Mandatory all-over three-dimensional gas mixing chamber

A gas-mixing chamber and full pre-mixing technology, applied in the directions of gas fuel burners, combustion methods, combustion types, etc., can solve the problems of increasing the failure rate of combustion equipment, increasing the economic cost of enterprises, reducing production efficiency, etc., and achieves the design structure. Reasonable, reduce economic cost and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

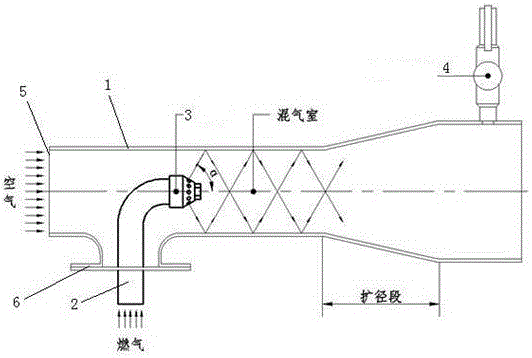

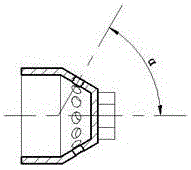

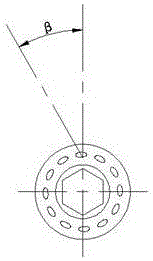

[0020] Such as figure 1 , figure 2 and image 3 The forced fully premixed three-dimensional air mixing chamber shown includes a pipe 1, an air inlet 5 arranged on the pipe 1, a gas pipe installation flange 6, and a gas pipe 2 arranged in the gas pipe installation flange 6 , and the nozzle 3 arranged at the end of the gas conduit 2, wherein the nozzle 3 is uniformly provided with a number of spray holes, and the connection between the gas conduit 2 and the nozzle 3 is arranged in a curved structure.

[0021] Further preferably, the forced fully premixed three-dimensional gas mixing chamber also includes a diameter-expanding section arranged on the pipeline 1 and located on one side of the gas-mixing chamber, wherein the diameter-expanding section is a trumpet-shaped structure, and the diameter-expanding section utilizes the Venturi principle, further Promote the mixing of air and gas; the forced full premixed three-dimensional air mixing chamber also includes an overpressure...

Embodiment 2

[0024] Such as Figure 4 , Figure 5 and Figure 6 The forced fully premixed three-dimensional air mixing chamber shown includes a pipe 1, an air inlet 5 arranged on the pipe 1, a gas pipe installation flange 6, and a gas pipe 2 arranged in the gas pipe installation flange 6 , and the nozzle 3 arranged at the end of the gas conduit 2, wherein the nozzle 3 is uniformly provided with several spray holes, and the connection between the gas conduit 2 and the nozzle 3 is a cylindrical structure (lower cost compared to the first embodiment) .

[0025] Further preferably, the forced fully premixed three-dimensional gas mixing chamber also includes a diameter-expanding section arranged on the pipeline 1 and located on one side of the gas-mixing chamber, wherein the diameter-expanding section is a trumpet-shaped structure, and the diameter-expanding section utilizes the Venturi principle, further Promote the mixing of air and gas; the forced full premixed three-dimensional air mixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com