Micro-premixing on-duty nozzle assembly and micro-premixing combustion chamber of gas turbine

A duty nozzle and combustion chamber technology, applied in combustion chambers, continuous combustion chambers, combustion methods, etc., can solve the problems of increased tempering, self-ignition and oscillation, reduction of fuel ignition delay time, and high adiabatic flame temperature, and achieves natural frequency. Differences, enhanced proportion uniformity, uniform heat release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

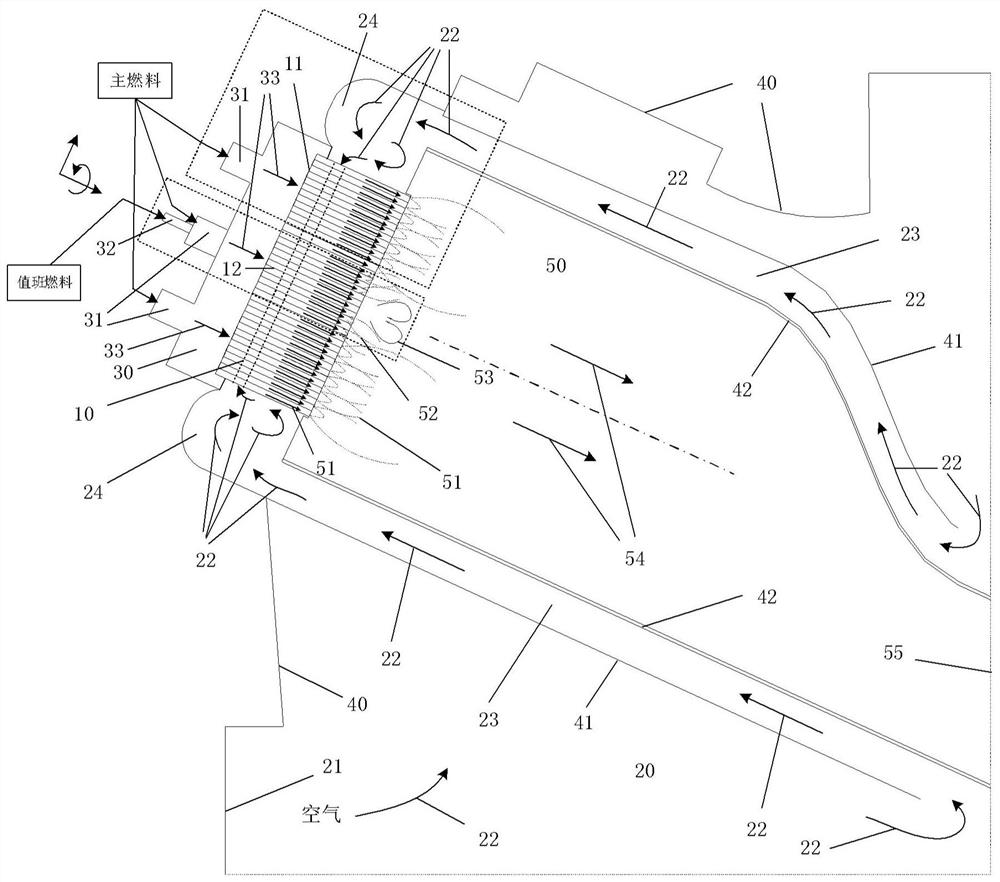

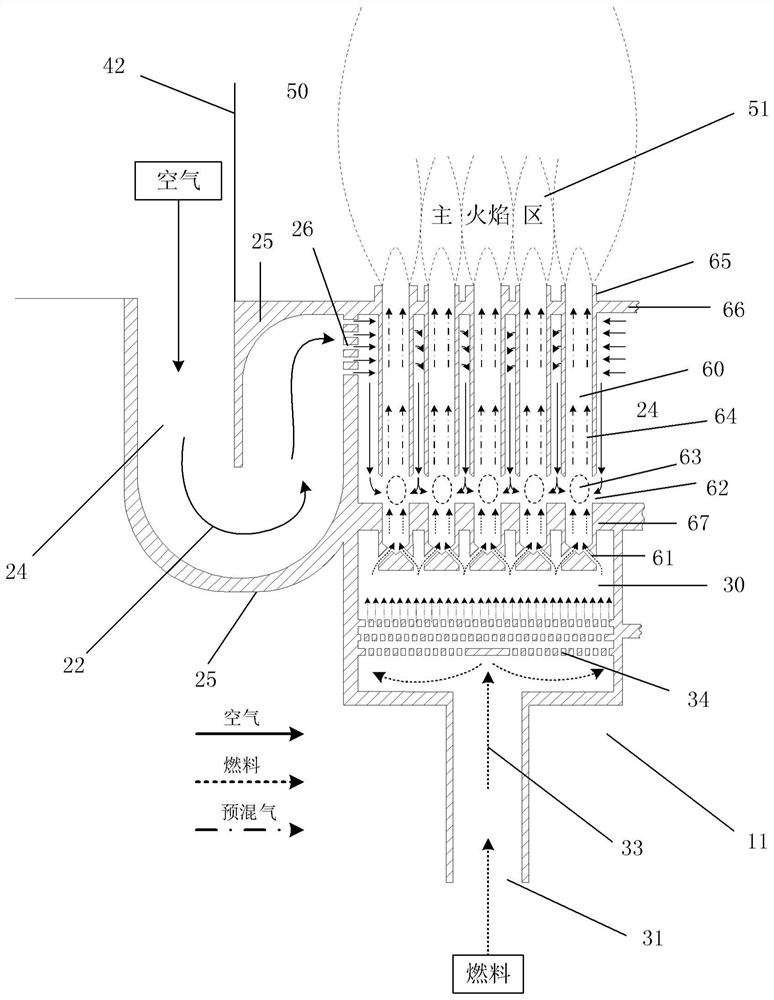

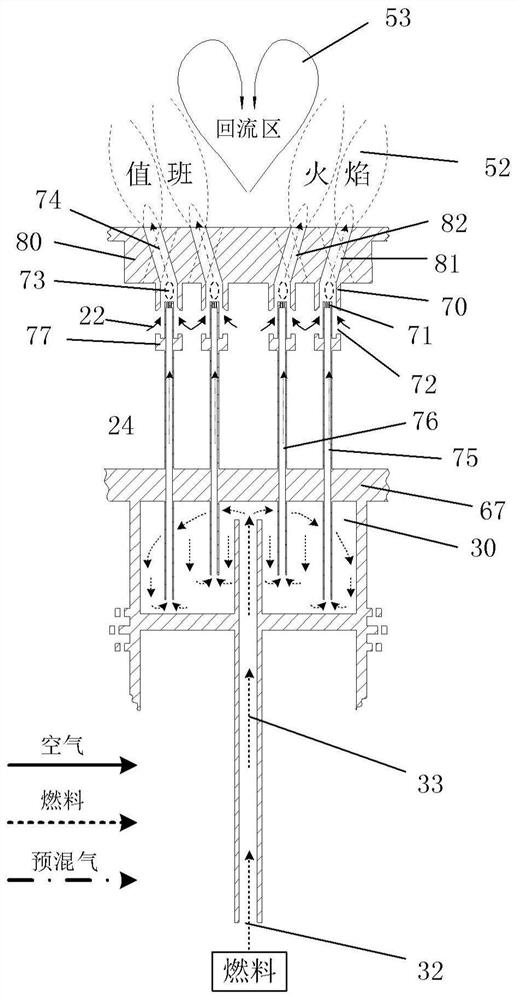

[0082] The invention provides a gas turbine micro-premix combustor to alleviate the problems of low expandability of the burner unit nozzle in the prior art, uneven mixing of fuel and air, flashback, spontaneous combustion and oscillation during operation, and at the same time alleviate the problems of nitrogen The problem of high oxide emissions.

[0083] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0084] As an aspect of the present invention, a kind of micro-premix nozzle assembly on duty is provided, comprising:

[0085] The nozzle top cover is provided with multiple inclined holes;

[0086] A plurality of micro-premixing tubes, one end of the plurality of micro-premixing tubes communicates with a plurality of inclined holes on the nozzle top cover; the other end of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Circumferential angle | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Major axis length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com