Upper air inlet combustor

A burner and outer ring technology, applied in the direction of burner, gas fuel burner, combustion method, etc., can solve the problem of unstable combustion state at the fire hole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

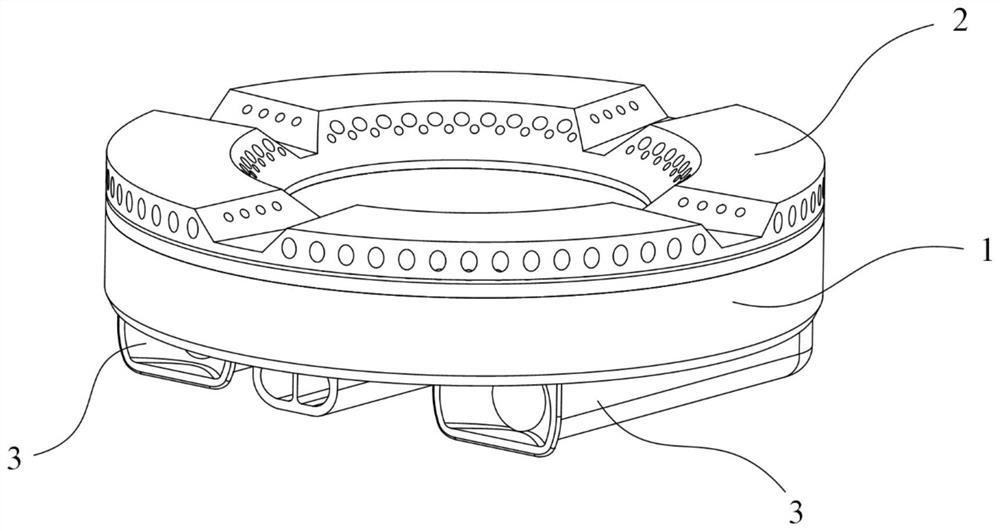

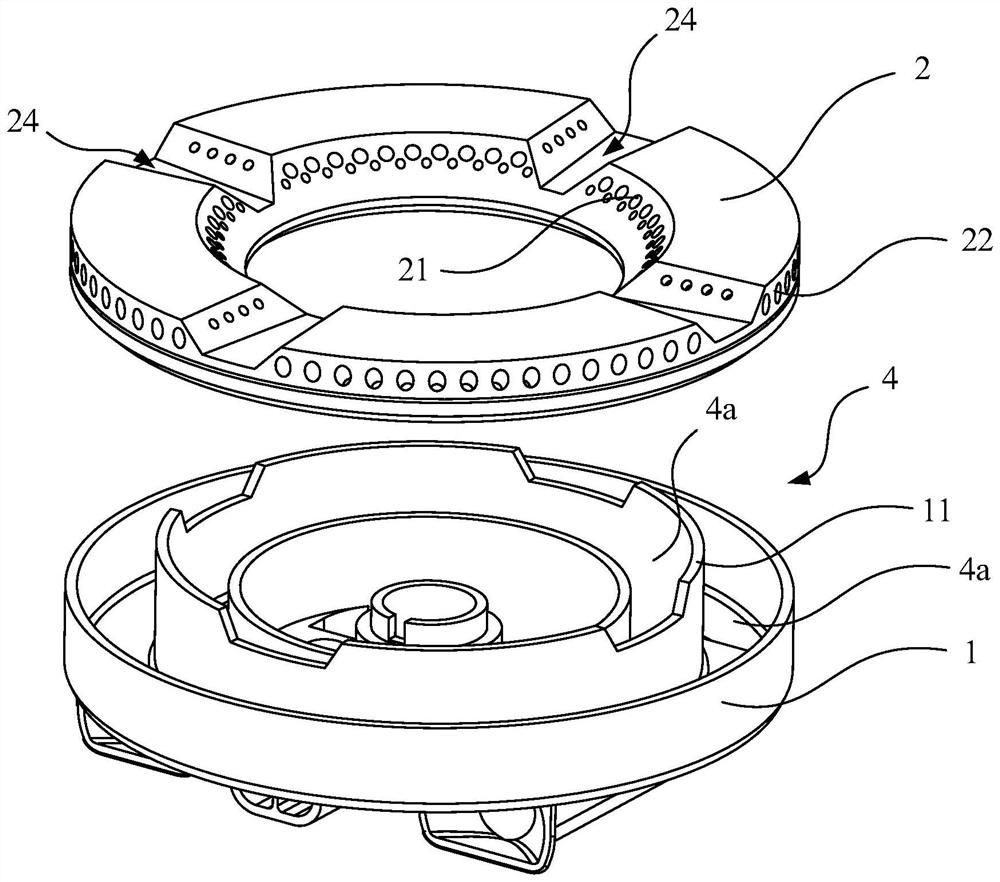

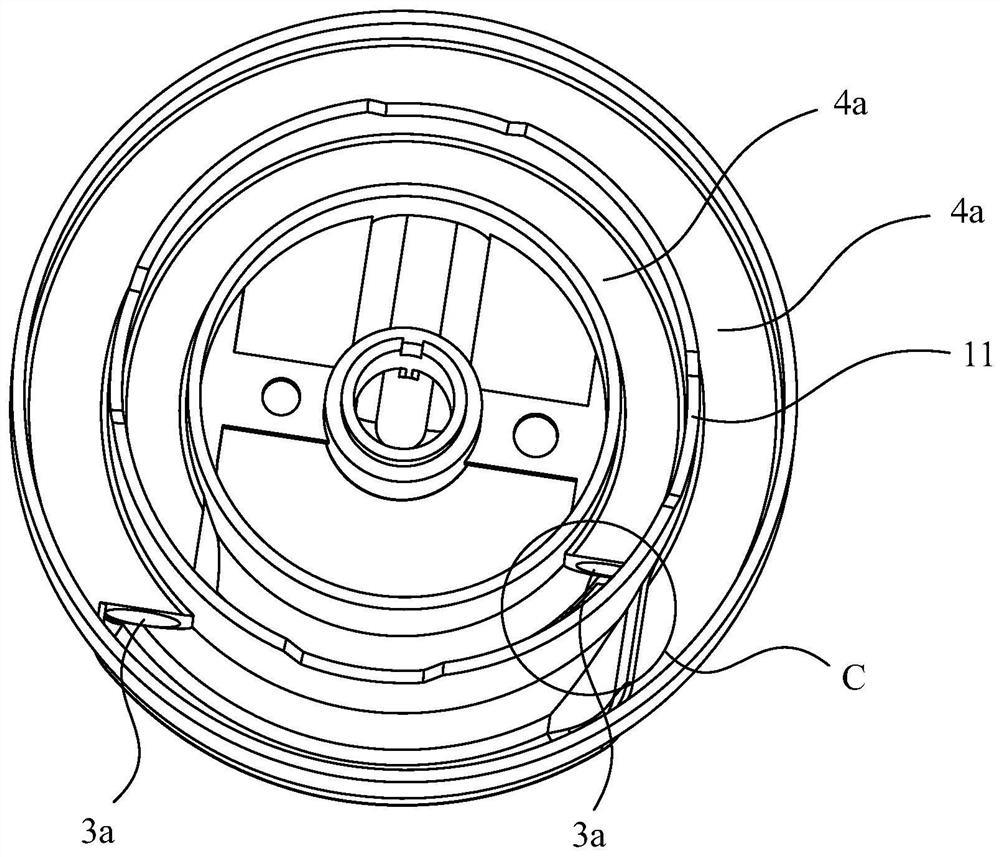

[0039] like figure 1 As shown, the present invention provides an upward air intake burner, which includes an outer ring base 1 and an outer ring fire cover 2 . like figure 2 and image 3 As shown, the upper part of the outer ring base 1 is open, and the outer ring fire cover 2 covers the opening of the outer ring base 1, and the inside of the outer ring base 1 and the outer ring fire cover 2 jointly form an outer ring air mixing chamber 4. The upper air intake burner also includes two outer ring injection tubes 3 arranged on the lower surface of the outer ring base 1, and the gas outlet ends 3a of the two outer ring injection tubes 3 are connected to the outer ring gas mixing chamber 4 , the two gas outlet ports 3a are arranged facing each other in the outer ring gas mixing chamber 4, and the outer ring gas mixing chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com