Energy-saving burner for premixed fuel gas to be burnt at positive pressure and steam generator

A positive pressure combustion and burner technology, which is applied in the direction of steam generation, gas fuel burner, burner, etc., can solve the problems of low mechanical strength, low opening rate, and increased gas volume, and achieve enhanced safety and environmental protection The effect of reducing the consumption of raw materials and reducing the formation of scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

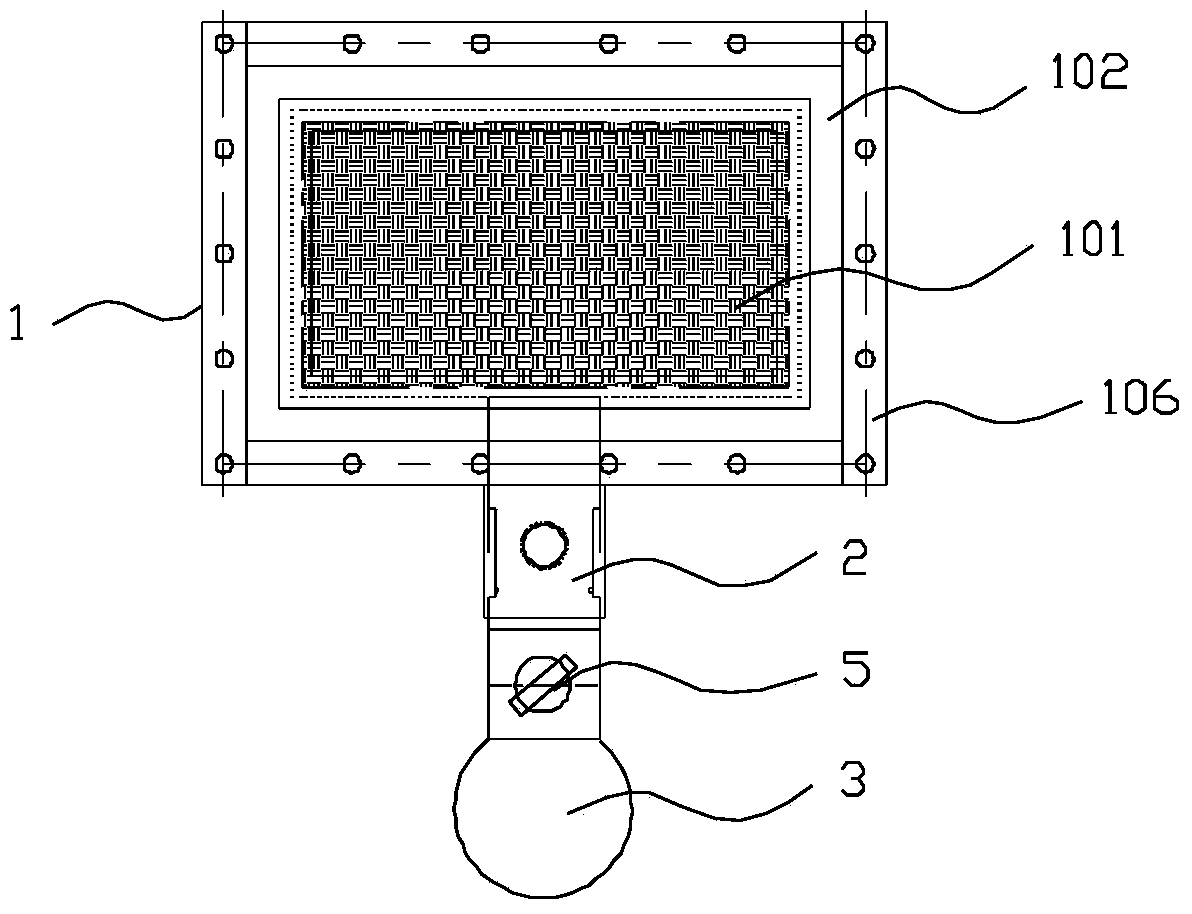

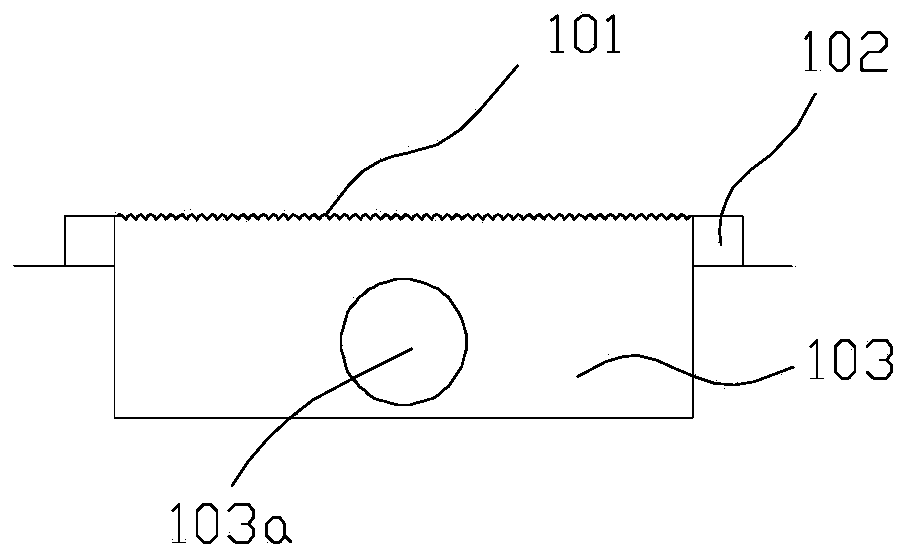

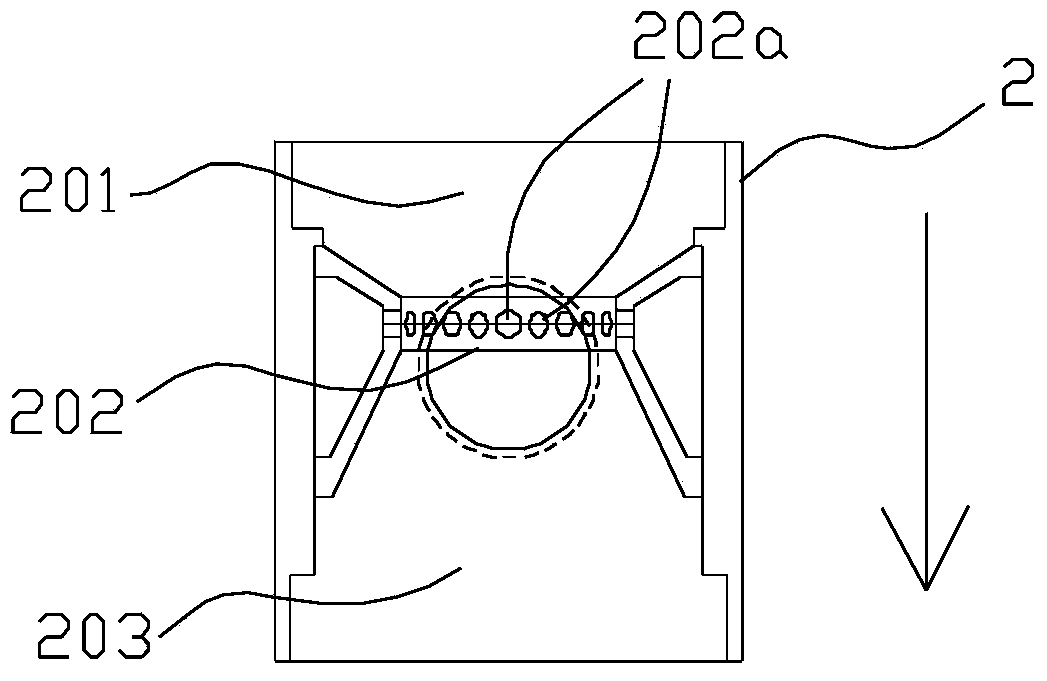

[0045] Refer to attached figure 1 To attach image 3 As shown, an energy-saving burner for positive pressure combustion of premixed gas includes a combustion part 1, a fan 3 and a mixer 2 for mixing gas and air. The combustion part 1 includes a pre-combustion chamber 103 provided with an air inlet 103a, a combustion surface 101 positioned on one side of the pre-combustion chamber and a water-cooled pipe 102 arranged around the combustion surface, and the water-cooled pipe 102 is closely connected with the combustion surface 101; The combustion surface 101 is made of iron-chromium-aluminum alloy fiber fabric, and the shape of the surface of the combustion surface 101 is planar (in other embodiments, the shape of the surface of the combustion body can also be curved or spherical). On the back of the iron-chromium-aluminum alloy fiber fabric, there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com