Slurry bubble column reactor with needle type fin column tube bundle

A bubbling tower and reactor technology, which is applied in the field of gas-liquid/gas-liquid-solid multiphase strong exothermic/endothermic reaction process, can solve the problems of reducing the heat transfer coefficient of the tubes and reducing the flow rate of the tower, and improve the flow rate distribution. , The effect of improving flow and strengthening heat transfer capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

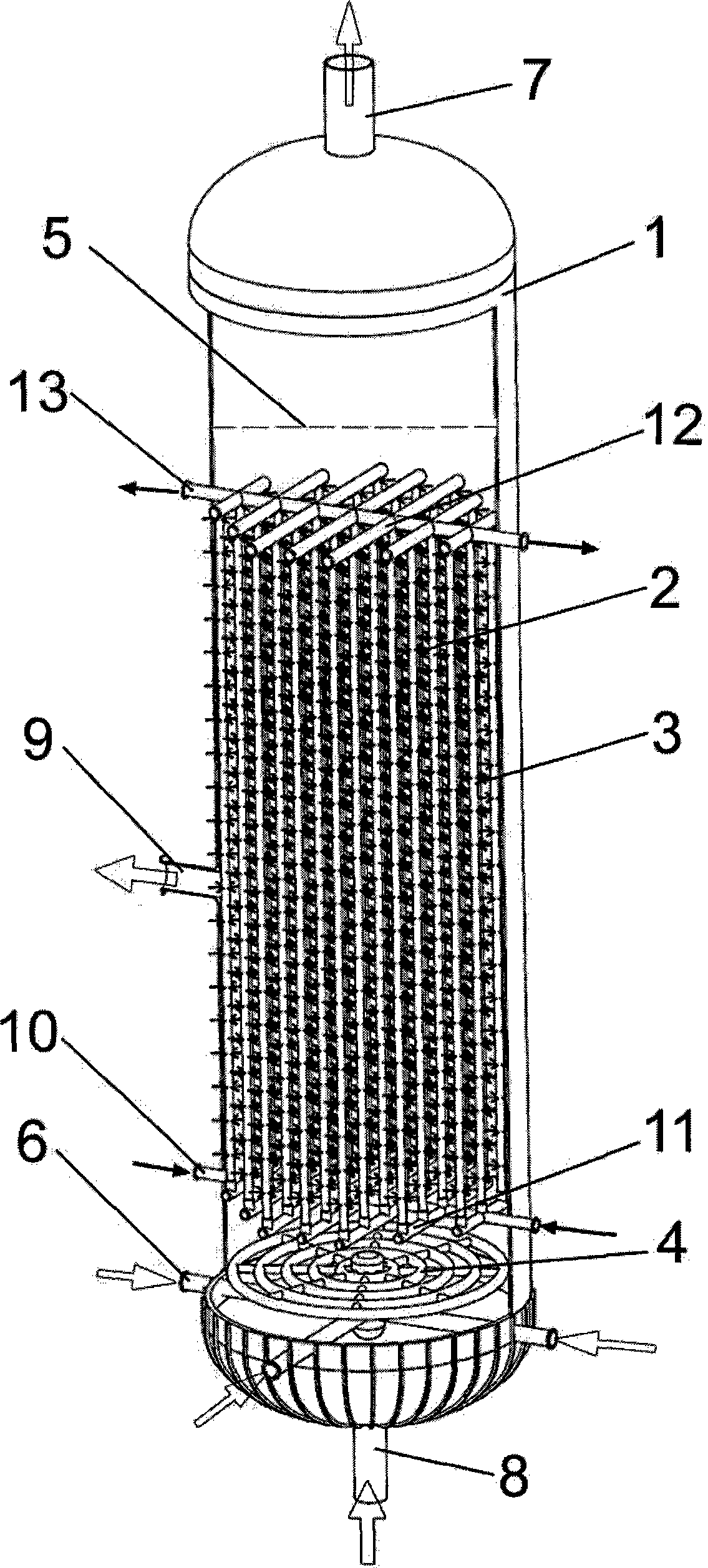

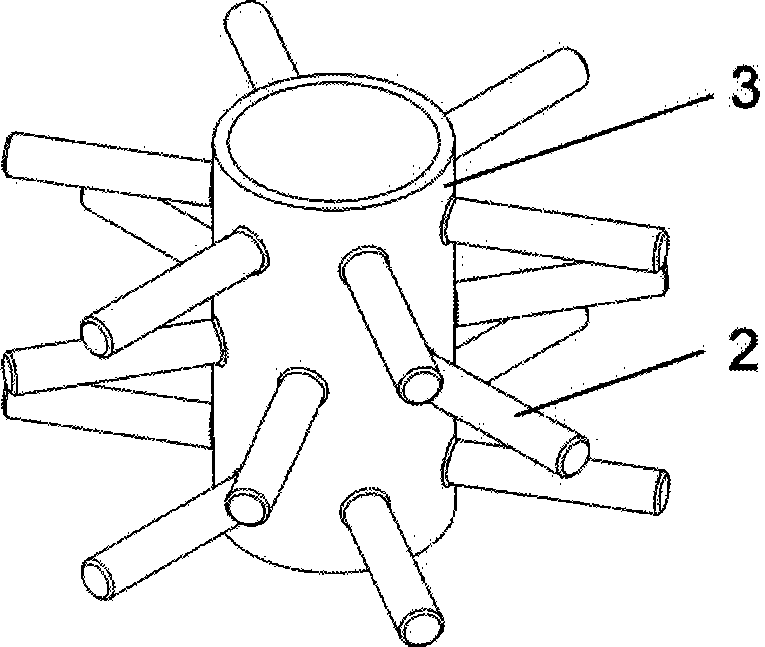

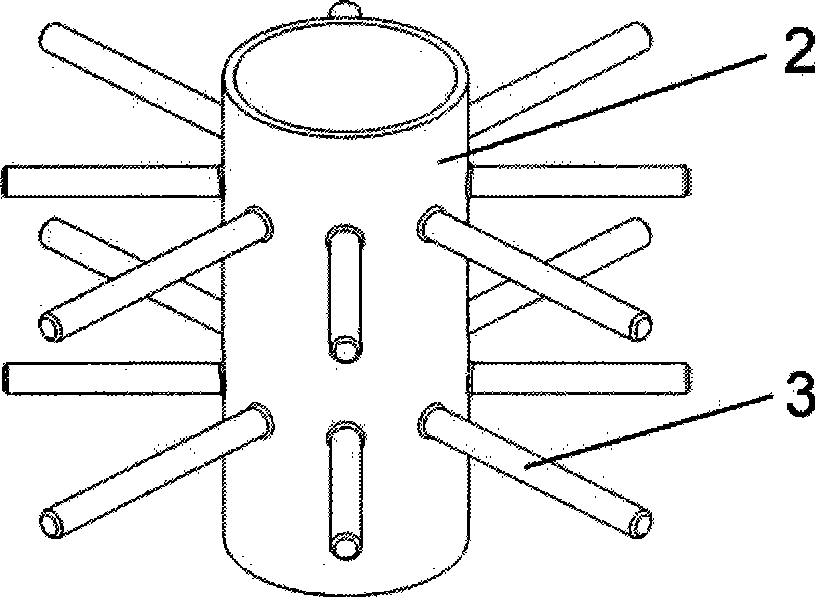

[0036] Slurry bubble column reactor device such as figure 1 As shown, the diameter is 500mm, the liquid level is 4000mm high, and a perforated plate gas distributor is installed at the bottom. In the tower, 30 round heat exchange tubes with a length of 4000 mm and a diameter of 25 mm are evenly arranged with pin-shaped fins, and the distance between the tubes is 70 mm. The pin fins are thin round metal rods, and the arrangement on the heat exchange tube is as follows: figure 2 The structural parameters of the pin fins are listed in Table 1. The measured liquid velocity in the center of the bubble column and the calculated heat transfer coefficient are listed in Table 2.

[0037] Table 1 Structural parameters of heat exchange tubes with pin fins

[0038] Fin density

(branch / m)

Needle Fin Diameter(mm) Needle fin length

(mm) Pin fin damping area

Density (m 2 / m 3 ) 500 4 17 6.37 500 4 13 4.85 571 4 10 4.26 571 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Tube spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com