Overground dry distillation process capable of treating small-particle raw material self-heating type oil shale

A technology of oil shale and small particles, which is applied in the field of self-heating oil shale aboveground carbonization process that can handle small particle raw materials, and can solve the problems of reduced resource utilization, resource waste, and huge oil recovery system, and achieve resource utilization Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. The specific embodiments described here are only used to explain the present invention, not to limit the invention.

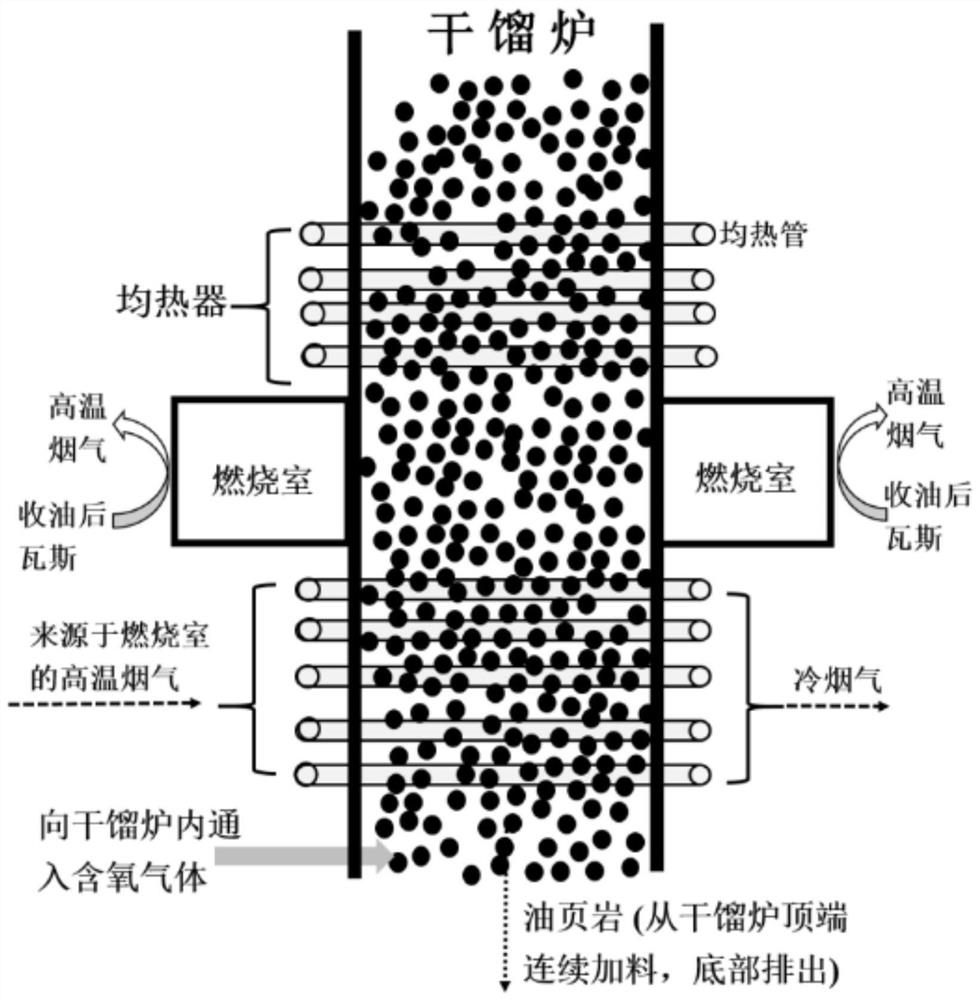

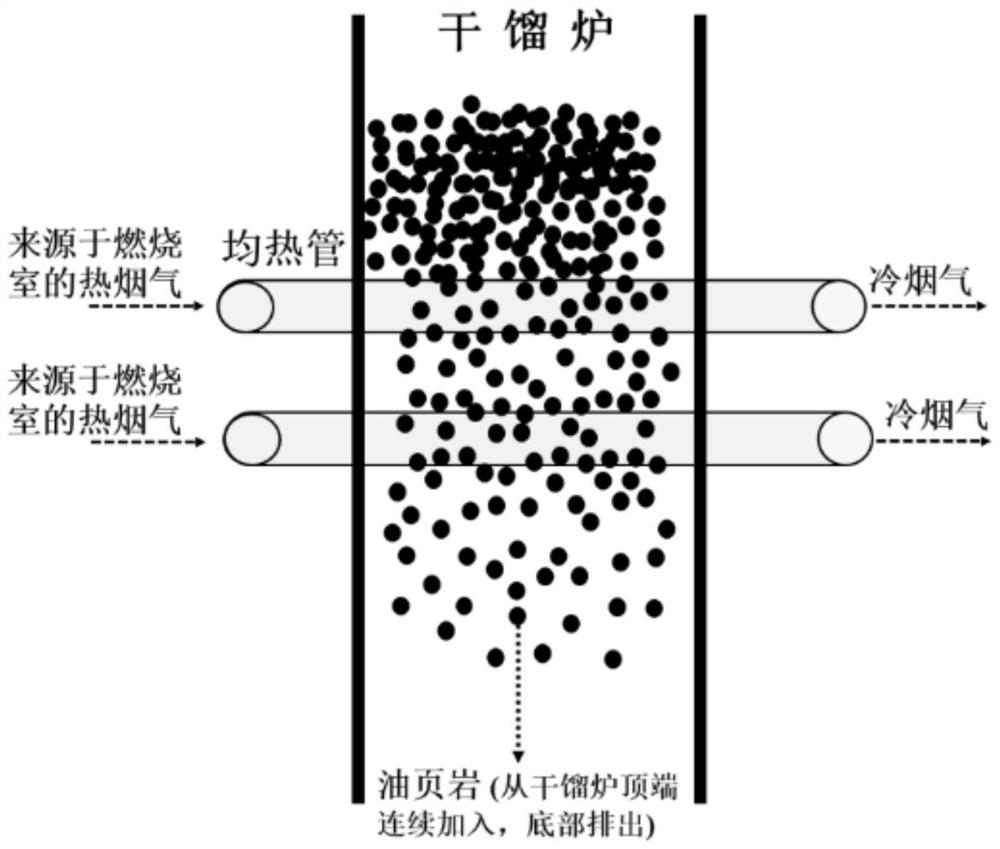

[0027] Since the principle of the traditional gas heat carrier process is to feed high-temperature gas into the oil shale in the carbonization furnace, the high-temperature gas is used to heat the oil shale by directly mixing with the oil shale material, that is to say, the high-temperature heat transfer is carried out through heat transfer. The heat of the gas is transferred to the oil shale to raise the temperature of the oil shale. Since the oil shale needs to be heated to above 500°C, a large amount of heat carrier gas needs to be used. The small grains of oil shale below 12mm are closely packed so that the gaps between the grains are very small, and a lar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com