A kind of cooling method of cast aluminum products to prevent steam explosion

A cooling method and technology for aluminum products, applied in the field of casting and cooling of aluminum products, can solve the problems of environmental pollution, large manpower and time cost, and expensive explosion-proof coatings, and achieve environmental friendliness, simple method, and prevention of steam explosion accidents Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

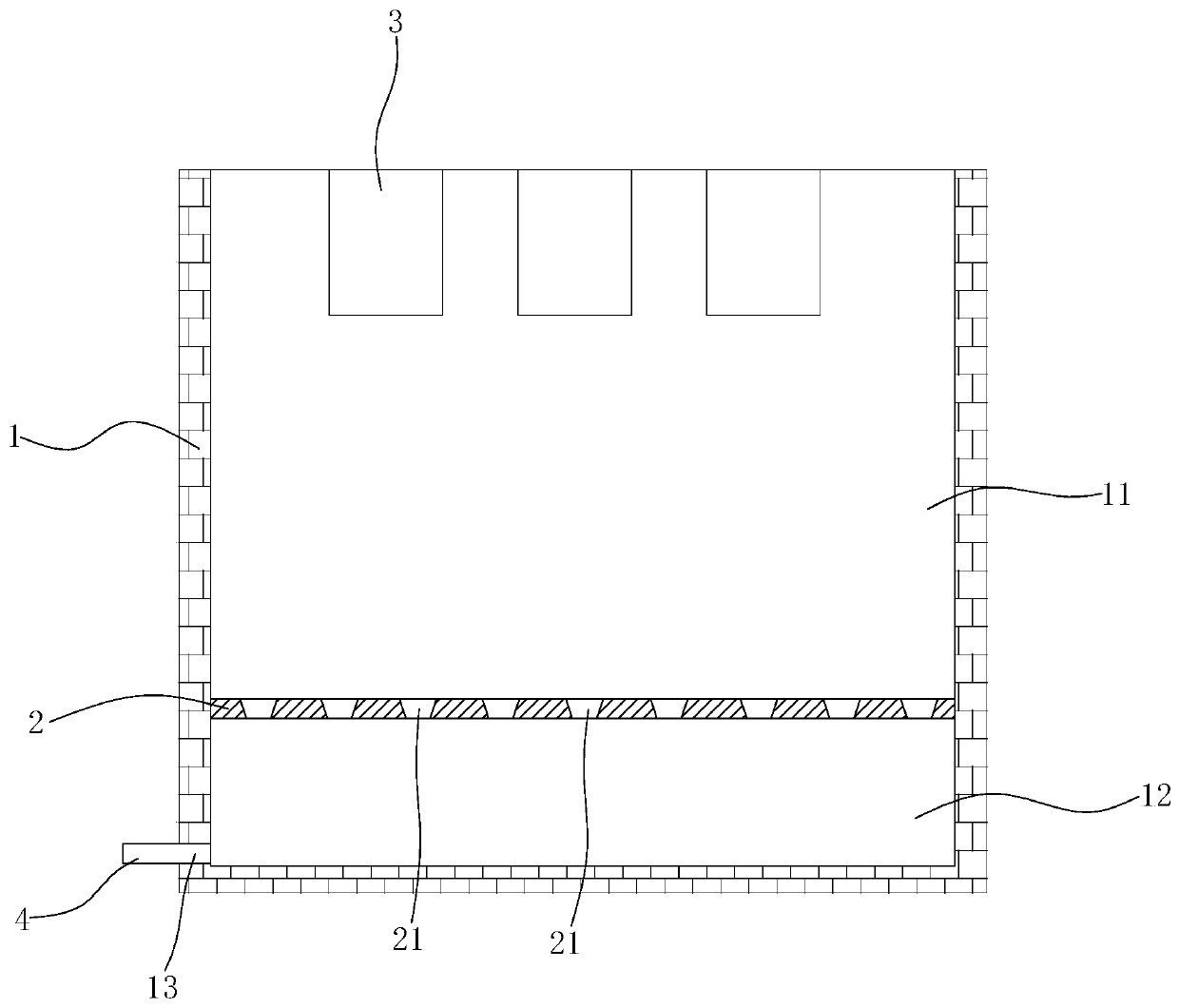

[0024] Such as figure 1 and figure 2 As shown, the cast aluminum product cooling well structure includes:

[0025] The cooling well body 1 is in the shape of a pool, in which cooling water is stored; its upper part is used to place the casting mold 3 for aluminum products, and the cooling water in the cooling well body is pumped to cool the aluminum products. The cooling well body and cooling method are conventional structures.

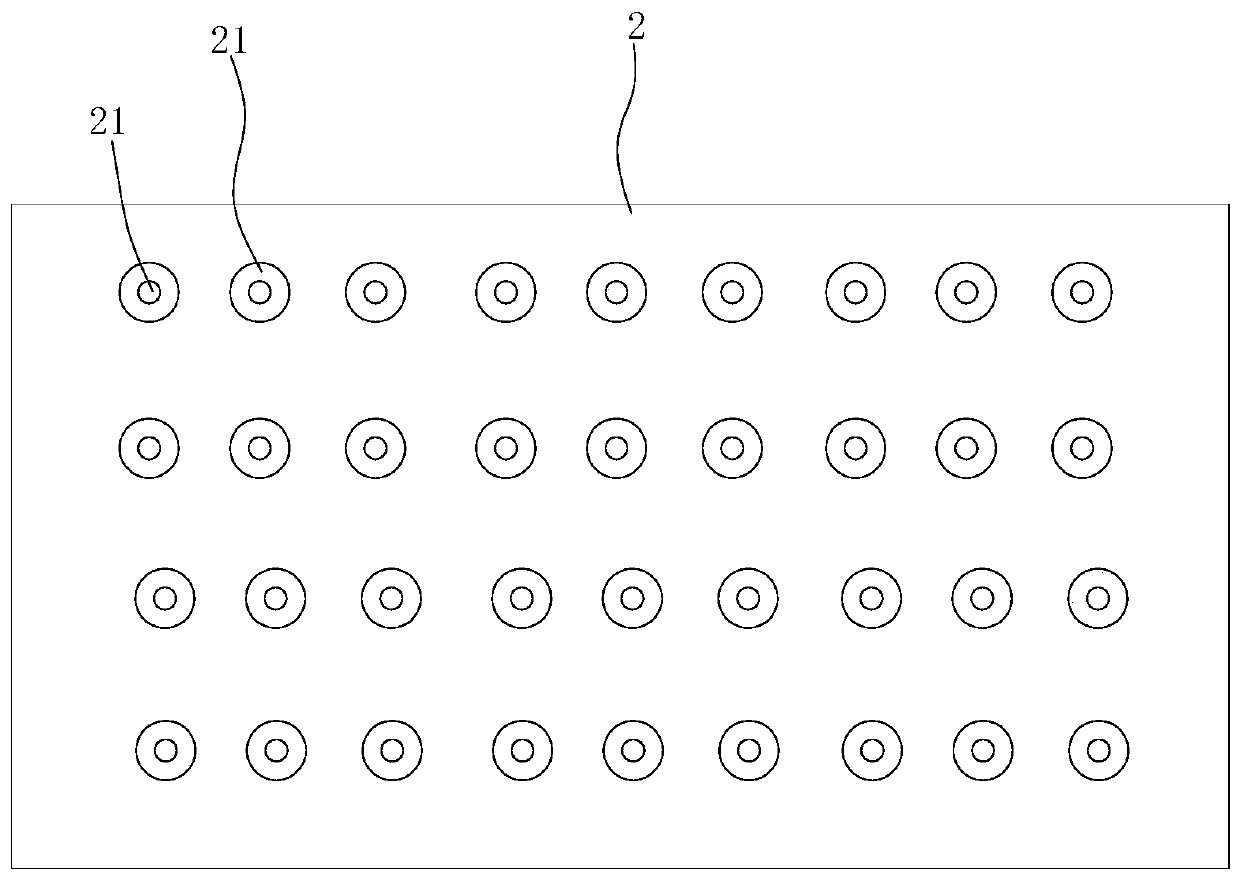

[0026] The partition 2 is detachably arranged in the cooling well body 1, and divides the inner cavity of the cooling well body into an upper chamber 11 and a lower chamber 12 that are independent of each other. The partition 2 is provided with a plurality of connected upper chambers 11 and lower chambers at intervals. The through hole 21 of 12; the side wall of the cooling well body 1 is provided with an air inle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com