Anti-explosion device for combustible gas

An explosion-proof device and gas technology, applied in gas/liquid distribution and storage, container filling methods, piping systems, etc., can solve problems affecting the service life of the cooker, damage to the cooker, and reduce gas combustion efficiency, so as to improve the service life and prevent Effects of tempering and prevention of tempering problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

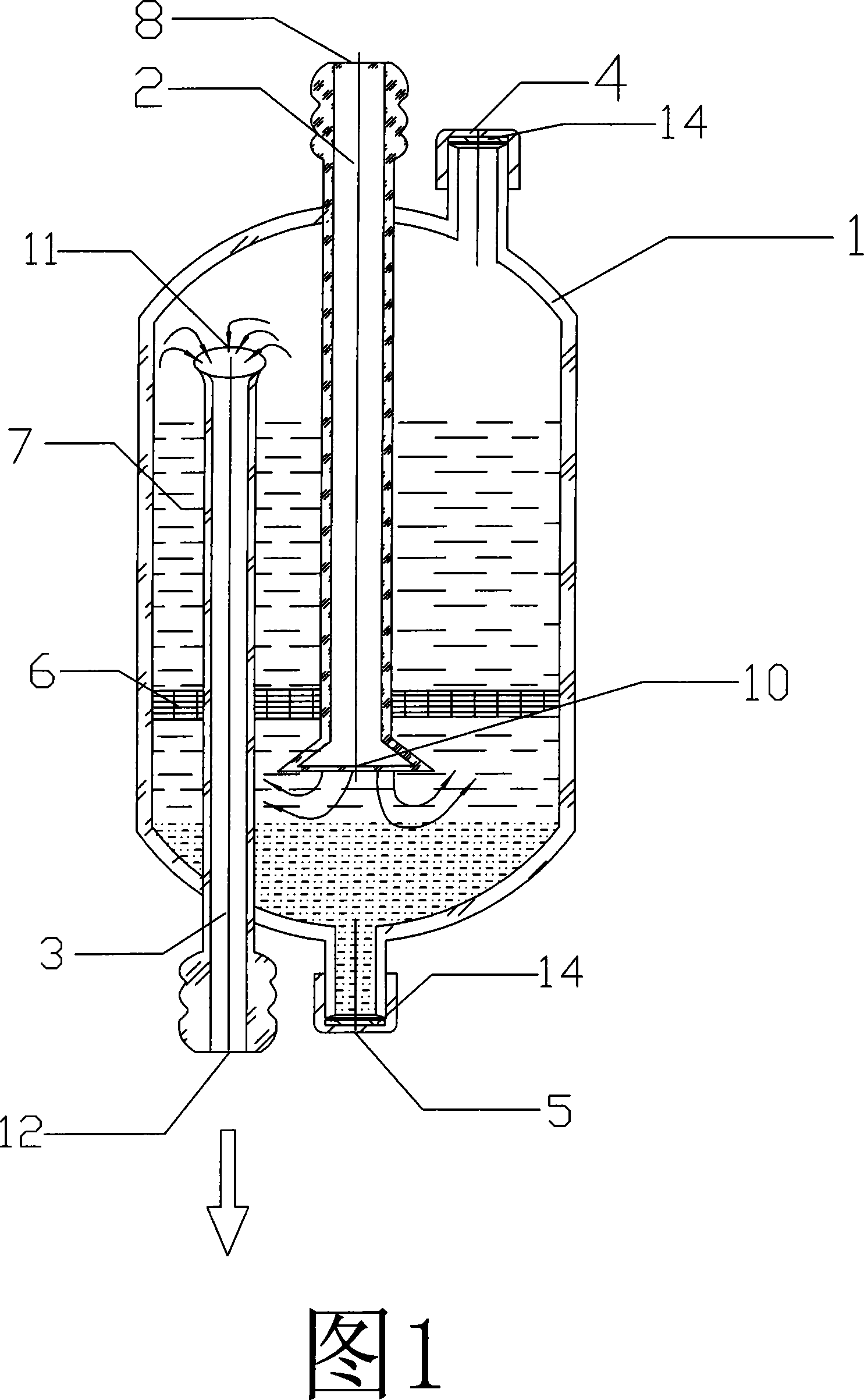

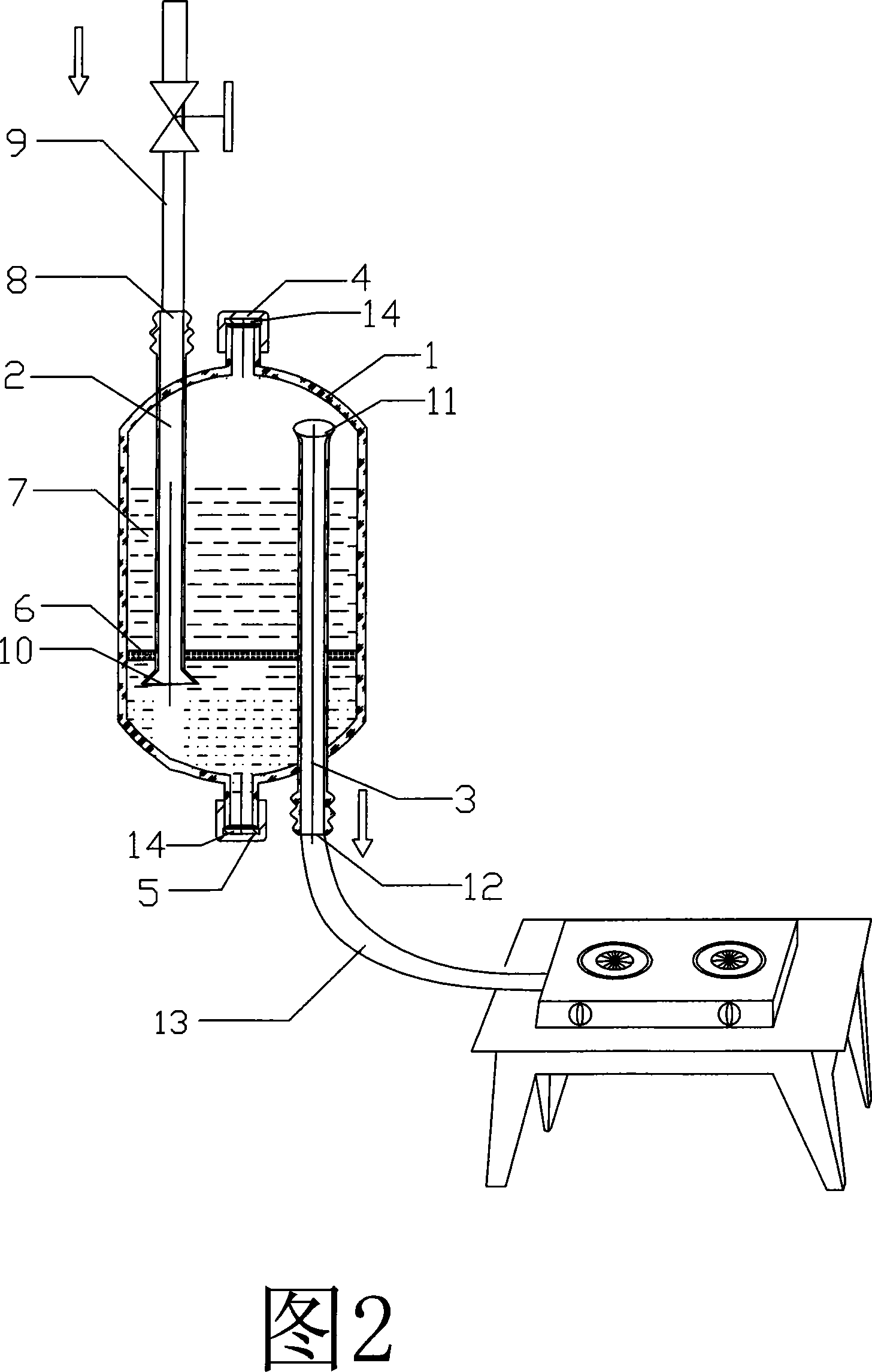

[0014] Embodiment 1: As shown in Figure 1 and Figure 2, a combustible gas explosion-proof device includes a tank body 1, and an air inlet pipe 2, an exhaust pipe 3, an upper sealing cover 4, and a lower sealing cover 5 are arranged in the tank body 1 , a filter screen 6 is provided in the tank body 1, and the surroundings of the filter screen 6 are connected with the inner wall of the tank body 1, and there is water 7 in the tank body 1, and the minimum water level of the water 7 is limited to the top of the filter screen 6, and the intake pipe 2 The air inlet 8 is connected to the air outlet pipe 9 of the combustible liquid, the air nozzle 10 of the air inlet pipe 2 is placed at the bottom of the filter screen 6, and the upper air intake port 11 of the exhaust pipe 3 is placed above the maximum water level limit of the water in the tank body 1, and the discharge The lower exhaust port 12 of the air pipe 3 is placed outside the tank body 1 and connected to the air intake pipe 1...

Embodiment 2

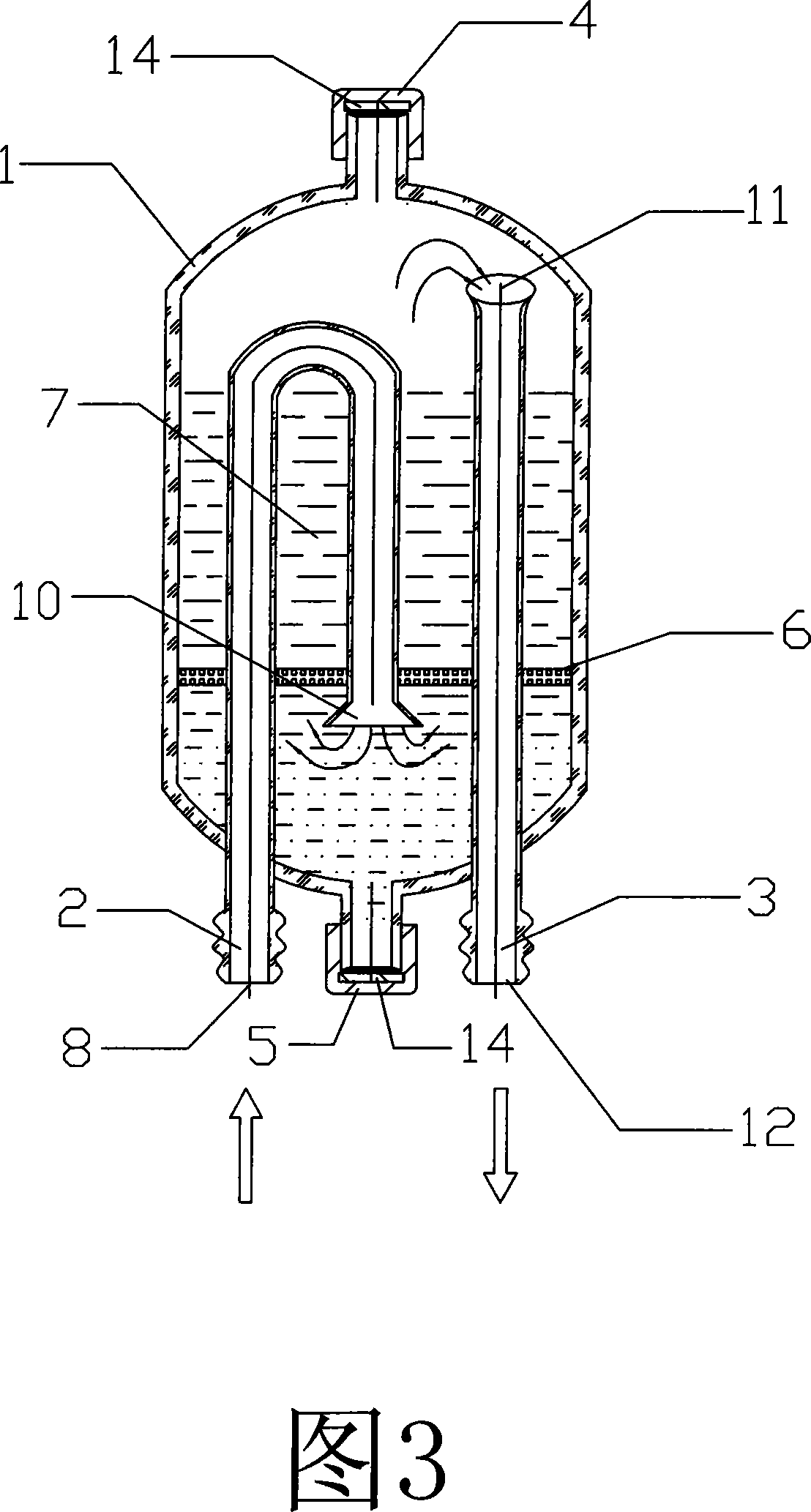

[0015] Embodiment 2: As shown in Figure 3 and Figure 4, a combustible gas explosion-proof device includes: a tank body 1, which is provided with an air intake pipe 2, an exhaust pipe 3, an upper sealing cover 4, and a lower sealing cover 5 , a filter screen 6 is provided in the tank body 1, and the surroundings of the filter screen 6 are connected with the inner wall of the tank body 1. There is water 7 in the tank body 1, and the minimum water level of the water 7 is limited to the upper part of the filter screen 6, and the intake pipe 2 The air port 8 is connected to the outlet pipe port 9 of the combustible liquid, the air nozzle 10 of the air intake pipe 2 is placed at the bottom of the filter screen 6, the upper air intake port 11 of the exhaust pipe 3 is placed above the maximum water level limit of the water in the tank, and the exhaust pipe The lower exhaust port 12 of 3 is placed outside the tank body 1 and is connected to the air intake pipe 13 of the cooking range. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com