Atmosphere isolation device of horizontal annealing furnace

A horizontal annealing furnace and isolation device technology, applied in the direction of furnaces, furnace components, lighting and heating equipment, etc., can solve the problems of inconvenient installation, poor sealing, and bulky itself, so as to prevent pollution, reduce self-weight, simplify structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040]The following description is merely exemplary in nature and not intended to limit the disclosure, application or uses. It should be understood that throughout the drawings, corresponding reference numerals indicate like or corresponding parts and features.

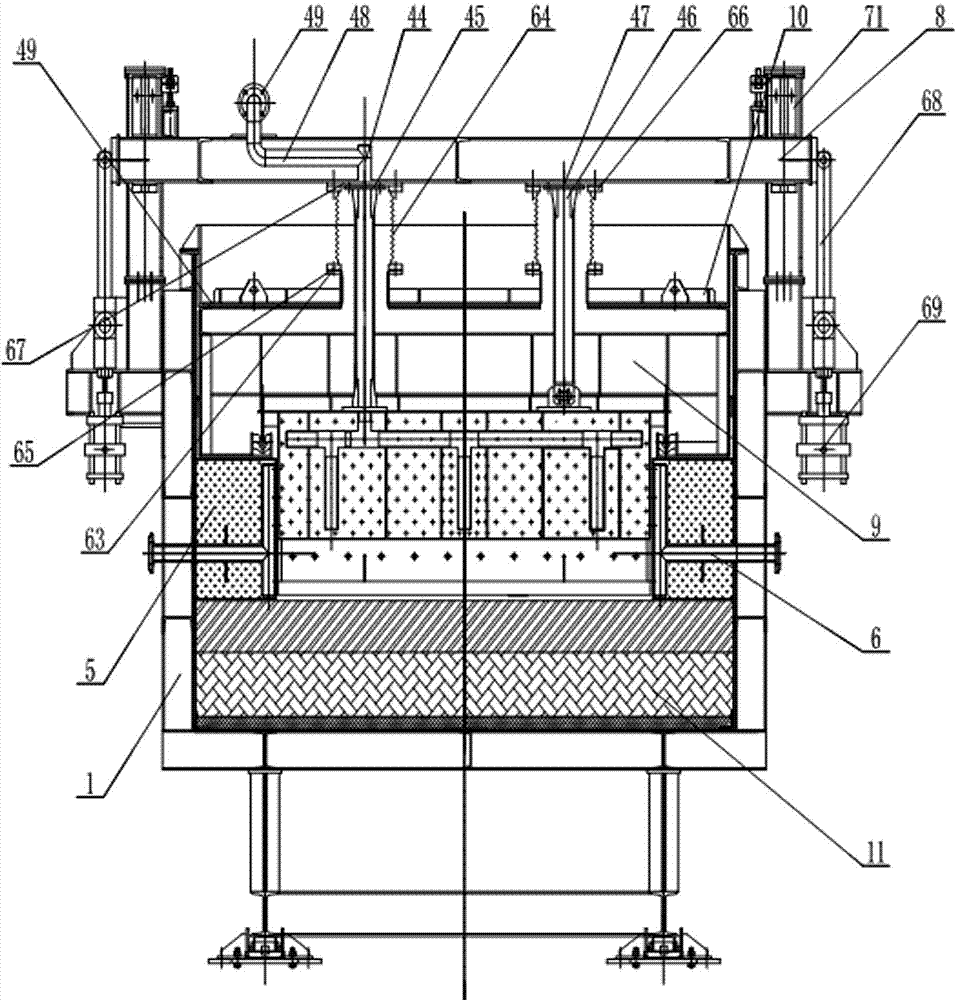

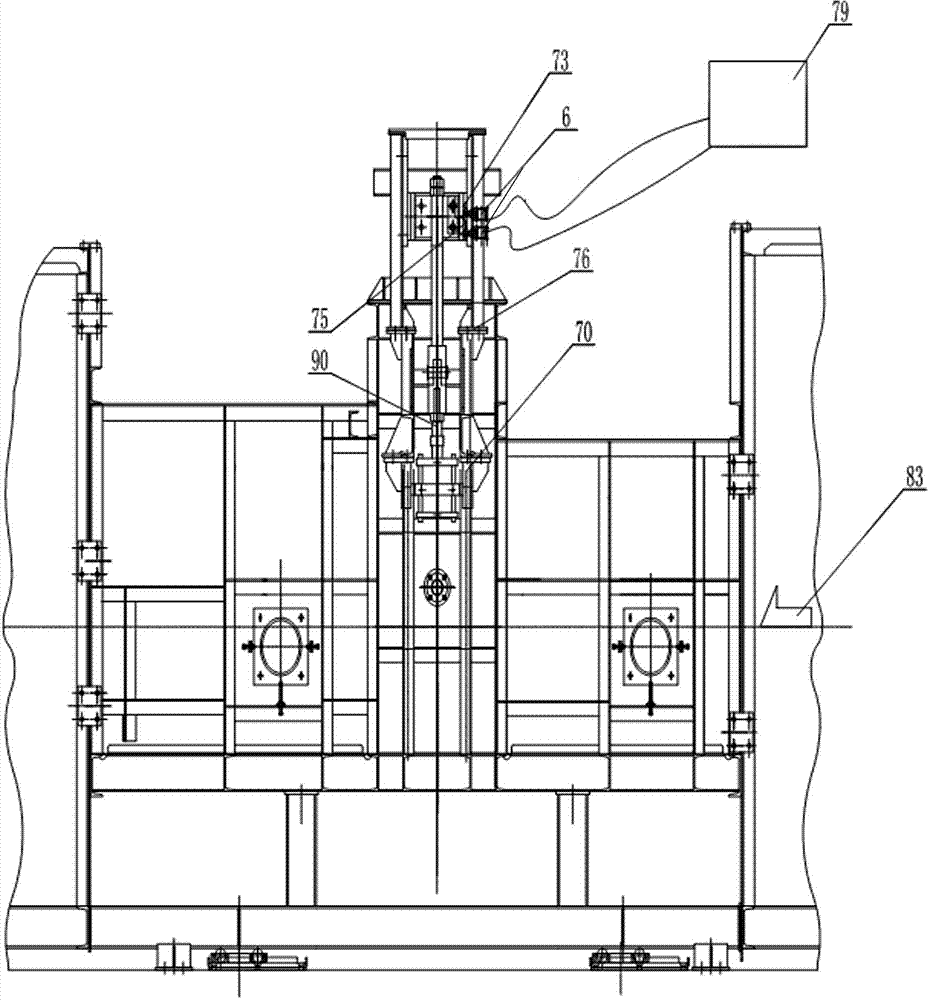

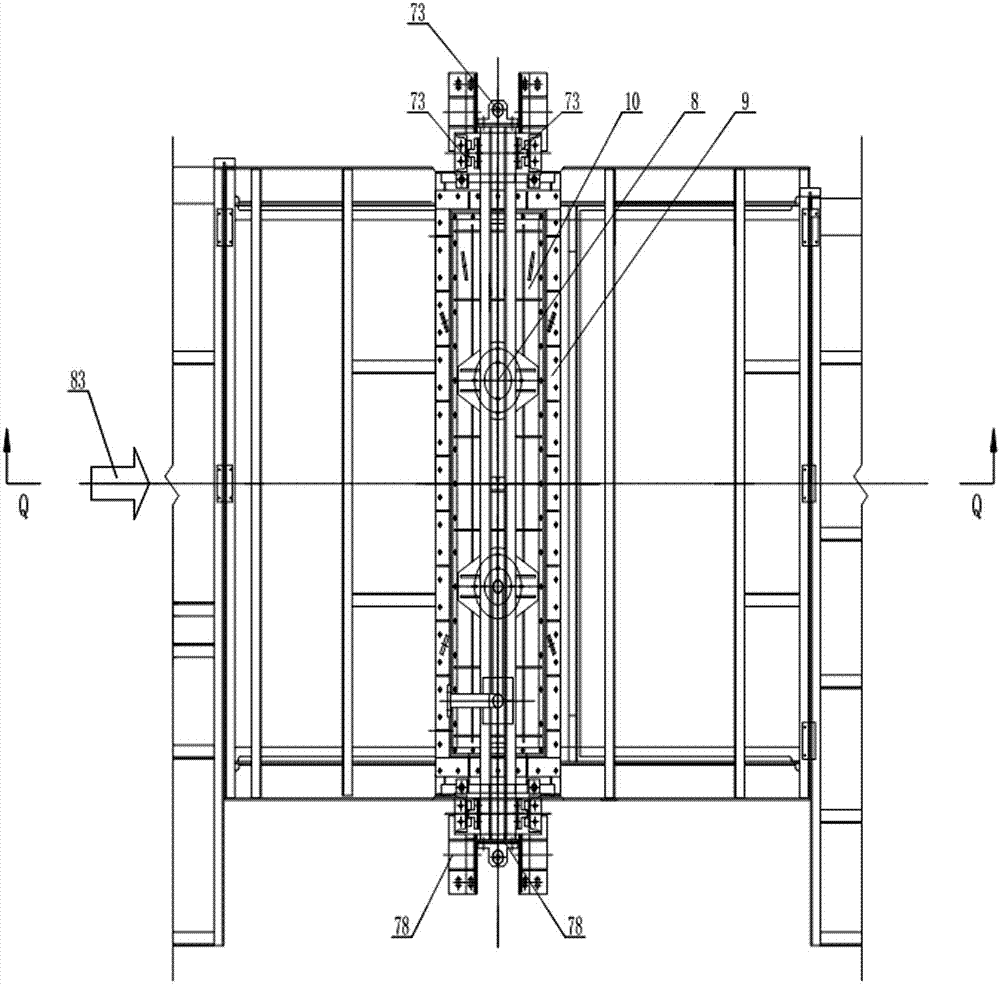

[0041] Figure 1A to Figure 1D Collectively referred to as FIG. 1 , FIG. 1 is a schematic structural diagram of an atmosphere isolation device for a horizontal annealing furnace according to the present invention. Referring now to Fig. 1, the horizontal annealing furnace atmosphere isolation device according to the present invention is installed between the annealing furnace preheating non-oxidizing heating section 2 and the radiant tube heating section 3, for isolating the preheating non-oxidizing section 2 and the radiant tube heating section 3 atmospheres.

[0042] The horizontal annealing furnace atmosphere isolation device of the present invention comprises a furnace shell 1, a baffle plate 1, a baffle plate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com