Multifunctional lead-acid battery with explosion-proof structure

A lead-acid battery, explosion-proof structure technology, applied in the direction of structural parts, battery pack parts, circuits, etc., can solve the problems of high hazard, no explosion-proof structure, weak protection performance, etc., to achieve effective protection, excellent explosion-proof performance, Avoid explosion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

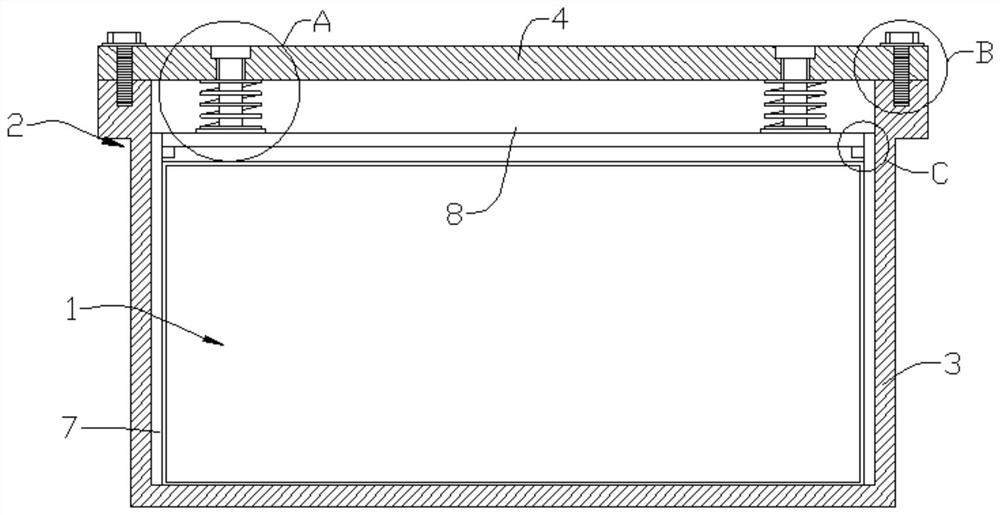

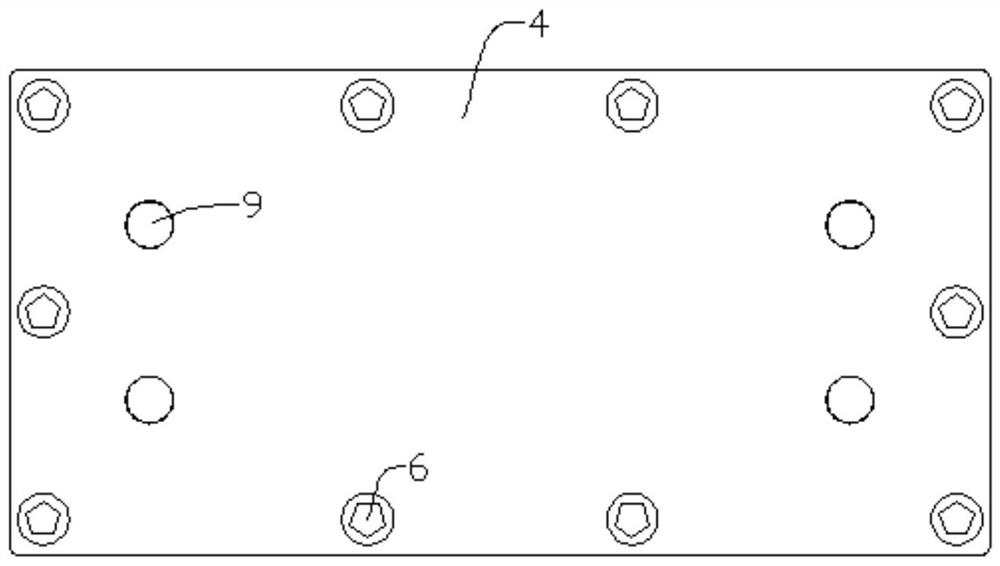

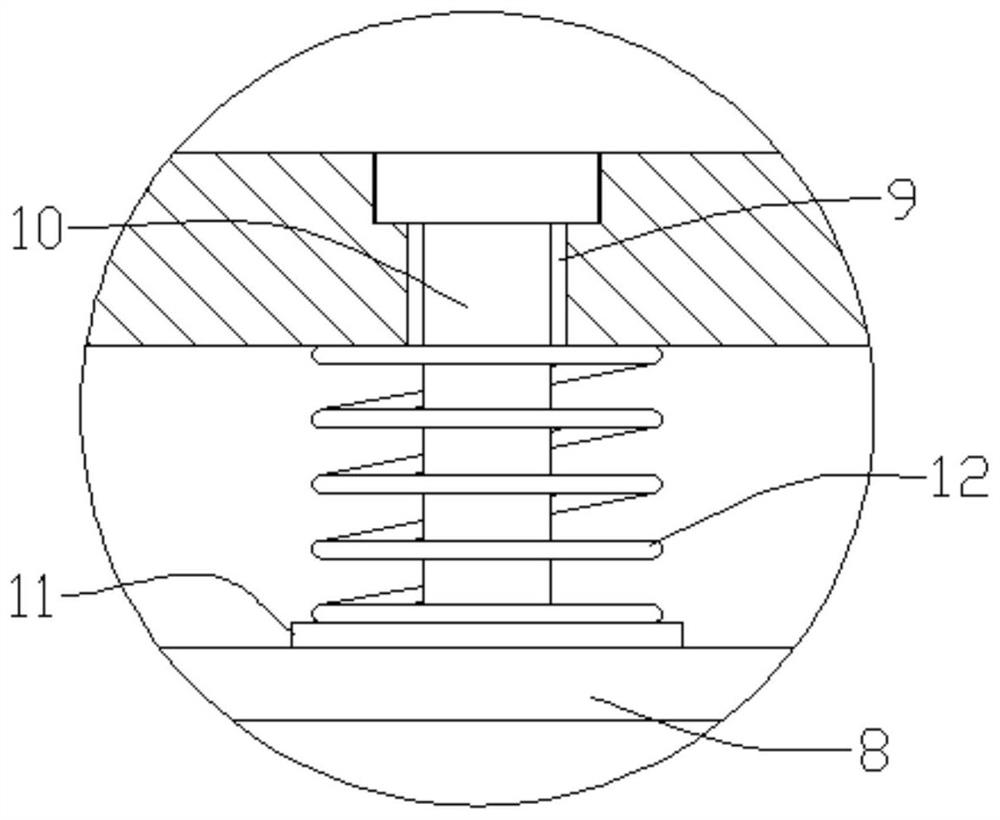

[0033] A multifunctional lead-acid battery with an explosion-proof structure, comprising a lead-acid battery body 1 and a housing 2 for storing the lead-acid battery body 1: the housing 2 includes a housing 3, and a housing cover is provided at the port of the housing 3 4. A plurality of positioning holes 5 are provided at the connection between the housing case 3 and the housing cover 4, and the positioning holes 5 are evenly arranged on the edges of the housing case 3 and the housing cover 4. The positioning holes 5 are provided with holes for connection and fixing. The positioning part 6, the inner wall of the housing shell 3 is fixedly connected with a flame retardant plate 7, the inner cavity of the housing shell 3 is provided with a moving plate 8 at the end of the flame retardant plate 7, the edge of the moving plate 8 is connected to the edge of the housing shell 3 The inner wall is sealed and slidingly connected, and the shell cover 4 is provided with a plurality of ex...

Embodiment 2

[0049] In this embodiment, preferably, the main body 1 of the lead-acid battery also includes an electrolyte solution for chemical reactions, and the preparation method of the electrolyte solution is as follows:

[0050] Step 1. Prepare the following components by weight: 5 parts of polyethylene glycol, 3 parts of stannous sulfate, 8 parts of sodium sulfate, 5 parts of organic silicon polymer, 0.5 part of acetylene black, 6 parts of metal compound solution, fumed silica 7 parts, 5 parts of sulfuric acid and 25 parts of deionized water;

[0051] Step 2. Polyethylene glycol, stannous sulfate, sodium sulfate, organosilicon polymer, metal compound solution, sulfuric acid and deionized water in the above-mentioned raw materials are put into the reactor, and the rotating speed of the control reactor is 180r / min, The temperature is 75°C, and acetylene black is added after continuous mixing for 5 minutes, and the pH value in the reactor is controlled by the amount of acetylene black t...

Embodiment 3

[0054] In this embodiment, preferably, the main body 1 of the lead-acid battery also includes an electrolyte solution for chemical reactions, and the preparation method of the electrolyte solution is as follows:

[0055] Step 1. Prepare the following components by weight: 5 parts of polyethylene glycol, 4 parts of stannous sulfate, 8 parts of sodium sulfate, 5 parts of organic silicon polymer, 1 part of acetylene black, 6 parts of metal compound solution, fumed silica 7 parts, 7 parts of sulfuric acid and 25 parts of deionized water;

[0056] Step 2. Polyethylene glycol, stannous sulfate, sodium sulfate, organosilicon polymer, metal compound solution, sulfuric acid and deionized water in the above-mentioned raw materials are put into the reactor, and the rotating speed of the control reactor is 180r / min, The temperature is 75°C, and acetylene black is added after continuous mixing for 5 minutes, and the pH value in the reactor is controlled by the amount of acetylene black to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com