Combustion gas turbine low-emission combustion chamber and variable load air distribution adjusting method

A gas turbine and air distribution technology, applied in the direction of combustion methods, combustion chambers, continuous combustion chambers, etc., can solve the problems of reducing combustion air flow, increasing total pressure loss, etc., to achieve stable duty-level flames, improve stability, and reduce pollutants The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

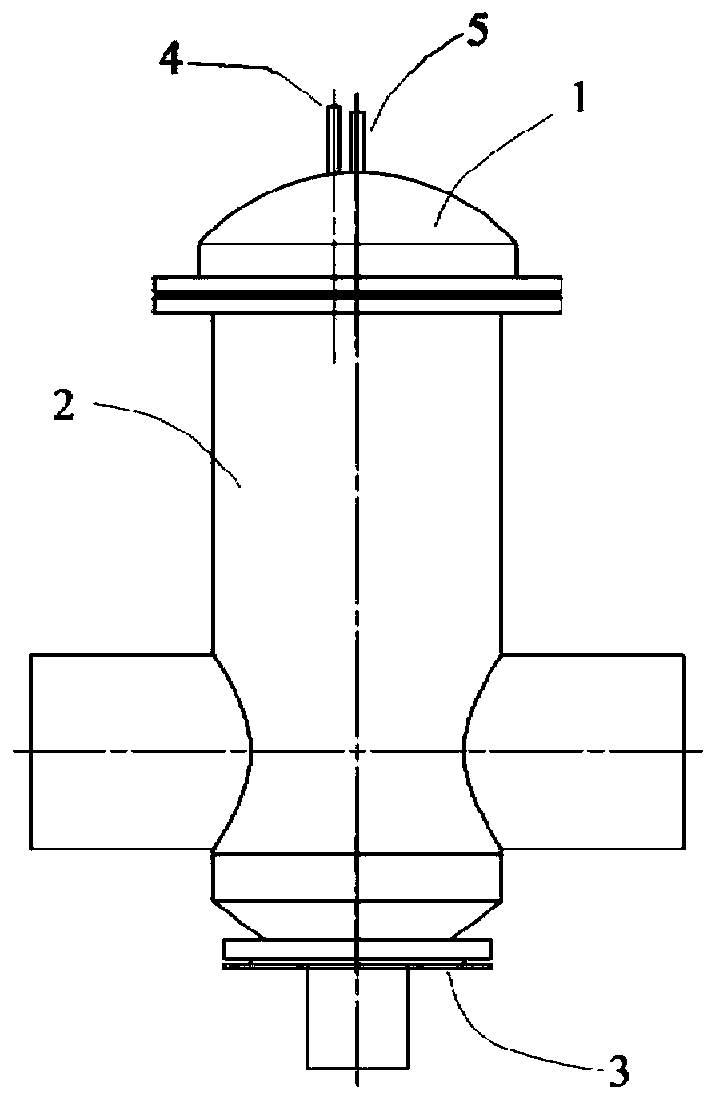

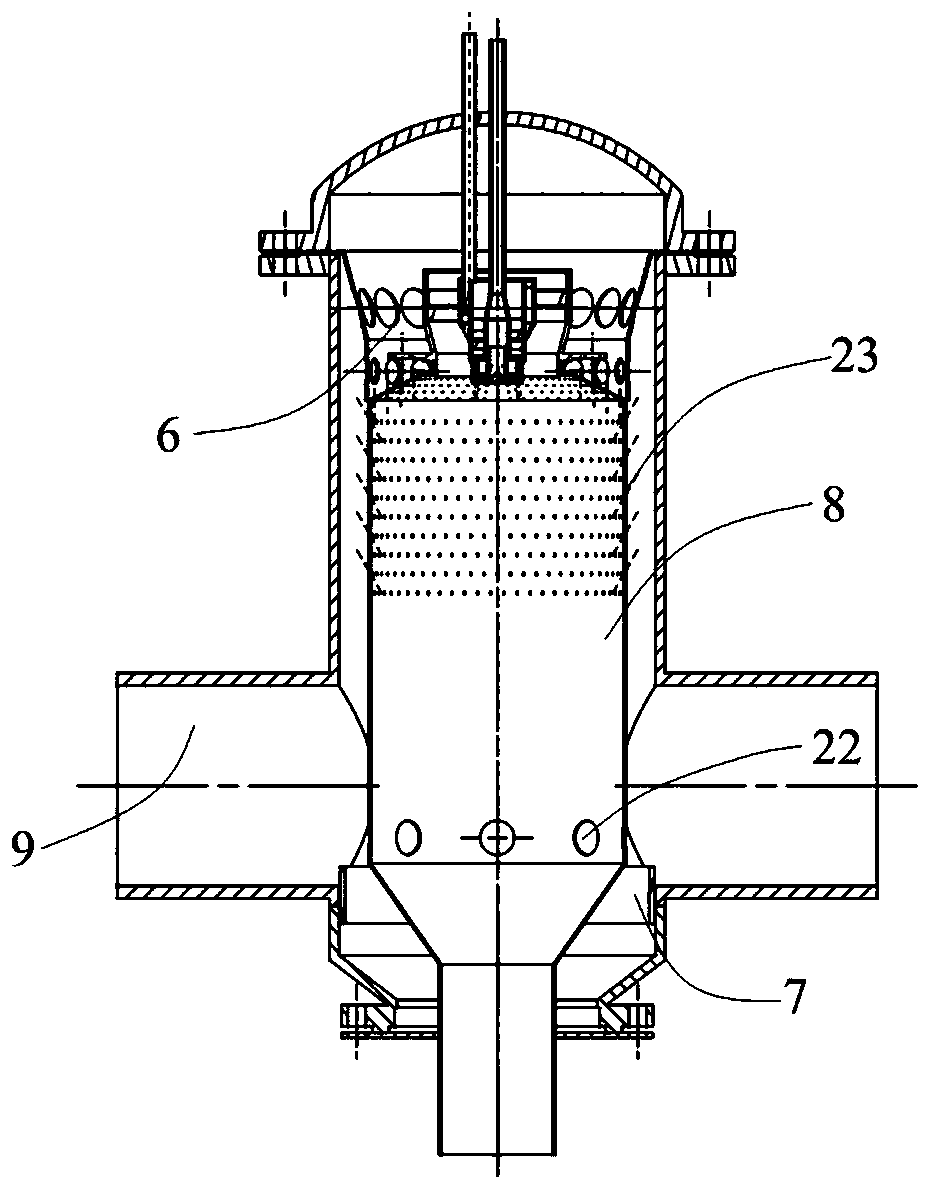

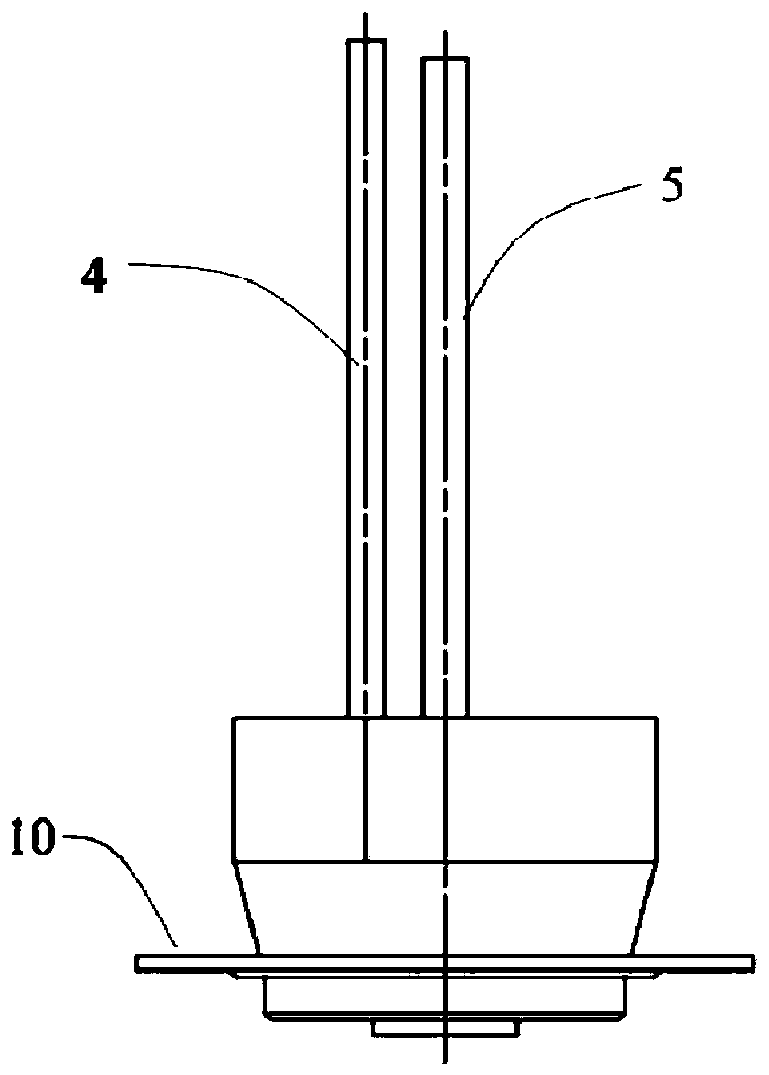

[0045] Such as Figure 1-9 As shown, a gas turbine low-emission combustor includes casing top cover 1, casing 2, combustor head (including main fuel level gas pipe 4, duty level gas pipe 5, premixing swirler 11, stabilizer Flame swirler 12, duty-level nozzle 13, main gas pressure stabilizing chamber 14, impingement cooling flame stabilizer 15, main combustion level gas flow equalizer 20 and head upper flange 10), flame tube 8, auxiliary positioning ring cone 6 and the tail baffle flange 3 of the flame tube.

[0046] The inside of the main fuel gas plenum 14 is a ring-column cavity, and the height of the cavity is not less than 4 times of its width. The outer wall of the main gas pressure stabilizing chamber 14 is connected to the premixing swirler 11, and the inner wall is connected to the flame stabilizing swirler 12, and the three are coaxially connected in series. The blades of the pre-mixing swirler 11 are straight blades, and the light transmission area of the pre-mix...

Embodiment 2

[0058] A gas turbine low emission combustor such as Figure 1-9 As shown, the main components of the combustion chamber include: casing upper cover 1, casing 2, flame tube tail baffle flange 3, auxiliary positioning ring cone 6, flame tube 8, air regulating plate 7 and gas inlet pipe road including the combustion chamber head.

[0059] Such as figure 1 As shown, the top cover 1 of the casing, the casing 2 and the tail baffle flange 3 of the flame tube of the combustion chamber are connected up and down in sequence and arranged coaxially. A pair of air inlets 9 are arranged symmetrically near the rear of the casing 2 .

[0060] Such as figure 2 As shown, the auxiliary positioning ring cone 6, the flame tube 8, the air regulating plate 7 and the head of the combustion chamber are coaxially arranged. Wherein, the head of the combustion chamber and the flame tube 8 are connected up and down through the flange, and the flange part of the auxiliary positioning ring cone 6 is ar...

Embodiment 3

[0072] Such as figure 1 , figure 2A gas turbine low-emission combustor shown includes a casing 2, a casing top cover 1 arranged on the top of the casing 2, an air inlet 9 arranged on the side of the casing 2, and an air inlet 9 arranged inside the casing 2. The flame tube 8, the combustion chamber head arranged on the top of the flame tube 8 and the air distribution mechanism arranged on the side of the flame tube 8 and adapted to the air inlet 9.

[0073] The air distribution mechanism includes a mixing hole 22 provided on the side of the flame tube 8 and adapted to the air inlet 9, and an air regulating plate 7 that is arranged on the outside of the flame tube 8 and is compatible with the mixing hole 22. The plate 7 can reciprocate axially along the flame tube 8 . A wall surface cooling hole 23 is also opened on the side of the flame tube 8 , and the wall surface cooling hole 23 is located above the mixing hole 22 .

[0074] Such as image 3 , Figure 4 , Figure 5 As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com