Patents

Literature

31results about How to "Avoid direct mixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gas mixing device for engine exhaust gas recycling system

ActiveCN106884746AWell mixedPromote precipitationExhaust gas recirculationMachines/enginesExhaust gasProcess engineering

The invention provides a gas mixing device for an engine exhaust gas recycling system, and relates to a gas mixing device. The gas mixing device comprises an air circulation pipe and a gas mixing pipe communicated with an EGR valve; one end of the air circulation pipe is communicated with an air inlet pipe, the other end of the air circulation pipe is communicated with a compressor of a supercharger, and the air circulation pipe is used for receiving air flowing in from the air inlet pipe; the gas mixing pipe is arranged outside the air circulation pipe in a sleeving manner so as to receive exhaust gas exhausted from an engine and flowing through the EGR valve; the air circulation pipe is provided with a plurality of air inlet holes and a plurality of air exhaust holes, and therefore air flows into the gas mixing pipe from the air inlets, the air and exhaust gas are mixed to form mixed gas, and the mixed gas is exhausted to the compressor; and the gas mixing pipe is provided with the gas inlet end communicated with the EGR valve, an included angle is formed between the gas inlet end and the gas mixing pipe, and therefore the mixed gas does helical motion in the axis direction of the air circulation pipe. The gas mixing device solves the problem that the exhaust gas and fresh air are insufficiently mixed.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

Flame-retardant microcapsule phase-change material

InactiveCN105112020AWon't happenNot volatileHeat-exchange elementsMicroballoon preparationBenzoyl peroxideSolvent

The invention relates to a flame-retardant microcapsule phase-change material. The flame-retardant microcapsule phase-change material is prepared from a core material, a flame-retardant wall material, an emulsifier, benzoyl peroxide (BPO) and deionized water, wherein the core material is fatty acid ester, the flame-retardant wall material is a crosslinking polymer of reactive phosphonate monomer and tetramethylol methane tetraacrylate, and the emulsifier is a mixture of nonionic surfactant and ionic surfactant. The flame-retardant microcapsule phase-change material provided by the invention has excellent performance and is safe and environment-friendly; since reactive phosphonate-modified acid ester polymer is used as the microcapsule wall material, good flame retardation effect, good water resistance and good solvent resistance are obtained, and reduction in phase change enthalpy of the phase-change material caused by an additive flame retardant can be avoided; and since aliphatic ester is used as a phase-change material, better thermal stability and chemical stability are obtained, and a heat release rate is lower.

Owner:NINGBO GREENTECH ENERGY SAVING TECH

Premixing agent for preventing and treating cage-cultured chicken cannibalism

InactiveCN102640869APeck PreventionIncrease production capacityAnimal feeding stuffBiotechnologyVitamin C

The invention provides a premixing agent for preventing and treating cage-cultured chicken cannibalism, which aims at solving the problems that in the prior art, considered factors for preventing and treating the chicken cannibalism are incomplete, used raw materials have high cost and potential safety hazards, and the like. The premixing agent is prepared according to the nutrition reason causing the chicken cannibalism. The used raw materials have wide sources, safety and reliability of the used raw materials can be ensured when the used raw materials are used in feed processing, and the fact that no food safety risk exists in the feed processing can be ensured. In addition, the premixing agent has low cost so that the premixing agent is suitable for livestock farms with different scales and can be used for preventing and treating the cage-cultured chicken cannibalism caused by nutrition. By means of the technical measures, the premixing agent for preventing and treating the cage-cultured chicken cannibalism is characterized by comprising the following raw materials, by weight, 5-10% of vitamin C (VC), 10-25% of methionine, 2-5% of complex vitamins, 20-35% of medical stones and 30-50% of feather meal.

Owner:YUXI KUAIDADUO ANIMAL HUSBANDRY TECH

Heat pump type steam generator

InactiveCN101078513AEfficient heatingReduce energy consumptionSteam generationThermal energyWarm water

The invention relates to a heat pump steam generator. Air source heating pump comprises compressor, primary end of energy coupling heat exchanger, expansion valve and air heat exchanger. Heating pump for high-temperature water of artificial source supplied by the air source heating pump comprises compressor, high-temperature water heat exchanger with electric heater, warm-water exchanger, expansion valve and secondary end of energy coupling heat exchanger. Heating pump for high-temperature water of air source comprises compressor, high-temperature water exchanger, warm-water exchanger, expansion valve and air exchanger through allocation valve. The invention makes use of the heating pump of air source to obtaining heat quantity in air and provides an artificial heating source for the heating pump for high-temperature water of artificial source so that it is realized that steam is heated in high efficiency. And steam can be generated by high-temperature exchanger with electric heater. Because 90% or so of total heat energy for generating steam is provided by the heating pump and only 10% or so for steam is provided with the electric heater, energy consumption for steam can be decreased greatly and working efficiency of steam generator can be improved.

Owner:王全龄

Anti-flaming phase change microcapsule and preparation method thereof

InactiveCN109225085AImprove flame retardant performanceHigh energy storage densityHeat-exchange elementsMicroballoon preparationHigh energyMelamine formaldehyde resin

The invention discloses an anti-flaming phase change microcapsule and a preparation method thereof and relates to the technical field of energy-saving materials. The anti-flaming phase change microcapsule comprises an organic phase change material and a capsule wall for wrapping the organic phase change material; the organic phase change material is one or more of straight-chain paraffin or branched paraffin with general formula of CnH2n+2, higher aliphatic acid with general formula of CnH2nCOOH and higher aliphatic alcohol with general formula of CnH2nOH; n=12-32; the capsule wall is made from phosphorous diamine monomer, melamine, formaldehyde solution, emulgator and deionized water. Phosphorous melamine-formaldehyde resin is taken as a capsule wall material of the anti-flaming phase change microcapsule disclosed by the invention, so that the flame resistance of the phase change microcapsule is greatly promoted, the defect of flammability of the organic phase change material is overcome, the direct mixing of fire retardant and organic phase change material can be avoided and higher energy density of the phase change microcapsule can be guaranteed.

Owner:SICHUAN UNIV

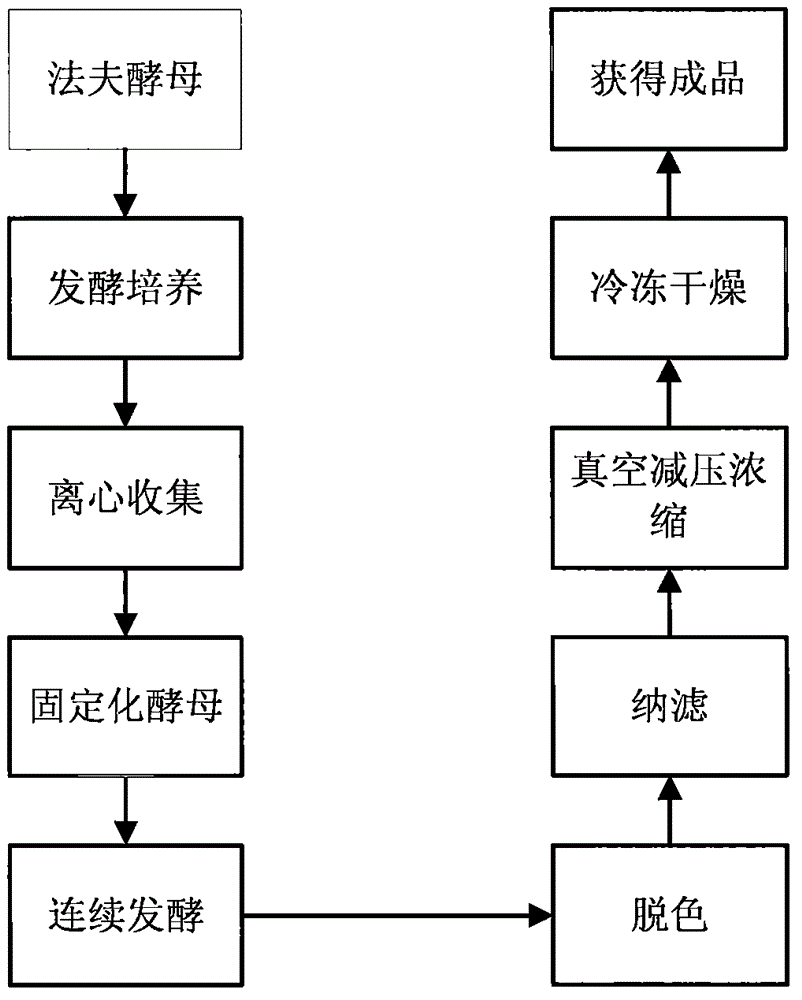

Production process of fructo-oligosaccharide-neokestose

InactiveCN105112473AEfficient removalEasy to separateChemical industryMicroorganism based processesYeastHigh intensity

The ivneniton discloses a production process of fructo-oligosaccharide-neokestose. Immobilized phaffia rhodozyma cells are used repeatedly, continuous and high-intensity production of fructo-oligosaccharide-neokestose is performed through phaffia rhodozyma cells immobilized with an embedding method, the production cycle is shortened, the yield of neokestose is increased, the production cost is reduced, industrial and large-scale production of fructo-oligosaccharide-neokestose is successful, and the production process has excellent application prospect.

Owner:董晓娜

Method and device for processing explosion exhaust air

The invention provides a disposal method and a device used for disposing explosion waste gas, consisting of a separator, a high-efficiency filter, a molecular sieve drier, a NOx adsorbing device, a NOx reducer, a burner, a deodorizer, a circulation fan, an electric heater, etc. The disposal method of the invention comprises the steps as follows: a: waste gas disposal process: the explosion waste gas is disposed by a cyclone filter, the high-efficiency filter, a molecular sieve dehydrator, the NOx adsorbing device and the deodorizer, burned by entering the burner and is exhausted; b: system inerting process: the air feeding of the waste gas disposal device is cut off, nitrogen is filled into the system so as to lead the oxygen content to be less than 2%; c: desorption and reducing process: the circulation fan is started; gas circulation between the circulation fan, the gas electric heater, the NOx reducer and the NOx adsorbing device is established, the reducing gas is filled into the system, the gas electric heater is started, the temperature of the circulation gas is gradually increased, the NOx is de-adsorbed and reduced as N2. After continuous running, the content of the NOx achieves the exhaust standard requirement.

Owner:YANTAI UNIV

Multi-cavity rotary inter-wall heat exchanger for hot semi-coke and coal

InactiveCN106118700AAchieve coolingAchieve dryingSpecial form destructive distillationMoving conduit heat exchangersPlate heat exchangerEngineering

The invention provides a multi-cavity rotary type inter-wall heat exchanger for semi-coke and coal. The heat exchange comprises a rotary cylinder which is inclined and has a feed end higher than a discharge end thereof; the feeding end of the rotary cylinder is connected with the semi-coke distributing box, a kiln box and a feeding screw in sequence, and the feed screw is connected with the semi-coke distributing box through the kiln box, the semi-coke distributing box is arranged in the rotary cylinder, and the kiln box is provided with a down chute; the discharge end of the rotary cylinder is connected with the kiln tail box and the semi-coke aggregate box in sequence, and the semi-coke collecting box is located inside the rotary cylinder through the kiln tail box and extends externally; the semi-coke collecting box is connected with the semi-coke discharge box after extending out of the rotary cylinder; the rotary cylinder is provided with an actuator. In the invention, the semi-coke and the coal respectively pass through different channels to realize the heat transfer between the walls. After passing the equipment, the semi-coke has been cooled, and coal is partially dehydrated to achieve partial drying, while the temperature will increase to some extent.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

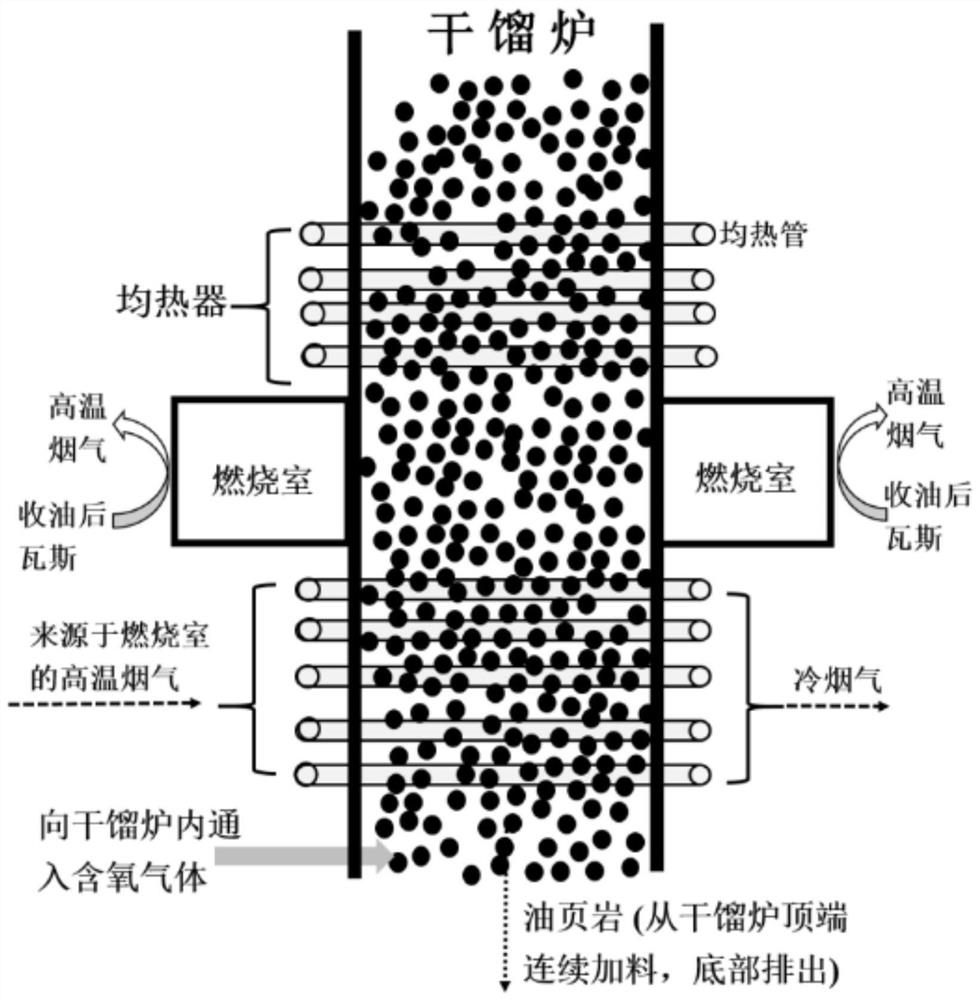

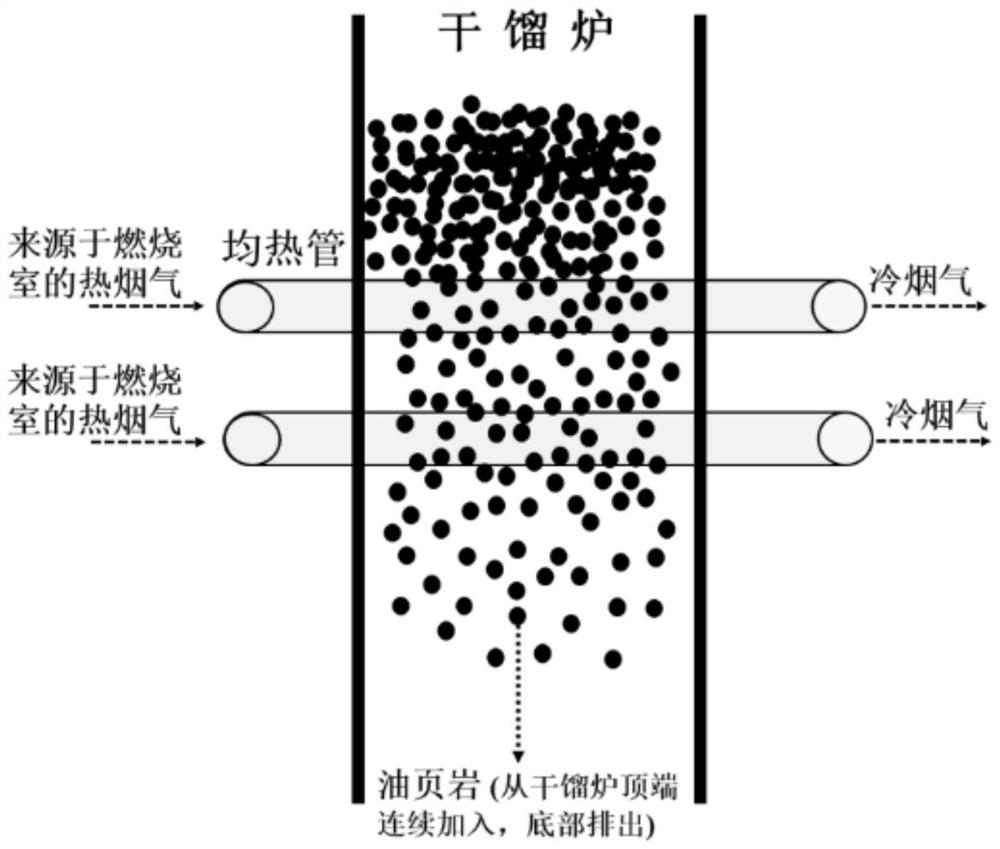

Overground dry distillation process capable of treating small-particle raw material self-heating type oil shale

PendingCN113416568AImprove resource utilizationPromote pyrolysis to generate oilLiquid hydrocarbon mixture productionSpecial form destructive distillationWater savingPartial oxidation

The invention discloses an overground dry distillation process capable of treating small-particle raw materials self-heating type oil shale. The process comprises the following steps: utilizing low-temperature partial oxidation reaction generated by oil shale for in-situ heat release; and meanwhile, arranging a plurality of combustion chambers and soaking devices around the dry distillation furnace, and enabling high-temperature flue gas generated by combustion in the combustion chambers to radiate and conduct heat to the oil shale to be subjected to dry distillation through the devices, namely, the flue gas is not directly mixed with dry distillation materials and oil gas. In addition, the oil shale particles collide with the metal soaking pipe penetrating through the oil shale material layer in the descending process in the dry distillation furnace, so that gaps among the oil shale particles are enlarged. The method improves the utilization rate of resources, and has the advantages of high energy efficiency and resource utilization rate, water saving, small environmental influence, simplified process, no high-temperature heat carrier and relatively mild reaction conditions.

Owner:郭洪范 +1

Device for preparing pure water for analytical laboratory by ion exchange method

InactiveCN102515390AAvoid direct mixingHigh water purityMultistage water/sewage treatmentIon exchangeIon-exchange resin

The invention discloses a device for preparing pure water for an analytical laboratory by an ion exchange method. A multistage multi-column exchange column is connected behind a multi-column system in series, so as to form a multi-column-multistage multi-column ion exchange pure water device; and cation exchange resin and anion exchange resin are alternately filled in a shorter exchange column according to a certain proportion, the two kinds of resin are separated by a sieve plate so as to form a multistage multi-column unit, and a plurality of multistage multi-column units are connected in series to from the multistage multi-column. Compared with a multi-column method, in the ion exchange method, as one multistage multi-column is connected in series, a plurality of times of exchange balance can be realized in the multi-column, and the water purity is increased; and compared with a mixing column, in the multi-column, the cation exchange resin and the anion exchange resin are separated by the sieve plate, the direct mixing of the two kinds of the resin can be avoided, and the regeneration is easy.

Owner:HENAN UNIV OF SCI & TECH

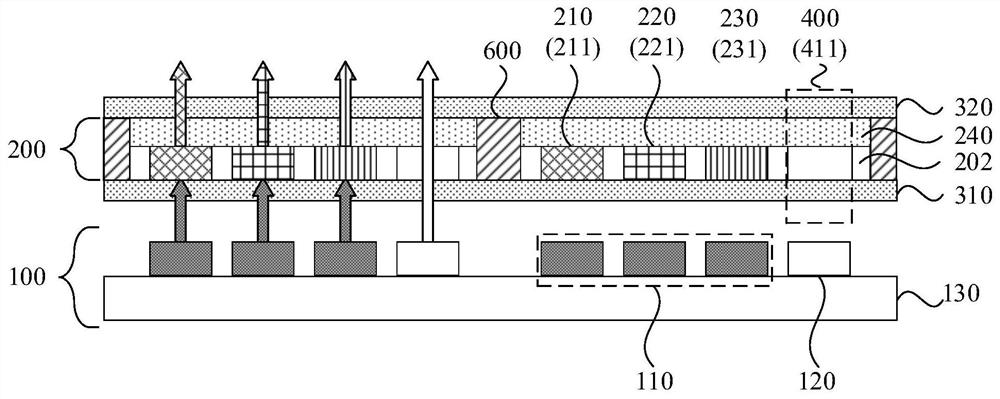

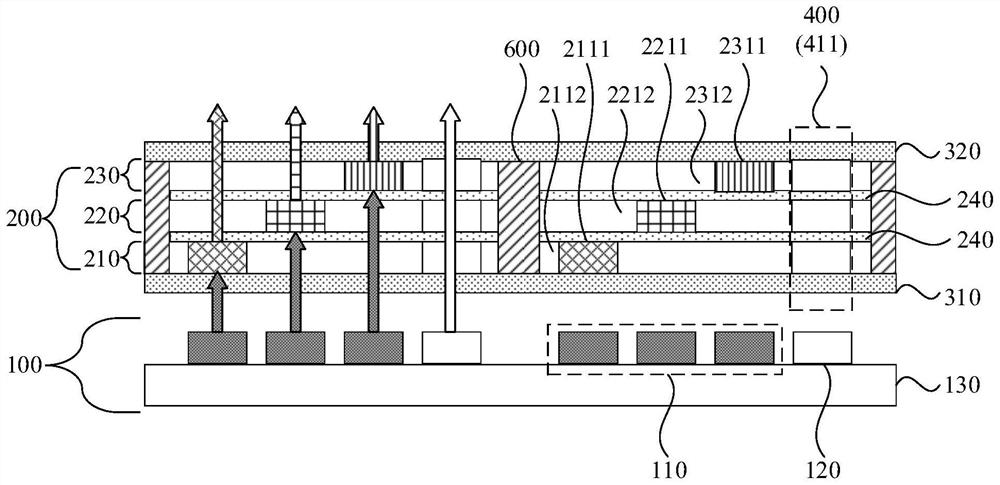

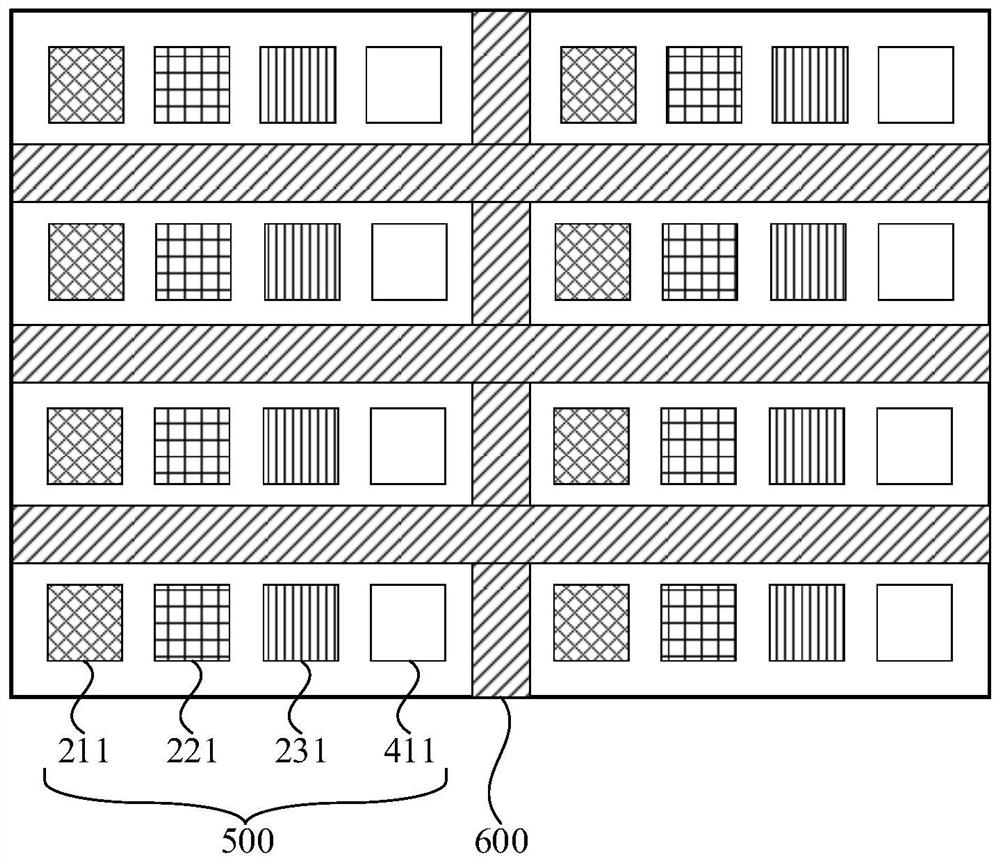

Quantum dot display panel and quantum dot display device

ActiveCN112631023AAvoid mutual interferenceGuaranteed reliabilityNon-linear opticsVertical projectionColor gel

The embodiment of the invention provides a quantum dot display panel and a quantum dot display device. The quantum dot display panel comprises a backlight module composed of an ultraviolet light backlight module and a white light backlight module, a quantum dot color film structure and a white light transmitting area located on the light emitting side of the backlight module. The quantum dot color film structure covers the ultraviolet backlight module, and the white light transmitting area covers the white light backlight module; the vertical projections of a plurality of red light quantum dot substructures of the red light quantum dot color film structure, a plurality of green light quantum dot substructures of the green light quantum dot color film structure, a plurality of blue light quantum dot substructures of the blue light quantum dot color film structure and a plurality of white light transmitting sub areas of the white light transmitting area on the plane where the backlight module is located are not overlapped. According to the technical scheme provided by the embodiment of the invention, the use of a color filter is avoided, and the light emitting efficiency is improved; the quantum dot performance is optimized, and the reliability of the color film structure is ensured; the display brightness can be enhanced directly through the white light transmitting area, and maximum utilization of backlight source energy is achieved.

Owner:深圳扑浪量子半导体有限公司

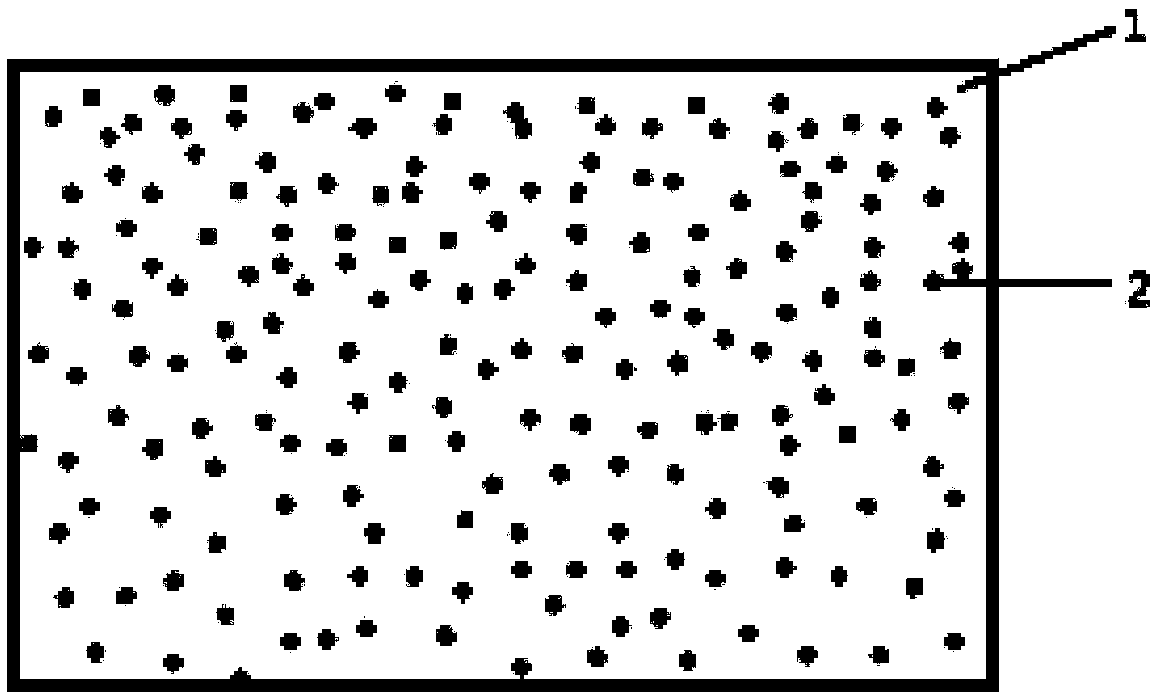

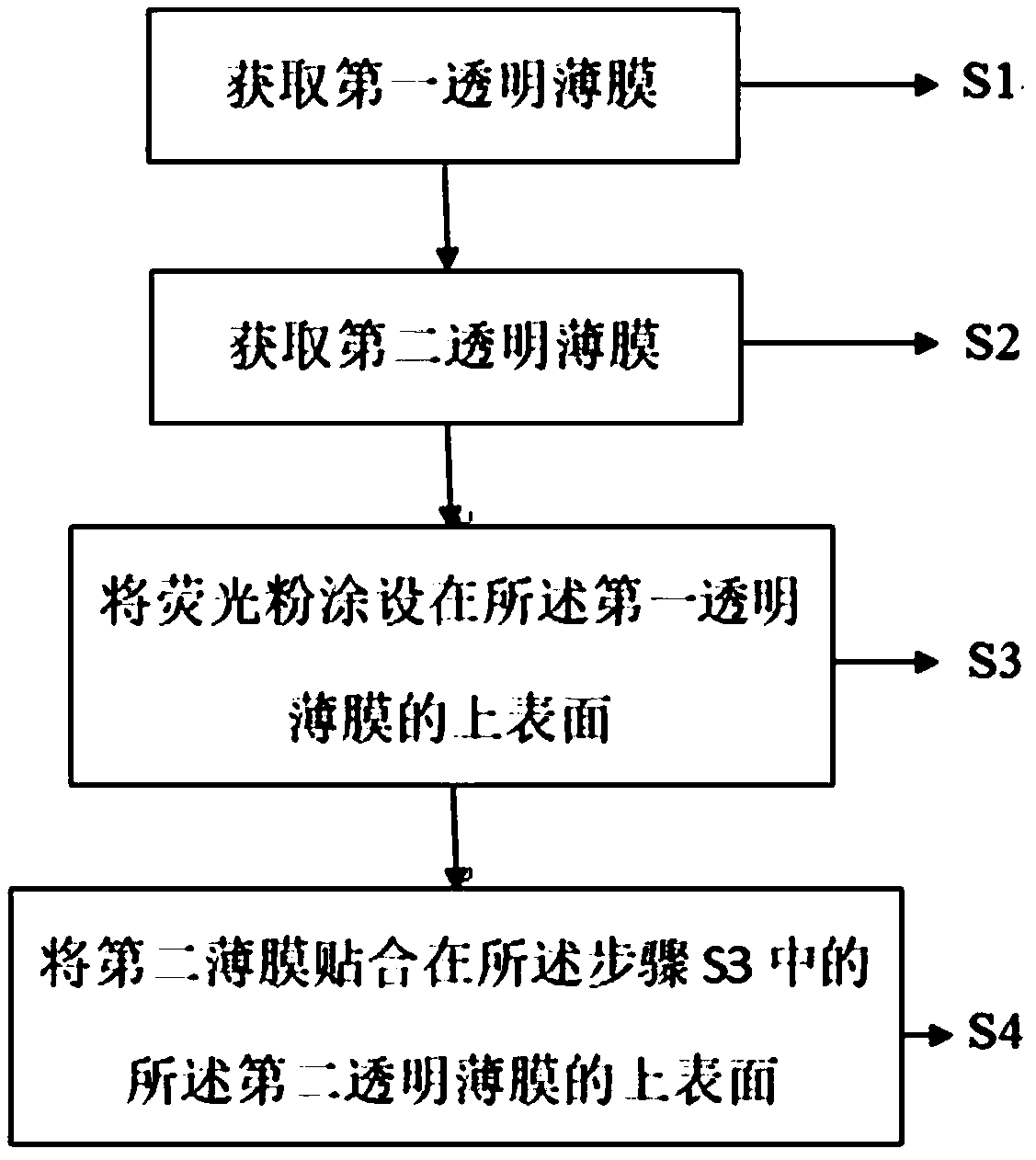

Fluorescent thin film structure for LED, preparation method thereof and light-emitting light source

ActiveCN109390454AGood optical performanceAvoid direct mixingSemiconductor devicesPhosphorFluorescence

The invention relates to a fluorescent thin film structure for an LED, a preparation method thereof and a light-emitting light source. The fluorescent thin film structure for an LED comprises a firsttransparent thin film, phosphor powder applied on the upper surface of the first transparent thin film and a second transparent thin film bonded to the first transparent thin film coated with the phosphor powder. The preparation method of the fluorescent thin film structure for an LED includes: obtaining a first transparent thin film, obtaining a second transparent thin film, applying phosphor powder on the upper surface of the first transparent thin film, and bonding the second transparent thin film to the upper surface of the first transparent thin film coated with the phosphor powder. An LED light-emitting light source includes the fluorescent thin film structure for an LED. The invention solves the problems of fluorescent powder precipitation and poor consistency of light and color inthe packaging process, meanwhile shortens the packaging process and reduces the production cost.

Owner:NINGBO LONGER LIGHTING

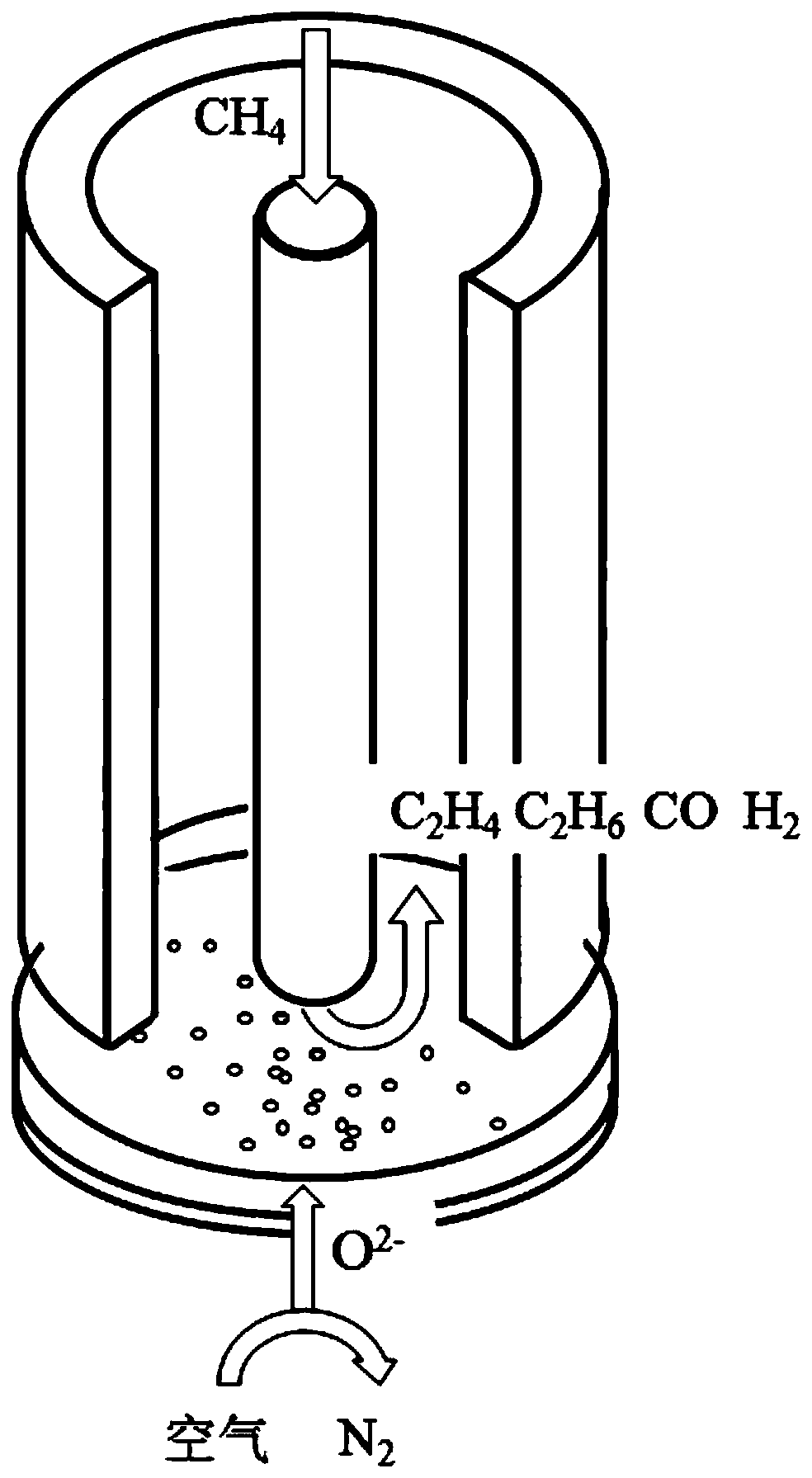

Method for converting methane into aliphatic hydrocarbons, fuel cell and fuel cell preparation method

ActiveCN109385643BRealize integrationAvoid demandElectrolysis componentsCell electrodesPtru catalystFuel cells

Owner:PETROCHINA CO LTD

X wav band frequency conversion assembly

ActiveCN104901628AImprove frequency conversion stabilityAvoid direct mixingMulti-frequency-changing modulation transferenceIntermediate frequencyWave band

The present invention provides an X waveband frequency conversion assembly. The assembly includes: a first frequency multiplier, a first mixer, a first filtering amplifier, a second mixer, a second filtering amplifier, a first frequency divider, a third mixer, a third filtering amplifier, a first power divider, a second power divider, a second frequency multiplier and a second frequency divider, wherein the input end of the first frequency multiplier receives an intermediate frequency signal; the input end of the first power divider receives a high frequency local oscillator signal; an output end of the first frequency multiplier is connected to the input end of the third filtering amplifier sequentially via the first mixer, the first filtering amplifier, the second mixer, the second filtering amplifier, the first frequency divider and the third mixer; the output end of the first power divider is divided into two paths, one path is directly connected to the first mixer, while the other path is connected to the second power divider; and the output end of the second power divider is divided into two paths, one path is connected to the second mixer via the second frequency multiplier, while the other path is connected to the third mixer via the second frequency divider. The X waveband frequency conversion assembly of the present invention can increase frequency conversion stability.

Owner:SICHUAN SIAIPU ELECTRONICS TECH CO LTD

x-band inverter

ActiveCN104917465BAvoid direct mixingImprove frequency conversion stabilityMulti-frequency-changing modulation transferenceAudio power amplifierFrequency conversion

The invention provides an X-band frequency converter. The X-band frequency converter comprises a first frequency multiplier, a first frequency mixer, a first filter amplifier, a first frequency divider, a second frequency mixer, a second filter amplifier, a third frequency mixer, a third filter amplifier, a first power divider, a second power divider and a second frequency divider, wherein the input end of the first frequency multiplier is used for receiving an intermediate-frequency signal; the input end of the first power divider is used for receiving a high-frequency intrinsic signal; the output end of the first frequency multiplier is connected with the input end of the third filter amplifier after passing through the first frequency mixer, the first filter amplifier, the first frequency divider, the second frequency mixer, the second filter amplifier and the third frequency mixer in sequence; the output end of the first power divider is divided into two paths; one path is directly connected with the first frequency mixer, and the other path is connected with the second power divider; the output end of the second power divider is divided into two path; and one path is directly connected to the second frequency mixer, and the other path is connected with the third frequency mixer through the second frequency divider. Through adoption of the X-band frequency converter, the frequency conversion stability can be enhanced

Owner:SICHUAN SIAIPU ELECTRONICS TECH CO LTD

Method and device for processing explosion exhaust air

Owner:YANTAI UNIV

Pre-filled culture dish containing beta-lactamase and preparation method thereof

InactiveCN113214985APrevent solidificationGuaranteed continuityBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringCulture mediums

The invention belongs to the technical field of culture dish filling and particularly relates to a pre-filled culture dish containing a beta-lactamase and a preparation method thereof. The pre-filled culture dish comprises a culture medium storage tank, a beta-lactamase storage tank, a stirring tank A and a stirring tank B; the culture medium storage tank communicates and is connected with a first three-way pipe, a first tank bottom valve, a second tank bottom valve, a second discharging pipe, a first discharging pipe, a first three-way valve, a first feeding pipe, a first circulating pipe, a second three-way valve, a second feeding pipe and a second circulating pipe; and the beta-lactamase storage tank communicates and is connected with a second three-way pipe, a third tank bottom valve, a fourth tank bottom valve, a fourth discharging pipe, a third discharging pipe, a third three-way valve, a third feeding pipe, a third circulating pipe, a fourth three-way valve, a fourth feeding pipe and a fourth circulating pipe, and the stirring tank A and the stirring tank B are connected with a filling mechanism through a fifth tank bottom valve, a sixth tank bottom valve and a fifth three-way valve. A culture medium and a beta-lactamase solution can be stored, fluidity of the culture medium and activity of the beta-lactamase are ensured by controlling states of the valves, such that the quality control level of the pre-filled culture dish containing beta-lactamase is effectively improved.

Owner:侯亚

Preparation method of quantum dot display panel and quantum dot display panel

The invention provides a preparation method of a quantum dot display panel and the quantum dot display panel. The preparation method comprises the following steps of preparing a red light quantum dot solution and a green light quantum dot solution of which external ligands are magnetic, preparing a first magnetic material with a first curie point temperature to cover the first area of the transparent substrate, and preparing a second magnetic material with a second curie point temperature to cover the second area of the transparent substrate, wherein the first area, the second area and the non-deposited third area are not overlapped with one another to obtain a magnetic deposition substrate, immersing the magnetic deposition substrate into a red light quantum dot solution to obtain a red light quantum dot color film structure, and immersing the magnetic deposition substrate into a green light quantum dot solution to obtain a green light quantum dot color film structure and a quantum dot color film substrate, arranging the quantum dot color film substrate on the light emitting side of the blue light backlight module, and arranging the blue light reflecting layer on the side, deviating from the blue light backlight module, of the quantum dot color film substrate. According to the technical scheme provided by the invention, the use of a color filter is avoided, blue light waste is avoided, the quantum dot performance can be optimized, and the light emitting efficiency is improved.

Owner:SHENZHEN PLANCK INNOVATION TECH CO LTD

A quantum dot display panel and quantum dot display device

ActiveCN112631023BAvoid mutual interferenceGuaranteed reliabilityNon-linear opticsColor gelUltraviolet lights

An embodiment of the present invention provides a quantum dot display panel and a quantum dot display device. The quantum dot display panel includes: a backlight module composed of an ultraviolet light backlight module and a white light backlight module; The color film structure and the white light transmission area, the quantum dot color film structure covers the ultraviolet light backlight module, and the white light transmission area covers the white light backlight module; the red light quantum dot color film structure has multiple red light quantum dot structures, and the green light quantum dot color film The vertical projections of the multiple green light quantum dot substructures of the structure, the multiple blue light quantum dot substructures of the blue light quantum dot color film structure, and the multiple white light transmission subregions of the white light transmission region on the plane where the backlight module is located do not overlap. The technical solution provided by the embodiment of the present invention avoids the use of color filters and improves luminous efficiency; optimizes the performance of quantum dots to ensure the reliability of the color filter structure; directly enhances the display brightness through the white light transmission area to maximize the energy of the backlight source use.

Owner:深圳扑浪量子半导体有限公司

Fluorescent thin film structure for LED, preparation method thereof, and luminescent light source

ActiveCN109390454BGood optical performanceAvoid direct mixingSemiconductor devicesFluorescencePhysical chemistry

The invention relates to a fluorescent thin film structure for an LED, a preparation method thereof and a light-emitting light source. The fluorescent thin film structure for an LED comprises a firsttransparent thin film, phosphor powder applied on the upper surface of the first transparent thin film and a second transparent thin film bonded to the first transparent thin film coated with the phosphor powder. The preparation method of the fluorescent thin film structure for an LED includes: obtaining a first transparent thin film, obtaining a second transparent thin film, applying phosphor powder on the upper surface of the first transparent thin film, and bonding the second transparent thin film to the upper surface of the first transparent thin film coated with the phosphor powder. An LED light-emitting light source includes the fluorescent thin film structure for an LED. The invention solves the problems of fluorescent powder precipitation and poor consistency of light and color inthe packaging process, meanwhile shortens the packaging process and reduces the production cost.

Owner:NINGBO LONGER LIGHTING

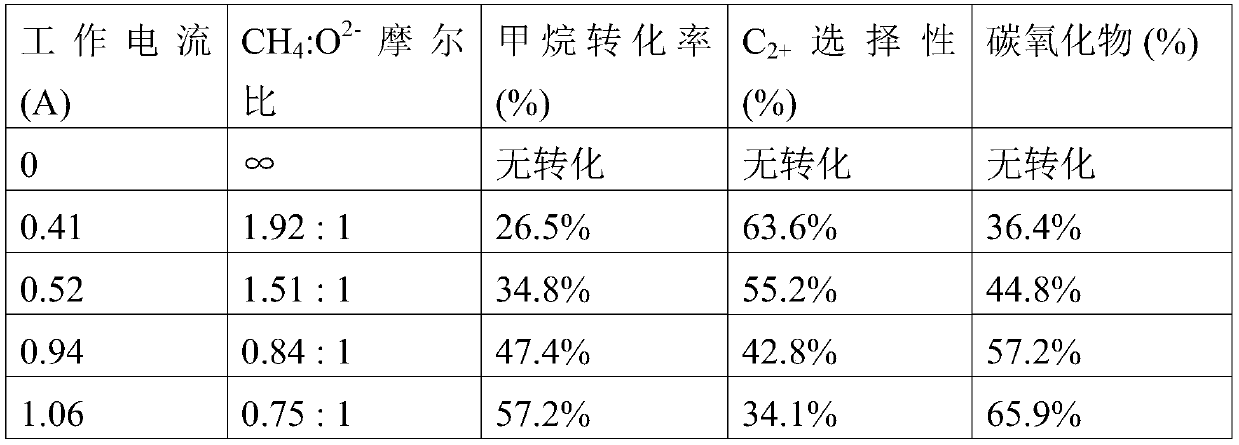

A small detachable soil column simulation device

ActiveCN106501490BSimple structureImprove sampling efficiencyWithdrawing sample devicesEarth material testingInfrared lampEvaporation

The invention relates to a small detachable soil column simulation device, which is characterized in that the device includes: a liftable support platform; a soil column bottom unit; and a number of combined column units with openings at both ends connected in series from top to bottom. , the bottom of the combined column unit at the bottom can be detachably connected to the top of the soil column bottom unit; a detachable screen is fixed above the interior of the soil column bottom unit. The detachable screen can prevent direct mixing between soil and quartz sand. ; An infrared lamp located above the uppermost combined column unit and fixedly installed on the top of the liftable support platform for simulating the evaporation process; a liquid adder fixedly installed on the top of the liftable support platform for simulating the water adding process; and , a jet is hung above the uppermost combined column unit, and the liquid doser outlet is connected to the jet through a pipeline. The invention can be widely used in soil column simulation tests.

Owner:INST OF AGRI RESOURCES & REGIONAL PLANNING CHINESE ACADEMY OF AGRI SCI

X-band frequency converter

ActiveCN104917465AAvoid direct mixingImprove frequency conversion stabilityMulti-frequency-changing modulation transferenceAudio power amplifierFrequency mixer

The invention provides an X-band frequency converter. The X-band frequency converter comprises a first frequency multiplier, a first frequency mixer, a first filter amplifier, a first frequency divider, a second frequency mixer, a second filter amplifier, a third frequency mixer, a third filter amplifier, a first power divider, a second power divider and a second frequency divider, wherein the input end of the first frequency multiplier is used for receiving an intermediate-frequency signal; the input end of the first power divider is used for receiving a high-frequency intrinsic signal; the output end of the first frequency multiplier is connected with the input end of the third filter amplifier after passing through the first frequency mixer, the first filter amplifier, the first frequency divider, the second frequency mixer, the second filter amplifier and the third frequency mixer in sequence; the output end of the first power divider is divided into two paths; one path is directly connected with the first frequency mixer, and the other path is connected with the second power divider; the output end of the second power divider is divided into two path; and one path is directly connected to the second frequency mixer, and the other path is connected with the third frequency mixer through the second frequency divider. Through adoption of the X-band frequency converter, the frequency conversion stability can be enhanced

Owner:SICHUAN SIAIPU ELECTRONICS TECH CO LTD

A kind of flame-retardant phase change microcapsule and preparation method thereof

InactiveCN109225085BImprove flame retardant performanceHigh energy storage densityHeat-exchange elementsMicroballoon preparationPolymer scienceMelamine formaldehyde resin

The invention discloses a flame-retardant phase-change microcapsule and a preparation method thereof, and relates to the technical field of energy-saving materials. The capsule contains an organic phase-change material and a capsule wall wrapping the organic phase-change material; the general formula of the organic phase-change material is C n h 2n+2 straight-chain or branched-chain alkanes, the general formula is C n h 2n The higher fatty acid of COOH, the general formula is C n h 2n One or more of the higher fatty alcohols of OH, wherein, n=12-32; the capsule wall is made of phosphorus-containing diamine monomer, melamine, formaldehyde solution, emulsifier and deionized water. The flame-retardant phase-change microcapsules of the present invention use phosphorus-containing melamine-formaldehyde resin as the capsule wall material, which greatly improves the flame-retardant performance of the phase-change microcapsules, makes up for the flammability defects of organic phase-change materials, and can also avoid The direct mixing of flame retardants and organic phase change materials ensures that the phase change microcapsules have a high energy storage density.

Owner:SICHUAN UNIV

Water dispenser internal cold water mixing speed adjustable water dispenser water dispenser and control mode of water dispenser internal cold water mixing speed adjustable water dispenser water dispenser

The invention discloses a water dispenser internal cold water mixing speed adjustable drinking water device comprising a cold tank, the top of the cold tank is provided with a cover plate, the outer side of the lower side wall of the cold tank is provided with an evaporator, the cold tank is internally provided with a water distributor, the water distributor comprises an upper water distribution disc and at least one lower water distribution disc, the cover plate, the upper water dividing disc, the lower water dividing disc and the bottom wall of the cold tank are arranged at intervals, the lower water dividing disc has a first state and a second state, and the lower water dividing disc can be switched between the first state and the second state. The invention further provides a control mode of the water drinking device. The mixing speed of cold water at the lower part of the drinking water device can be adjusted, the heating speed of the cold water at the bottom is delayed, and the cold water release capacity is improved.

Owner:SHANGHAI JIAO TONG UNIV +1

X-band frequency conversion components

ActiveCN104901628BAvoid direct mixingImprove frequency conversion stabilityMulti-frequency-changing modulation transferenceLocal oscillator signalAudio power amplifier

The present invention provides an X waveband frequency conversion assembly. The assembly includes: a first frequency multiplier, a first mixer, a first filtering amplifier, a second mixer, a second filtering amplifier, a first frequency divider, a third mixer, a third filtering amplifier, a first power divider, a second power divider, a second frequency multiplier and a second frequency divider, wherein the input end of the first frequency multiplier receives an intermediate frequency signal; the input end of the first power divider receives a high frequency local oscillator signal; an output end of the first frequency multiplier is connected to the input end of the third filtering amplifier sequentially via the first mixer, the first filtering amplifier, the second mixer, the second filtering amplifier, the first frequency divider and the third mixer; the output end of the first power divider is divided into two paths, one path is directly connected to the first mixer, while the other path is connected to the second power divider; and the output end of the second power divider is divided into two paths, one path is connected to the second mixer via the second frequency multiplier, while the other path is connected to the third mixer via the second frequency divider. The X waveband frequency conversion assembly of the present invention can increase frequency conversion stability.

Owner:SICHUAN SIAIPU ELECTRONICS TECH CO LTD

A kind of preparation method of quantum dot display panel and quantum dot display panel

The invention provides a preparation method of a quantum dot display panel and a quantum dot display panel. The preparation method comprises: preparing a red light quantum dot solution and a green light quantum dot solution whose external ligands are magnetic; A magnetic material covers the first region of the transparent substrate, and a second magnetic material with a second Curie point temperature covers the second region of the transparent substrate; the first region, the second region and the third region without deposition do not overlap each other , to obtain the magnetic deposition substrate; the magnetic deposition substrate is immersed in the red light quantum dot solution to obtain the red light quantum dot color film structure, and is immersed in the green light quantum dot solution to obtain the green light quantum dot color film structure and the quantum dot color film substrate; the quantum dot color film substrate is set in the blue light On the light emitting side of the backlight module, the blue light reflective layer is located on the side of the quantum dot color film substrate away from the blue light backlight module. The technical solution provided by the invention avoids the use of color filters, avoids the waste of blue light, optimizes the performance of quantum dots, and improves luminous efficiency.

Owner:SHENZHEN PLANCK INNOVATION TECH CO LTD

A new type of shaped phase change material and its preparation method

ActiveCN103740337BImprove performanceImprove flame retardant performanceHeat-exchange elementsMicroballoon preparationPhase change enthalpyFunctional monomer

The invention relates to a novel shaped phase-change material and a preparation method thereof. The novel shaped phase-change material is prepared from the following raw materials in parts by weight: 1-10 parts of acrylic monomers, 1-10 parts of phosphate ester functional monomer, 0.005-0.03 parts of initiator, 10-40 parts of organic phase-change materials, 50-90 parts of deionized water and 0.1-1 part of emulsifier. The novel shaped phase-change material is excellent in performance, safe and environment-friendly, not only can play good fire retardation by modification on a capsule wall through phosphate, but also compensates the defects of inflammable performance of the organic phase-change material, as a phosphate ester group is led to the capsule wall, the flame retardant property of the phase-change material is greatly improved, application of the phase-change material in the energy-saving field is expanded, direct mixing of the fire retardant and a phase-change master batch also can be avoided, high phase-change enthalpy of the phase-change material is ensured, and negative effects caused by the heat storage performance of the phase-change material is avoided.

Owner:江苏丰彩建材(集团)有限公司 +2

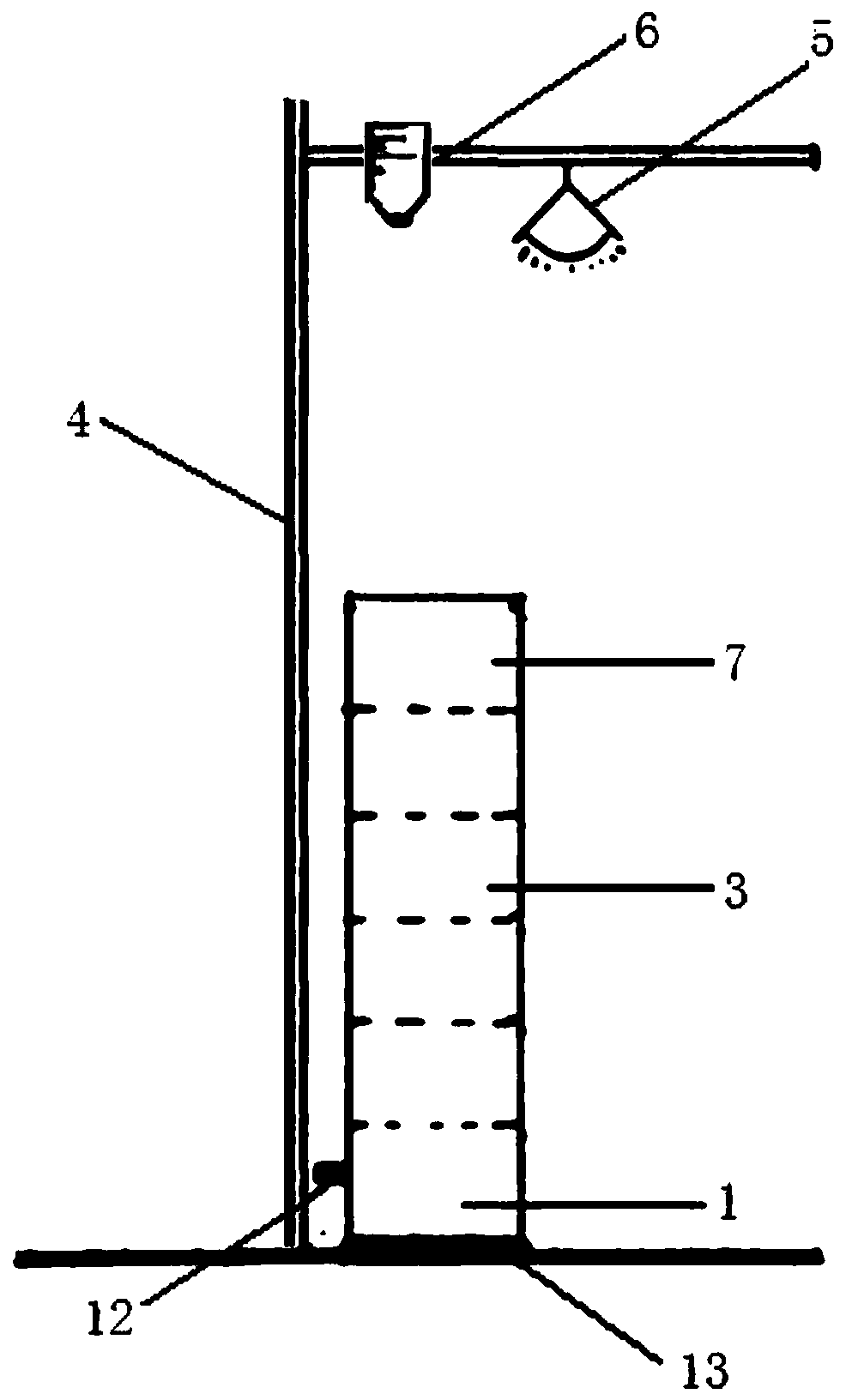

Combined fluidized bed and fixed bed coal catalytic gasification reaction device and method thereof

ActiveCN107760377BImprove conversion rateAchieve couplingGasification processes detailsCombustible gas productionPtru catalystMethanation

The invention relates to a fluidized bed and fixed bed combination type catalytic gasification apparatus and a fluidized bed and fixed bed combination type catalytic gasification method. A purpose ofthe present invention is to solve the problems of low carbon conversion rate, low gasification intensity, low methane yield, and poor operation stability and poor reliability of the gasification furnace in the prior art. The technical scheme of the present invention comprises that the fluidized bed and fixed bed combination type catalytic gasification apparatus comprises a fluidized bed gasification section on the upper portion and a fixed bed gasification section on the lower portion, the two gasification sections are connected by using a throat, a raw material inlet, a circulation synthesisgas inlet, a first-stage return material inlet and a gas distributor are arranged in the fluidized bed gasification section, and a furnace grate and a second-stage return material inlet are arranged in the fixed bed gasification section. The fluidized bed and fixed bed combination type catalytic gasification method mainly comprises that a carbon-containing raw material, a catalyst, the semi-coke particles of a first-stage return material, circulation synthesis gas and high-temperature mixed gas are subjected to pyrolysis, gasification and methanation in the fluidized bed gasification section,the incompletely-reacted coarse residue and second-stage fine ash particles enter the fixed bed gasification section, and a combustion gasification reaction is performed. With the technical scheme ofthe present invention, the problem in the prior art is well solved. The apparatus and the method of the present invention can be used in the field of the preparation of methane-rich synthesis gas fromcoal.

Owner:CHINA PETROLEUM & CHEM CORP +1

Heating body with water inlet loop air exhausting device

InactiveCN105465997ASmooth water intakeAvoid direct mixingWater heatersWater columnPneumatic pressure

A heating body with a water inlet loop air exhausting device comprises a preheating pipe, a heating pipe, a base, a cooling shell and an air-liquid separator, wherein the preheating pipe is connected with a water inlet pipe, the bottom of the preheating pipe is connected with the base and connected with the bottom of the heating pipe through a connecting pipe in the base, and the air-liquid separator is arranged on the top of the heating pipe. An exhaust outlet is formed in the top of the air-liquid separator, a slope is arranged on the inner wall of the air-liquid separator, and a water outlet is formed in the bottom of the slope. The air-liquid separator and the top of the preheating pipe are connected through an air exchange pipe which is located above the preheating pipe. A separating plate is arranged at the bottom of the air exchange pipe, and the bottom of the separating plate is lower than the joint of the water inlet pipe and the preheating pipe. The heating body with the water inlet loop air exhausting device has the advantages that when water is injected into an empty pipe of a heater, the problem of unsmooth exhausting of a U-shaped pipe is solved, the air pressure difference in water injection is eliminated, and zero-pressure water injection is achieved; in addition, through the added separating plate, the problem that the air exchange pipe loses efficacy due to the fact that a water column is sealed in the pipe because of the siphonic effect of the air exchange pipe can be solved.

Owner:NINGBO SUNLIGHT ELECTRICAL APPLIANCE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com