Super capacitor-based energy-saving drive circuit of motor and control method

A super capacitor and circuit technology, applied in the field of motor energy-saving drive circuits, can solve the problems of low battery cycle life, affecting power supply quality, and high maintenance costs, and achieve the effects of improving safety, reliability, easy maintenance, and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

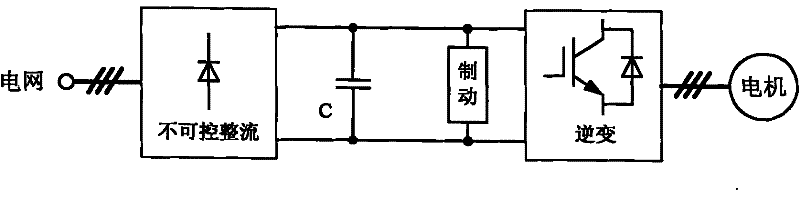

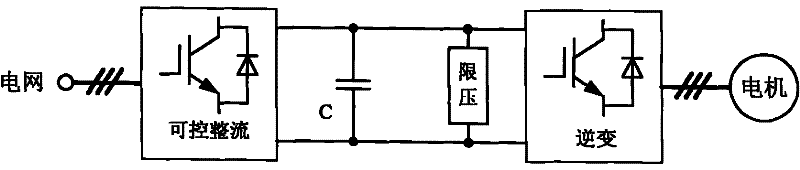

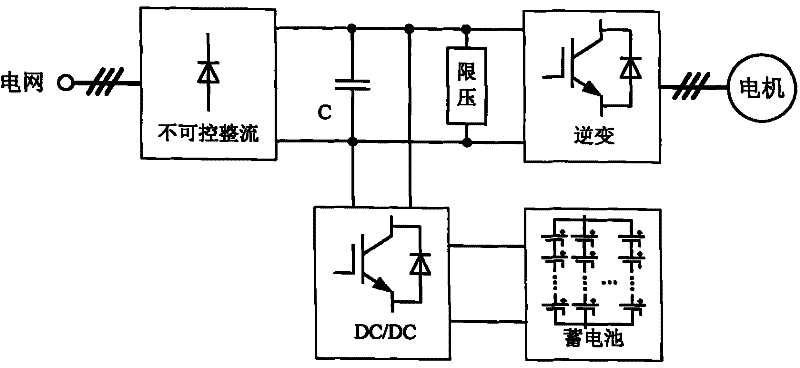

[0056] According to the operating power of elevators, cranes and other systems and the actual capacity, cost, and life of energy storage devices, it is unrealistic to use batteries and supercapacitors to store the energy fed back by elevators. Controlled rectification with two-way energy flow is used. Has a cost advantage. However, there are large positive and negative power peaks in the process of elevator starting and braking, and the use of bidirectional controllable rectification will have an impact on the power system.

[0057] The invention proposes an energy feedback type elevator drive system combining controllable rectification and supercapacitor energy storage. The energy storage function of the supercapacitor in the system can reduce the surge power impact of the elevator on the grid system, reduce the peak power demand of the controllable r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com