Grading air distribution type heat accumulating type incinerator

A graded air distribution and regenerative technology, applied in incinerators, combustion methods, combustion types, etc., can solve the problems of inability to completely treat organic waste gas without oxygen and oxygen content, and high treatment costs, and achieve significant economic effects. , the effect of improving economy and increasing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

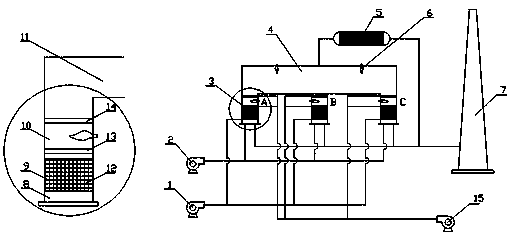

[0028] Such as Figure 1-2 shown.

[0029] One of technical solutions of the present invention is:

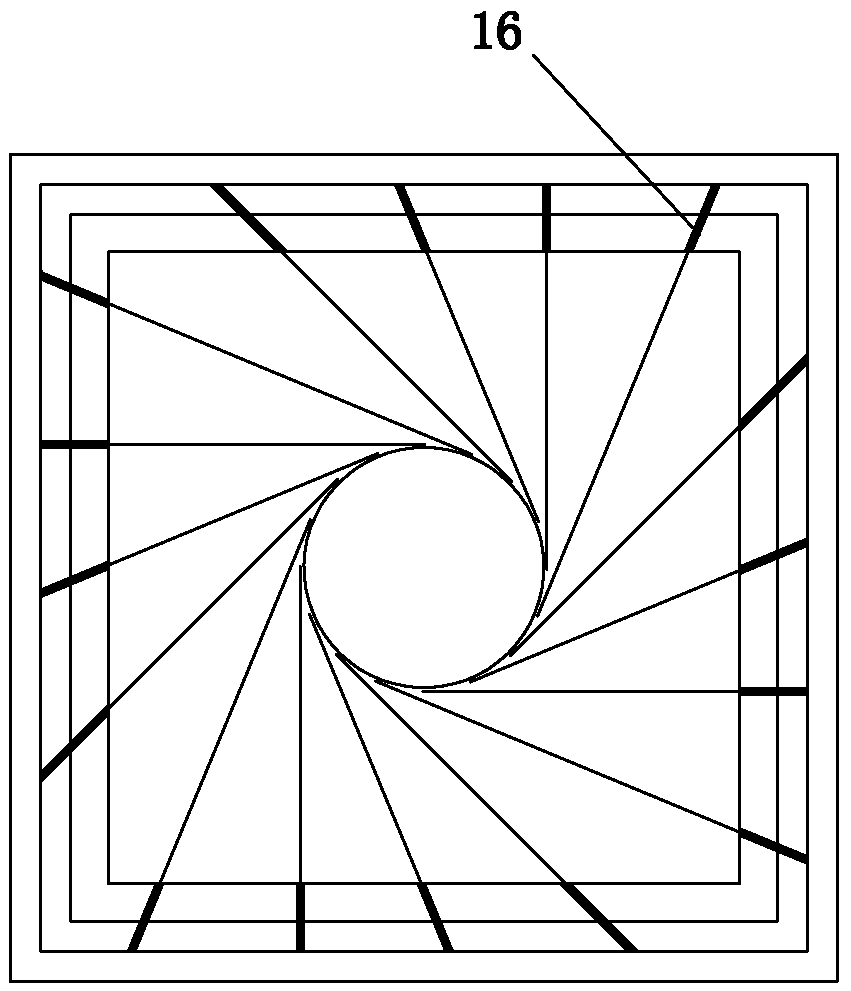

[0030] A graded air distribution type regenerative incinerator, which includes a main fan 1, an auxiliary blower fan 2, a combustion-supporting fan 15 and a regenerator 3, such as figure 1 As shown, the lower part of the regenerator 3 is provided with an air distribution section 8, the upper part of the air distribution section 8 is a heat storage section 9, the upper part of the heat storage section 9 is an ignition section 10, and the ignition section 10 is connected to the oxidation chamber 4 The primary air ring pipe 13 is installed on the bottom of the ignition section 10, and the secondary air ring pipe 14 is installed on the top. The primary air ring pipe 13 and the secondary air ring pipe 14 are both supplied by the combustion-supporting fan 15. The primary air ring pipe 13 and the secondary air ring pipe 14 are equipped with offset swirl air nozzle holes 16 (such as ...

Embodiment 2

[0032] Such as Figure 1-2 shown.

[0033] A graded air distribution type regenerative incinerator, which includes a main fan 1, an auxiliary blower fan 2, a combustion-supporting fan 15, and a regenerator 3, such as figure 1 As shown, according to the characteristics of the waste gas treatment capacity, the number of regenerators 3 in this embodiment is two, and the structures of the two regenerators 3 are the same. The hot section 9 and the upper part of the heat storage section 9 are ignition sections 10, and the two ignition sections 10 are all connected with the oxidation chamber 4. A primary air ring pipe 13 is installed at the bottom of the ignition section 10, and two The secondary air ring pipe 14, the primary air ring pipe 13 and the secondary air ring pipe 14 are all supplied with air by the combustion-supporting fan 15, and the above-mentioned primary air ring pipe 13 and secondary air ring pipe 14 are equipped with offset swirling air jets. hole 16 (as figure ...

Embodiment 3

[0035] Such as Figure 1-2 shown.

[0036] A heat storage type incinerator with graded air distribution, which includes a main blower 1, an auxiliary sweeping blower 2, a combustion-supporting blower 15, and a regenerator 3. The number of chamber 3 is three or more, figure 1 The number of middle regenerators 3 is three: A, B, and C. Each regenerator 3 has the same structure, and the lower part is equipped with an air distribution section 8. The upper part of the air distribution section 8 is a heat storage section 9. The heat storage section The top of 9 is the ignition section 10, and each ignition section 10 is connected with the oxidation chamber 4, and the primary air ring pipe 13 is installed at the bottom of the ignition section 10, and the secondary air ring pipe 14 is installed at the top, and the primary air Both the ring pipe 13 and the secondary air ring pipe 14 are supplied with air by the combustion-supporting fan 15, and the above-mentioned primary air ring pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com