Equal-proportion channel combustor achieving uniform gas discharge and gas stove

A proportional, burner technology, used in gas fuel burners, burners, combustion methods, etc., can solve the problems of excessive flameout and explosion sound, increased safety hazards, etc., achieve stable gas pressure, solve the problem of backfire, The effect of reducing the risk of tempering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

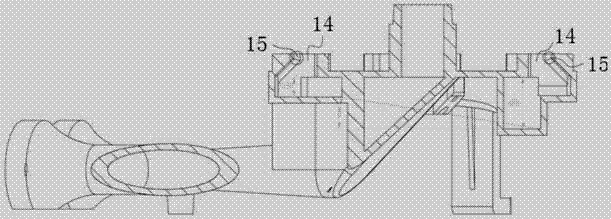

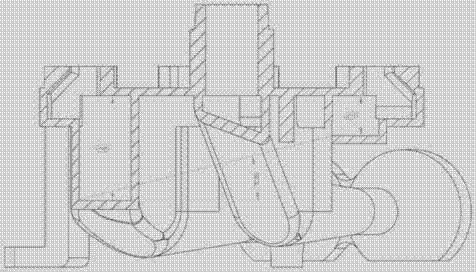

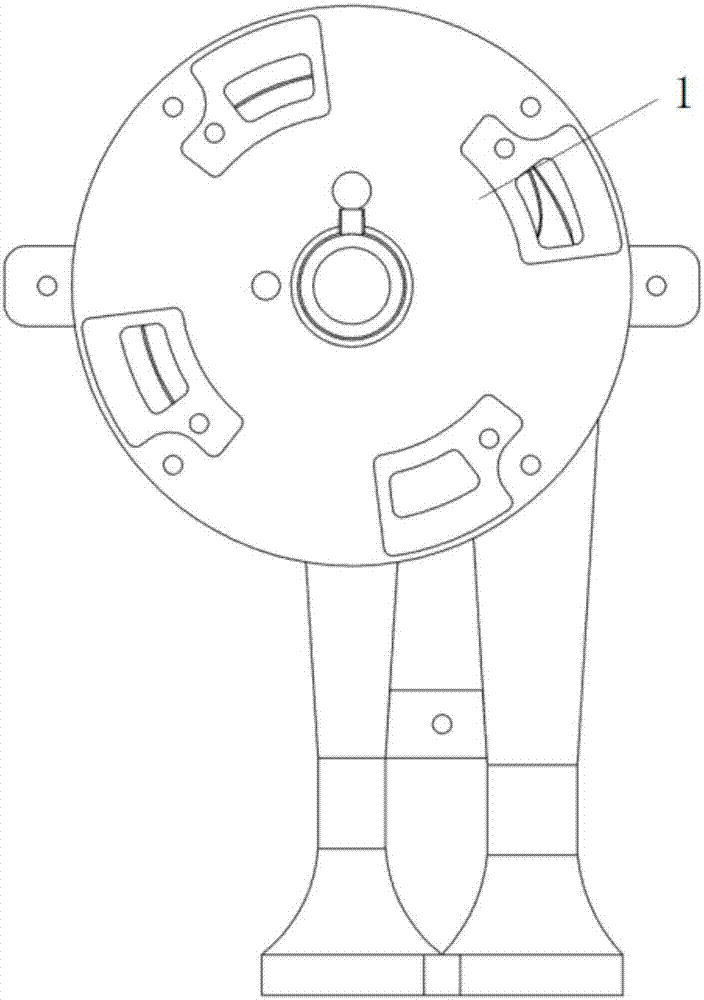

[0032] Embodiment 1: This equal-proportion channel burner with uniform gas outlet includes a burner head 1, a base 2, a large fire cover 3, and a small fire cover 4. The burner head 1 is a gradual change type burner head, including a Venturi ejector tube 11. Outer ring equal-proportion gradient channel 12, inner ring gas mixing chamber 13; gas passes through Venturi injection tube 11, and after being pre-mixed in the primary air mixing chamber, enters the outer ring equal-proportion gradual change channel 12, inner ring gas mixing chamber respectively Cavity 13, wherein: the gas in the inner ring gas mixing chamber 13 enters the small fire cover 4 through the inner ring passage;

Embodiment 2

[0033] Embodiment 2: In the above embodiment, if figure 2 As shown, a straight pipe 113 is added between the throat 111 and the bell mouth 112 of the Venturi ejector 11, so that the flow rate of the gas entering the throat increases to stabilize the pressure and improve the mixing stability of the gas and air. Let the premix go more fully.

Embodiment 3

[0034] Embodiment 3: The difference from Embodiment 2 is that the length of the straight pipe 113 is 15-22 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com