Rotary detonation combustion chamber adopting pneumatic inner column

A combustion chamber and detonation technology, applied in combustion chambers, continuous combustion chambers, combustion methods, etc., can solve the problems of unfavorable thermal cycle efficiency, increase the contact area between fresh air and high-temperature gas, and increase the proportion of fresh air. The effect of improving circumferential uniformity, reducing loss and full combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

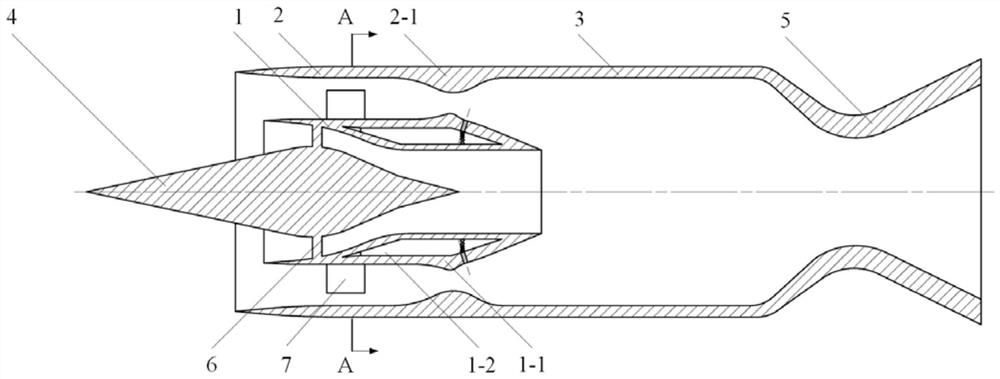

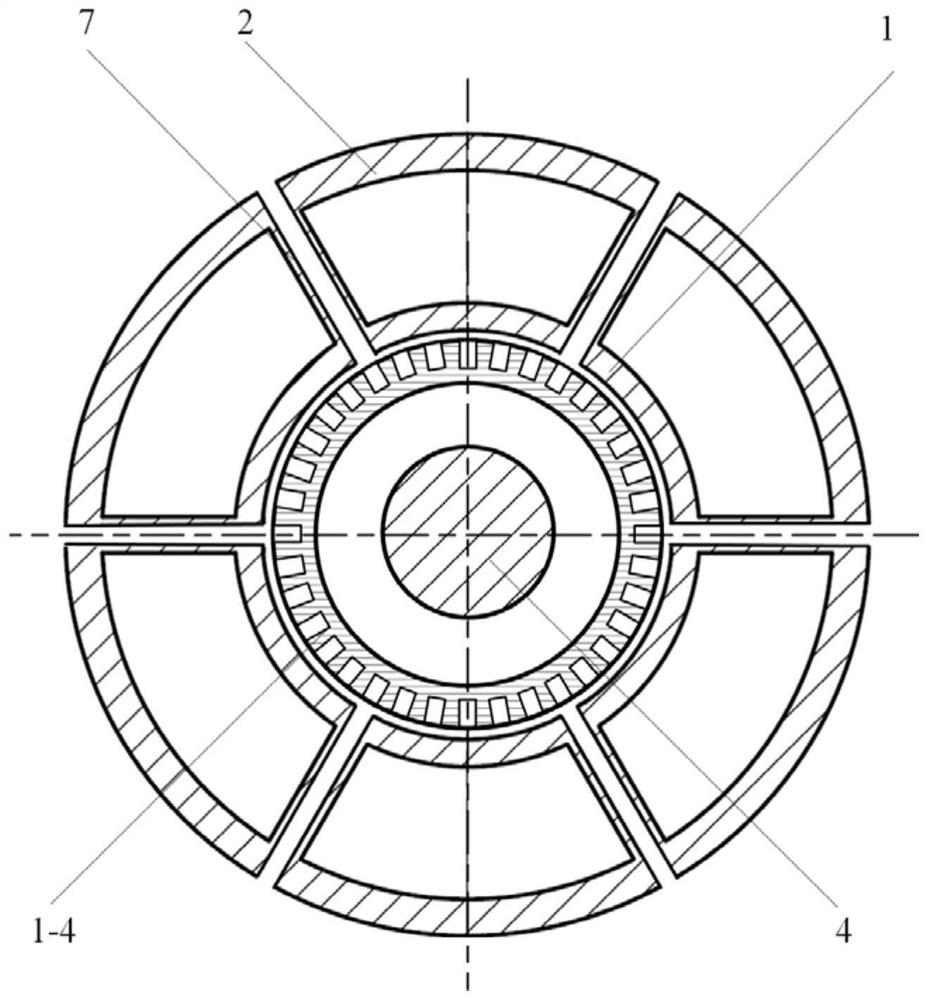

[0022] refer to figure 2 , when the rotary detonation combustor using the aerodynamic inner column in the present invention is applied to a ramjet engine, the injector housing 2 is optimized as the wall surface of the air inlet in this embodiment, and the flow divider 1 divides the air inlet into outer culverts and connotation, the inlet culvert is composed of the injector shell 2, the outer wall of the diverter and 6 outer culvert support plates 7 connecting the two, and the connotation of the inlet is composed of the inner wall of the diverter and the diversion cone 4 and the connection between the two It is composed of 6 inner support plates 6 . Inner diameter of combustion outer ring 3 D 1 , followed by the Laval nozzle 5.

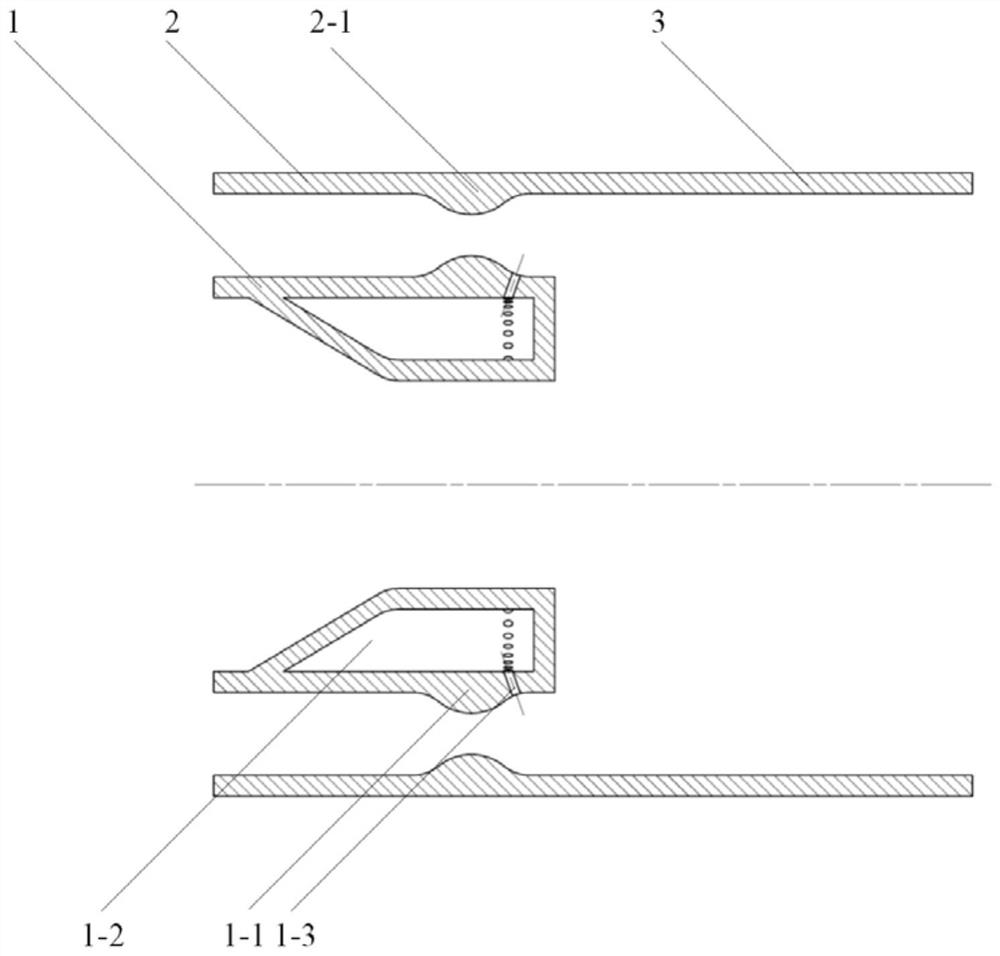

[0023] refer to image 3 , the interior of the outer culvert support plate 7 is a fuel supply passage, which uniformly supplies liquid fuel into the fuel storage tank 1-2 in the circumferential direction, and the fuel storage tank is designed as a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com