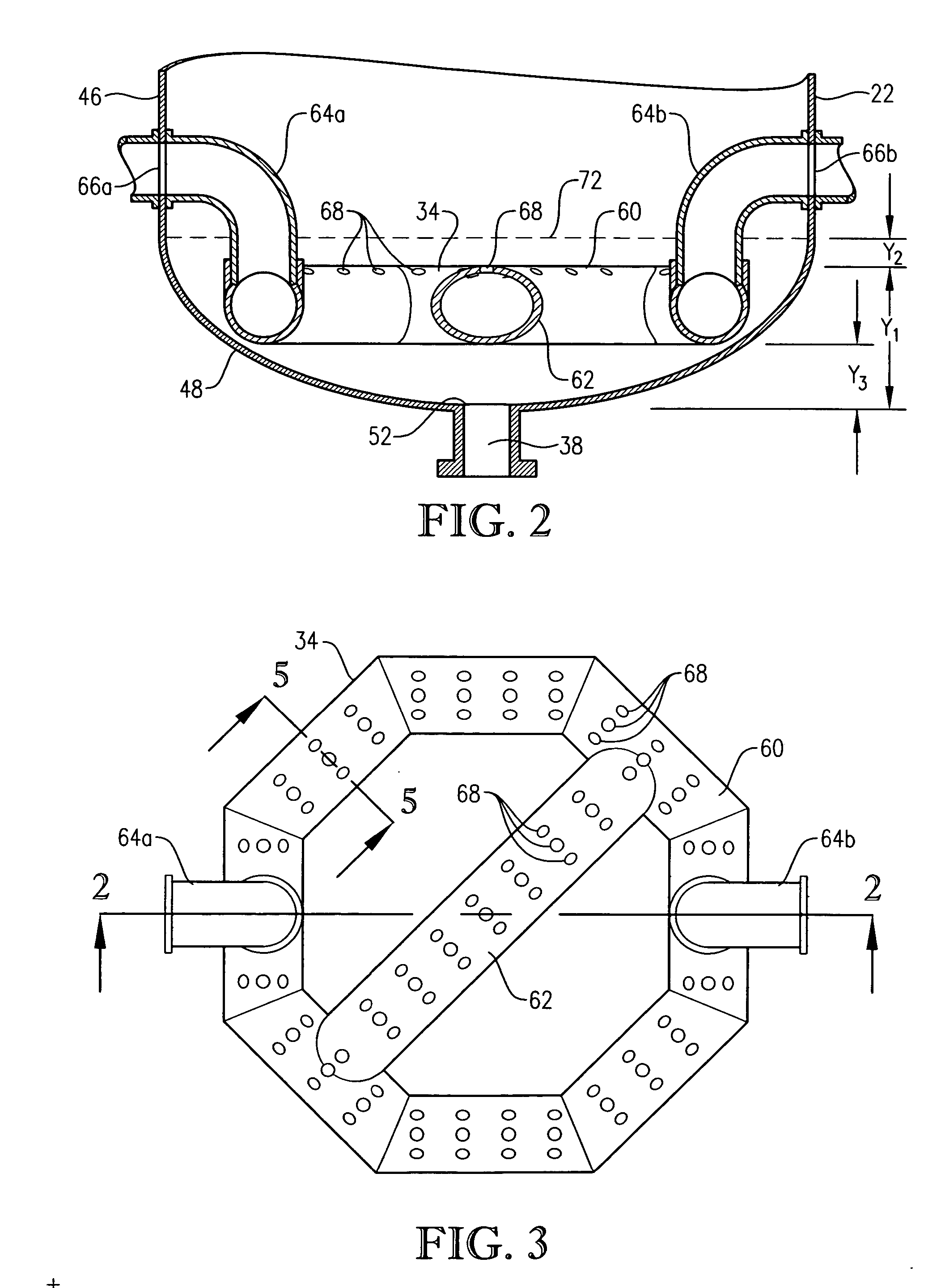

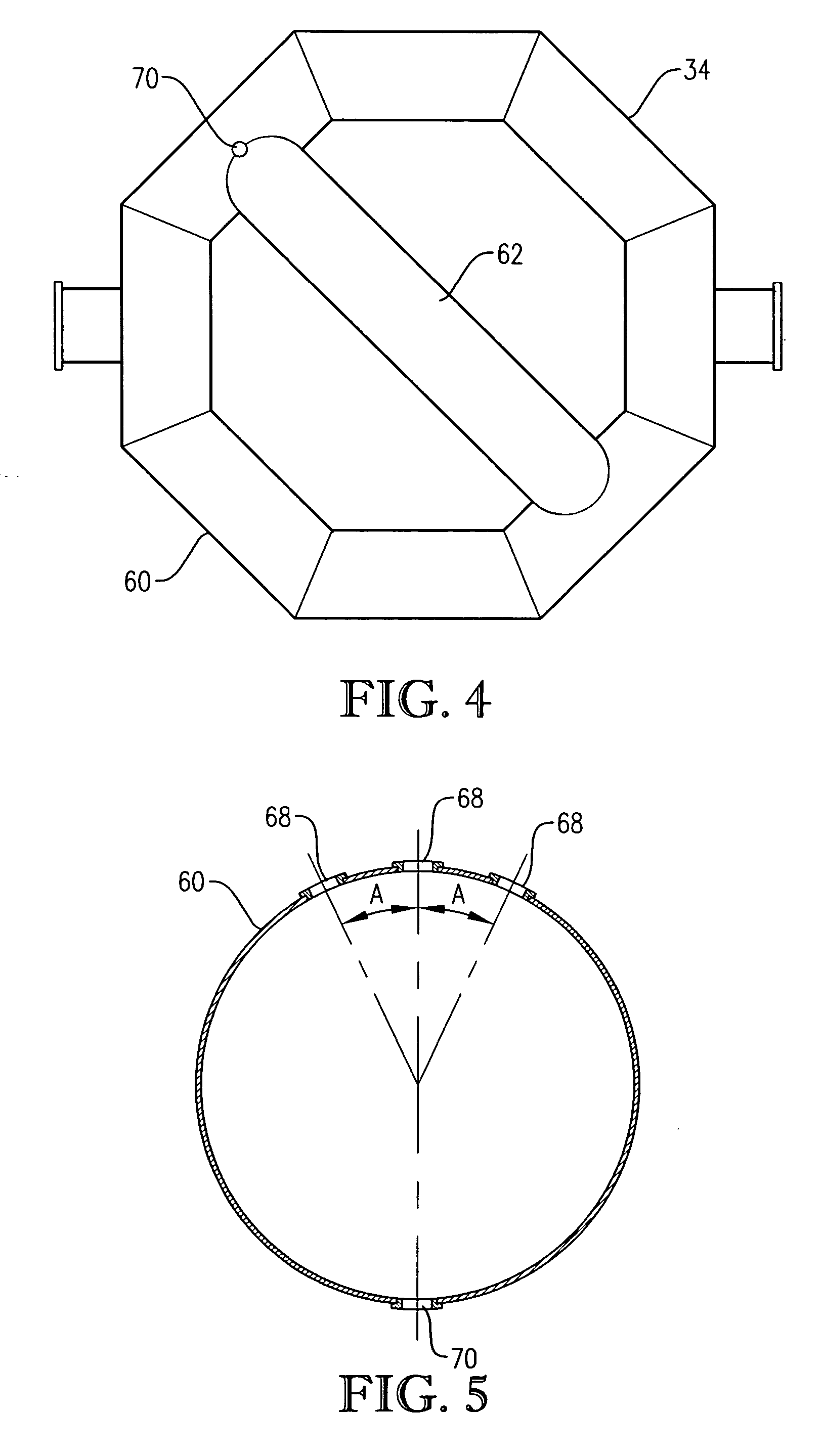

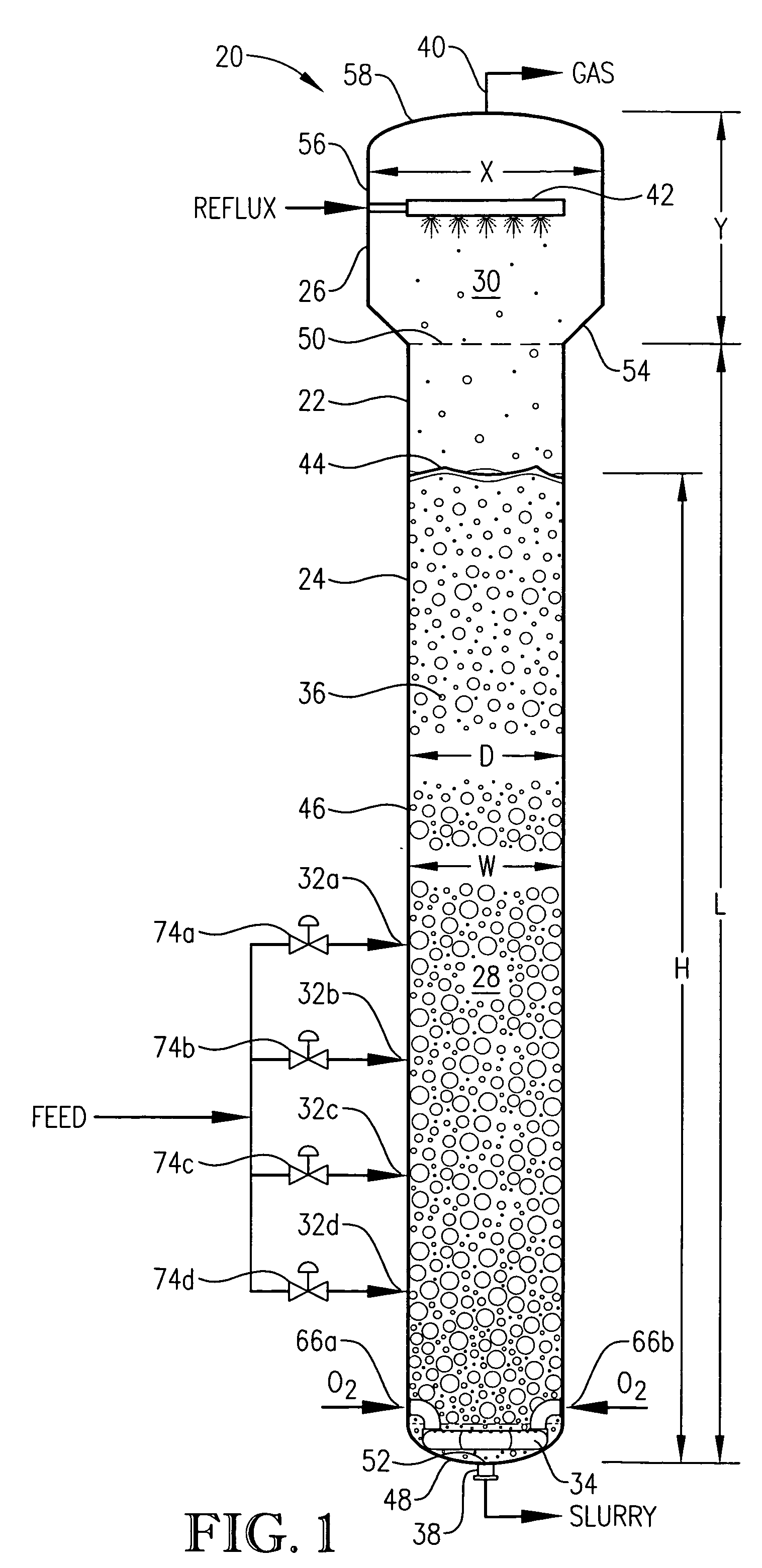

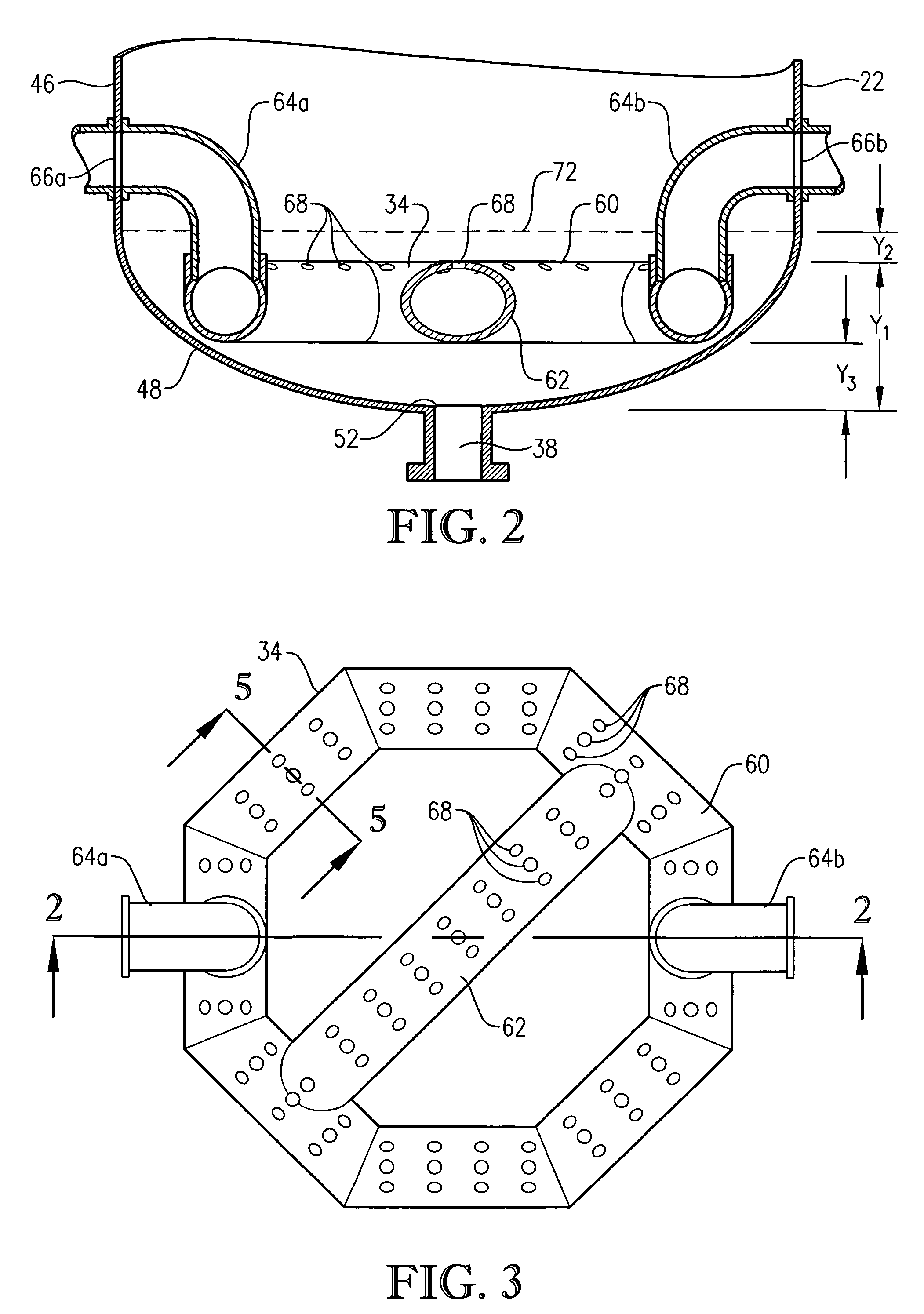

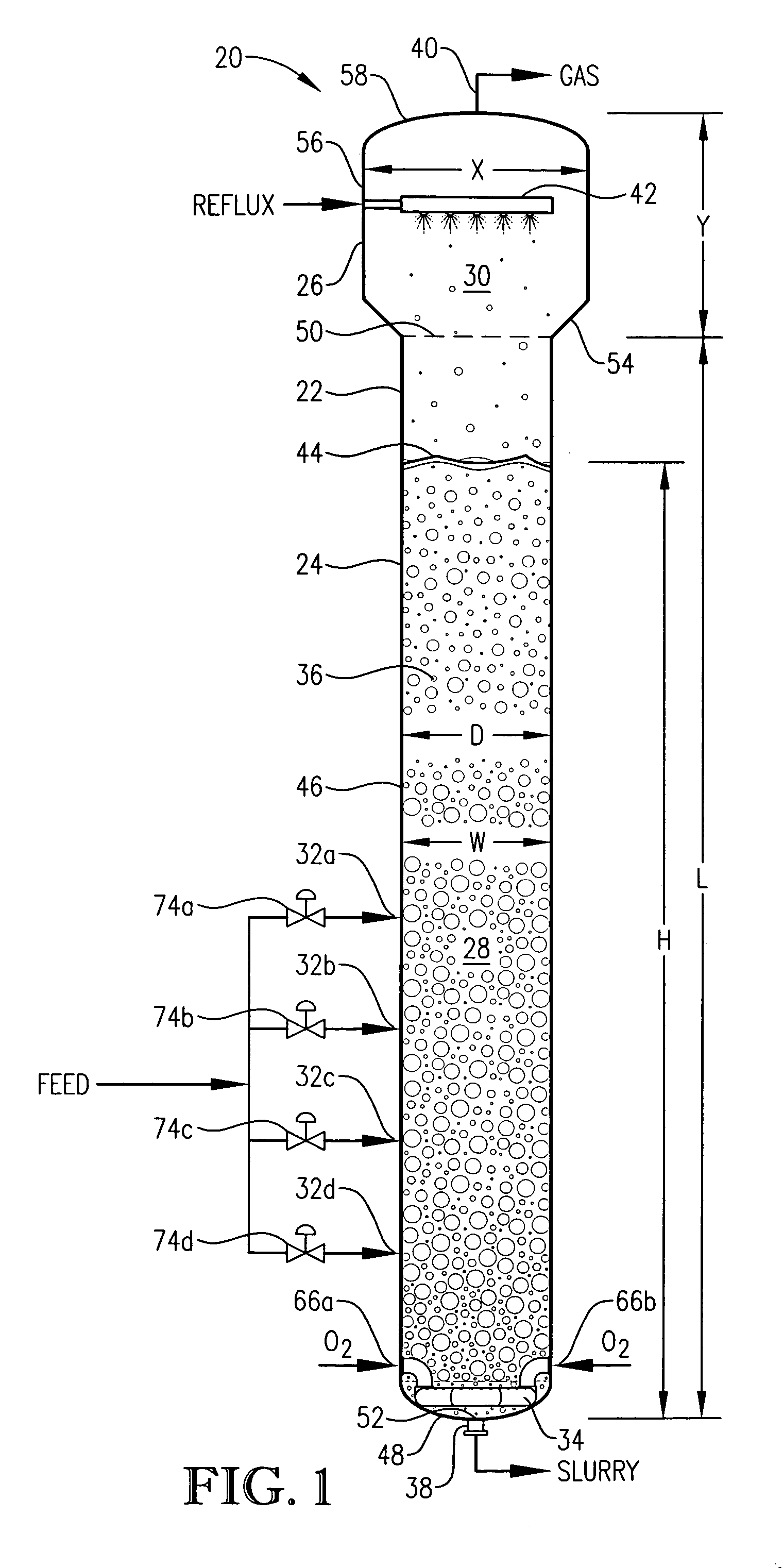

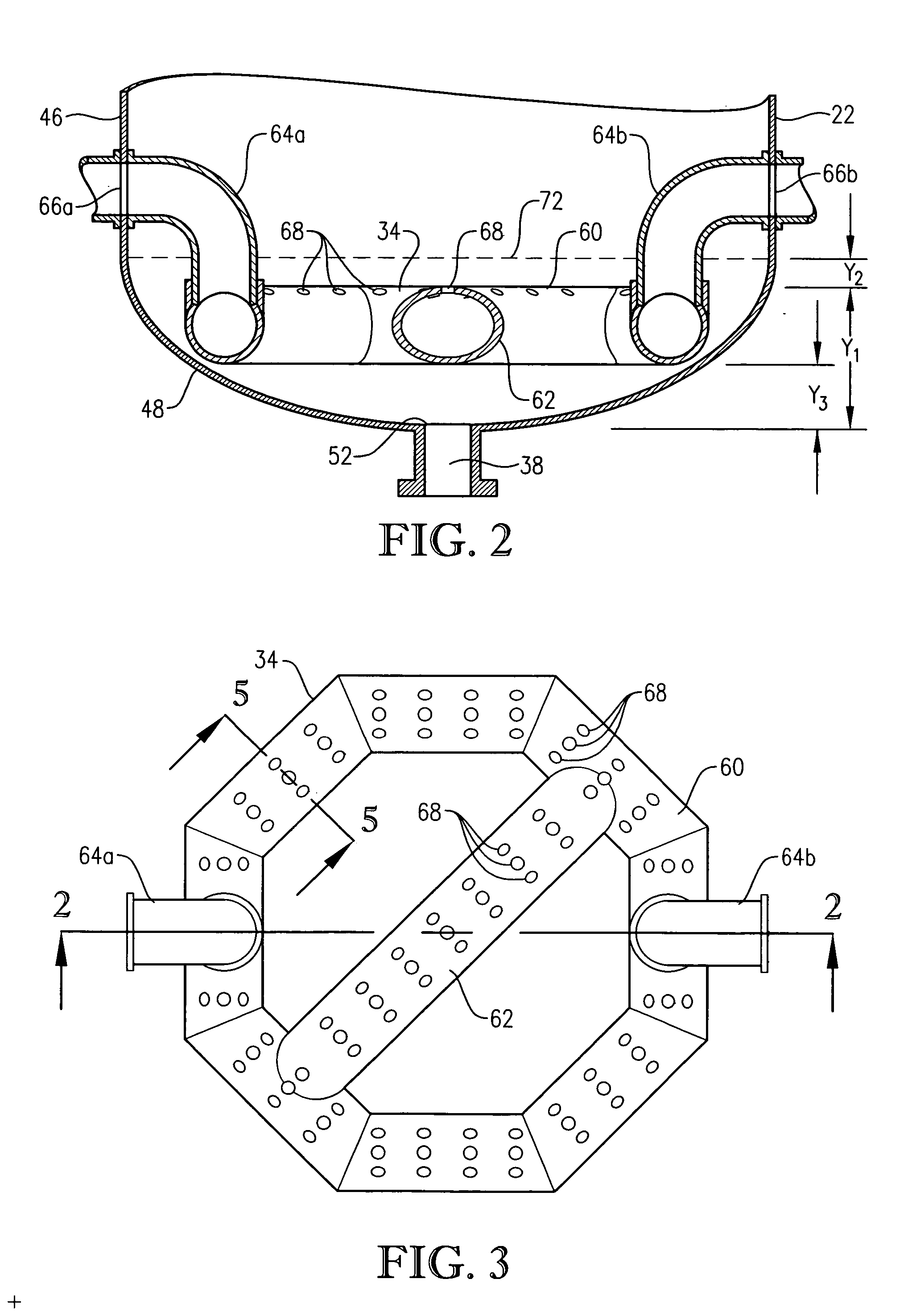

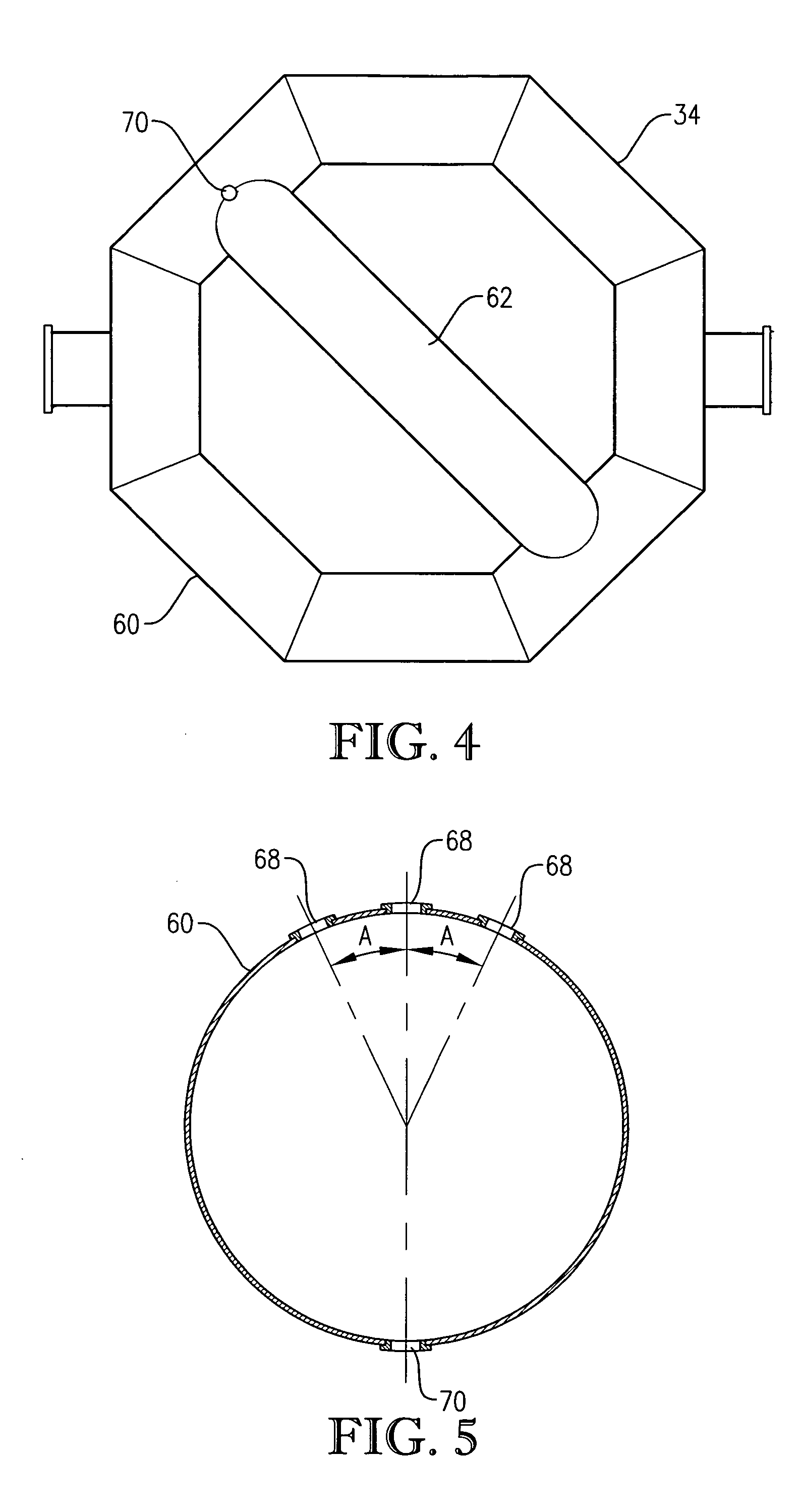

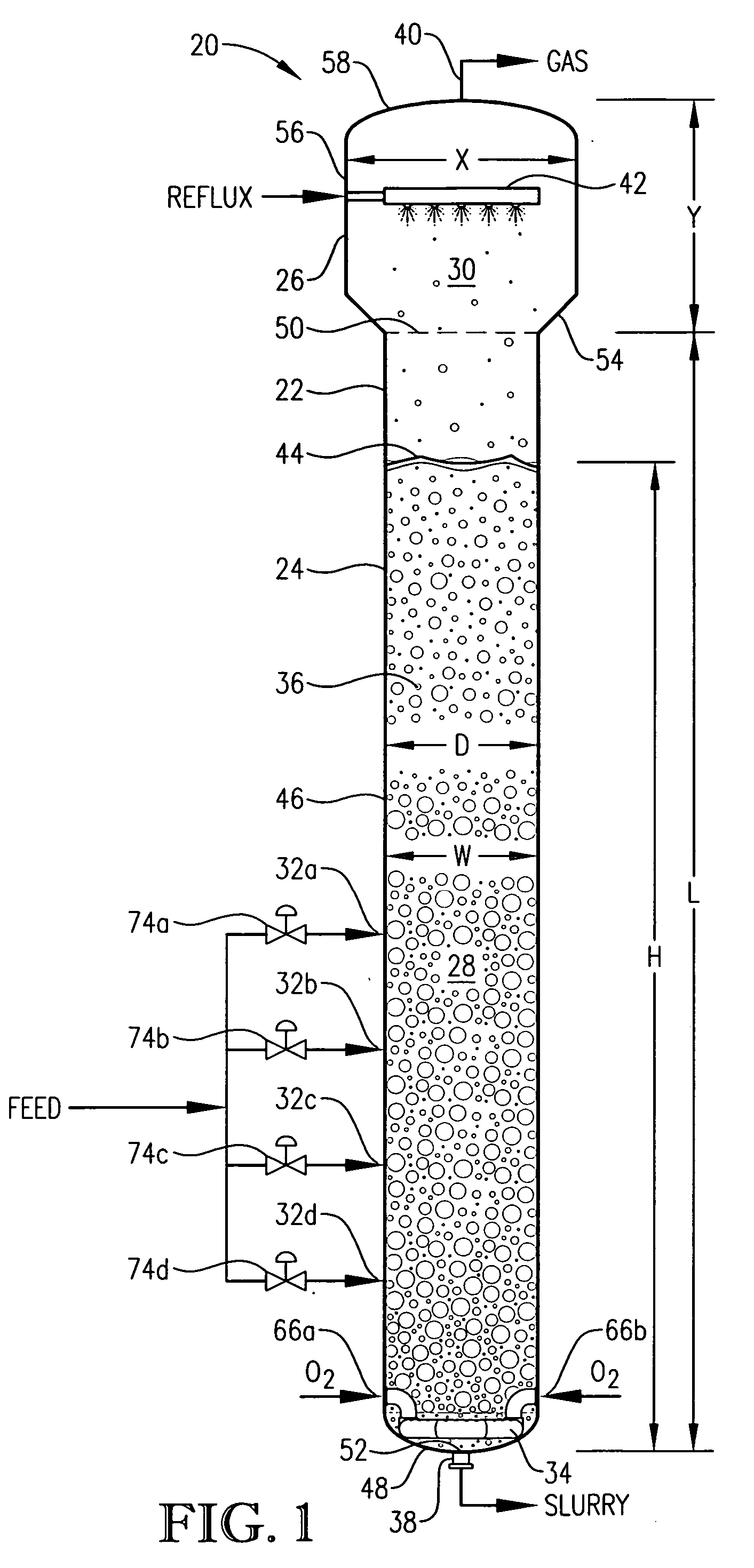

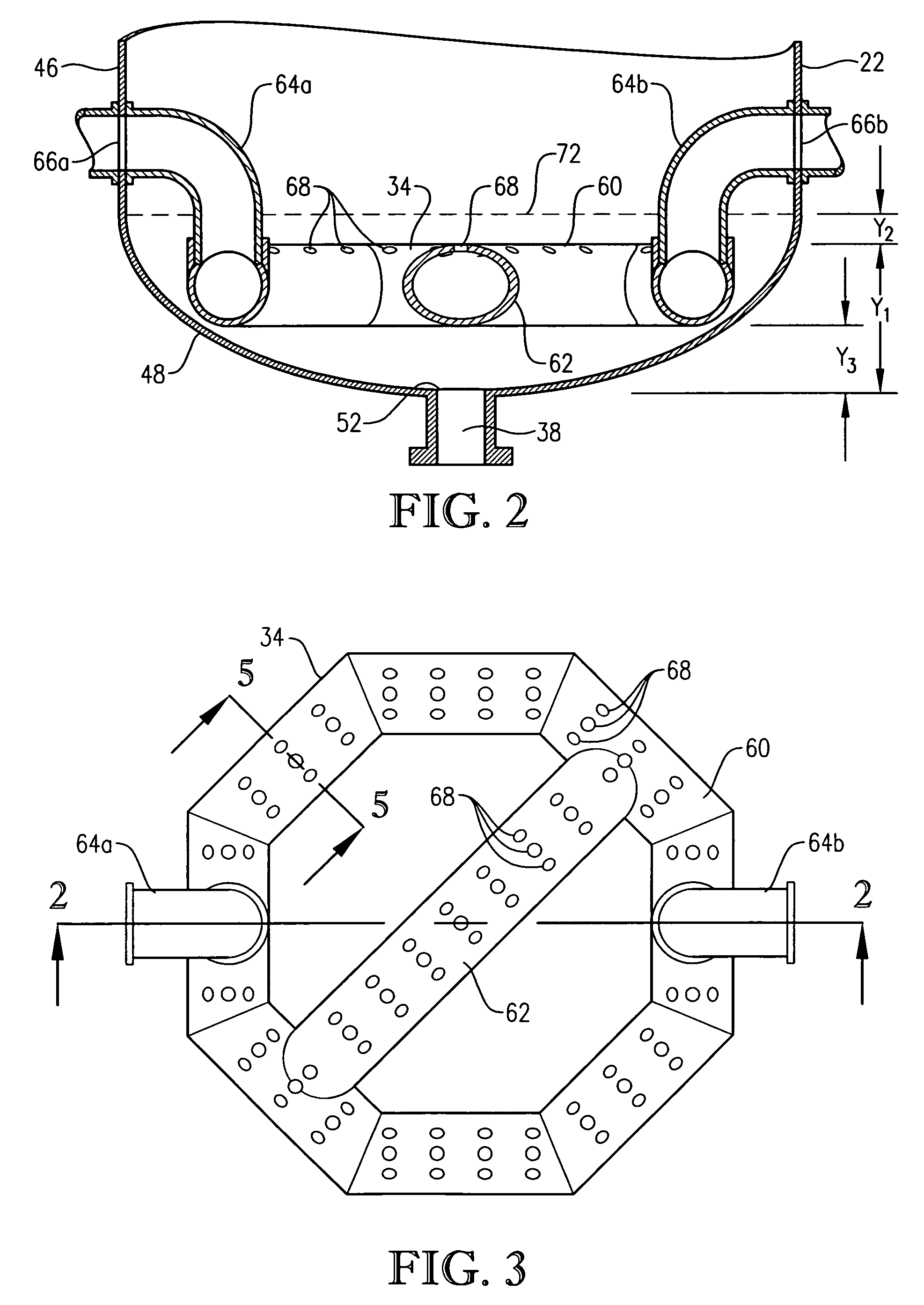

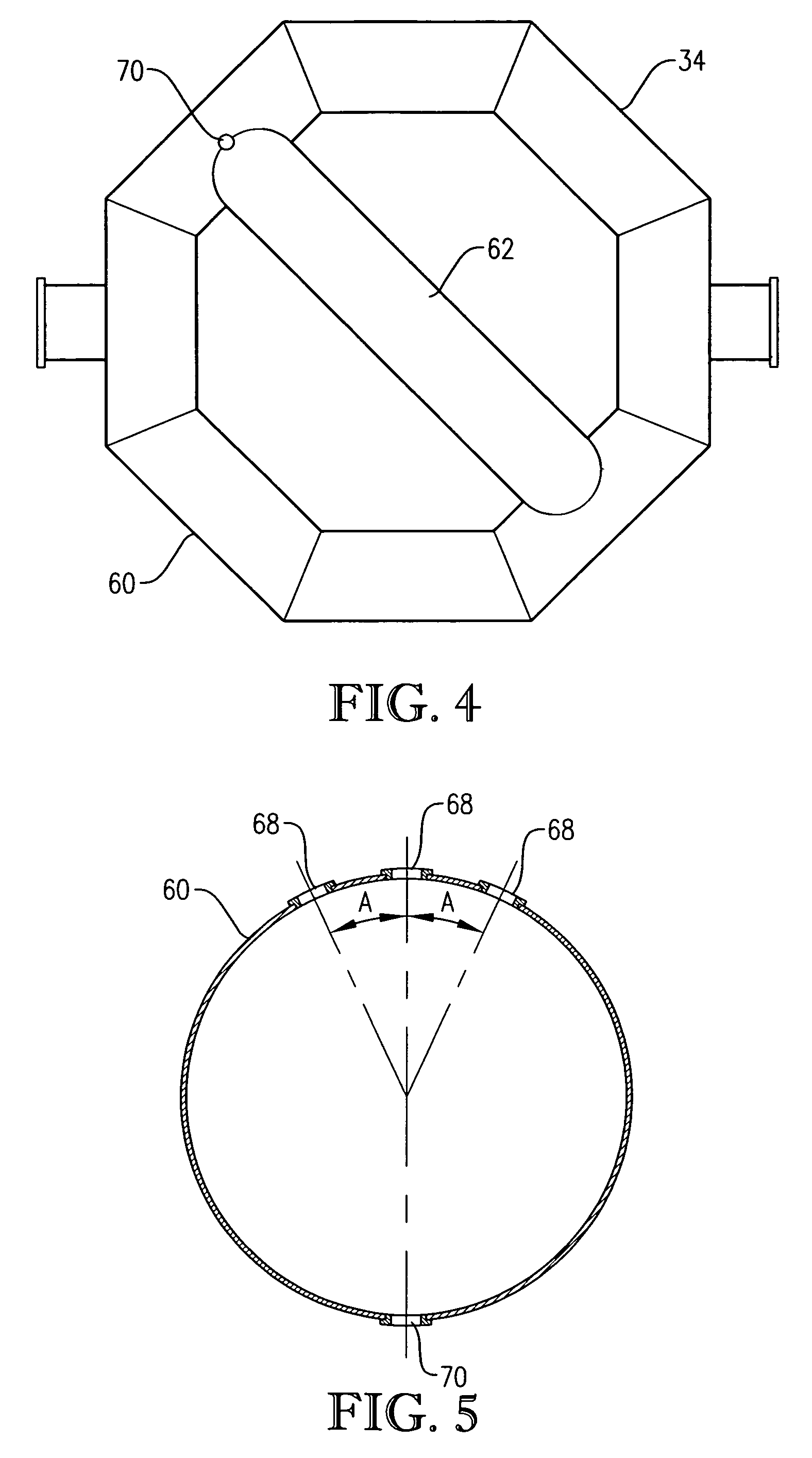

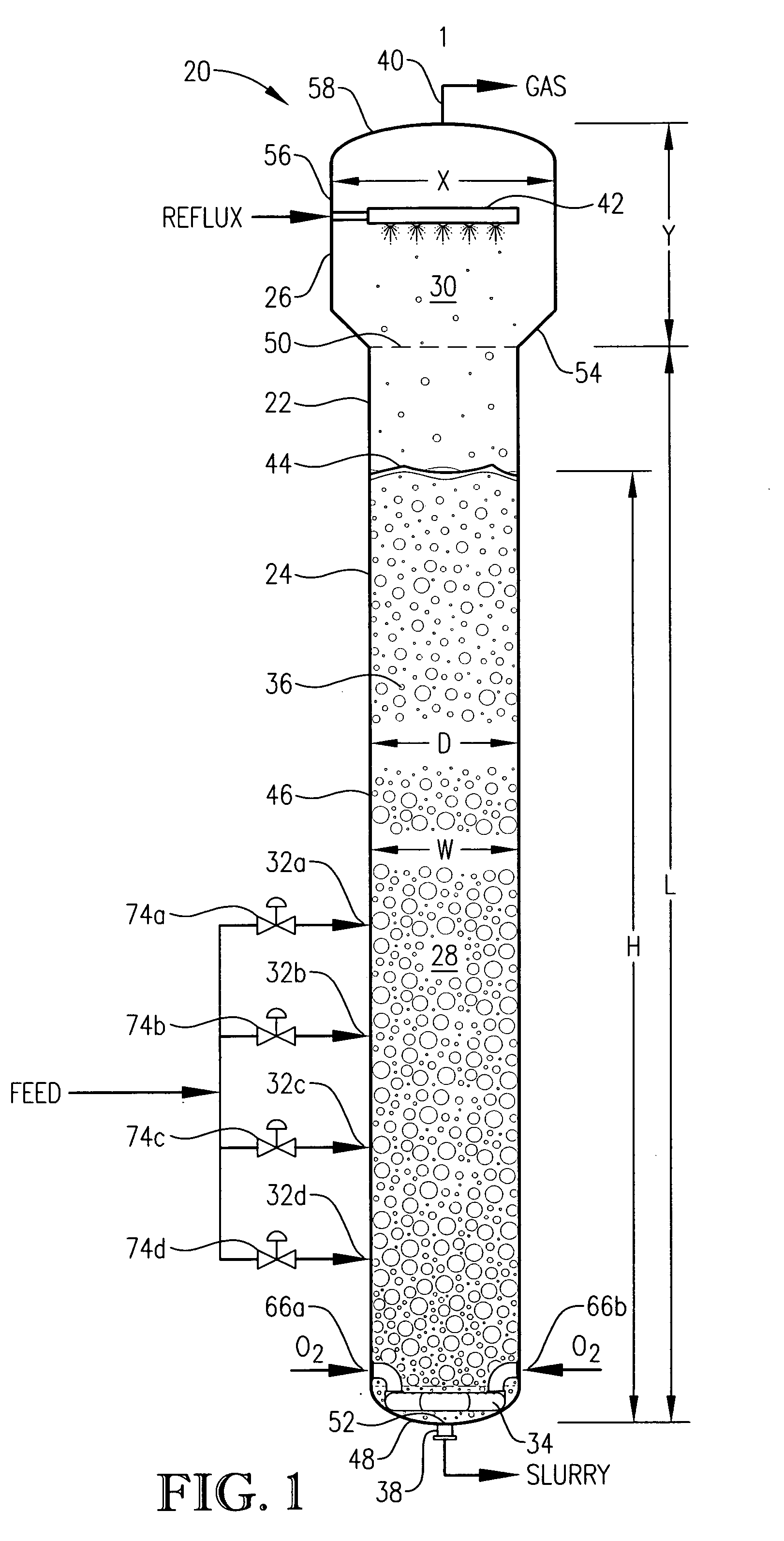

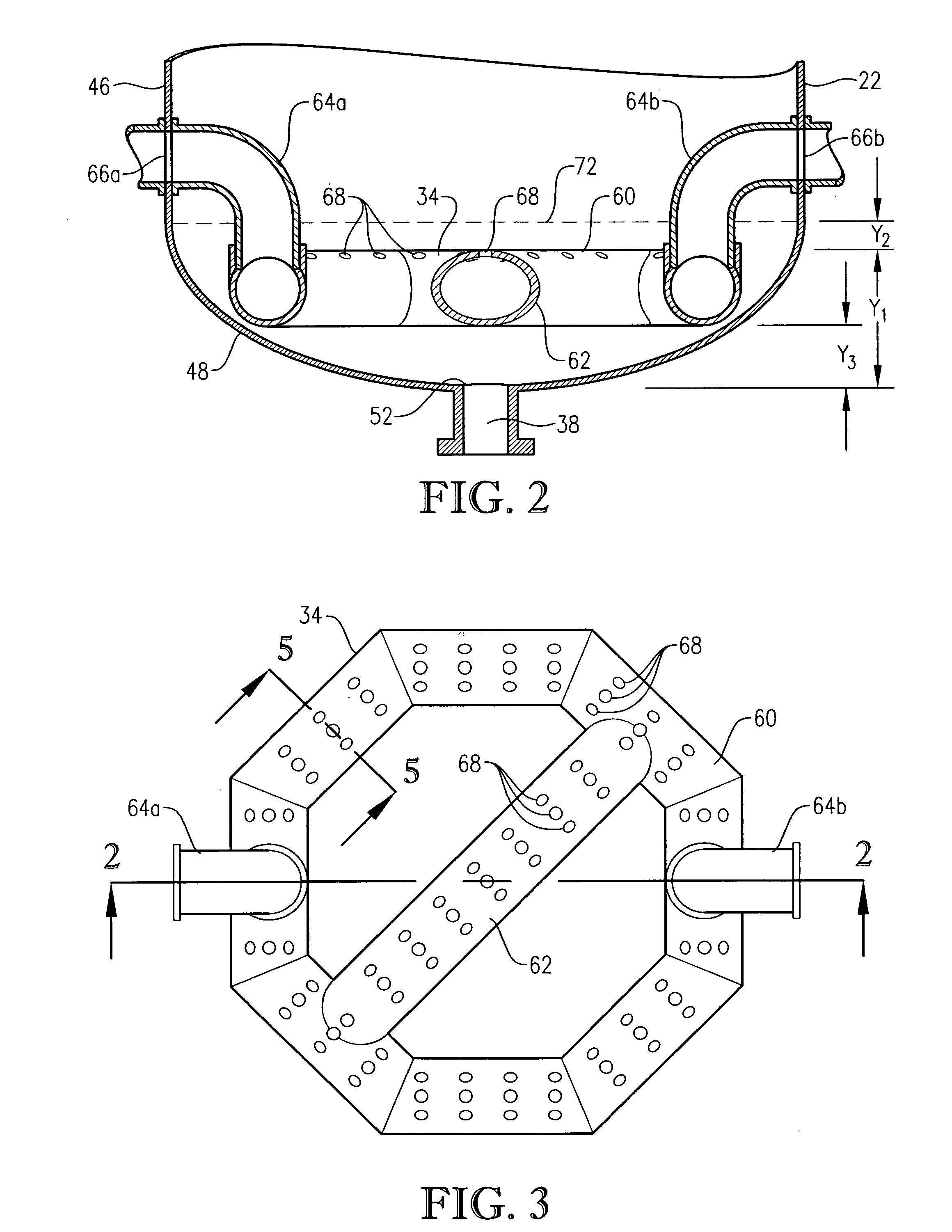

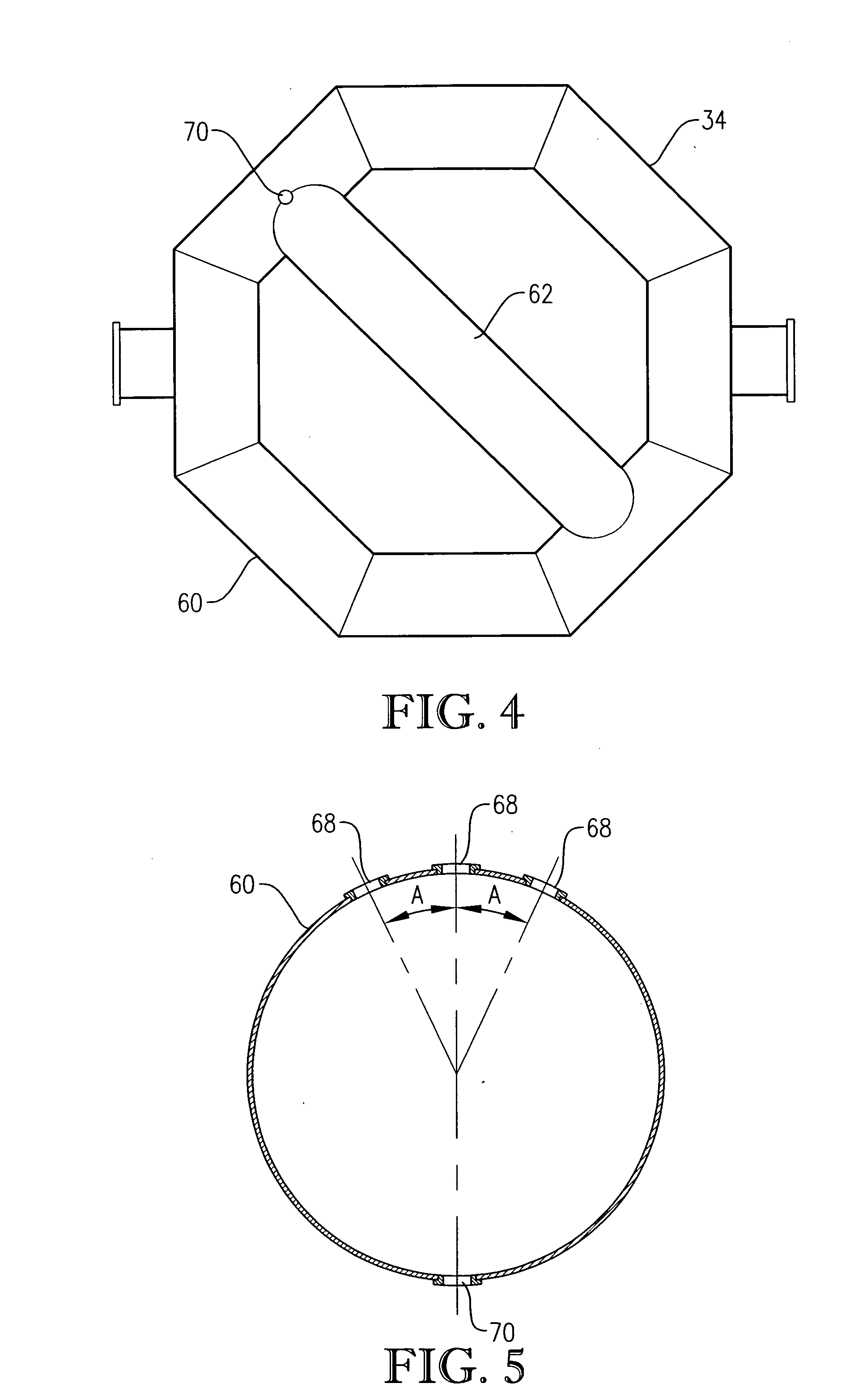

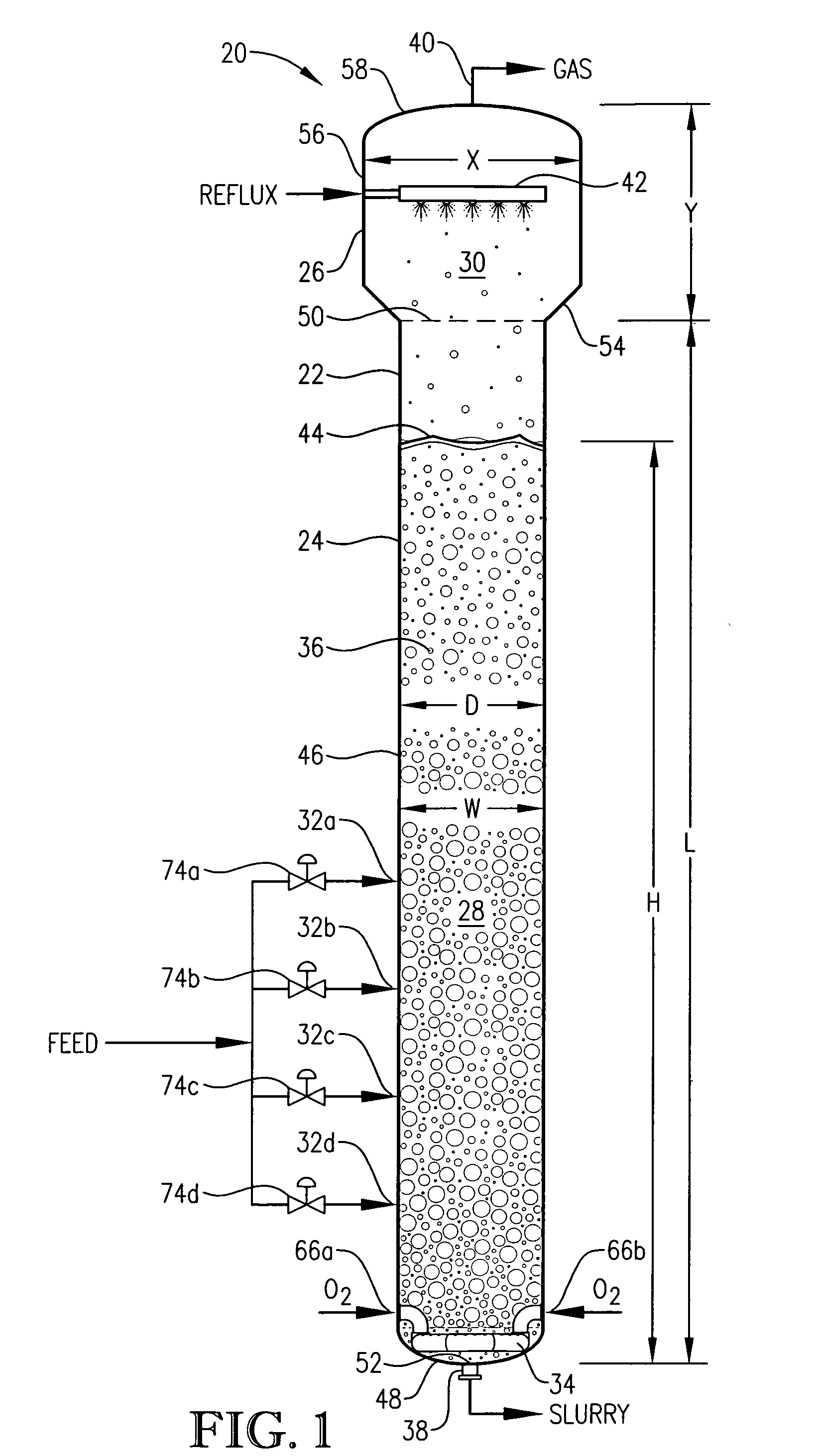

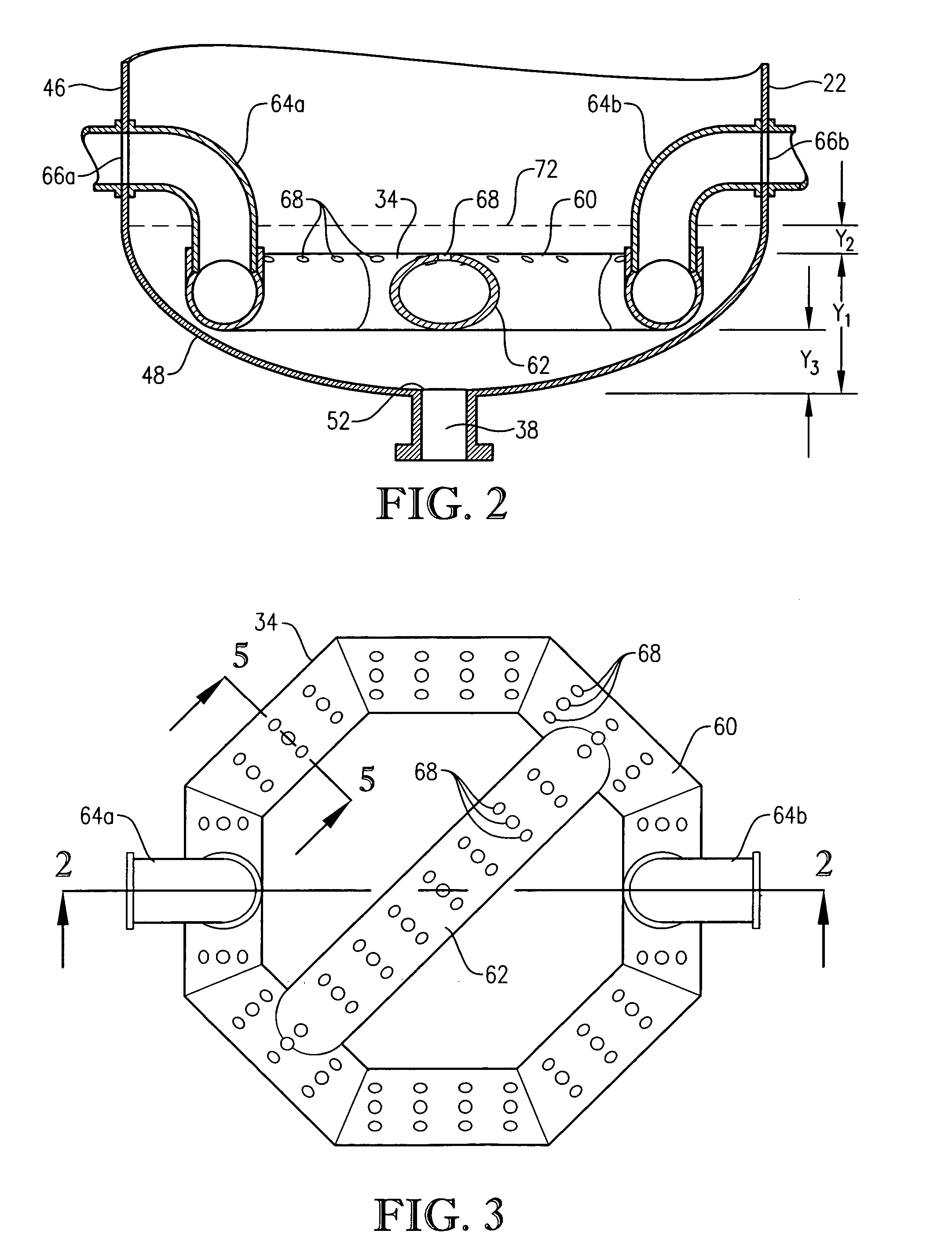

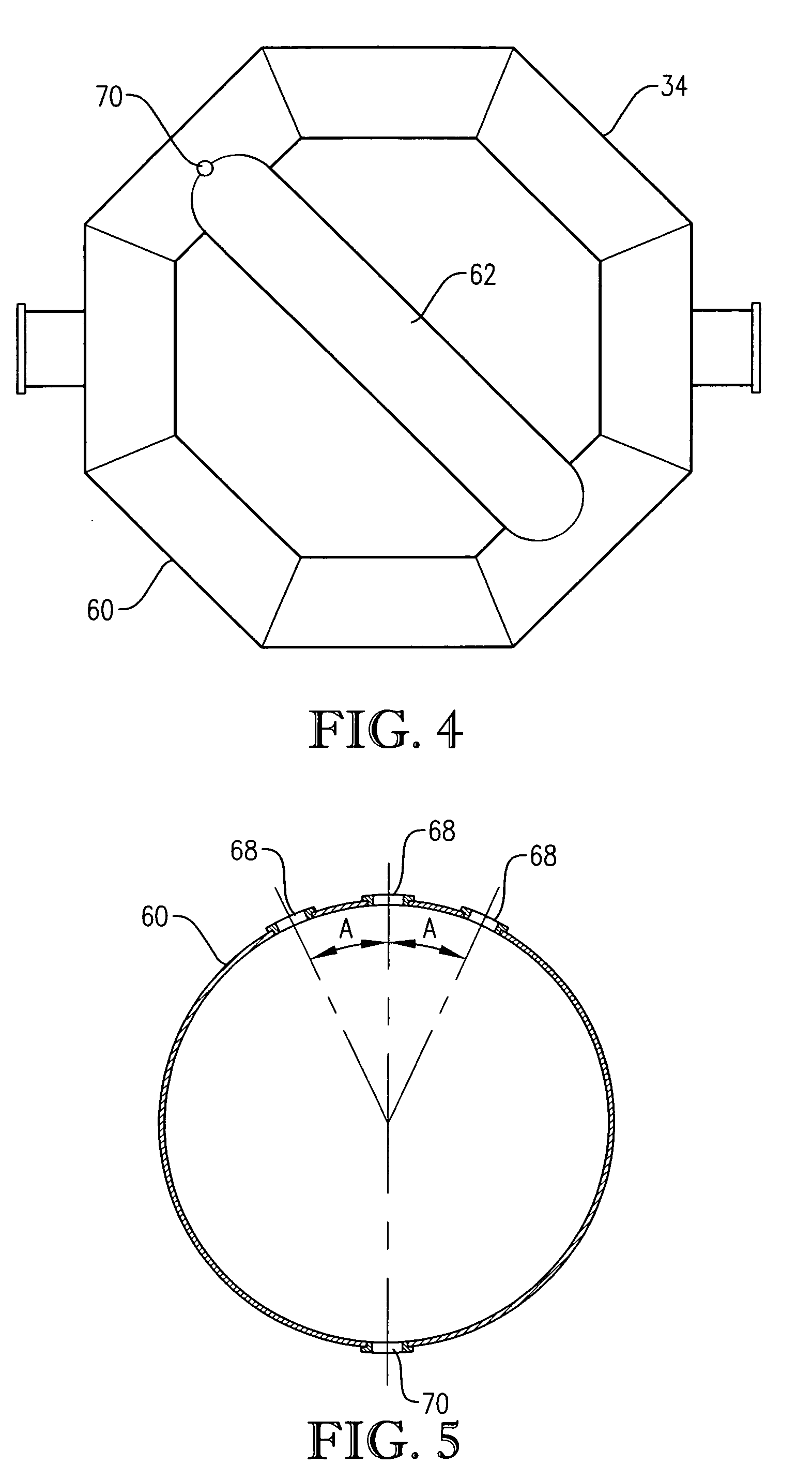

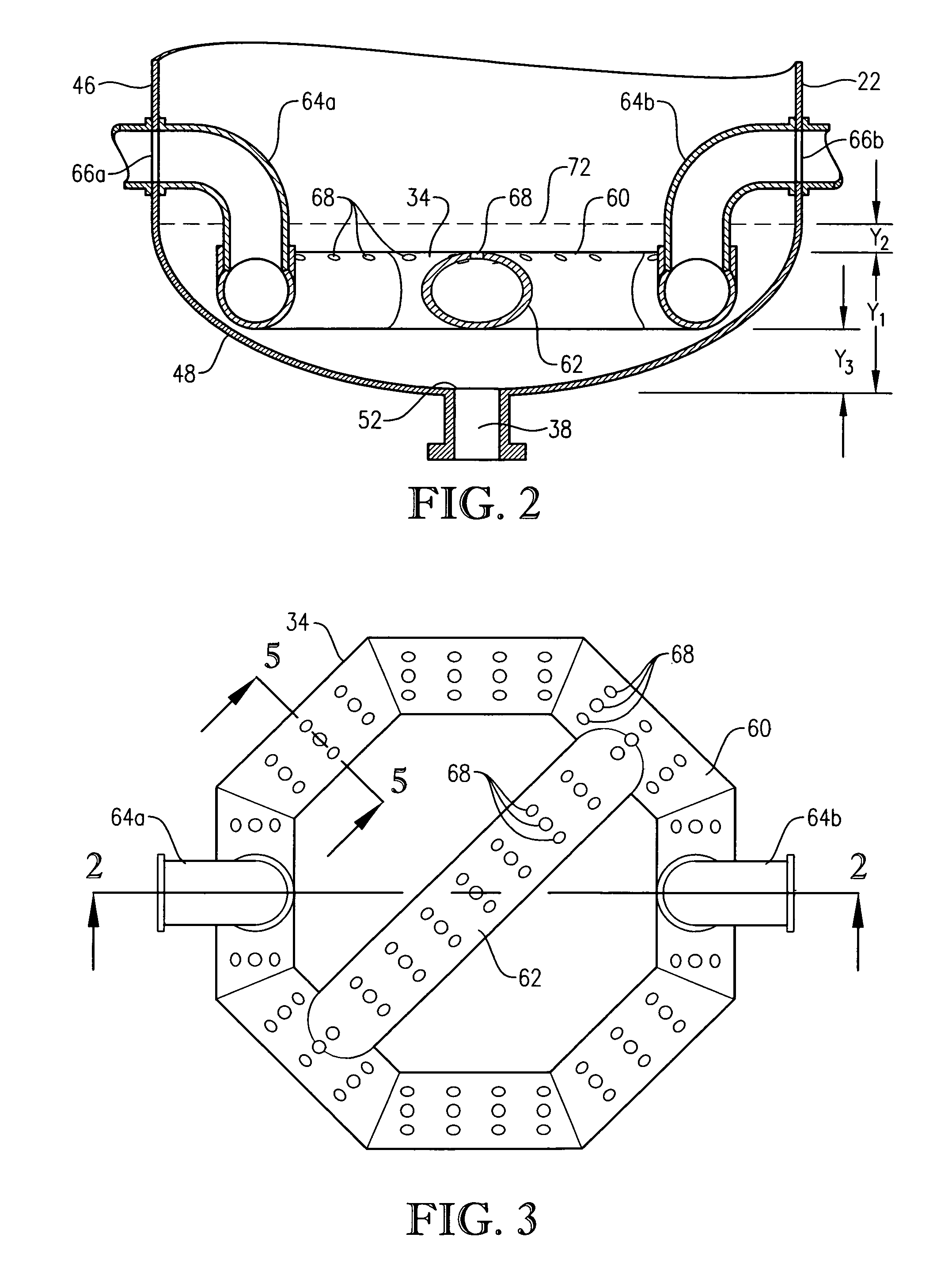

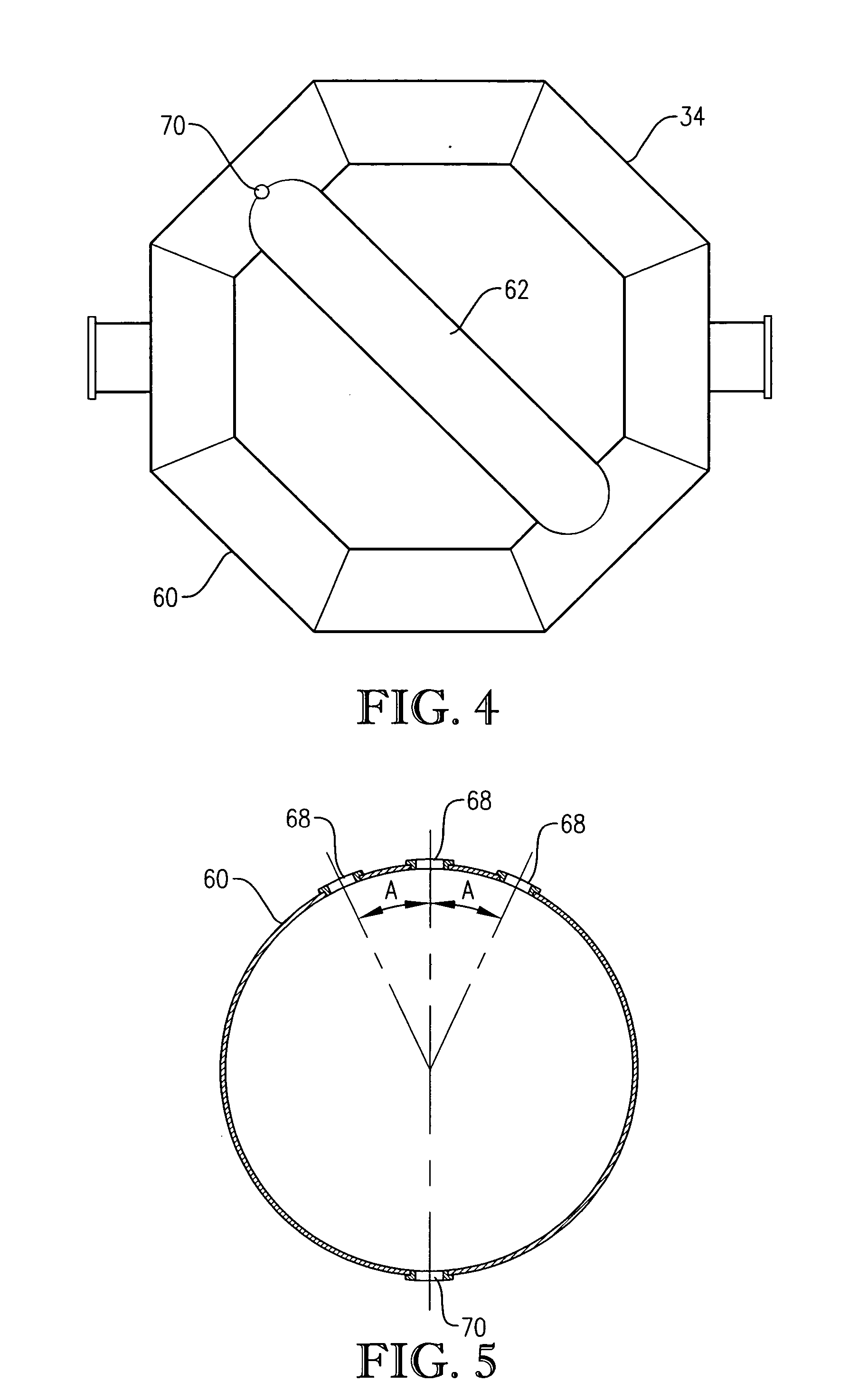

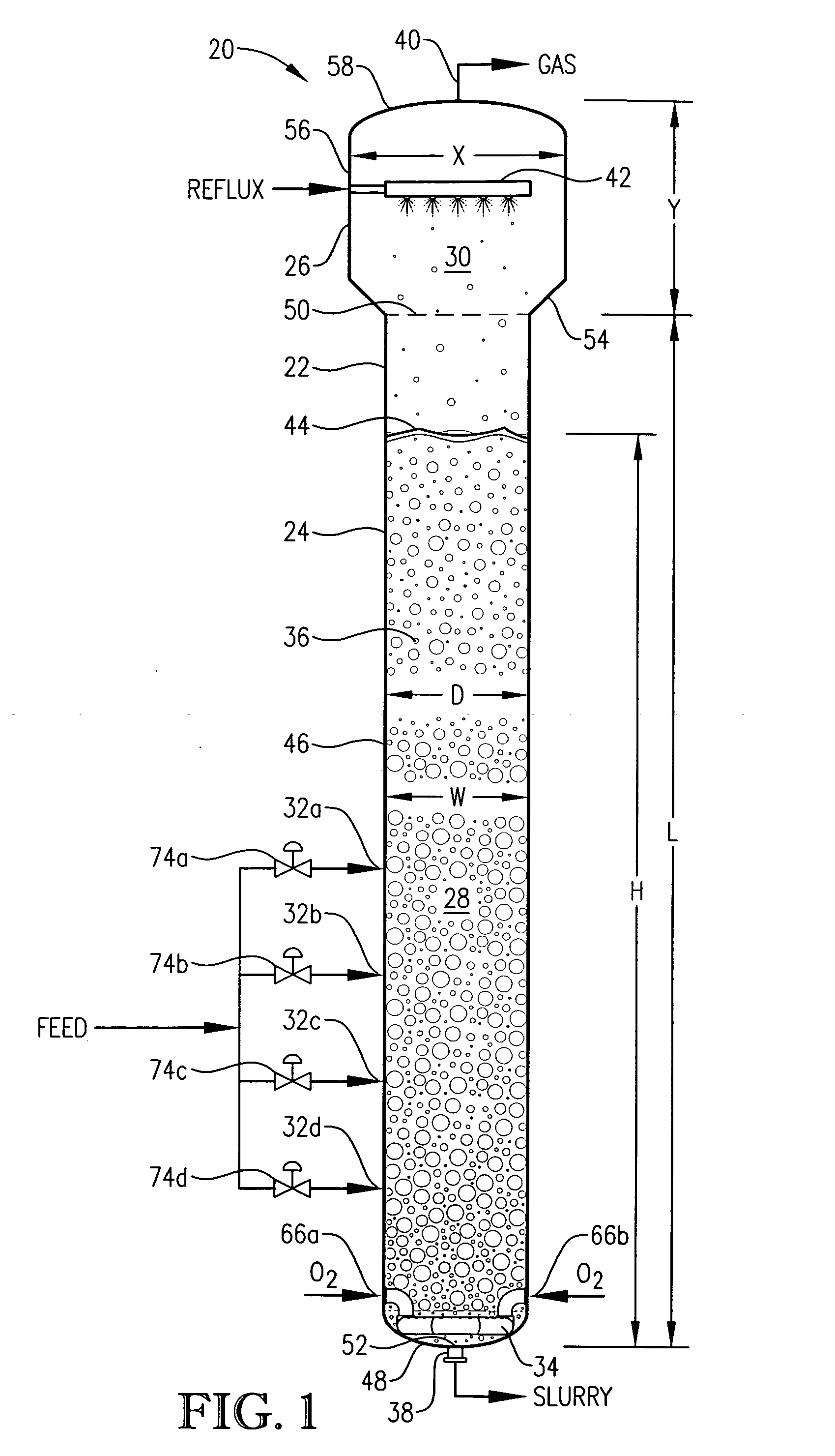

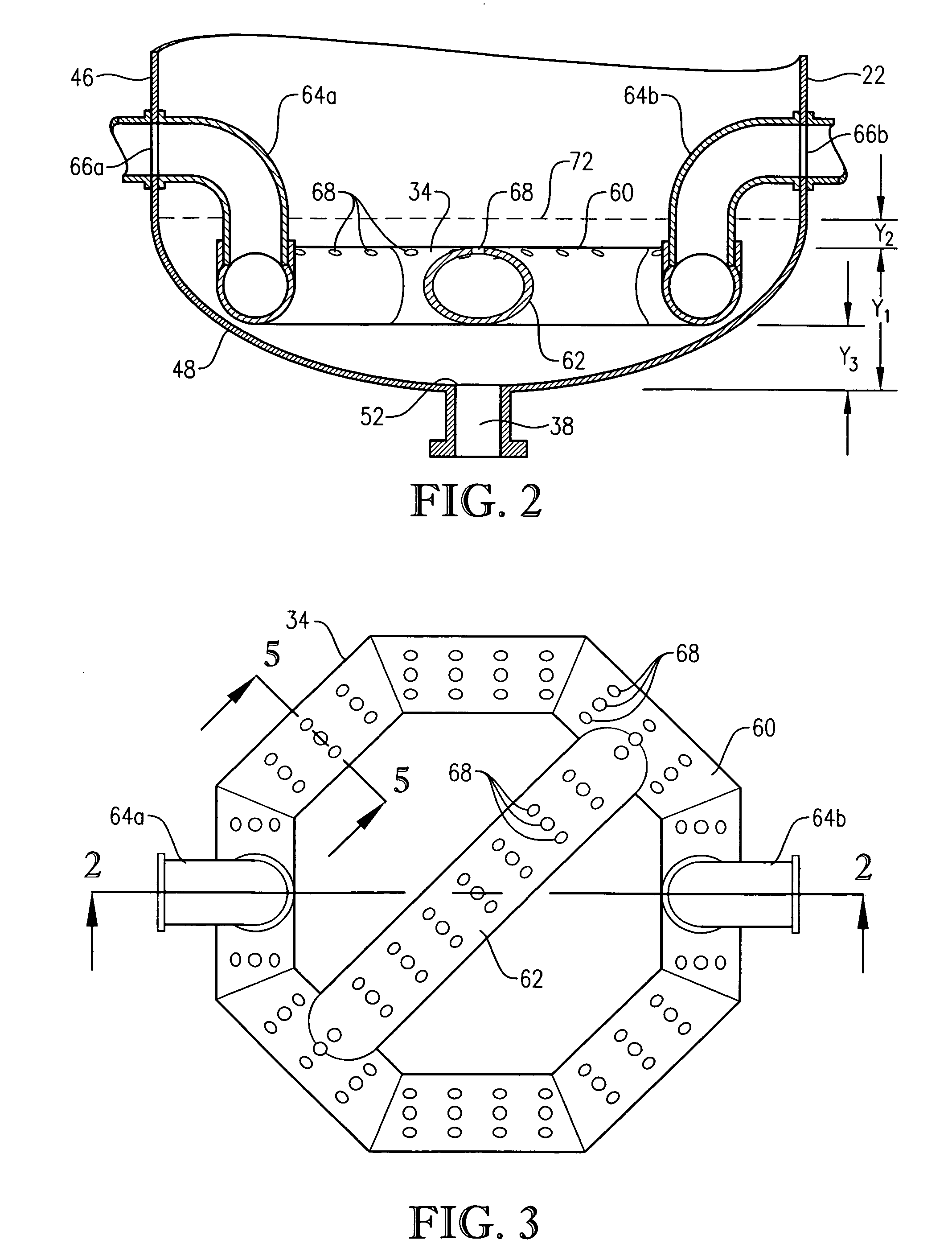

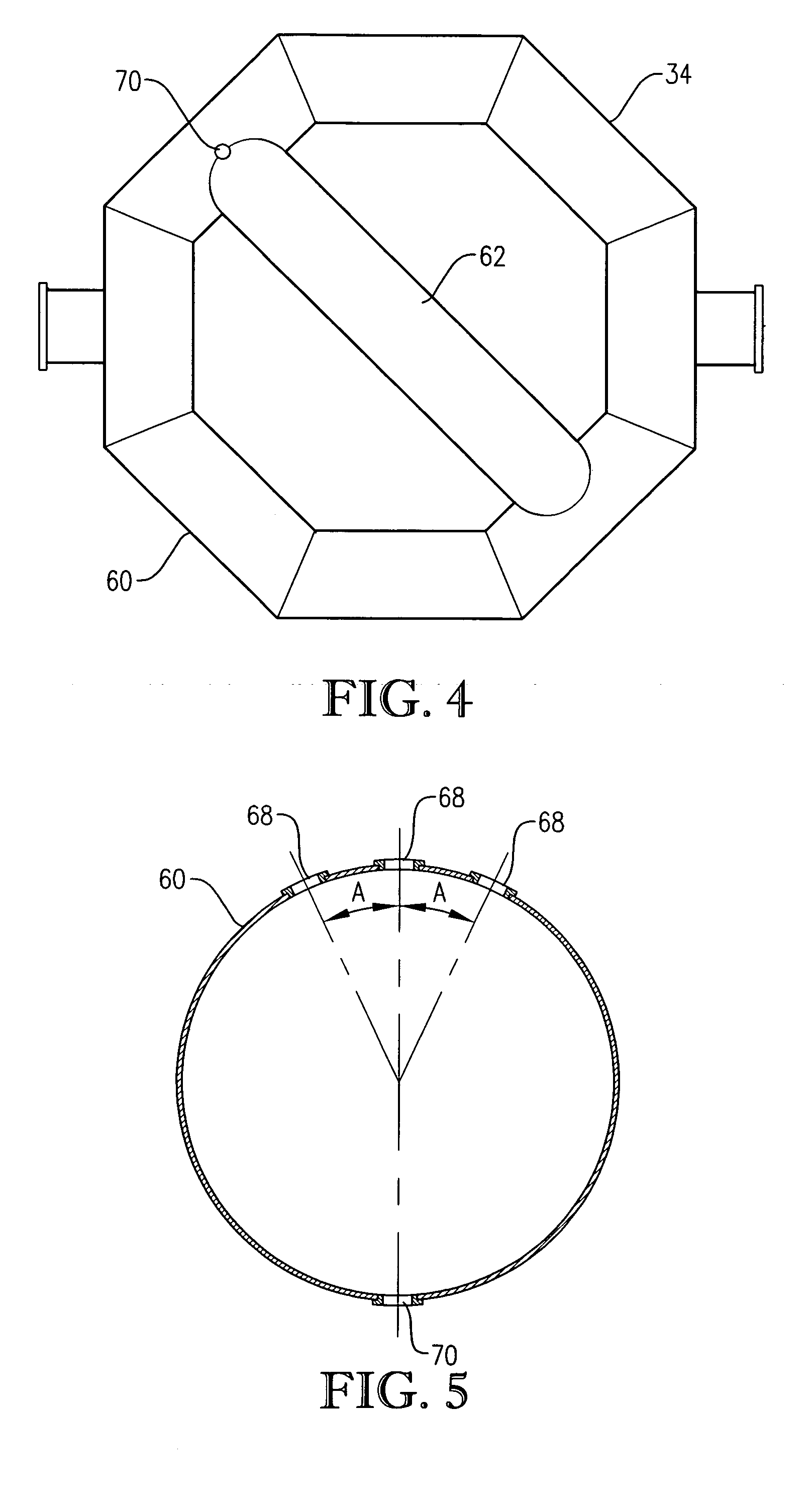

Disclosed is an optimized process and apparatus for more efficiently and economically carrying out the liquid-phase oxidation of an oxidizable compound. Such liquid-phase oxidation is carried out in a bubble column reactor that provides for a highly efficient reaction at relatively low temperatures. When the oxidized compound is para-xylene and the product from the oxidation reaction is crude terephthalic acid (CTA), such CTA product can be purified and separated by more economical techniques than could be employed if the CTA were formed by a conventional high-temperature oxidation process.

Owner:ALPEK POLYESTER SA DE CV

Optimized liquid-phase oxidation

ActiveUS20060047147A1Effective and economicalReduce formationOrganic compound preparationChemical/physical/physico-chemical stationary reactorsOrganic chemistryTerephthalic acid

Disclosed is an optimized process and apparatus for more efficiently and economically carrying out the liquid-phase oxidation of an oxidizable compound. Such liquid-phase oxidation is carried out in a bubble column reactor that provides for a highly efficient reaction at relatively low temperatures. When the oxidized compound is para-xylene and the product from the oxidation reaction is crude terephthalic acid (CTA), such CTA product can be purified and separated by more economical techniques than could be employed if the CTA were formed by a conventional high-temperature oxidation process.

Owner:ALPEK POLYESTER SA DE CV

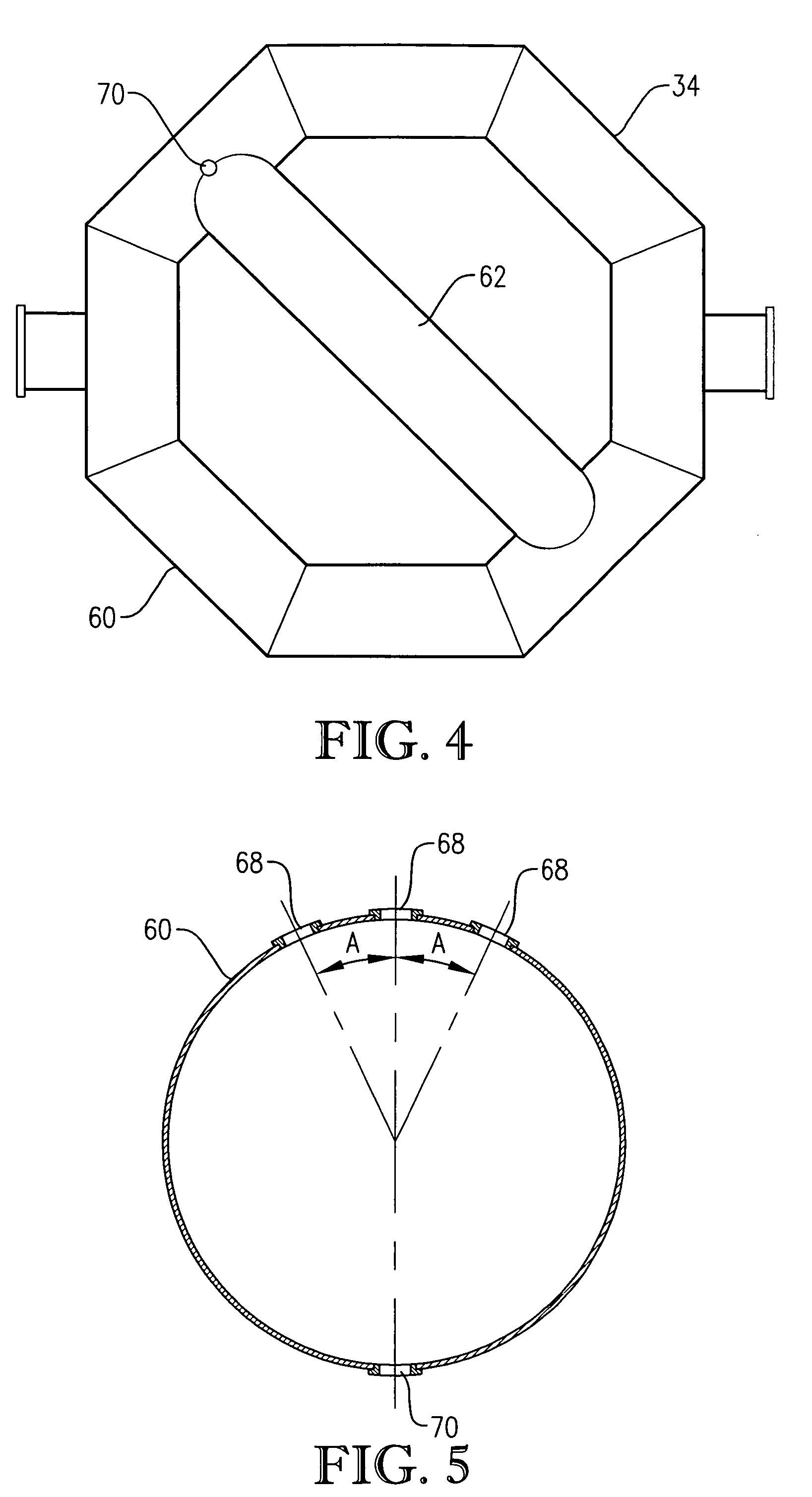

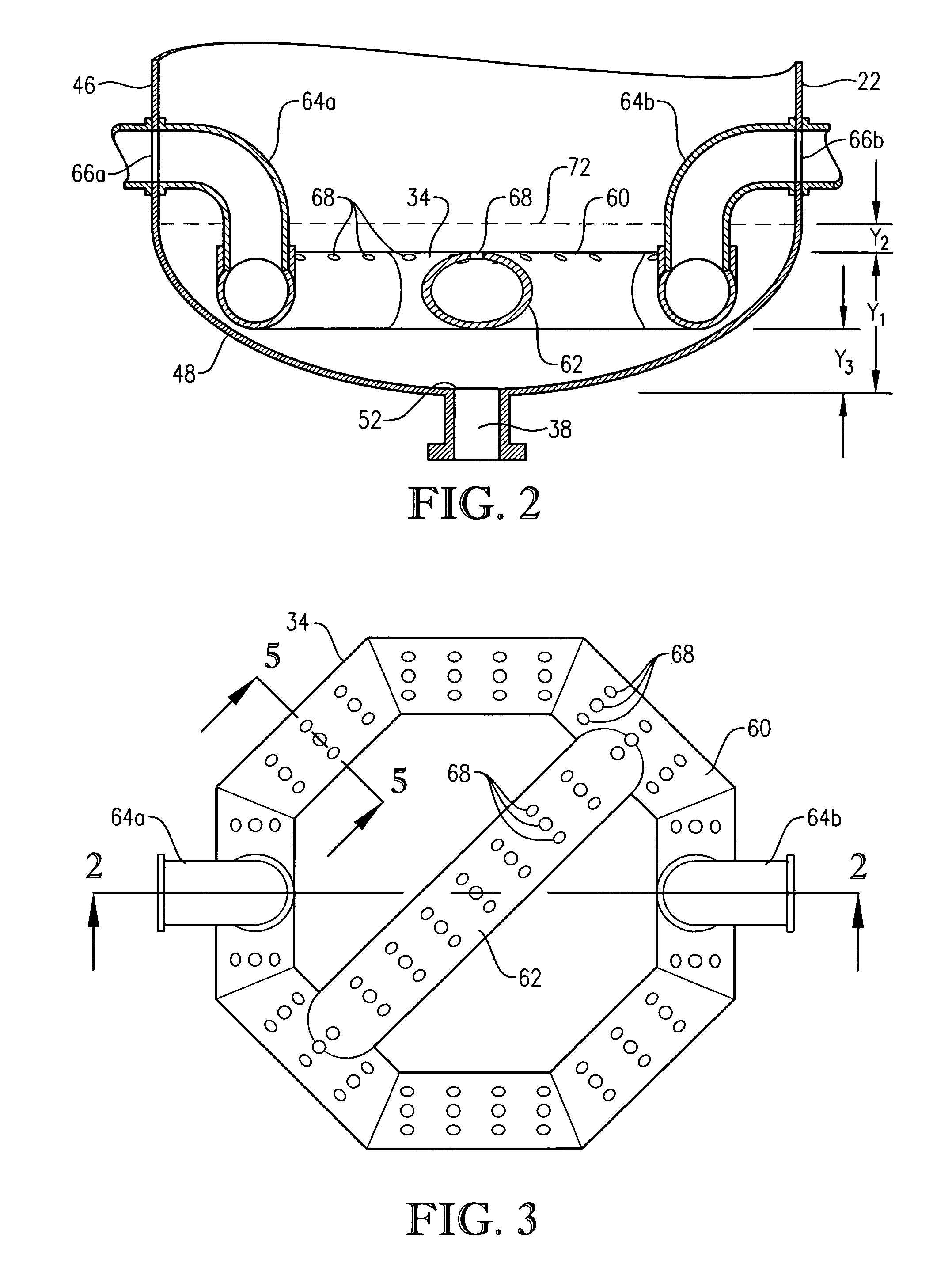

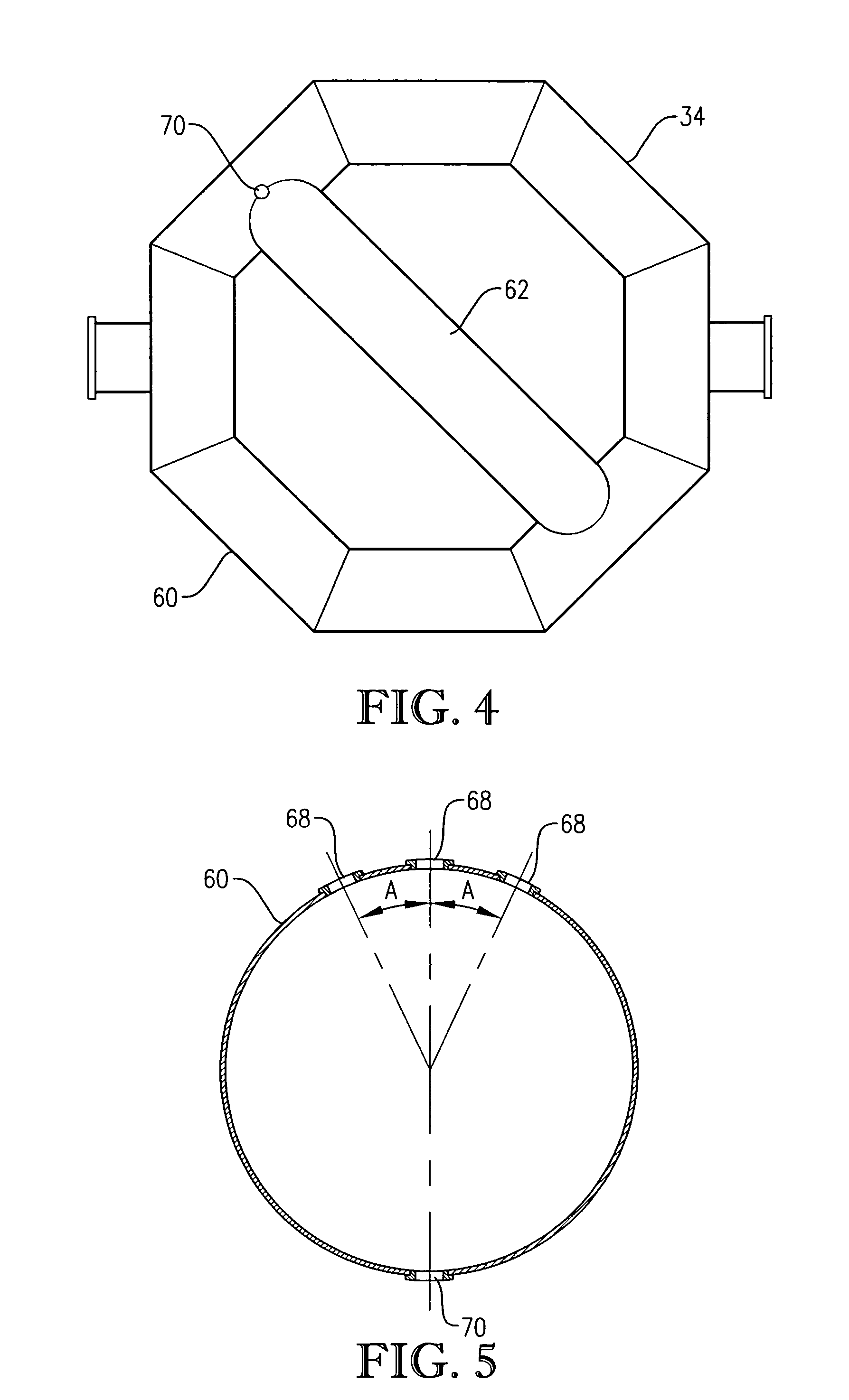

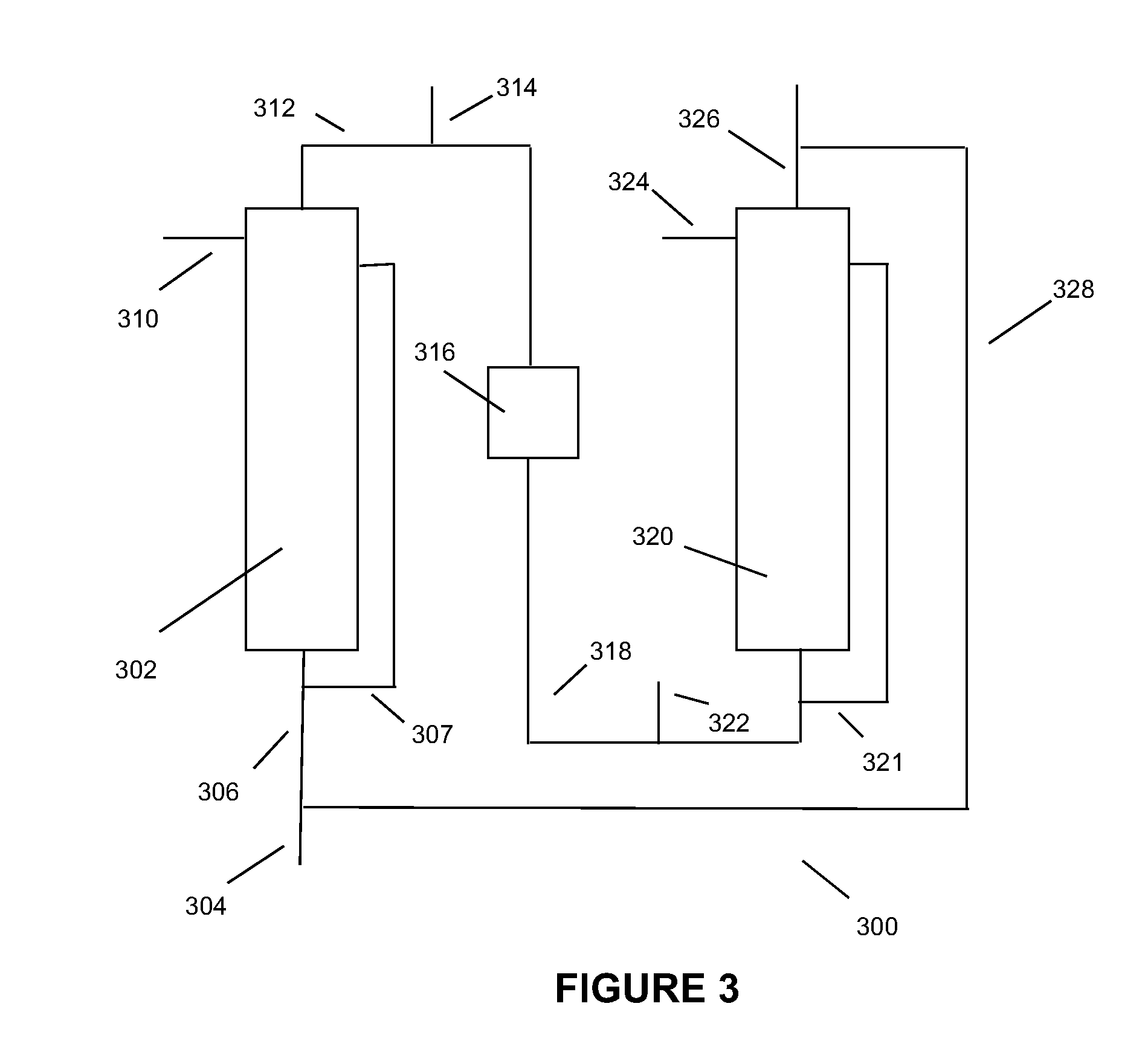

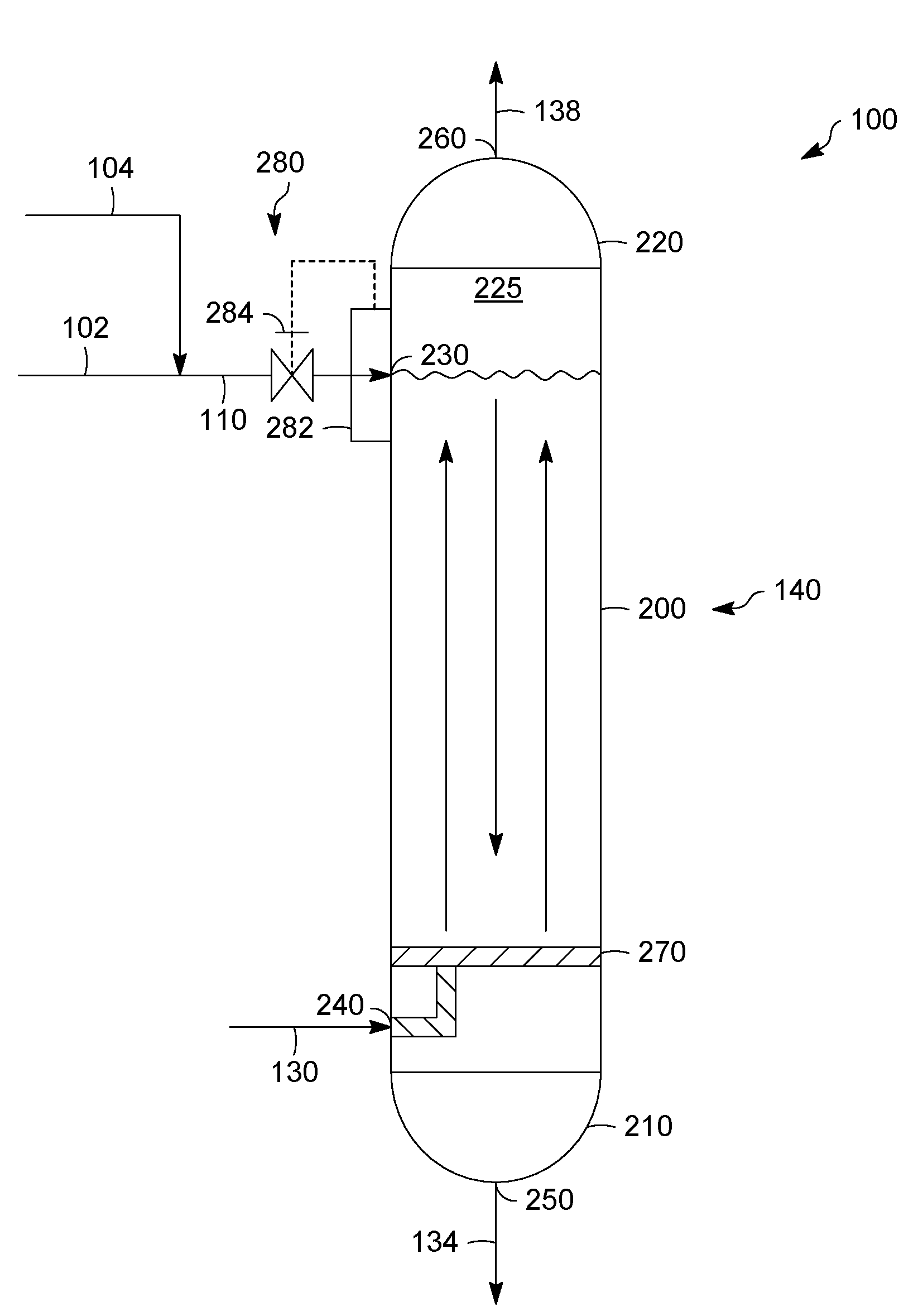

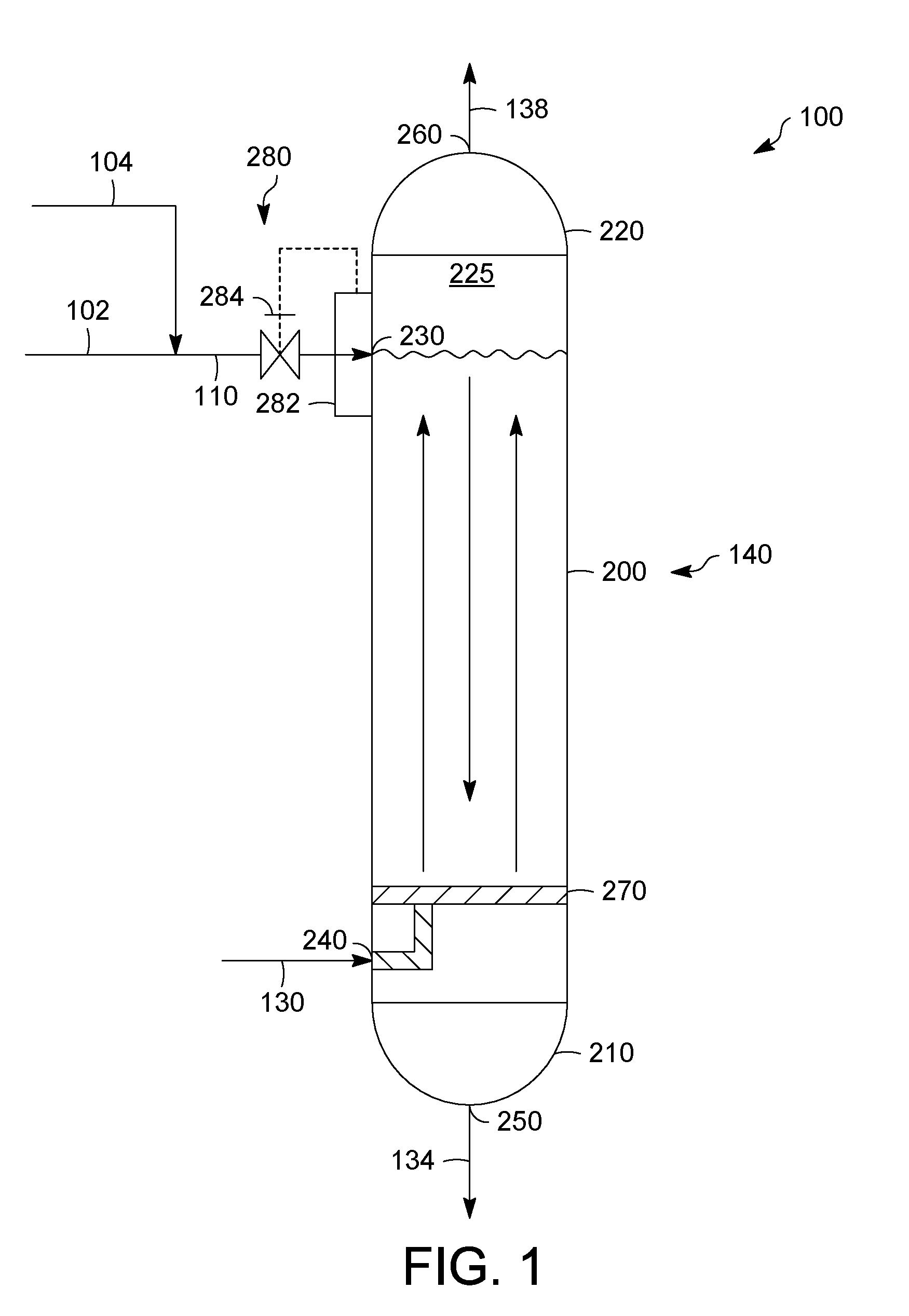

Oxidation system with internal secondary reactor

ActiveUS20070155985A1Effective and economicalReduce formationLiquid-gas reaction as foam/aerosol/bubblesOrganic compound preparationOrganic chemistryTerephthalic acid

Disclosed is an optimized process and apparatus for more efficiently and economically carrying out the liquid-phase oxidation of an oxidizable compound. Such liquid-phase oxidation is carried out in a bubble column reactor that provides for a highly efficient reaction at relatively low temperatures. When the oxidized compound is para-xylene and the product from the oxidation reaction is crude terephthalic acid (CTA), such CTA product can be purified and separated by more economical techniques than could be employed if the CTA were formed by a conventional high-temperature oxidation process.

Owner:ALPEK POLYESTER SA DE CV

Optimized liquid-phase oxidation

ActiveUS7692036B2Effective and economicalReduce formationOrganic compound preparationCarboxylic preparation by oxidationOrganic chemistryTerephthalic acid

Disclosed is an optimized process and apparatus for more efficiently and economically carrying out the liquid-phase oxidation of an oxidizable compound. Such liquid-phase oxidation is carried out in a bubble column reactor that provides for a highly efficient reaction at relatively low temperatures. When the oxidized compound is para-xylene and the product from the oxidation reaction is crude terephthalic acid (CTA), such CTA product can be purified and separated by more economical techniques than could be employed if the CTA were formed by a conventional high-temperature oxidation process.

Owner:ALPEK POLYESTER SA DE CV

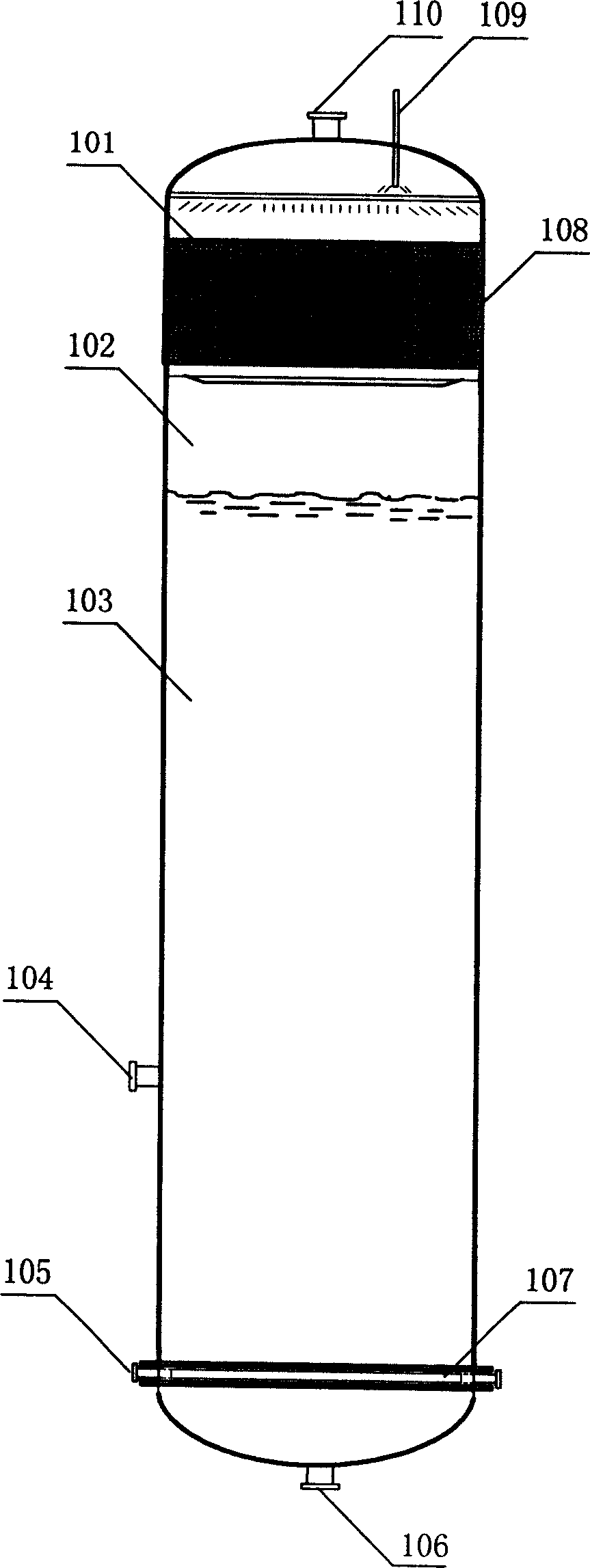

Bubbling tower reactor having damping internal construction member

InactiveCN1785495AIncrease mass transfer rateInhibit flow rateLiquid-gas reaction processesEngineeringTower

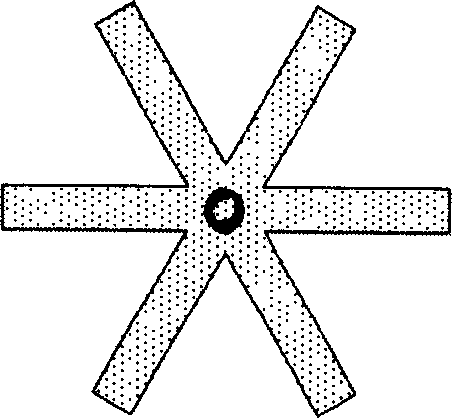

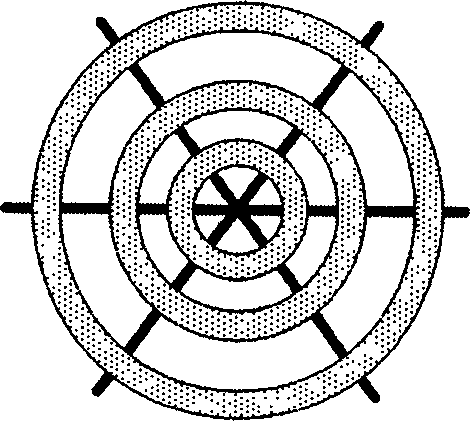

A bubbling column reactor with internal damping member features that said internal damping member is coaxially installed in the reaction region above gas distributor for suppressing the flow speed in central region to make the radial speed distribution more uniform and interferring the flow field to promote local turbulence and increase gas-liquid mass transfer speed.

Owner:ZHEJIANG UNIV

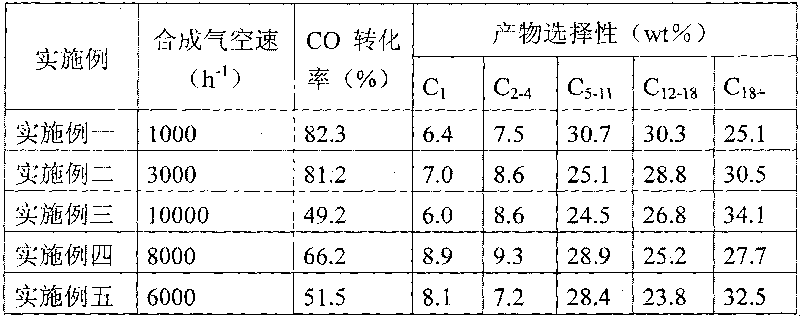

Cobalt-based compounded catalyst and preparing method and application thereof

InactiveCN101698152AHigh reactivityHigh activityLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsParaffin waxSlurry

The invention provides a cobalt-based compounded catalyst and preparing method and application thereof, comprising a carrier component and a metal component; the carrier uses spherical powder Al2O3; the metal component comprises a first metal component Co; a second metal component is one of Ce, La and Zr; a third metal component is one of Pt, Ru, Rh and Re; the weight percentage of each metal component in the finished catalyst is as follows: the first metal component is 10-35%; the second metal component is 0.5-10%; the third metal component is 0.05-3%; and the rest is aluminum oxide carrier. The invention is cobalt-based compounded catalyst with the diesel oil and paraffin as the main products; and the catalyst is applied for slurry bubble column reactor or continuous-stirring reactor with simple preparing method, less selectivity in methane, high reacting activity and good selectivity in C5+.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

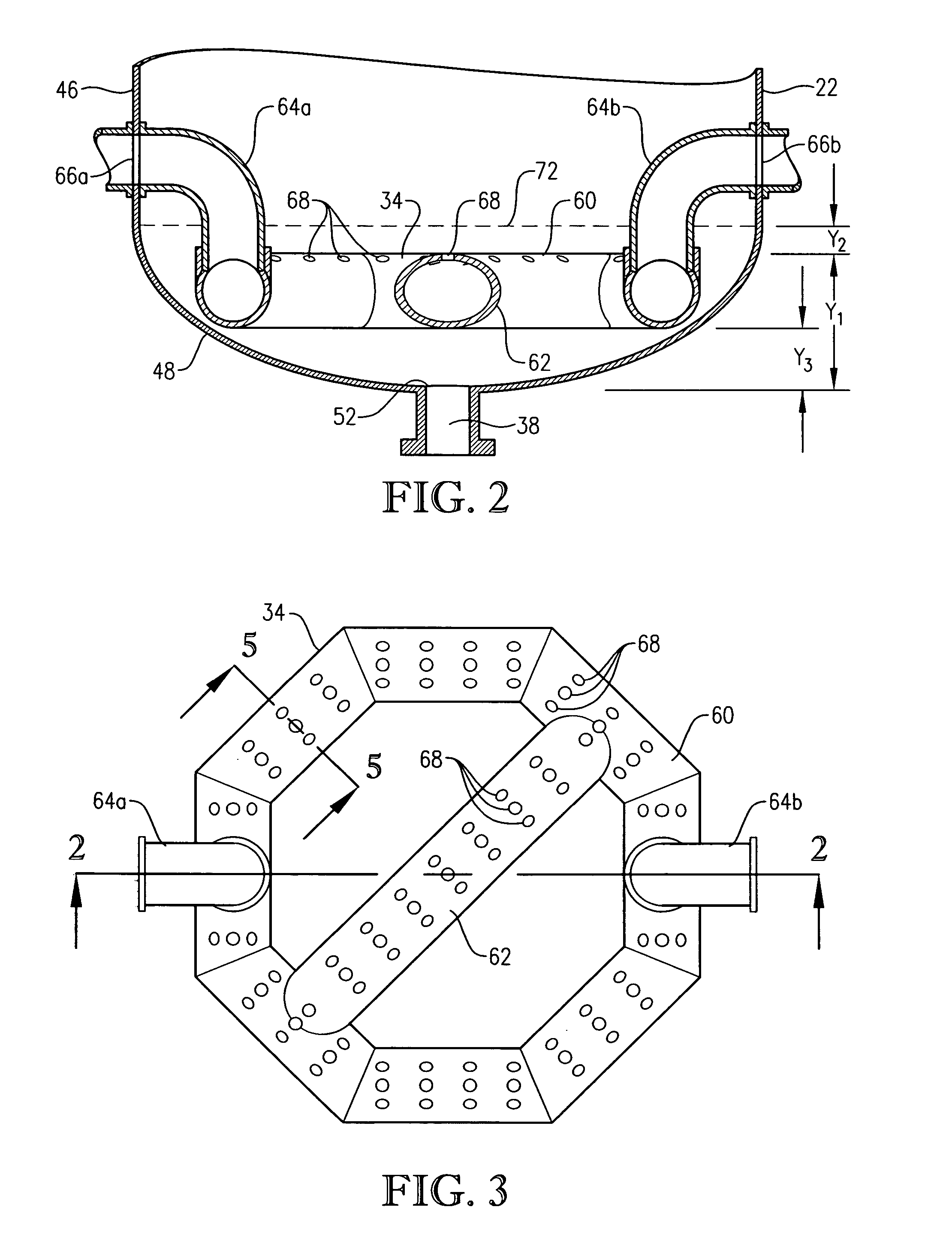

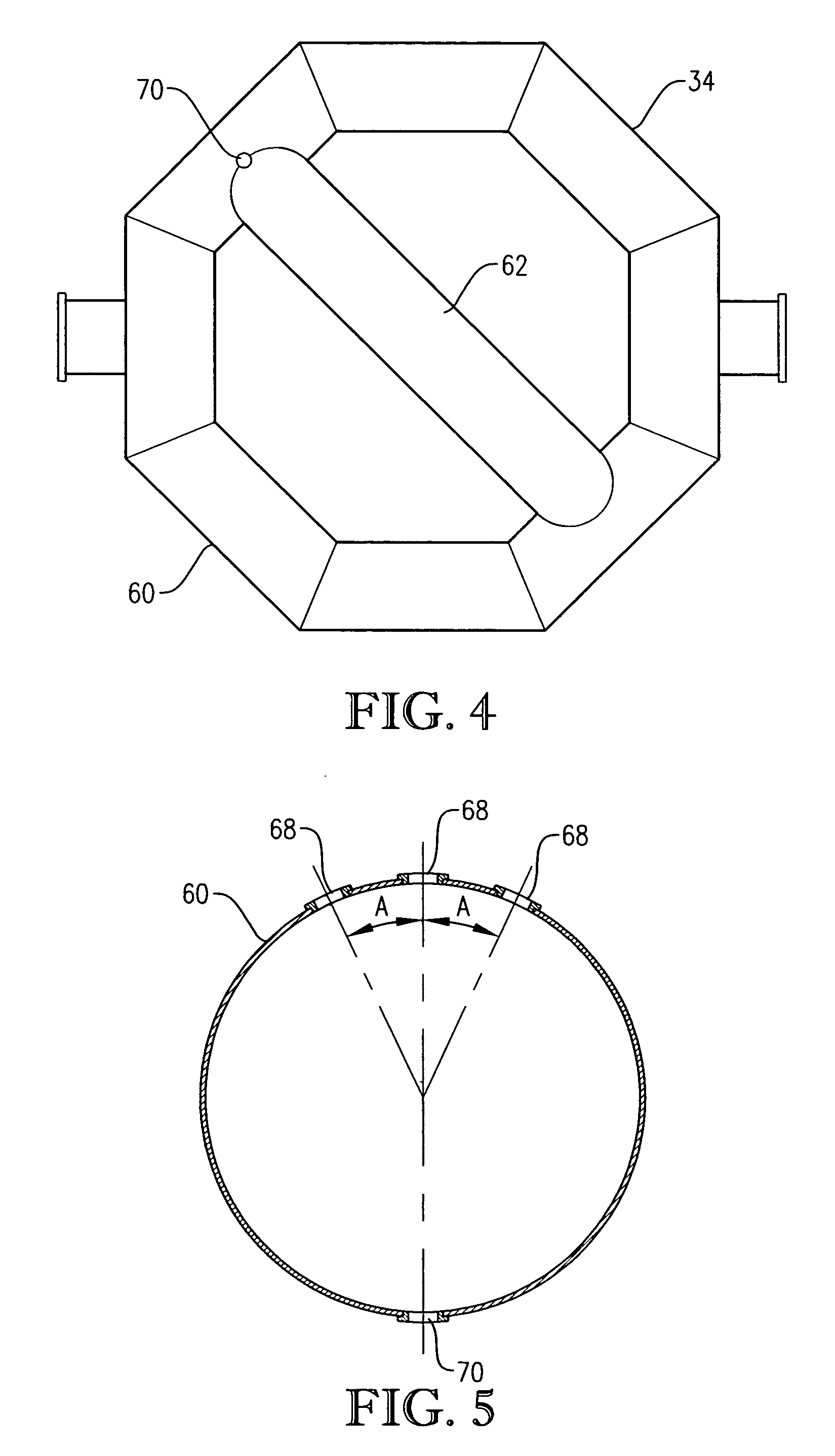

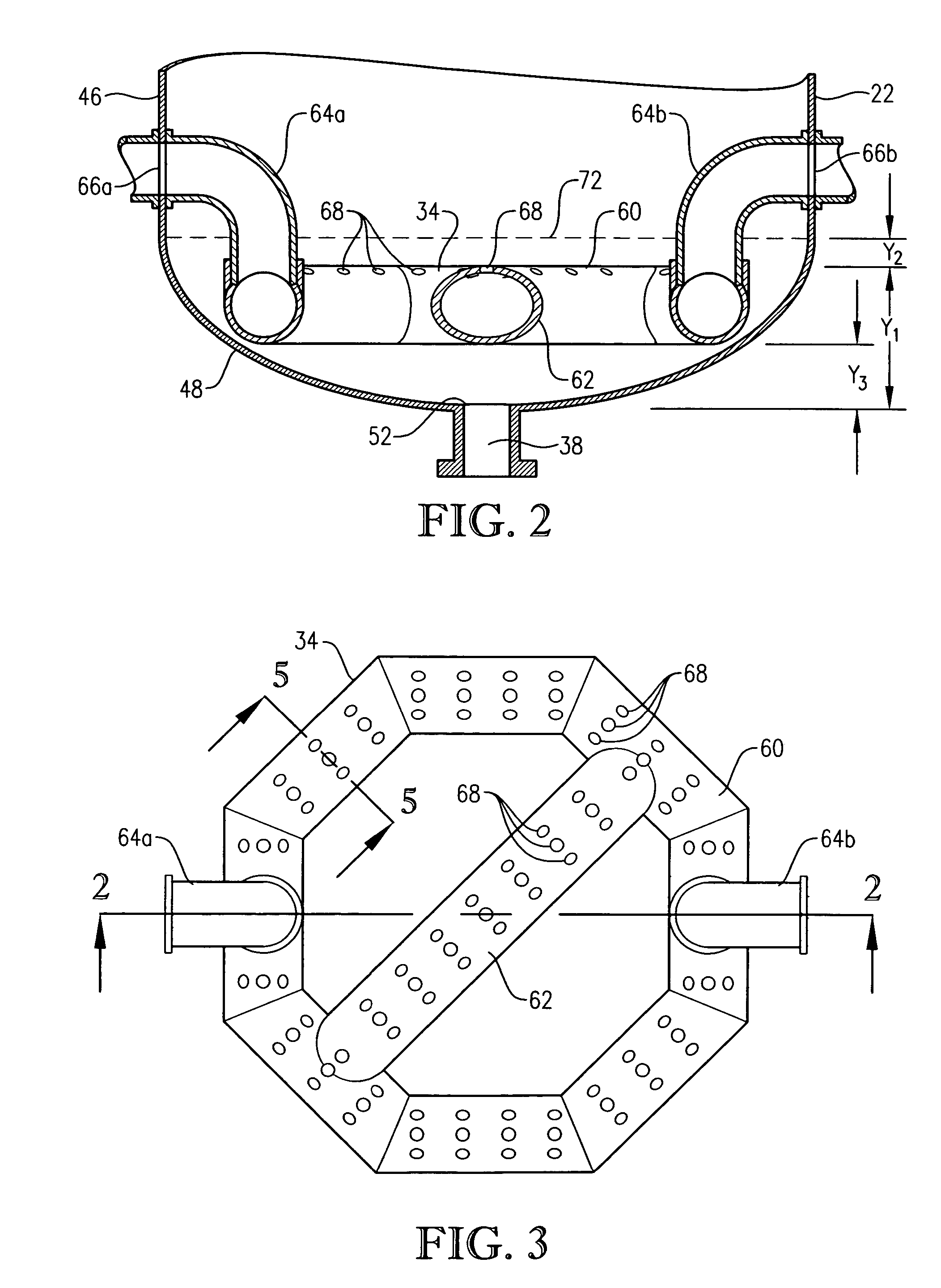

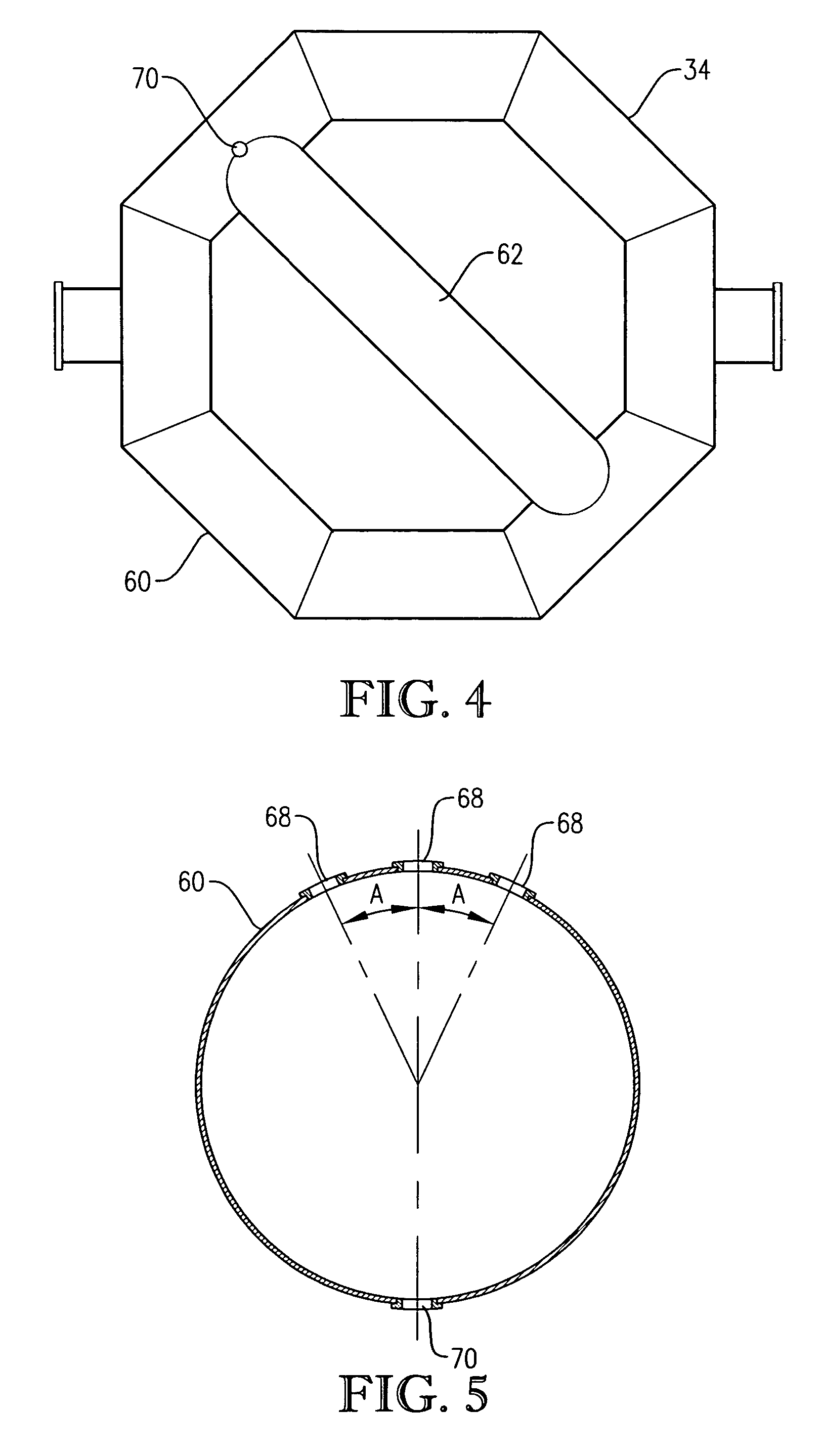

Oxidation system employing internal structure for enhanced hydrodynamics

ActiveUS20070155986A1Effective and economicalReduce formationLiquid-gas reaction as foam/aerosol/bubblesOrganic compound preparationOrganic chemistryTerephthalic acid

Disclosed is an optimized process and apparatus for more efficiently and economically carrying out the liquid-phase oxidation of an oxidizable compound. Such liquid-phase oxidation is carried out in a bubble column reactor that provides for a highly efficient reaction at relatively low temperatures. When the oxidized compound is para-xylene and the product from the oxidation reaction is crude terephthalic acid (CTA), such CTA product can be purified and separated by more economical techniques than could be employed if the CTA were formed by a conventional high-temperature oxidation process.

Owner:ALPEK POLYESTER SA DE CV

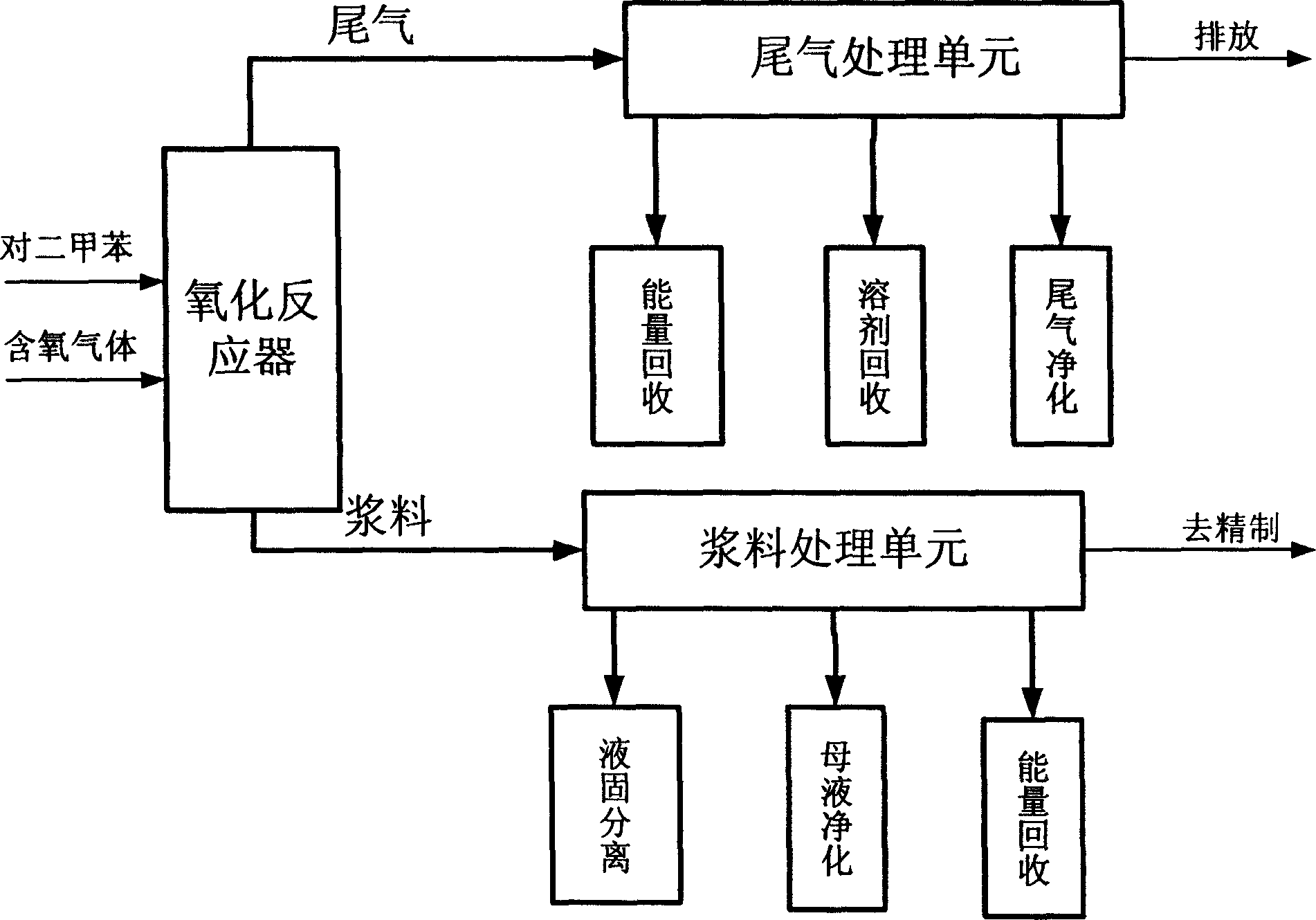

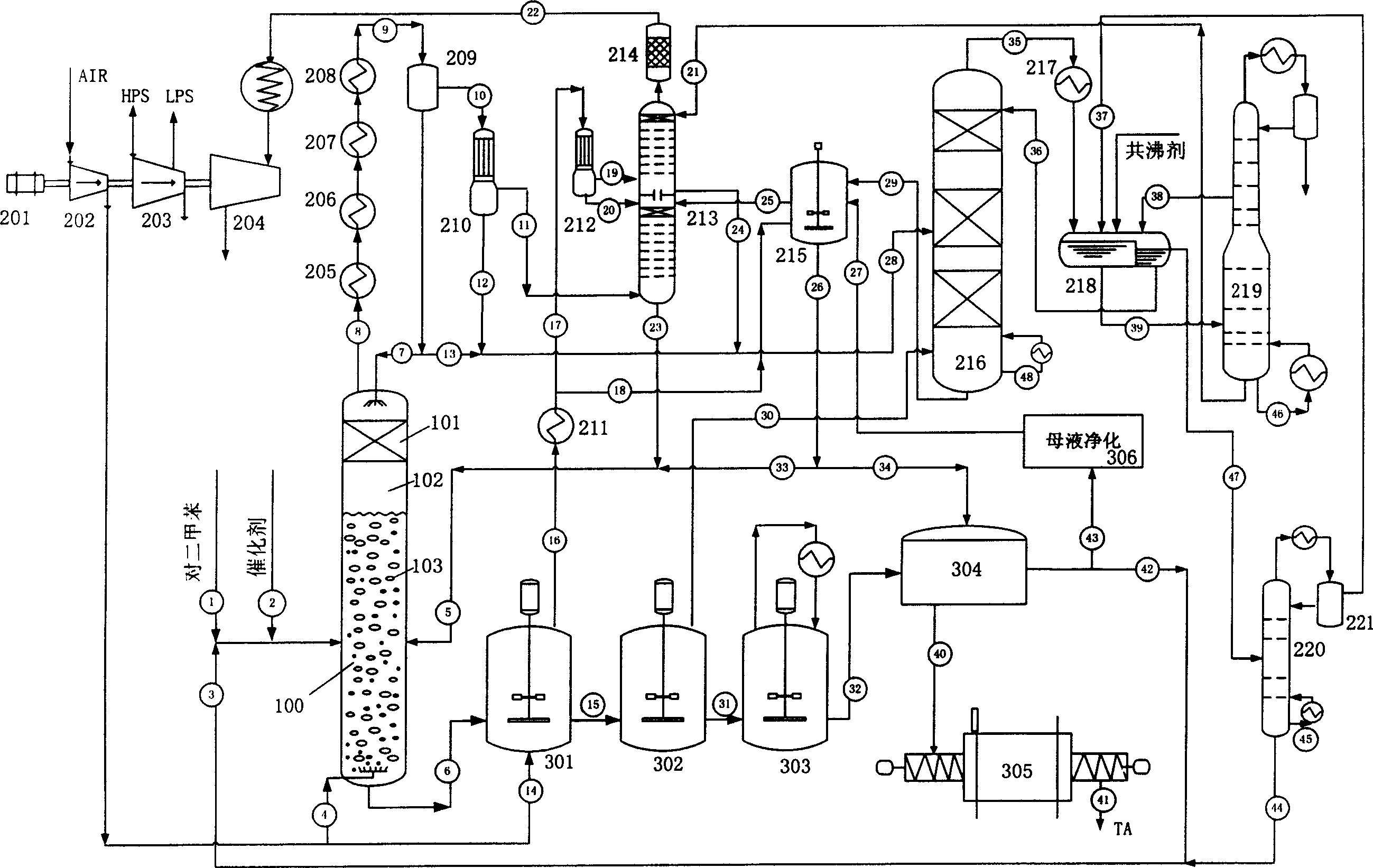

Process for producing terephthalic acid and device therefor

The invention discloses a method for producing terephthalic acid (TA) and its device. The device is composed of three parts: bubble column reactor, slurry treating device, and exhaust gas treating device. The method is provided as follows: Adopting bubble column reactor with gas separating zone for liquid phase catalytic oxidation of xylene; adopting multistage vaporization, filtering and drying in slurry treating device for recovering solid TA; adopting multistage condensation of byproduced steam for recovering reaction heat in the exhaust gas treating device and recovering solvent by using azeotropy rectification method; determining related process conditions according to the demand of minimum production cost.

Owner:ZHEJIANG UNIV

Optimized liquid-phase oxidation

InactiveUS20060047142A1Effective and economicalReduce formationOrganic compound preparationChemical/physical/physico-chemical reactor detailsOrganic chemistryTerephthalic acid

Disclosed is an optimized process and apparatus for more efficiently and economically carrying out the liquid-phase oxidation of an oxidizable compound. Such liquid-phase oxidation is carried out in a bubble column reactor that provides for a highly efficient reaction at relatively low temperatures. When the oxidized compound is para-xylene and the product from the oxidation reaction is crude terephthalic acid (CTA), such CTA product can be purified and separated by more economical techniques than could be employed if the CTA were formed by a conventional high-temperature oxidation process.

Owner:GRUPO PETROTEMEX DE C V

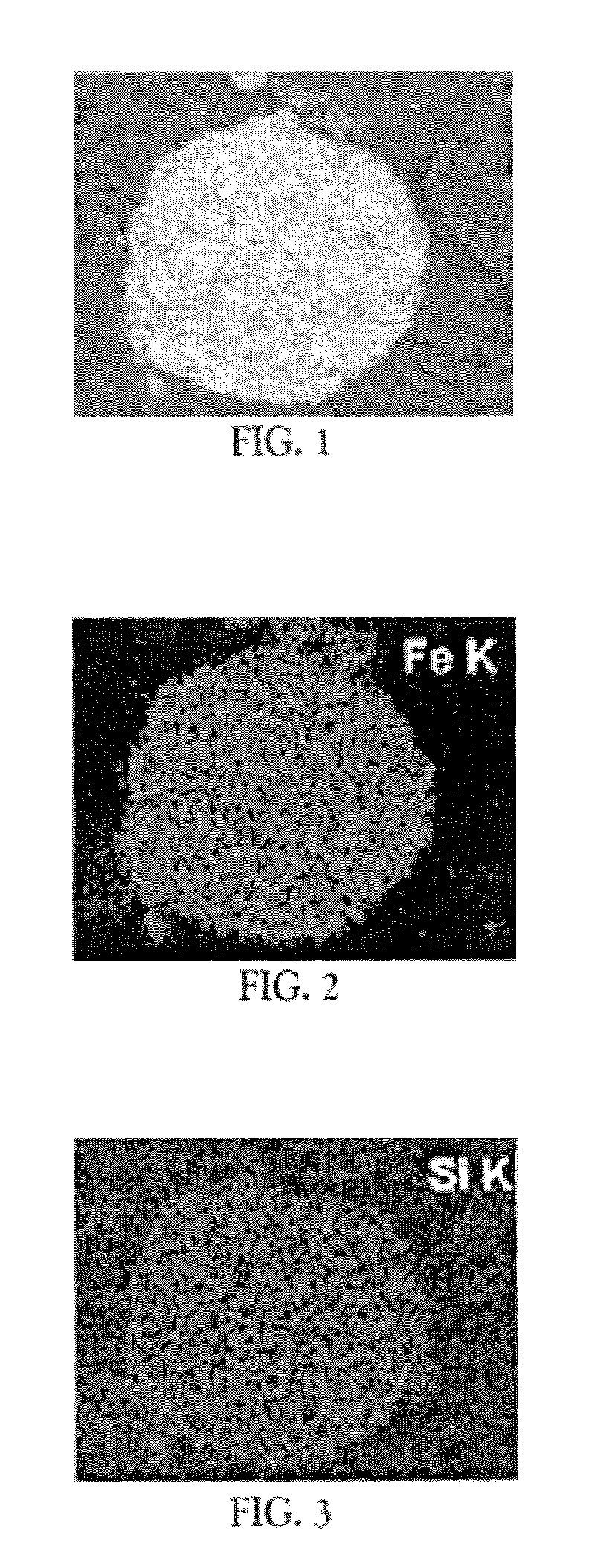

Attrition resistant bulk iron catalysts and processes for preparing and using same

InactiveUS7259286B2Improve wear performanceReduce wear lossLiquid hydrocarbon mixture productionAdditivesFluidized bedHydrogenation process

An attrition resistant precipitated bulk iron catalyst is prepared from iron oxide precursor and a binder by spray drying. The catalysts are preferably used in carbon monoxide hydrogenation processes such as Fischer-Tropsch synthesis. These catalysts are suitable for use in fluidized-bed reactors, transport reactors and, especially, slurry bubble column reactors.

Owner:RES TRIANGLE INST +1

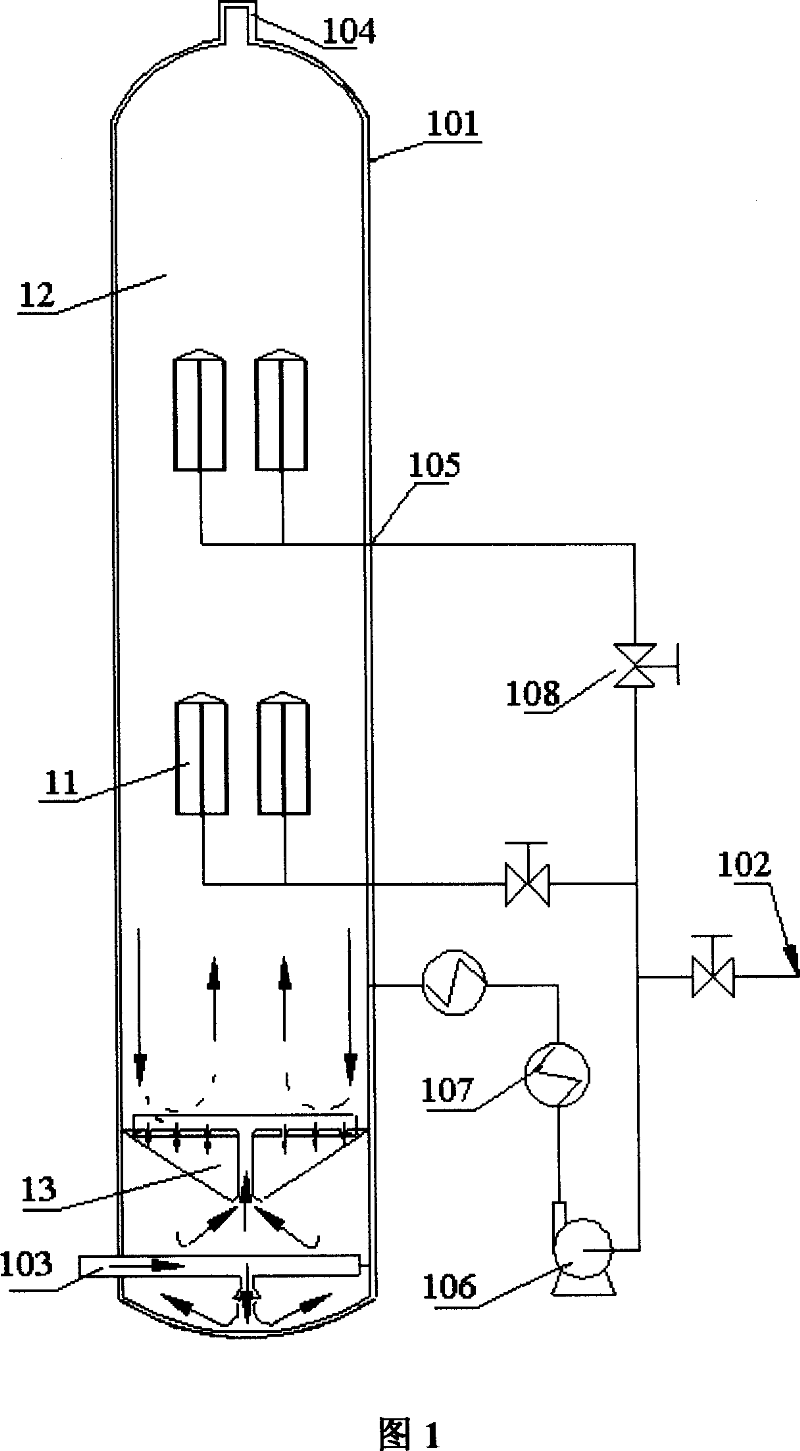

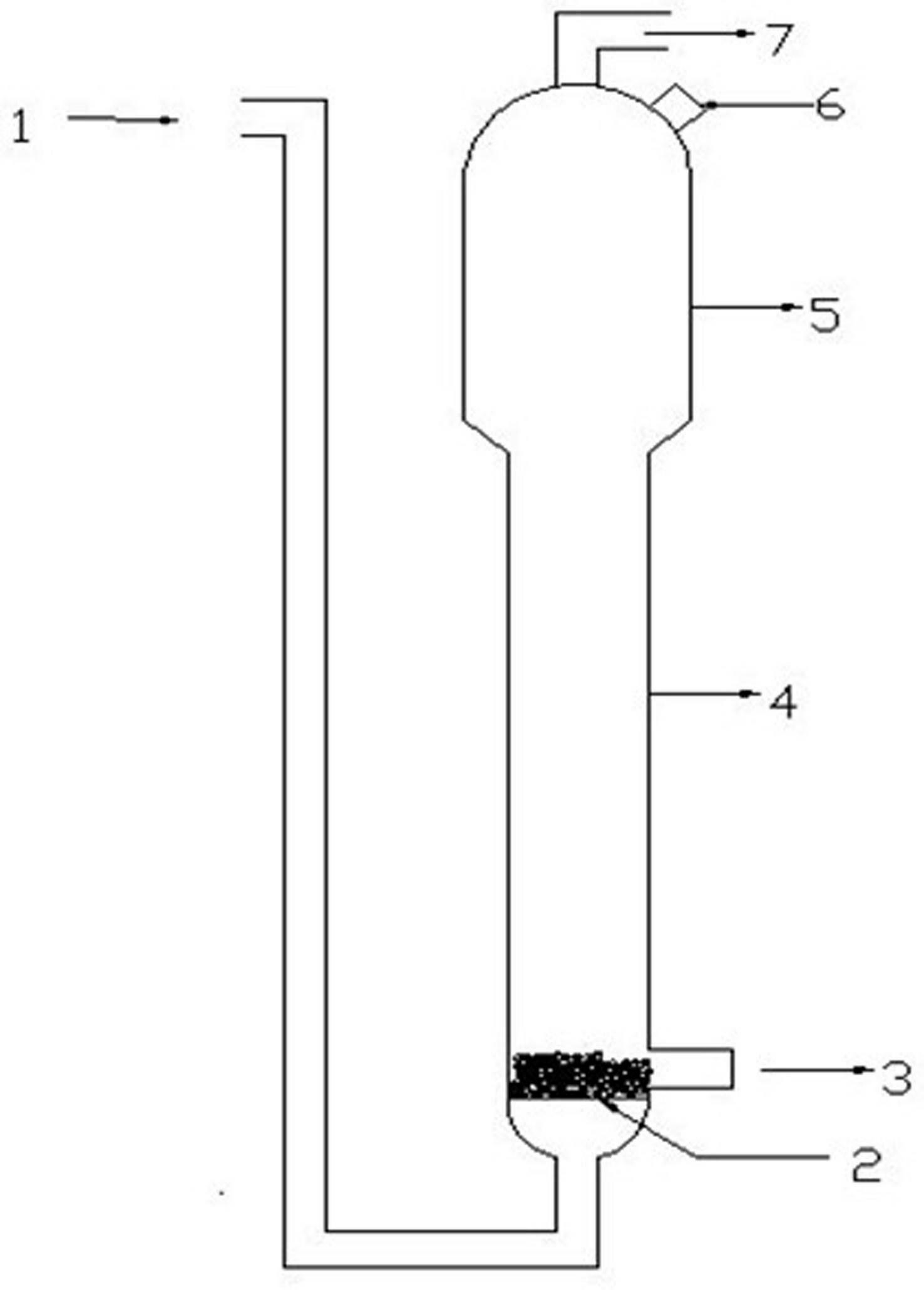

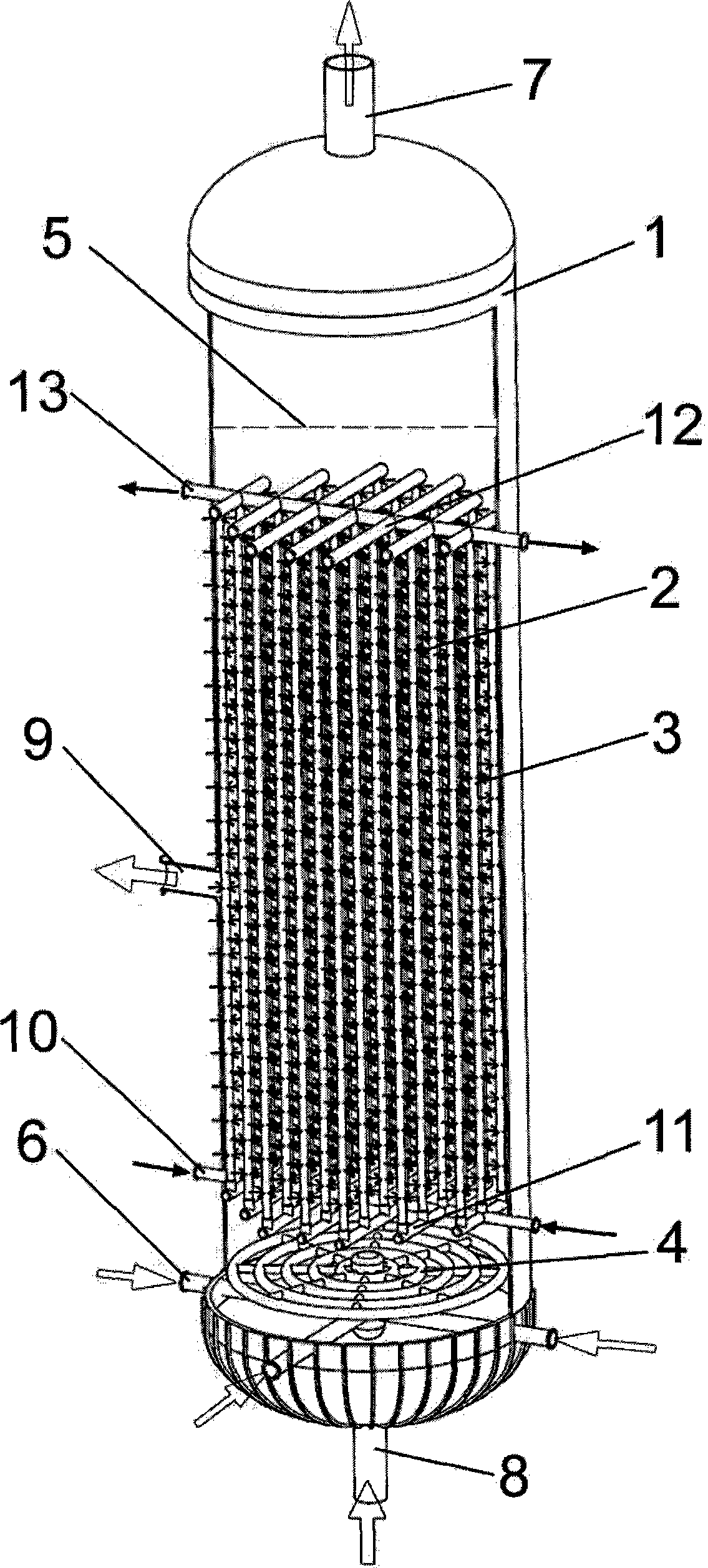

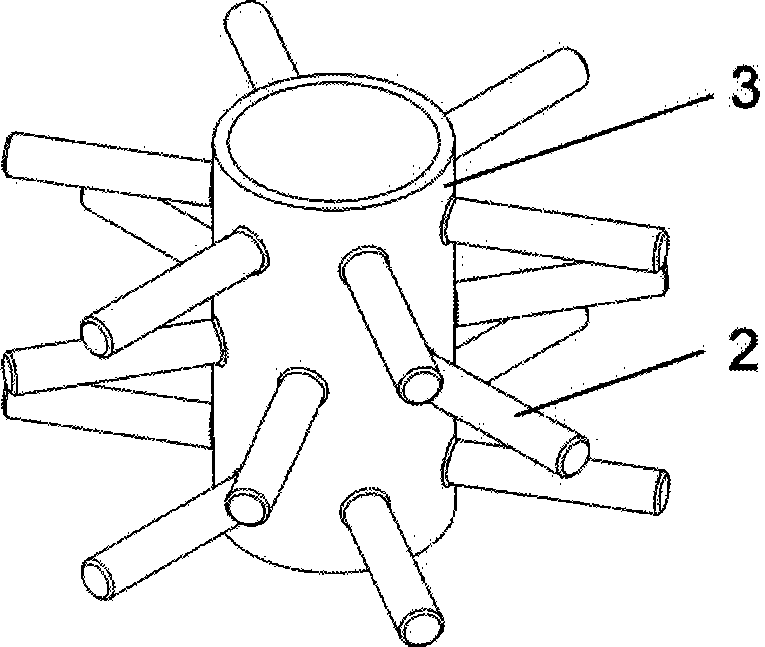

Slurry bubble columun reactor having internal circulation and external heat-exchanging and the application

ActiveCN101036865AReduce concentrationIncrease concentrationChemical/physical processesLiquid fuelSlurry

The invention discloses a slurry bed reactor with internal circulation and external heat exchange and its application. The slurry bed reactor comprises a tower-type Gas-Liquid-Solid three phase slurry bed reactor (12) with cylindrical casing, a tubular filter (11) arranged on the reactor (12), a sharp-crested orifice gas distributor, a heat exchanger (107), and a circulating pump (106), and can be used to generate gas or liquid fuel from synthetic gas in the presence of catalyst and liquid inert medium. In the invention, internal circulation of gas in the bottom of the reactor, on-line separation for catalyst inside the reactor, and carrying effect of fluid, form an internal circulation inside the reactor and a heat exchange outside the tower, thereby promoting axial even distribution of catalyst in the reactor and improving temperature distribution in tower, and the invention is provided with high space-time yield and low energy consumption, accordingly, mass production can be achieved easily.

Owner:EAST CHINA UNIV OF SCI & TECH

Optimized Liquid-Phase Oxidation

InactiveUS20070293699A1Effective and economicalReduce formationOrganic compound preparationCarboxylic compound preparationOrganic chemistryTerephthalic acid

Disclosed is an optimized process and apparatus for more efficiently and economically carrying out the liquid-phase oxidation of an oxidizable compound. Such liquid-phase oxidation is carried out in a bubble column reactor that provides for a highly efficient reaction at relatively low temperatures. When the oxidized compound is para-xylene and the product from the oxidation reaction is crude terephthalic acid (CTA), such CTA product can be purified and separated by more economical techniques than could be employed if the CTA were formed by a conventional high-temperature oxidation process.

Owner:EASTMAN CHEM CO

Optimized liquid-phase oxidation

ActiveUS20060047159A1Effective and economicalReduce formationOrganic compound preparationLighting and heating apparatusOrganic chemistryTerephthalic acid

Disclosed is an optimized process and apparatus for more efficiently and economically carrying out the liquid-phase oxidation of an oxidizable compound. Such liquid-phase oxidation is carried out in a bubble column reactor that provides for a highly efficient reaction at relatively low temperatures. When the oxidized compound is para-xylene and the product from the oxidation reaction is crude terephthalic acid (CTA), such CTA product can be purified and separated by more economical techniques than could be employed if the CTA were formed by a conventional high-temperature oxidation process.

Owner:ALPEK POLYESTER SA DE CV

Optimized liquid-phase oxidation

ActiveUS20060047143A1Effective and economicalReduce formationOrganic compound preparationLiquid-gas reaction processesOrganic chemistryTerephthalic acid

Disclosed is an optimized process and apparatus for more efficiently and economically carrying out the liquid-phase oxidation of an oxidizable compound. Such liquid-phase oxidation is carried out in a bubble column reactor that provides for a highly efficient reaction at relatively low temperatures. When the oxidized compound is para-xylene and the product from the oxidation reaction is crude terephthalic acid (CTA), such CTA product can be purified and separated by more economical techniques than could be employed if the CTA were formed by a conventional high-temperature oxidation process.

Owner:ALPEK POLYESTER SA DE CV

Optimized liquid-phase oxidation

ActiveUS20060047158A1Effective and economicalReduce formationOrganic compound preparationCarboxylic preparation by oxidationOrganic chemistryTerephthalic acid

Disclosed is an optimized process and apparatus for more efficiently and economically carrying out the liquid-phase oxidation of an oxidizable compound. Such liquid-phase oxidation is carried out in a bubble column reactor that provides for a highly efficient reaction at relatively low temperatures. When the oxidized compound is para-xylene and the product from the oxidation reaction is crude terephthalic acid (CTA), such CTA product can be purified and separated by more economical techniques than could be employed if the CTA were formed by a conventional high-temperature oxidation process.

Owner:ALPEK POLYESTER SA DE CV

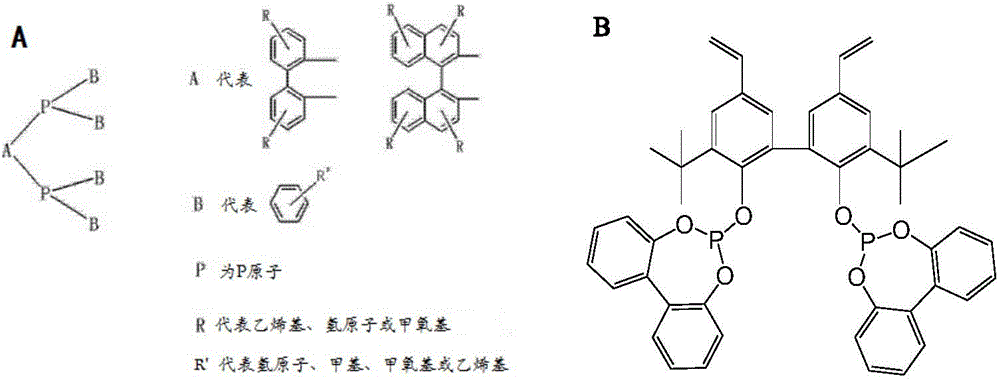

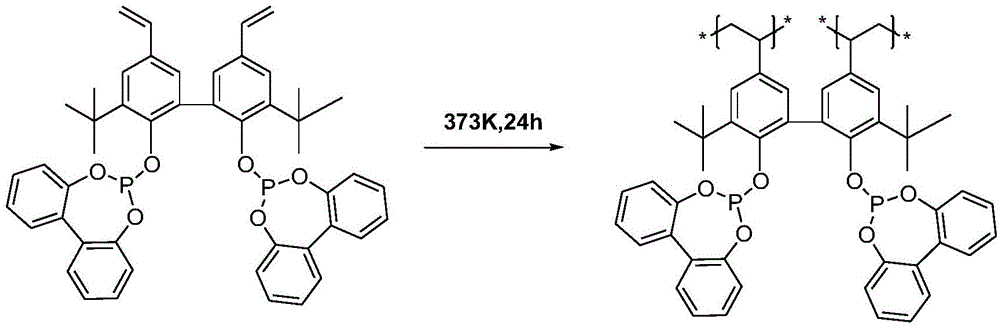

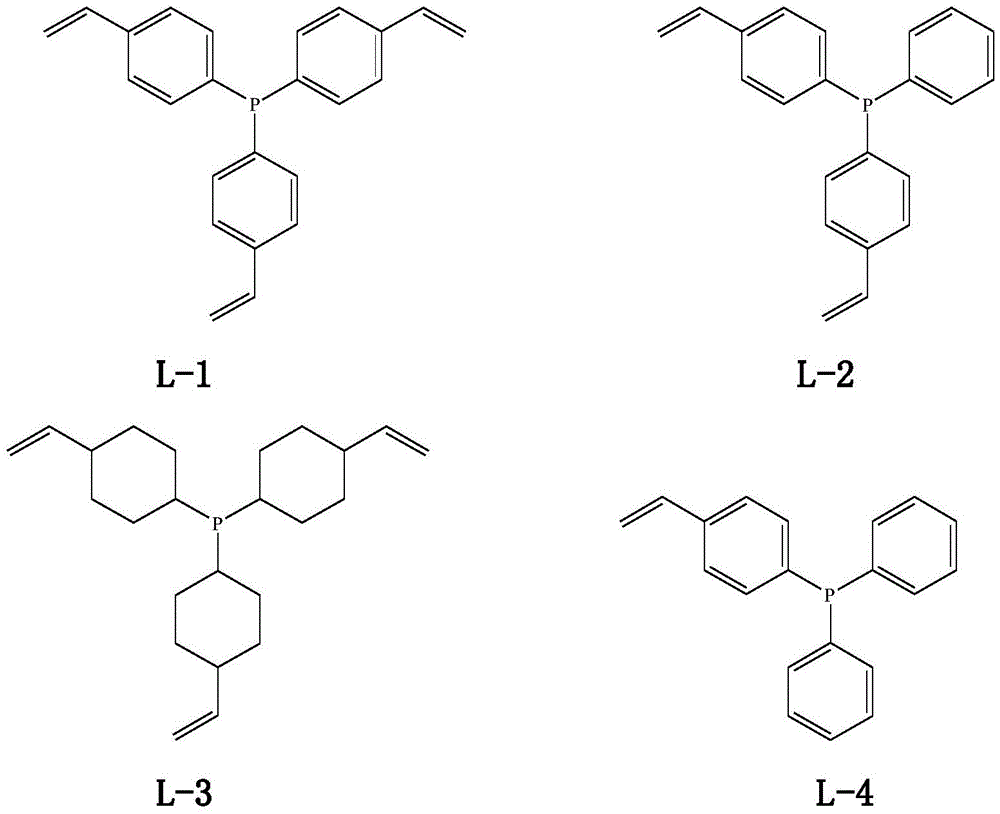

Heterogeneous catalyst adopting phosphine-containing organic mixed polymer-metal as well as preparation and application of heterogeneous catalyst

ActiveCN106140303ASolution to short lifeImprove utilization efficiencyOrganic-compounds/hydrides/coordination-complexes catalystsChemical industryAlkaneFormylation reaction

The invention discloses a heterogeneous catalyst adopting a hierarchical pore structure and adopting phosphine-containing organic mixed polymer-metal as well as preparation and an application of the heterogeneous catalyst in production of aldehyde with a high normal / isomeric ratio through internal olefin hydroformylation. In the heterogeneous catalyst, one, two or three of metal Rh, Co and Ir are taken as active components, and a phosphine-containing organic mixed polymer adopting the hierarchical pore structure is taken as a carrier and is prepared from multidentate organic phosphine ligands containing alkylene and monodentate organic phosphine ligands through copolymerization. The coordinate bond type heterogeneous catalyst is applicable to a fixed bed reactor, a slurry bed reactor, a bubble column reactor, a trickle-bed reactor and other reactors. The provided heterogeneous catalyst has good presentation in the internal olefin hydroformylation reaction, internal olefins are firstly isomerized to be terminal-group olefins under the action of the catalyst, a hydroformylation reaction is performed, corresponding normal aldehyde is selectively generated, accordingly, the normal / isomeric ratio of the product aldehyde is high and can be higher than 15, and the content of alkane in the obtained product is lower than 1%.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Optimized liquid-phase oxidation

ActiveUS20060047151A1Effective and economicalReduce formationOrganic compound preparationCarboxylic preparation by oxidationOrganic chemistryTerephthalic acid

Disclosed is an optimized process and apparatus for more efficiently and economically carrying out the liquid-phase oxidation of an oxidizable compound. Such liquid-phase oxidation is carried out in a bubble column reactor that provides for a highly efficient reaction at relatively low temperatures. When the oxidized compound is para-xylene and the product from the oxidation reaction is crude terephthalic acid (CTA), such CTA product can be purified and separated by more economical techniques than could be employed if the CTA were formed by a conventional high-temperature oxidation process.

Owner:ALPEK POLYESTER SA DE CV

Optimized liquid-phase oxidation

ActiveUS20060047146A1Effective and economicalReduce formationOrganic compound preparationChemical/physical/physico-chemical reactor detailsOrganic chemistryTerephthalic acid

Disclosed is an optimized process and apparatus for more efficiently and economically carrying out the liquid-phase oxidation of an oxidizable compound. Such liquid-phase oxidation is carried out in a bubble column reactor that provides for a highly efficient reaction at relatively low temperatures. When the oxidized compound is para-xylene and the product from the oxidation reaction is crude terephthalic acid (CTA), such CTA product can be purified and separated by more economical techniques than could be employed if the CTA were formed by a conventional high-temperature oxidation process.

Owner:ALPEK POLYESTER SA DE CV

Modeling of liquid-phase oxidation

InactiveUS20060116531A1Effective and economicalOrganic compound preparationCarboxylic preparation by oxidationChemical physicsLiquid phase

Disclosed is an optimized process for more effectively and efficiently modeling liquid-phase oxidation in a bubble column reactor.

Owner:SRI INTERNATIONAL +1

Optimized liquid-phase oxidation

ActiveUS20060047161A1Effective and economicalReduce formationOrganic compound preparationChemical/physical/physico-chemical reactor detailsOrganic chemistryTerephthalic acid

Disclosed is an optimized process and apparatus for more efficiently and economically carrying out the liquid-phase oxidation of an oxidizable compound. Such liquid-phase oxidation is carried out in a bubble column reactor that provides for a highly efficient reaction at relatively low temperatures. When the oxidized compound is para-xylene and the product from the oxidation reaction is crude terephthalic acid (CTA), such CTA product can be purified and separated by more economical techniques than could be employed if the CTA were formed by a conventional high-temperature oxidation process.

Owner:ALPEK POLYESTER SA DE CV

Optimized liquid-phase oxidation

ActiveUS7371894B2Effective and economicalReduce formationOrganic compound preparationChemical/physical/physico-chemical stationary reactorsOrganic chemistryTerephthalic acid

Disclosed is an optimized process and apparatus for more efficiently and economically carrying out the liquid-phase oxidation of an oxidizable compound. Such liquid-phase oxidation is carried out in a bubble column reactor that provides for a highly efficient reaction at relatively low temperatures. When the oxidized compound is para-xylene and the product from the oxidation reaction is crude terephthalic acid (CTA), such CTA product can be purified and separated by more economical techniques than could be employed if the CTA were formed by a conventional high-temperature oxidation process.

Owner:ALPEK POLYESTER SA DE CV

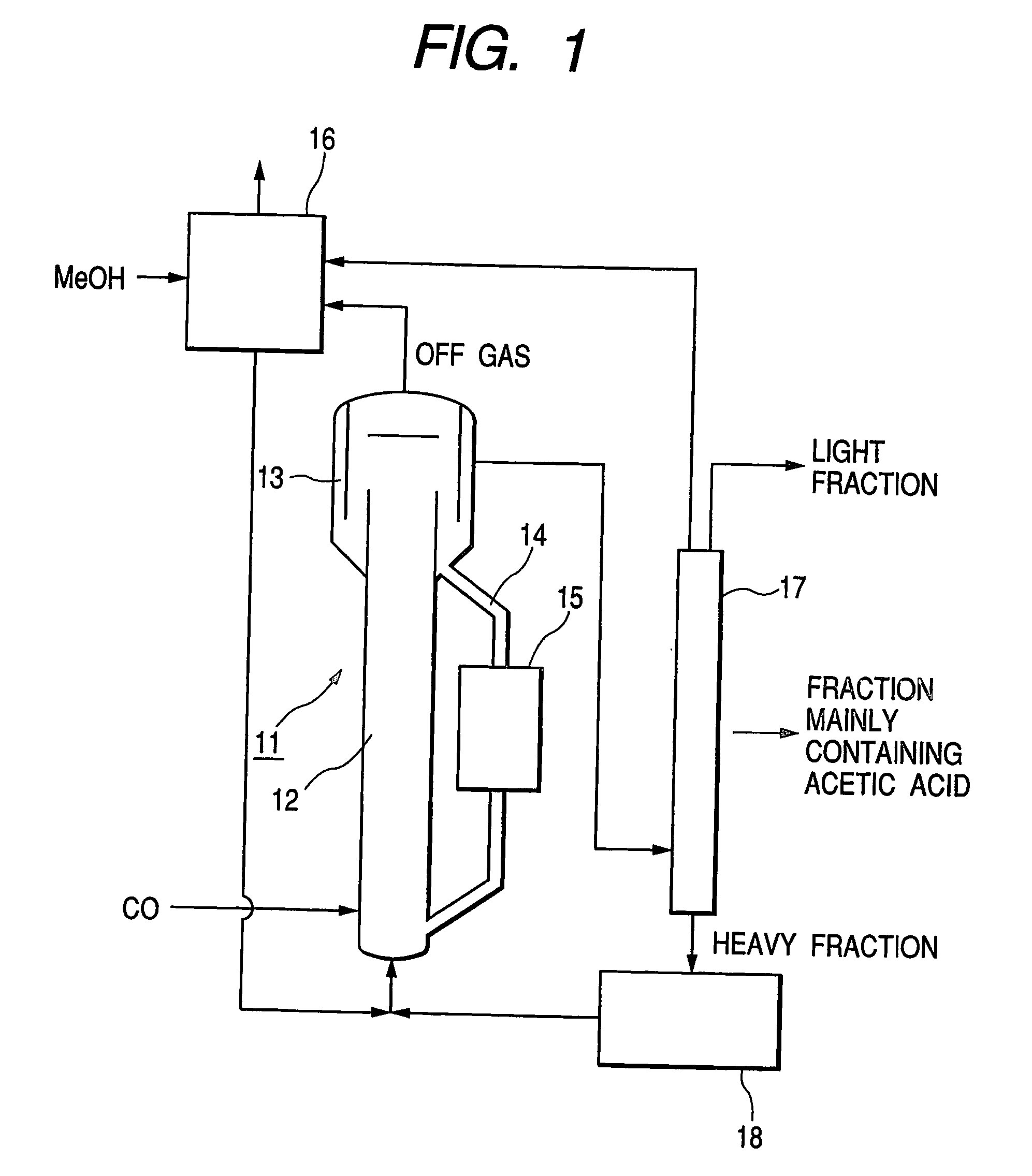

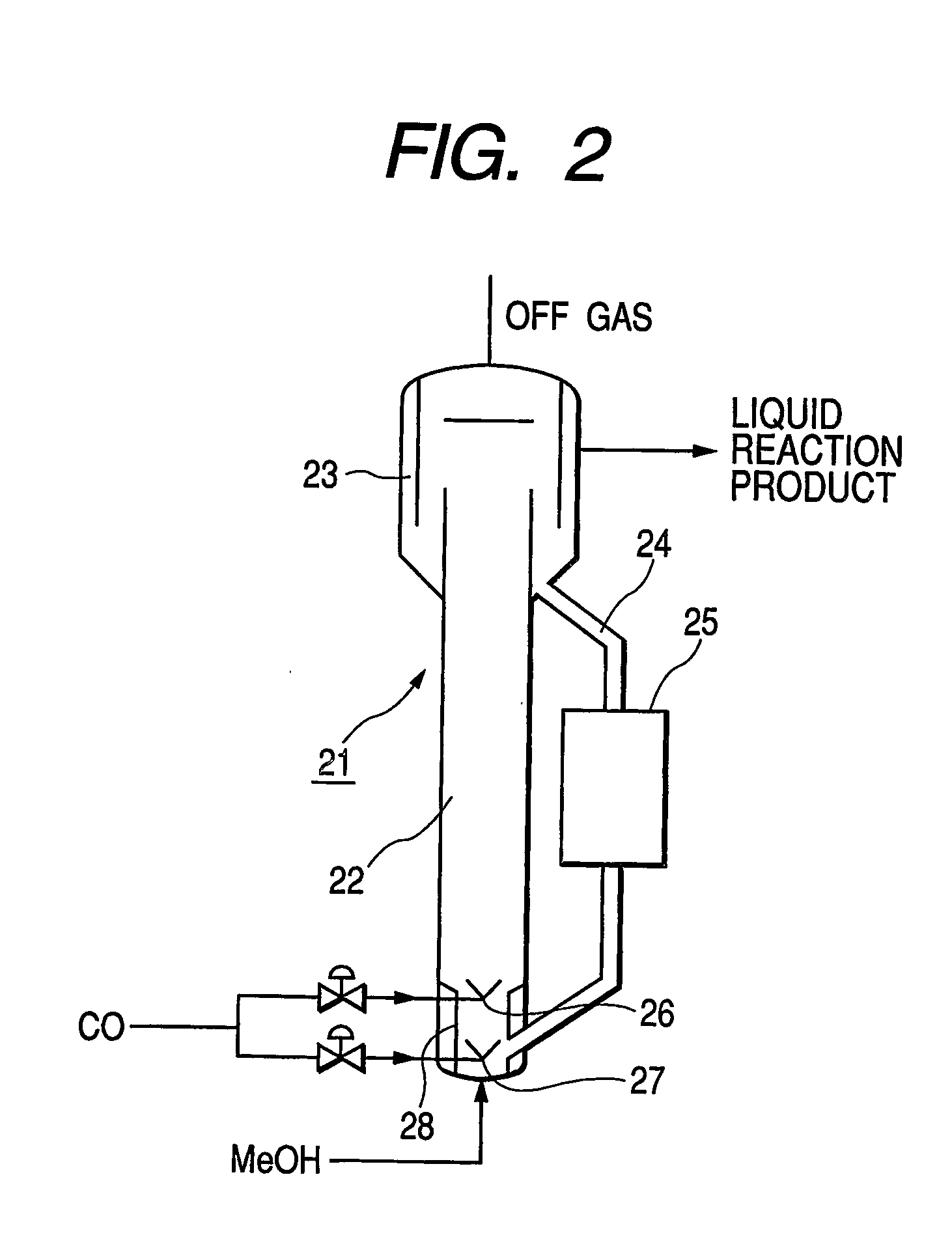

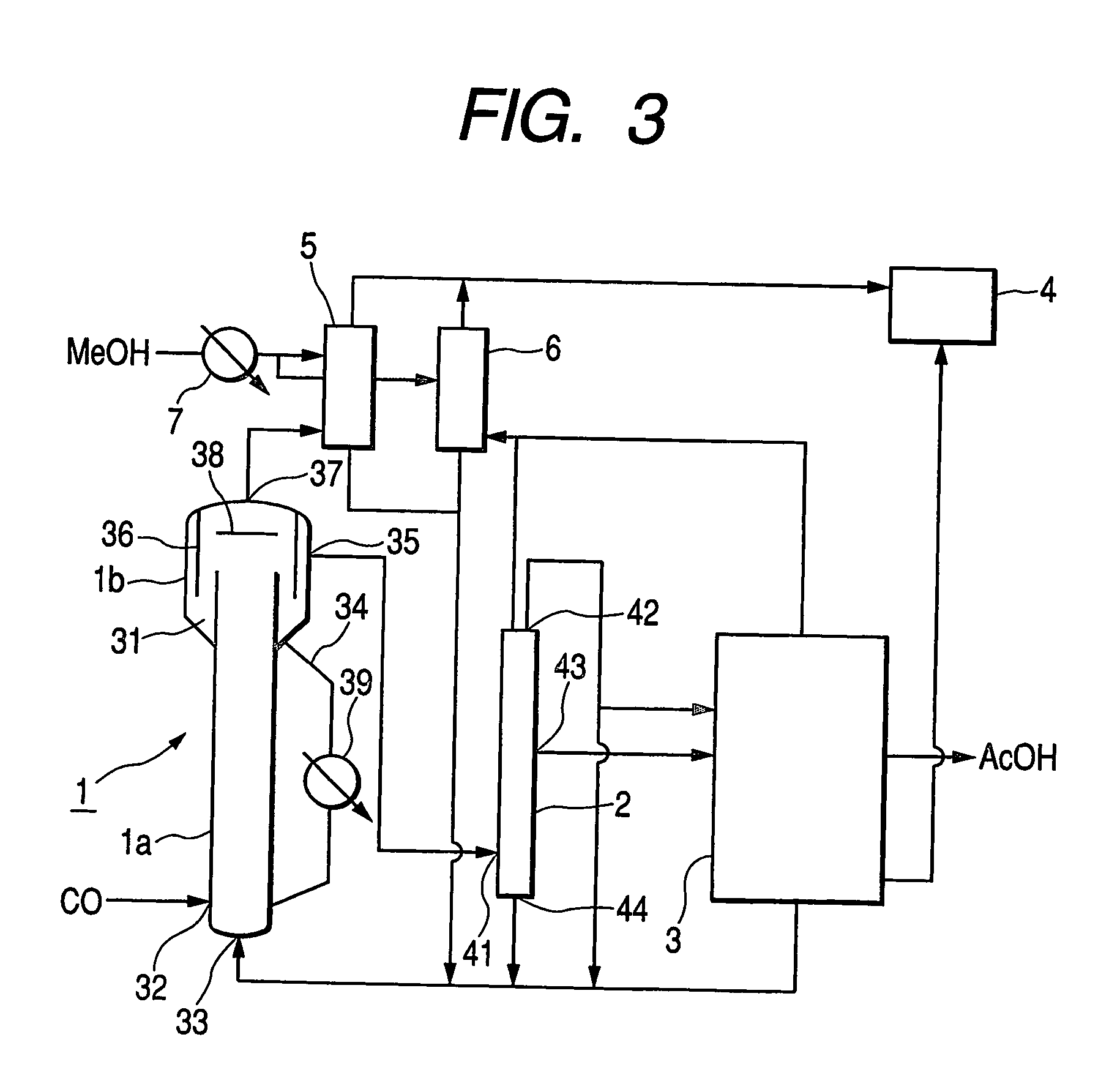

Method of manufacturing acetic acid

ActiveUS20060281944A1Decrease productivityImprove side effectsOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAcetic acidCarbonylation

Acetic acid is manufactured by carbonylating methanol with carbon monoxide by way of a heterogeneous catalytic reaction in a bubble column reactor. The carbonylating reaction is conducted with a solid catalyst concentration of not less than 100 kg / m3 in terms of the reaction volume. For the reaction, the partial pressure of carbon monoxide in the reactor is confined to a range between 1.0 and 2.5 MPa while the exhaustion ratio of carbon monoxide is confined to a range between 3 and 15% of the theoretical reaction volume of carbon monoxide and the liquid superficial velocity is made to be found in a range between 0.2 and 1.0 m / sec.

Owner:KELLOGG BROWN & ROOT LLC

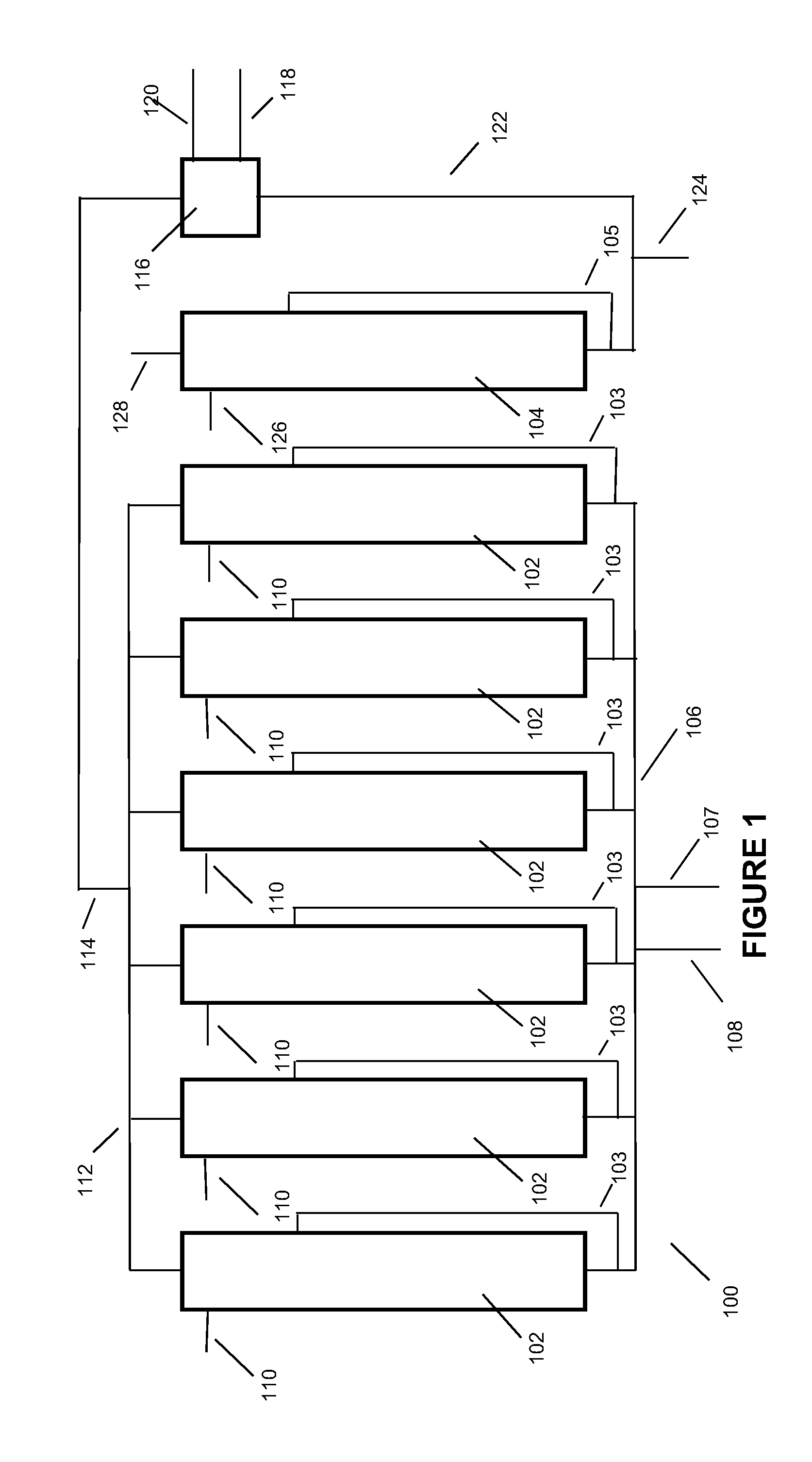

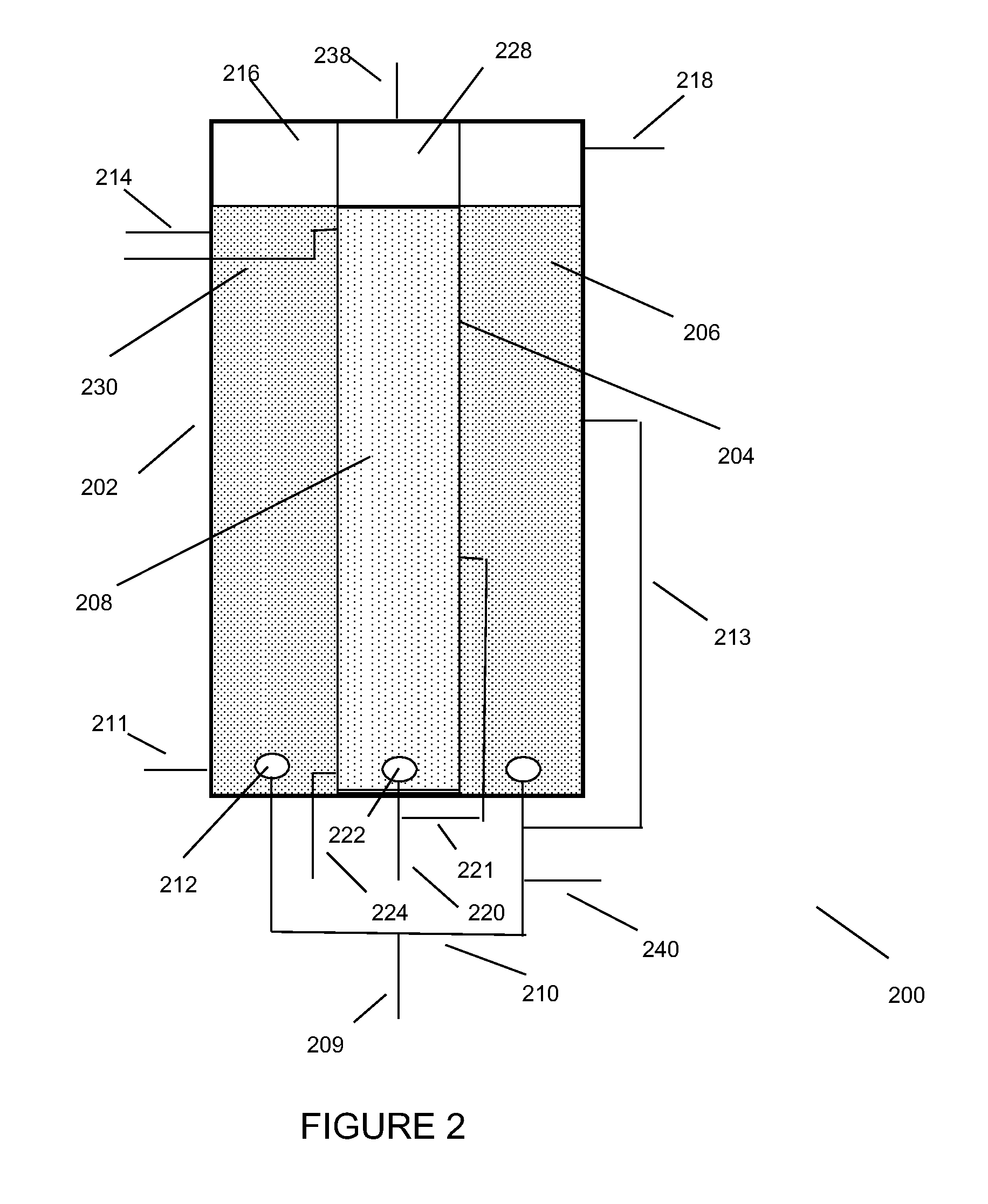

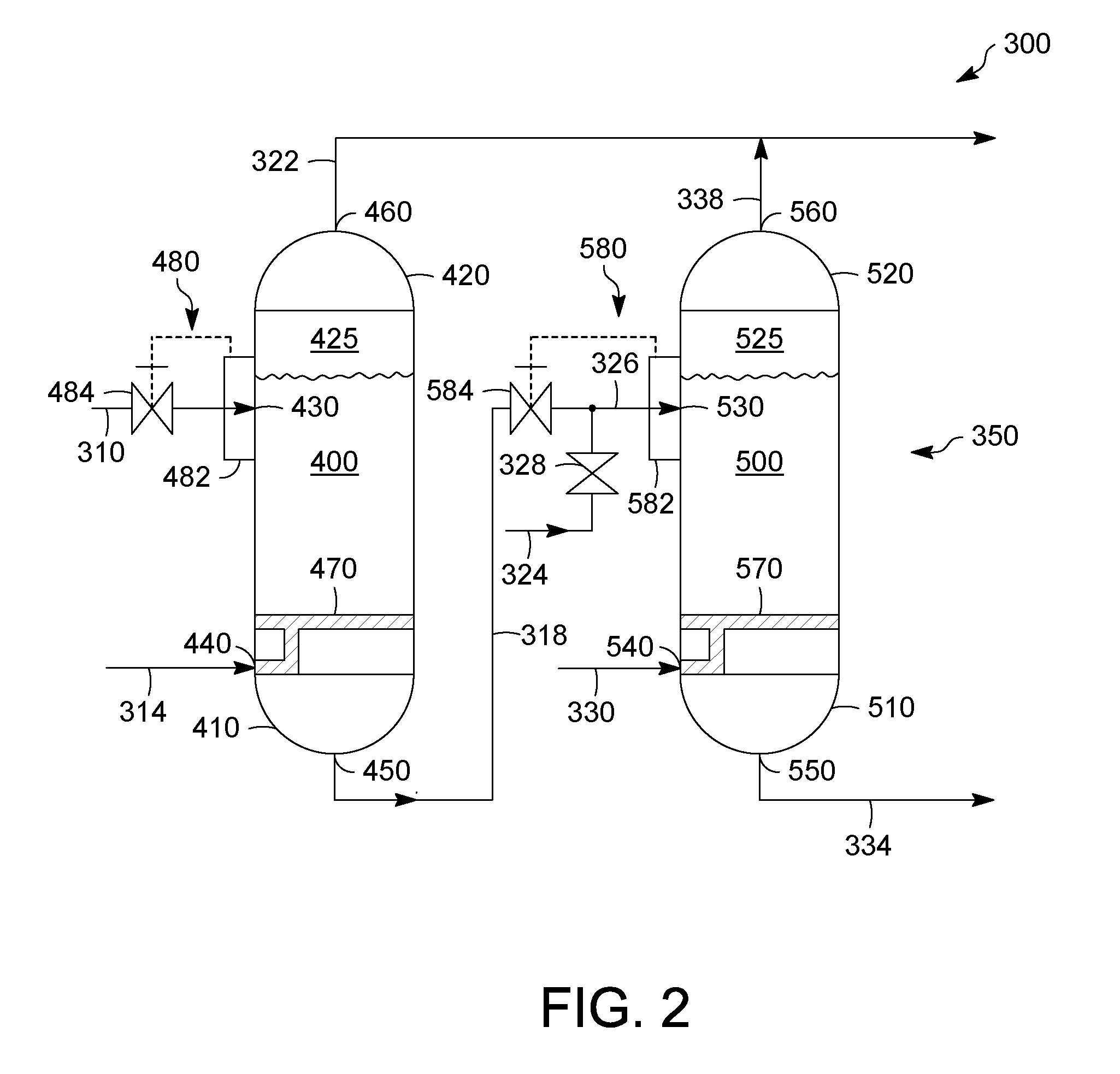

Low energy, high substrate efficiency, anaerobic, deep, bubble column fermentation processes

ActiveUS20130078688A1High conversion of carbon monoxideRisk minimizationBiofuelsChemical recyclingSimple Organic CompoundsHydrogen

Bioconversion processes are disclosed that enable high conversion efficiencies of gas substrate containing both carbon monoxide and hydrogen to oxygenated organic compounds via the carbon monoxide and hydrogen pathways using anaerobic, deep, bubble column fermentation in a cost effective manner. The high conversion efficiency processes of this invention comprise the combination of using at least two deep, bubble column reactors in flow series and using certain feed gas compositions and microbubbles while avoiding carbon monoxide inhibition.

Owner:SYNATA BIO INC

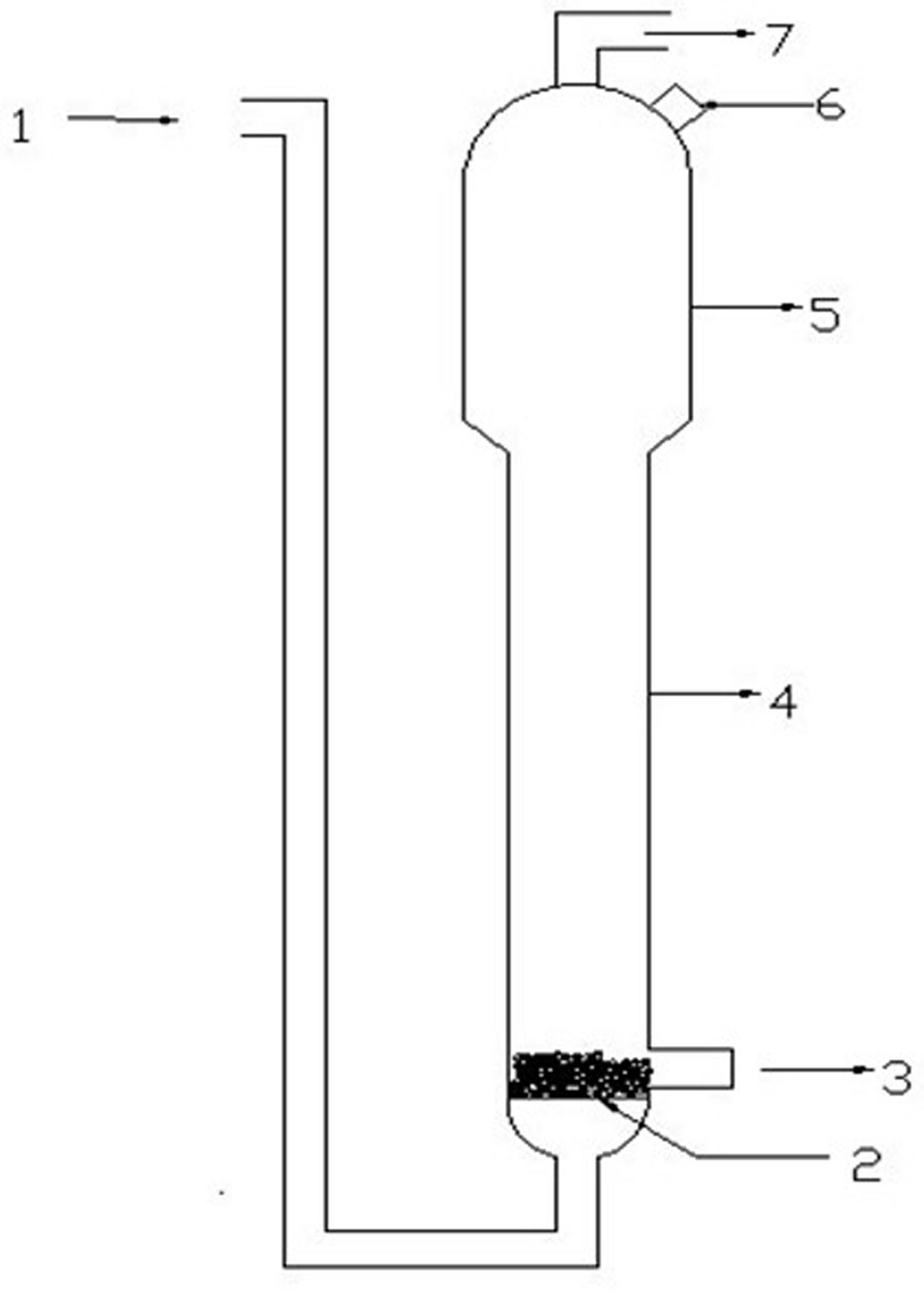

Slurry bubble column technology for preparing ethylene through acetylene hydrogenation and device thereof

InactiveCN102489225AExpand downstream fine chemical productsAvoid overwritingHydrocarbon by hydrogenationChemical/physical processesPtru catalystFixed bed

Provided are slurry bubble column technology for preparing ethylene through acetylene hydrogenation and a device thereof. The slurry bubble column technology includes adding water and then catalyst into a reactor, filling inert gases for replacing, heating, leading gas mixture of acetylene and hydrogen to enter in the reactor for reacting from the bottom of the reactor through a gas distributor, finally exhausting reaction products and unreacted feed gases from the top of the reactor, and separating to obtain the ethylene. The unreacted feed gases and the feed gases are mixed and then enter the reactor again for reacting. The reactor comprises a reaction gas inlet at the bottom, the gas distributor and a material liquid exhaust port, a reactor barrel body is arranged on an expended section on the upper portion of a slurry bubble column reactor, and a catalyst feeding port and a gas outlet are arranged at the top of the reactor. The slurry bubble column for preparing the ethylene through the acetylene hydrogenation is simple in structure, overcomes the phenomenon of temperature runaway in a fixed bed reactor and improves the conversion rate and selectivity of the reaction, and the operation is easy to control.

Owner:TAIYUAN UNIV OF TECH

Optimized liquid-phase oxidation

ActiveUS20060047144A1Effective and economicalReduce formationOrganic compound preparationChemical/physical/physico-chemical stationary reactorsOrganic chemistryTerephthalic acid

Disclosed is an optimized process and apparatus for more efficiently and economically carrying out the liquid-phase oxidation of an oxidizable compound. Such liquid-phase oxidation is carried out in a bubble column reactor that provides for a highly efficient reaction at relatively low temperatures. When the oxidized compound is para-xylene and the product from the oxidation reaction is crude terephthalic acid (CTA), such CTA product can be purified and separated by more economical techniques than could be employed if the CTA were formed by a conventional high-temperature oxidation process.

Owner:ALPEK POLYESTER SA DE CV

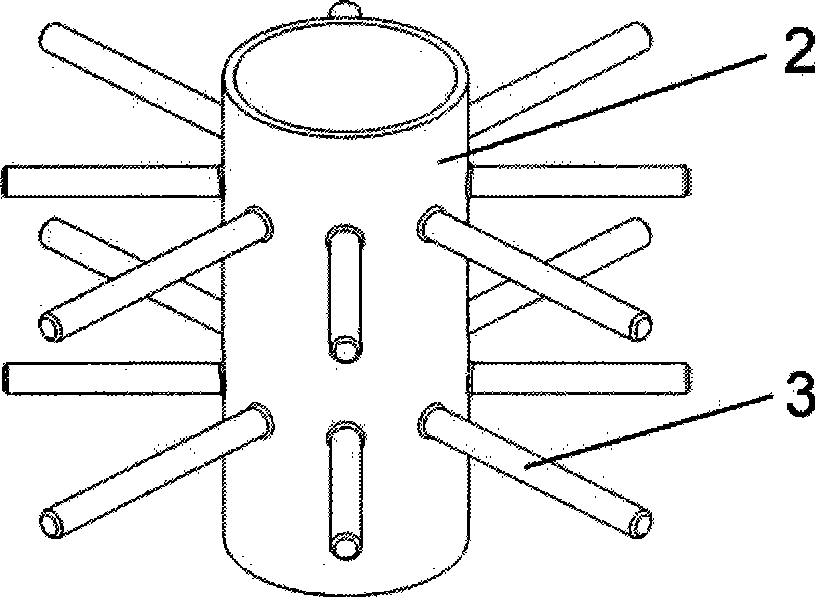

Slurry bubble column reactor with needle type fin column tube bundle

InactiveCN101480595AImprove velocity distributionImprove heat transfer effectStationary conduit assembliesChemical/physical processesSlurryEngineering

The invention discloses a slurry state bubble tower reactor with a needle type fin tube bundle. A plurality of vertical heat exchange tubes are arranged in the cylindrical reactor; the upper ends of the vertical heat exchange tubes are connected with a liquid distributor fixed below a container, while the upper ends are connected with a liquid collector fixed above the container; the outer walls of the heat exchange tubes are provided with horizontal needle type fins; the number of the needle fins arranged on the heat exchange tubes is 80-800 every meter, the diameter of the needle type fins is -10 mm, and the length of the needle type fins is 10 125 mm. The heat exchange tubes with the needle type fins are adopted to increase the heat exchange area and strength the heat exchange capability of the reactor on one hand, and on the other hand, the needle type fins distributed on the outer walls of the heat exchange tubes can obstruct the flowing of sizing agents and bubbles in the tower, can suppress the flow steeping effect caused by the vertical heat exchange tubes, improve the flow rate distribution of a slurry bed and achieve double functions of reinforcing heat transfer and improving the flow.

Owner:ZHEJIANG UNIV

Process for synthesizing methane through synthesis gas

ActiveCN102690157AUniform temperatureImprove heat transfer efficiencyHydrocarbon from carbon oxidesHydrocarbon from oxygen organic compoundsMethanationWater-gas shift reaction

The invention relates to a process for synthesizing methane through synthesis gas. The process comprises the following steps of: according to the weight ratio of slurry bubble column methanation catalyst to solvent being 10-30:100, feeding the slurry bubble column methanation catalyst into a slurry bubble column reactor, taking the synthesis gas as a raw material, carrying out methanation reaction, and forming slurry bubble column outlet gas through methane produced through reaction, unconverted CO, H2, a little dimethyl ether produced through reaction, CO2 produced through water gas shift reaction, and the like; and isobarically and isothermally feeding the slurry bubble column outlet gas into a fixed bed reactor filled with fixed bed methanation catalyst, carrying out methanation reaction again on unconverted H2, CO, the CO2 produced through water gas shift reaction, and the like, splitting the little dimethyl ether to generate methane, and separating fixed bed outlet gas to obtain the product gas in a condensation way. The process has the advantages of high CO conversion rate, and high methane selectivity.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Optimized liquid-phase oxidation

ActiveUS20060116530A1Effective and economicalReduce formationOrganic compound preparationCarboxylic preparation by oxidationOrganic chemistryTerephthalic acid

Disclosed is an optimized process and apparatus for more efficiently and economically carrying out the liquid-phase oxidation of an oxidizable compound. Such liquid-phase oxidation is carried out in a bubble column reactor that provides for a highly efficient reaction at relatively low temperatures. When the oxidized compound is para-xylene and the product from the oxidation reaction is crude terephthalic acid (CTA), such CTA product can be purified and separated by more economical techniques than could be employed if the CTA were formed by a conventional high-temperature oxidation process.

Owner:ALPEK POLYESTER SA DE CV

System and process for reacting a petroleum fraction

InactiveUS20090314686A1Facilitate converting pitchLow hydrogen purityHydrocarbon oils treatment control/regulationCatalytic naphtha reformingDistillates petroleumHydrogen

In one exemplary embodiment, a system for reacting a first feed can include a petroleum fraction having at least about 90%, by volume, with a boiling point of at least about 300° C. The system can include a bubble column reactor. The bubble column reactor, in turn, can include a first inlet for the first feed and a second inlet for a second feed including a gas rich in hydrogen. In addition, the petroleum fraction may be in counter-current flow with respect to the gas rich in hydrogen inside the bubble column reactor.

Owner:UOP LLC

Optimized liquid-phase oxidation

ActiveUS7910769B2Effective and economicalReduce formationOrganic compound preparationLiquid-gas reaction processesOrganic chemistryTerephthalic acid

Disclosed is an optimized process and apparatus for more efficiently and economically carrying out the liquid-phase oxidation of an oxidizable compound. Such liquid-phase oxidation is carried out in a bubble column reactor that provides for a highly efficient reaction at relatively low temperatures. When the oxidized compound is para-xylene and the product from the oxidation reaction is crude terephthalic acid (CTA), such CTA product can be purified and separated by more economical techniques than could be employed if the CTA were formed by a conventional high-temperature oxidation process.

Owner:ALPEK POLYESTER SA DE CV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com