Inter-stage air feeding structure of centrifugal compressor and design method thereof

A technology of centrifugal compressor and air filling structure, which is applied in mechanical equipment, computing, machine/engine, etc., and can solve the problems of increasing, rotating and stalling airflow, affecting the reliability and economy of the device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

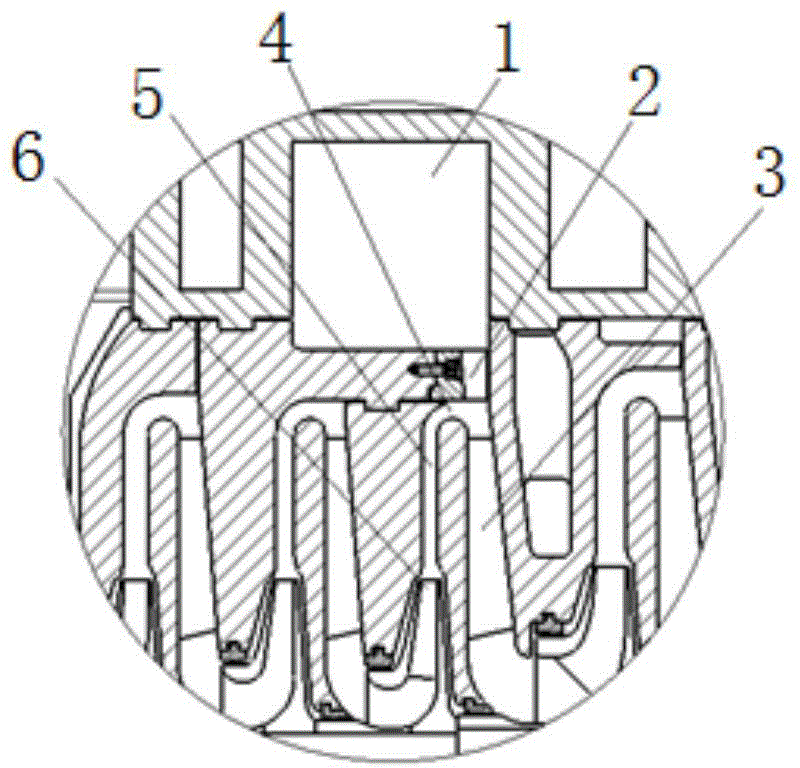

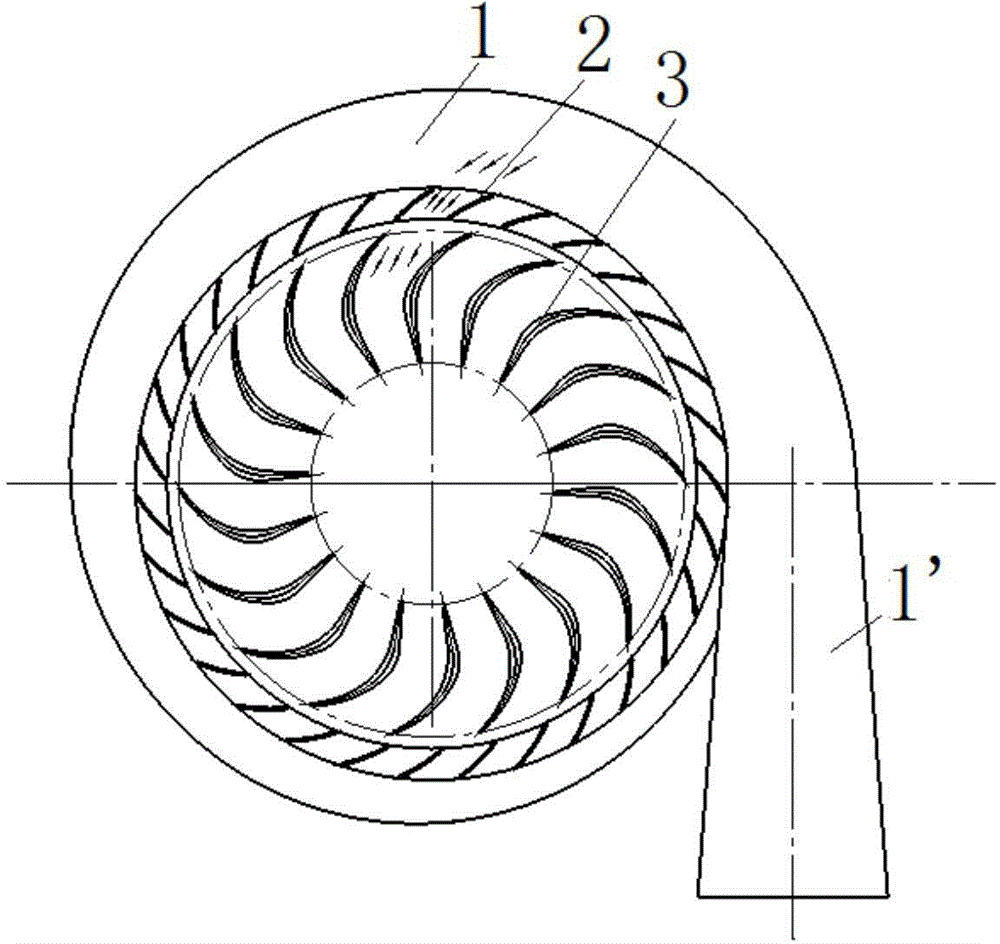

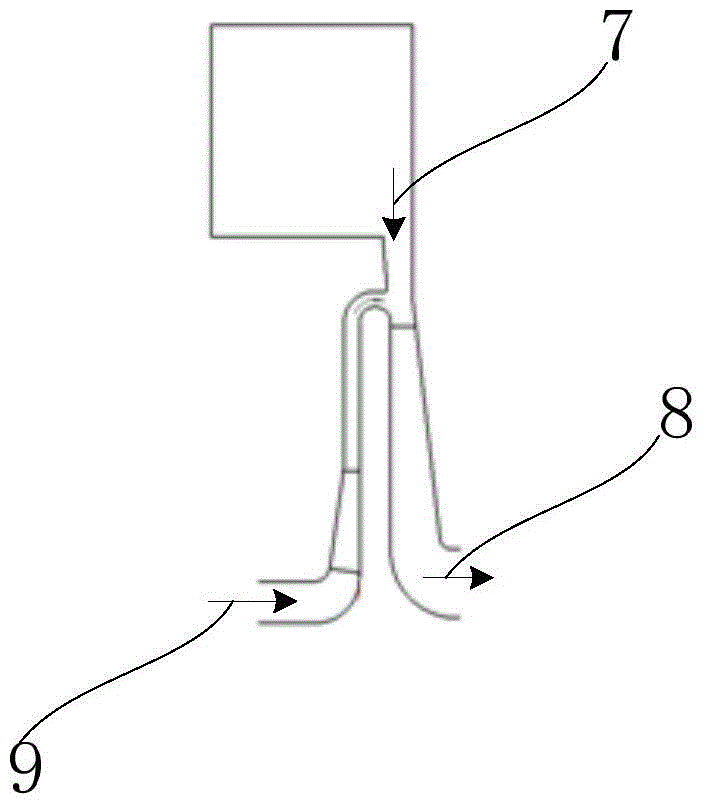

[0052] see Figure 1-3 As shown, the centrifugal compressor interstage air filling structure provided by the embodiment of the present invention is applied to the centrifugal compressor. Specifically, an air filling port is provided at the bend 4 of at least one stage of the centrifugal compressor, and an air filling structure is added to the air filling port, so that the main air flow 9 is introduced into the air filling airflow 7 . The aeration structure includes an aeration volute 1 and an aeration volute 2 . Wherein, the volute of the air-filled volute is a variable-section volute. The aeration guide vanes 2 are evenly distributed in the same shape along the circumference behind the volute of the aeration volute 1, so as to improve the circumferential uniformity of the air flow and change the air flow angle of the aeration, so as to ensure that the aeration air flow 7 is consistent with the main air flow 9. No large angle of attack will be produced when flowing into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com