Injection type combustion nozzle

A burner, jet technology, applied in burners, combustion methods, combustion types, etc., can solve hidden dangers, easy tempering, serious safety and other problems, and achieve the effect of solving flame separation, preventing flame separation, and preventing tempering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

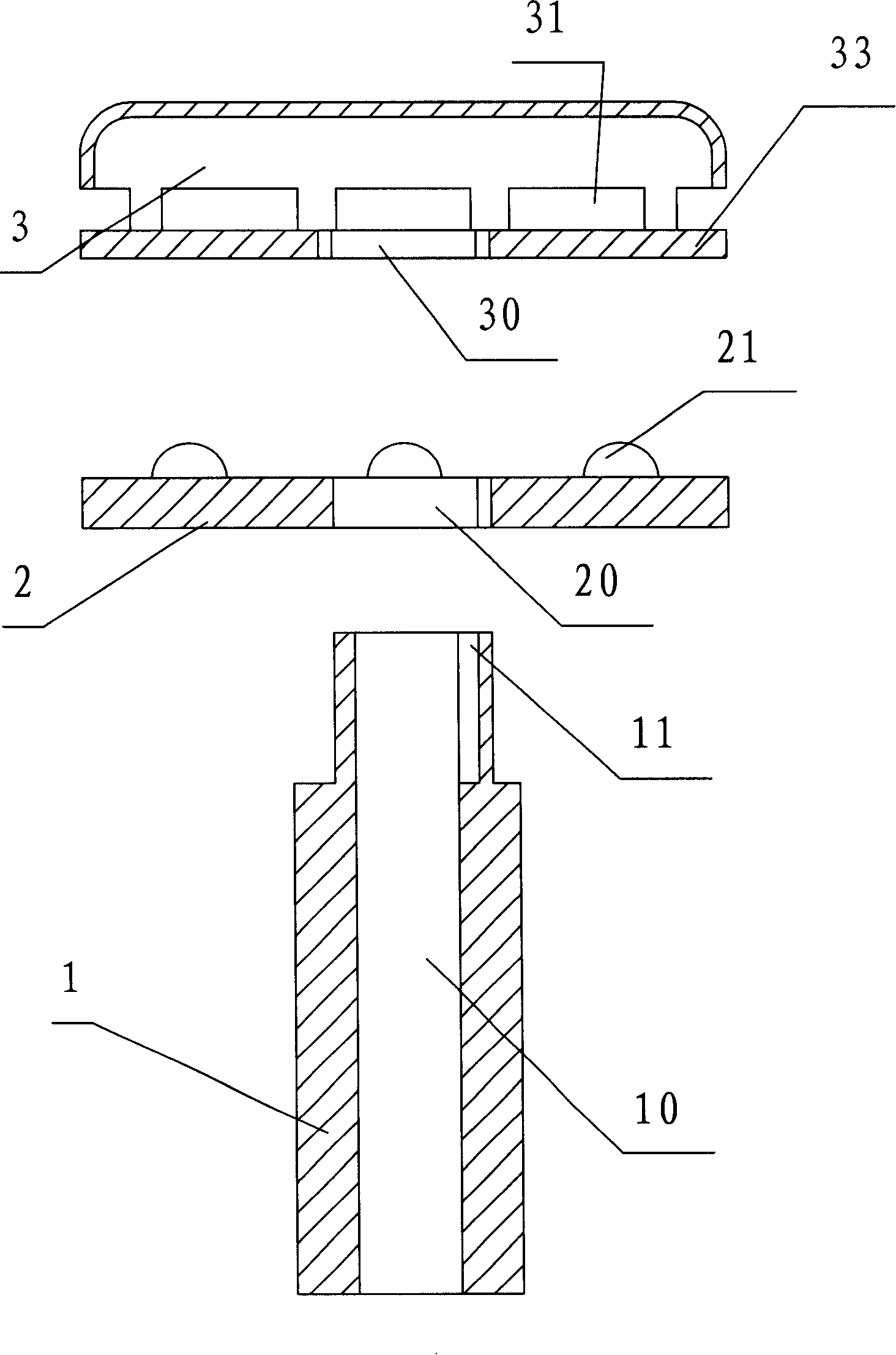

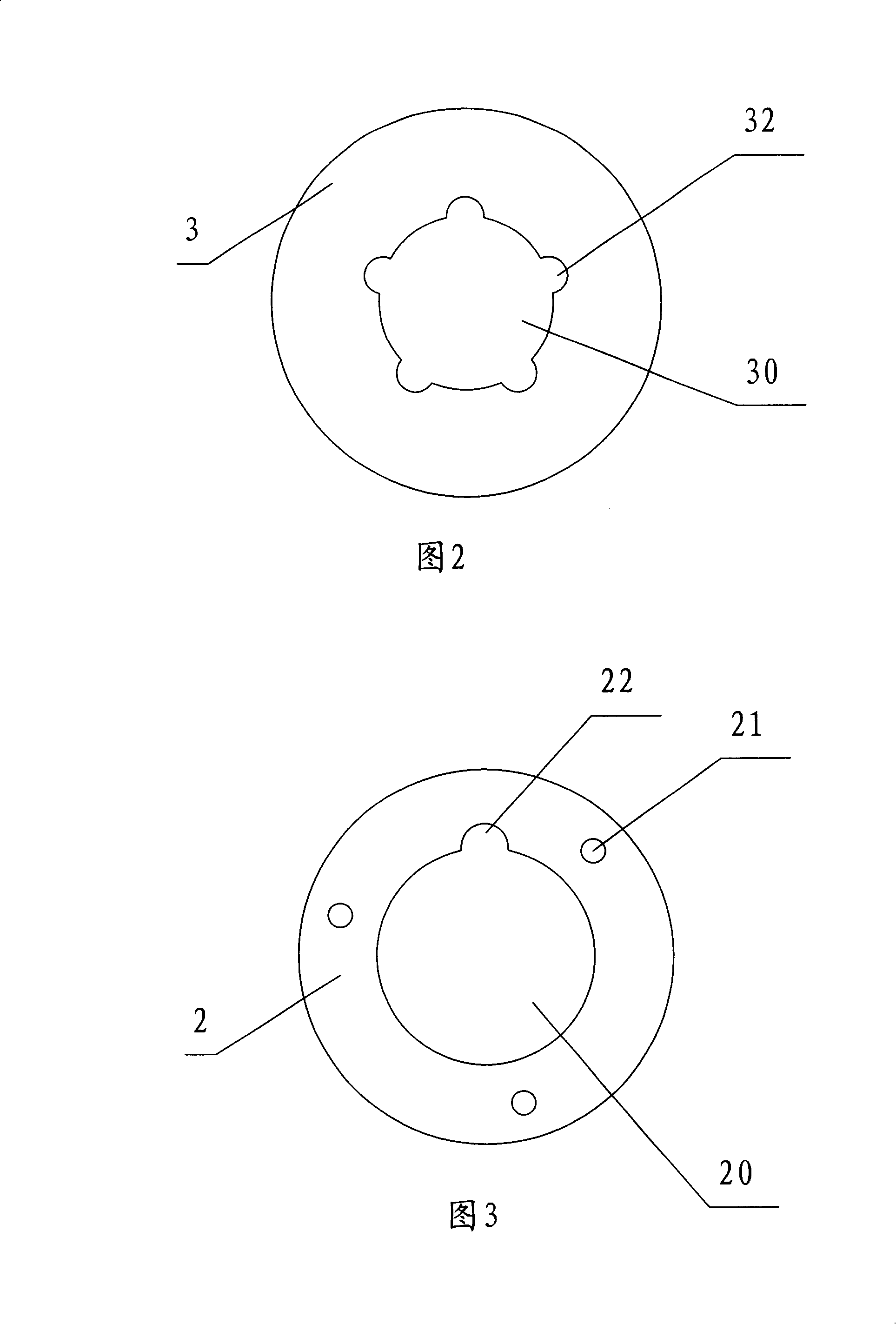

[0010] Such as figure 1 Shown is an exploded view of a jet burner body, the burner body includes a jet cylinder 1, a combustion stabilizing piece 2 and a reflection generator 3, the upper end of the jet cylinder 1 passes through the combustion stabilizing piece 2, and extends Into the retroreflection generator 3, the lower end of which is connected to the gas pipeline; the middle part of the combustion stabilizing sheet 2 is provided with a fixing hole 20 into which the spray cylinder 1 can extend, and the sheet extends upwards around the fixing hole 20 to form a protrusion 21. The retroreflection generator 3 is in the shape of an inverted pan, with a number of jet burners 31 on the side, and a support piece 33 is fixedly connected to the lower part of the side, and a spray cylinder is provided in the middle of the support piece 33 1. There are several gaps 32 (as shown in FIG. 2 ) in the shooter fixing port 30 which can be extended into. The gas returns to the combustion stab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com