Ion beam etching method and ion beam etching apparatus

A technology of ion beam etching and ion beam, which is applied in the direction of ion beam tube, magnetic recording, nanotechnology, etc., can solve the problems of uneven radial distribution of ion beam intensity and reduced efficiency of ion beam extraction, and achieve the purpose of improving extraction efficiency and diameter Uniform distribution and suppression of distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

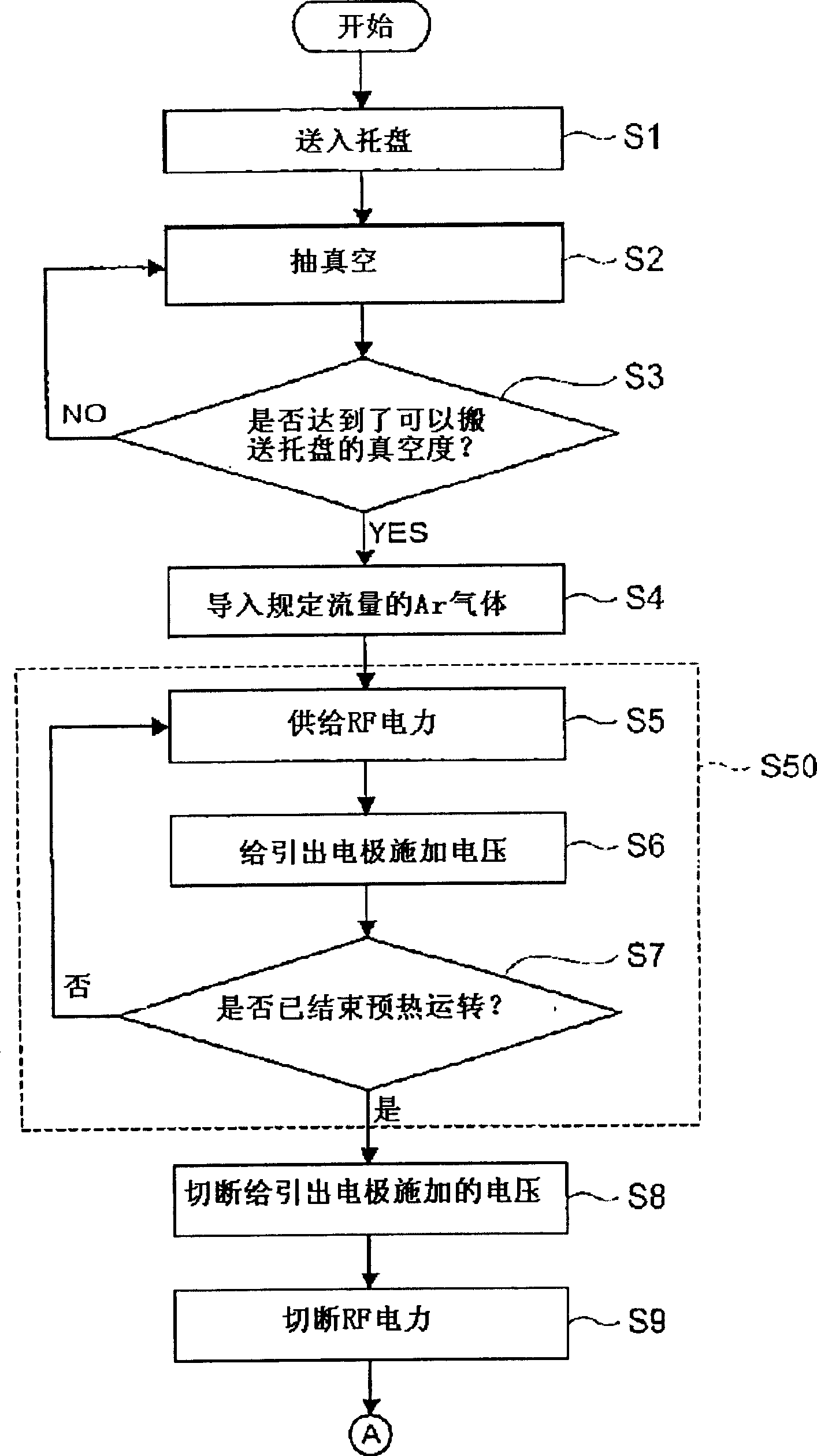

[0025] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. In addition, in the description of the drawings, the same reference numerals are used for the same or equivalent elements, and repeated descriptions are omitted.

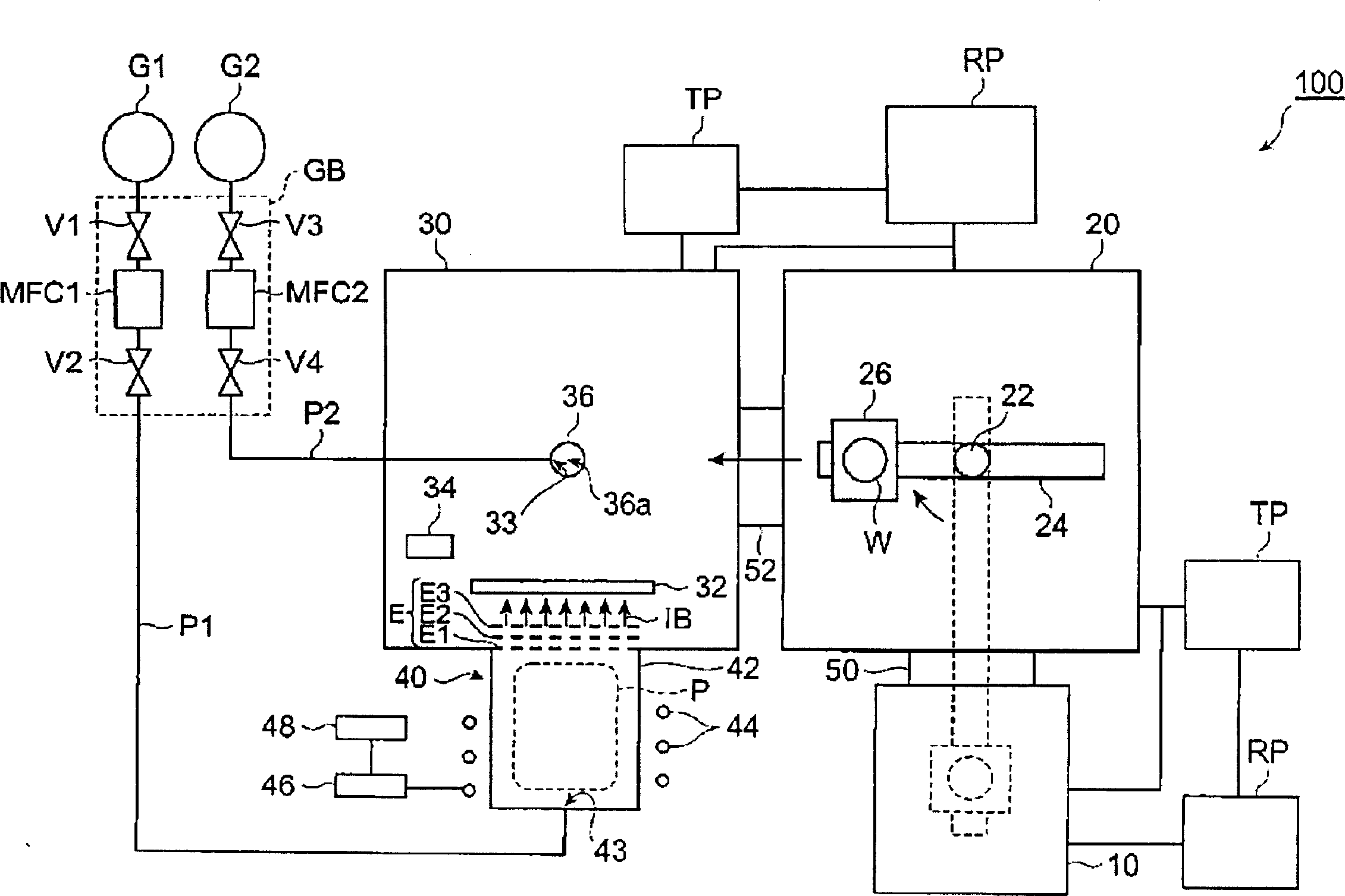

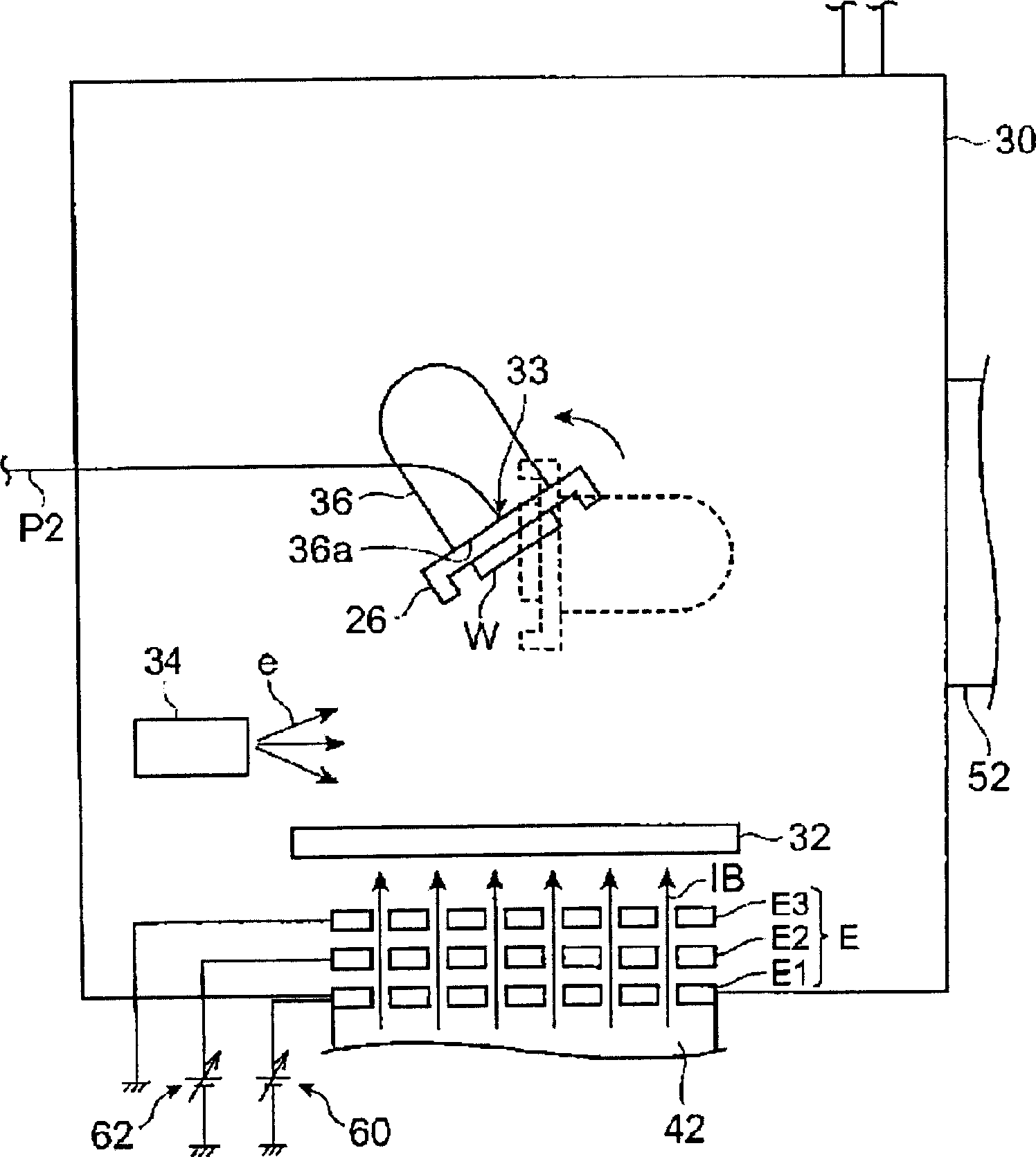

[0026] figure 1 It is a schematic diagram showing the configuration of an ion beam etching apparatus (also referred to as an ion milling apparatus) according to the embodiment. figure 2 yes means figure 1 A schematic diagram of the configuration of the main parts of the ion beam etching apparatus shown in .

[0027] figure 1 The ion beam etching apparatus 100 shown in is suitably used in the manufacture of thin-film magnetic heads for HDDs (for example, GMR magnetic heads, TMR magnetic heads). In particular, it can be favorably applied to the processing of the ABS surface and the chamfered portion which define the flying height of the thin-film magnetic head. The ion beam etching apparatus 100 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com