A Method for Improving the Hydraulic Flow State of Diffusion Divider Basin

A diffusion-type diversion pool technology, applied in river regulation and other directions, can solve problems such as flow disorder in diversion pools, washing bank slopes, bad flow conditions, etc., and achieve the effect of simple structure and easy construction and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

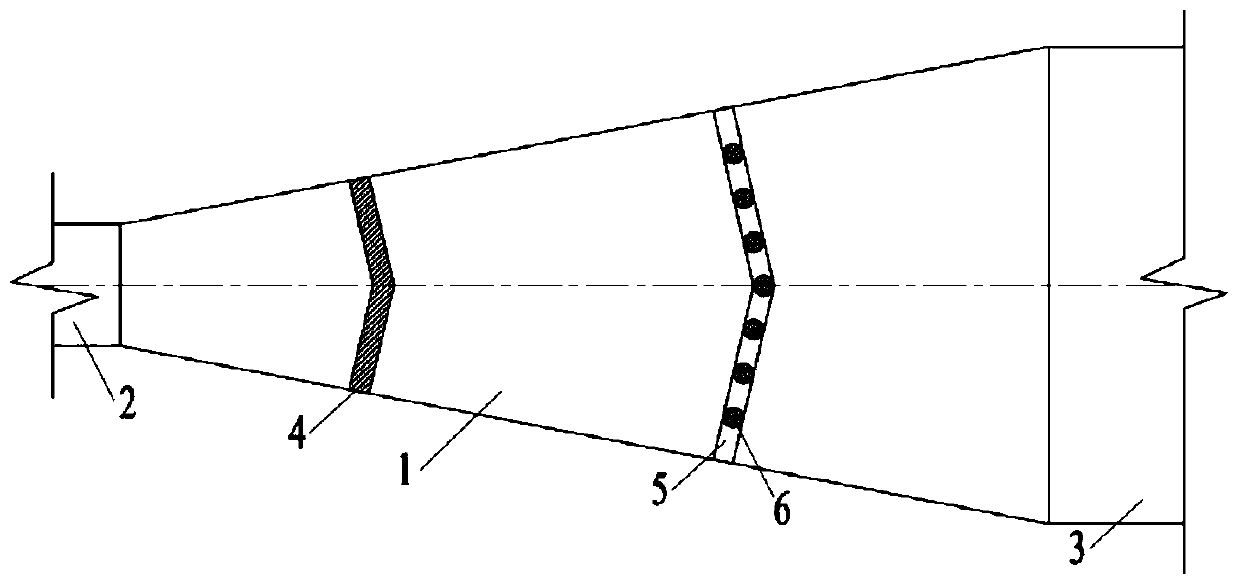

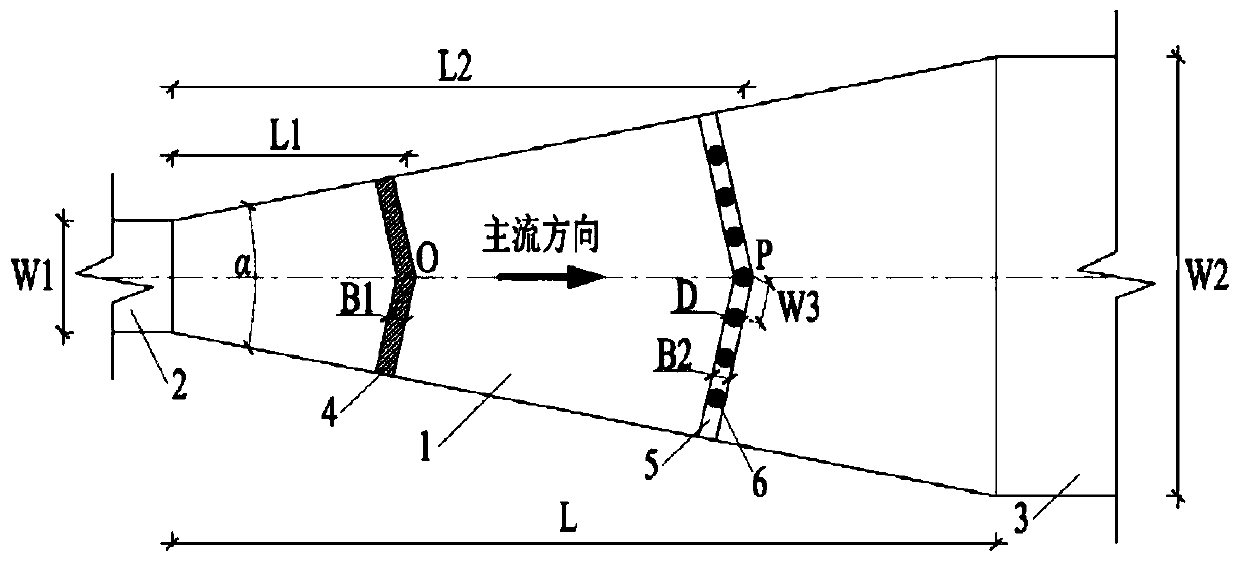

[0030] The schematic diagram of the plane and elevation structure dimensions of the diffusion type split flow pool with the compound rectification device proposed by the present invention in this embodiment is as follows figure 2 , 3 shown.

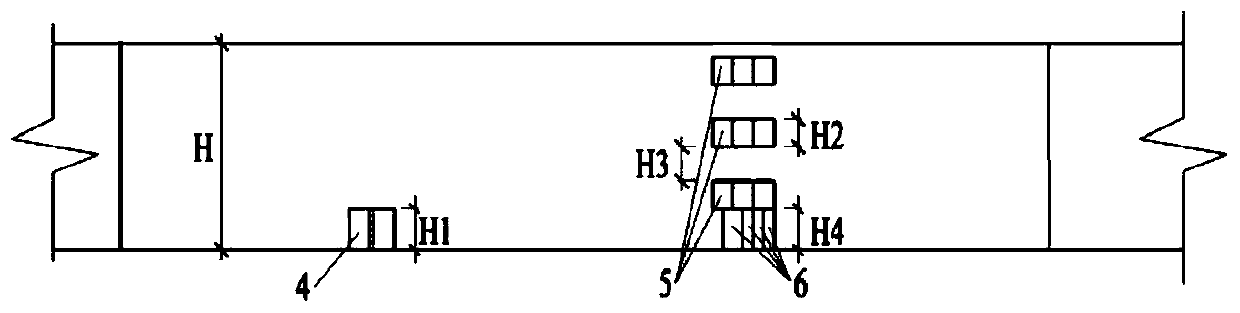

[0031] The length of the diffusion type splitter tank is L=40m, the diffusion angle α=30°, the water depth in the splitter tank is H=5m, the inlet width of the diffusion type splitter tank is W1=5m, the outlet width is W2=25.706m, and the height of the bottom plate is H1=0.2H=1m , Width B1=0.02L=0.8m, distance L1=0.3L=12m from the center point O of the V-shaped sill to the entrance of the diffusion type splitter tank, the number of beams N1=4, the width of the beams B2=0.02L=0.8m, The height of the single-layer beam H2=0.1H=0.5m, the distance between two adjacent beams H3=0.1H=0.5m, the distance between the center point P of the V-shaped composite beam and the entrance of the diffusion type splitter pool L2=0.5L=20m, The height of cyli...

Embodiment 2

[0033] The composite rectifying device described in this embodiment is different from Embodiment 1 in that: the height of the bottom plate H1=0.3H=1.5m, the width B1=0.03L=1.2m, and the distance between the center point O of the V-shaped bottom sill is diffuse type The distance of the entrance of the diversion pool L1=0.2L=8m, the number of beams N1=3, the width of the beams B2=0.03L=1.2m, the height of the single-layer beams H2=0.16H=0.8m, the distance between the two adjacent beams H3=0.2H=1m, distance L2=0.6L=24m from the center point P of the V-shaped composite beam to the entrance of the diffusion type splitter tank, the height of the cylindrical pier H4=0.2H=1m, the cross-sectional diameter of the cylindrical pier D=B2=1.2 m, the number of cylindrical piers N2=7 and N=3, the distance between two adjacent cylindrical piers W3=0.3W1=1.5m.

Embodiment 3

[0035] The composite rectification device described in this embodiment differs from Embodiments 1 and 2 in that: the height of the bottom plate H1=0.4H=2m, the width B1=0.05L=2m, and the distance between the center point O of the V-shaped bottom sill is diffuse type The distance of the inlet of the diversion pool L1=0.1L=4m, the number of beams N1=2, the width of the beams B2=0.05L=2m, the height of the single-layer beams H2=0.2H=1m, the distance between two adjacent beams H3= 0.3H=1.5m, the distance L2=0.7L=28m from the center point P of the V-shaped composite beam to the entrance of the diffusion type splitter tank, the height of the cylindrical pier H4=0.3H=1.5m, the cross-sectional diameter of the cylindrical pier D=B2=2m , the number of cylindrical piers N2=3 and N=1, the distance between two adjacent cylindrical piers W3=0.4W1=2m.

[0036] Such as Figure 4 As shown, the three-dimensional flow numerical simulation method is used to compare and analyze the vertical avera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com