Slurry bubble columun reactor having internal circulation and external heat-exchanging and the application

A slurry bed, internal circulation technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems of uneven solid suspension, space velocity can not be too large, catalyst sedimentation, etc., to achieve convenient removal of reaction heat, The effect of low energy consumption and high space-time yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

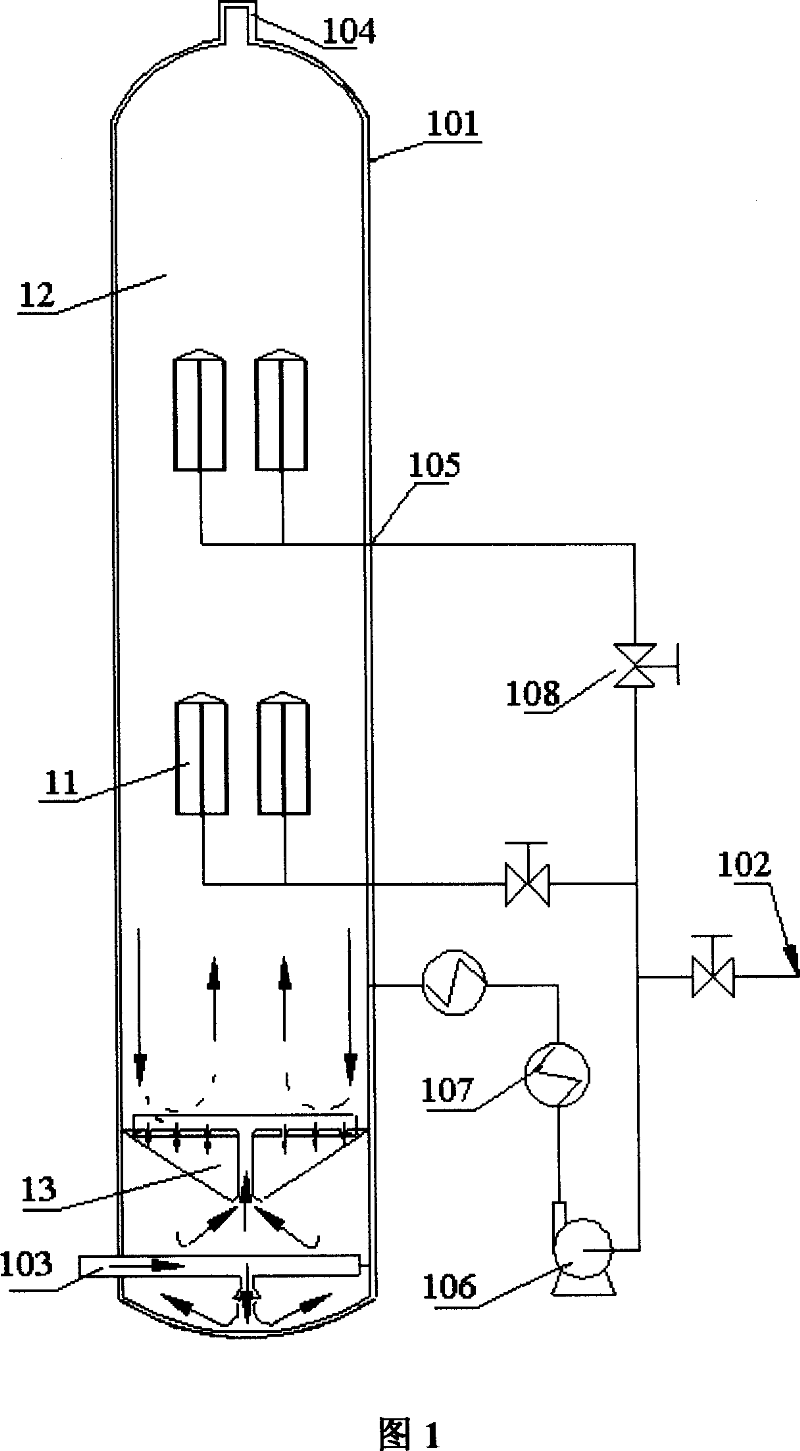

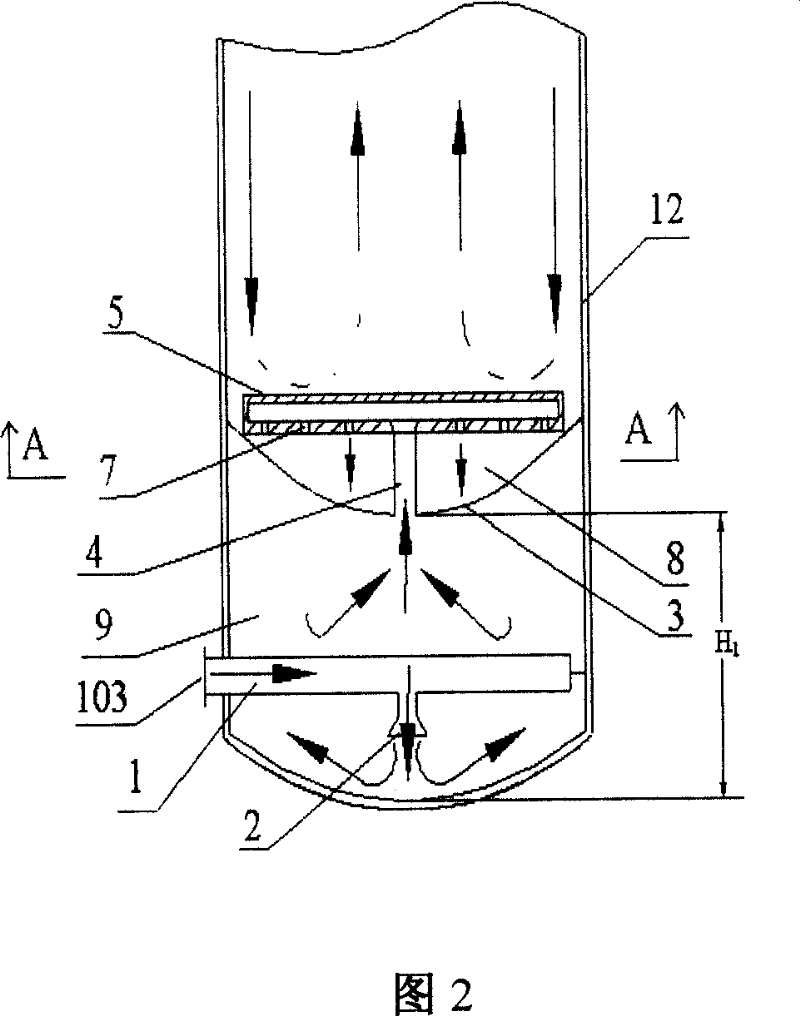

[0049] The reactor shown in Figure 1 and the orifice gas distributor shown in Figure 2 were used.

[0050] The effective diameter of the three-phase slurry bed reactor is 3.2m, the effective height is 10m, the orifice diameter of the orifice gas distributor is 10mm, the gas velocity at the orifice outlet is 180m / s, and there are 3 layers of filters built in.

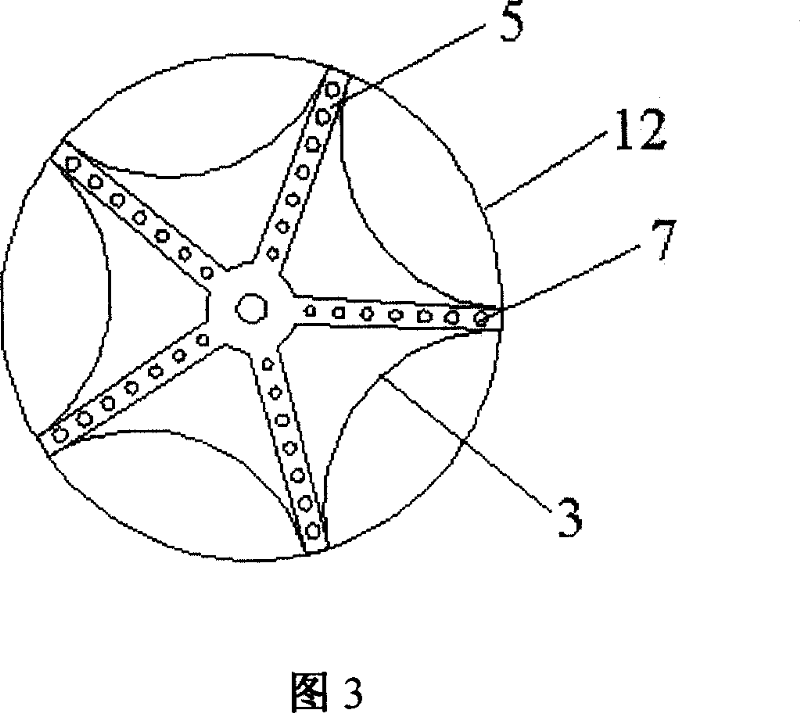

[0051] The diameter of the orifice 7 is 3mm, and the opening ratio is 0.33%;

[0052] The distance H from the bottom of the reactor to the impact plate 3 1 200mm;

[0053] The diameter of the gas inlet pipe 1 is 80 mm; the distance H from the bottom of the reactor to the impact plate 3 1 200mm;

[0054] The shape of the impact bottom plate 3 is arc-shaped, and the arc is 135°;

[0055] The diameter of air guide tube 4 is 80mm;

[0056] Said filter is a metal mesh with a pore size of 0.01mm.

[0057] Taking methanol synthesis with an annual output of 300,000 tons as an example, the raw material gas consists of H 2 = ...

Embodiment 2

[0060] Using the reactor shown in Fig. 1 and the orifice gas distributor shown in Fig. 4, the syngas is synthesized by Fischer-Tropsch to obtain related hydrocarbon products.

[0061] The effective diameter of the three-phase slurry bed reactor is 3m, the effective height is 12m, the orifice diameter of the orifice gas distributor is 2mm, the gas velocity at the orifice outlet is 150m / s, and 4 layers of filters are built in.

[0062] The diameter of the orifice (7) is 2mm, and the opening rate is 0.13%; the distance H from the bottom of the reactor to the impact base plate (3) 1 is 150mm; the diameter of the gas inlet pipe (1) is 60mm; the distance H from the bottom of the reactor to the impact bottom plate (3) 1 The impact base plate (3) is arc-shaped in shape, and the radian is 150°; the diameter of the air duct (4) is 60mm; said filter is a metal mesh with an aperture of 0.001mm. Raw gas composition CO / H 2 =3 / 2, the pressure of the synthesis gas entering the three-phase s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com