An internal combustion wave rotor exhaust mixing device based on vane guide and pressure relief

A technology of internal combustion wave rotor and wave rotor, which is applied in the direction of stator, machine/engine, mechanical equipment, etc., can solve the problem of uneven exhaust gas at the exhaust port, and achieve the effect of uniform and effective mixing of internal gas pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail in conjunction with accompanying drawing now. This figure is a simplified schematic diagram only illustrating the basic structure of the present invention in a schematic manner, so it only shows the components relevant to the present invention.

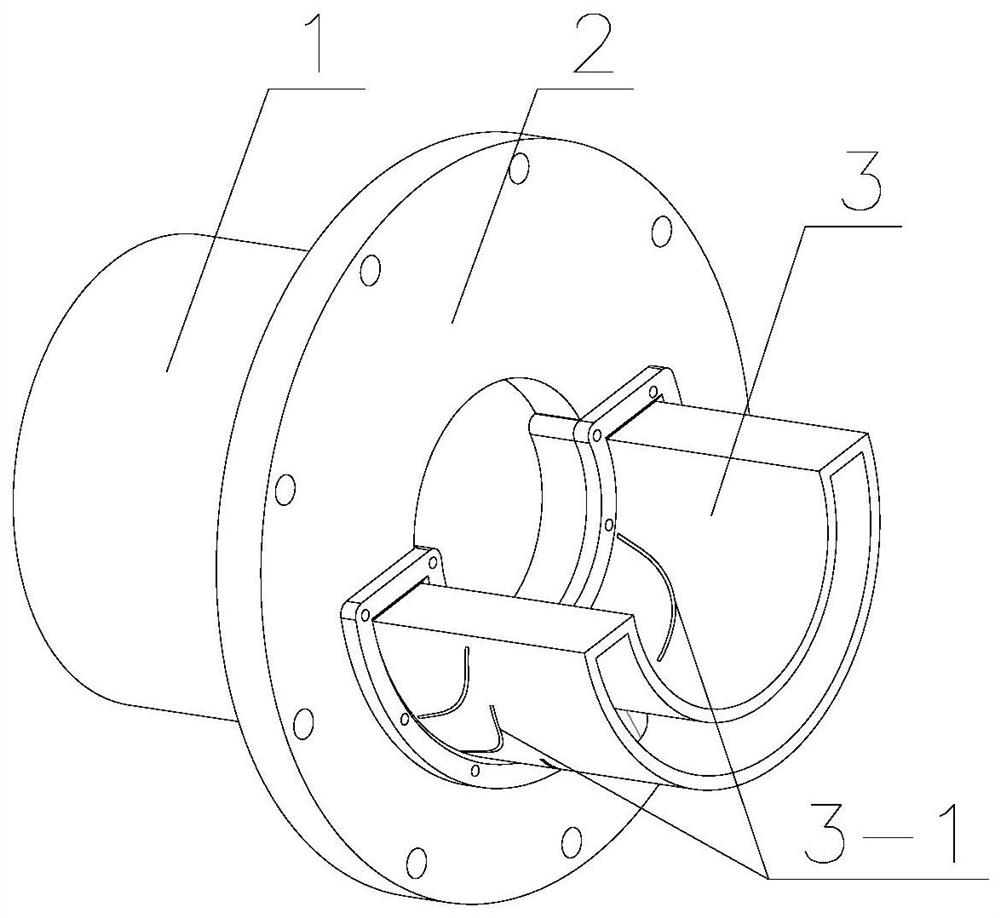

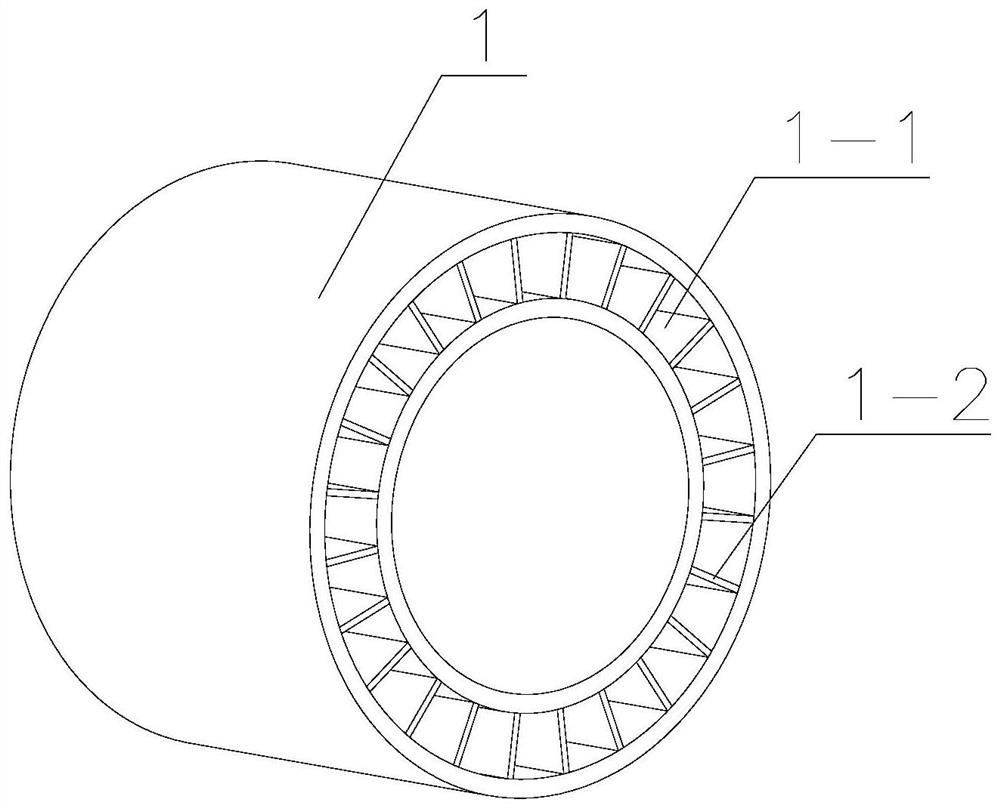

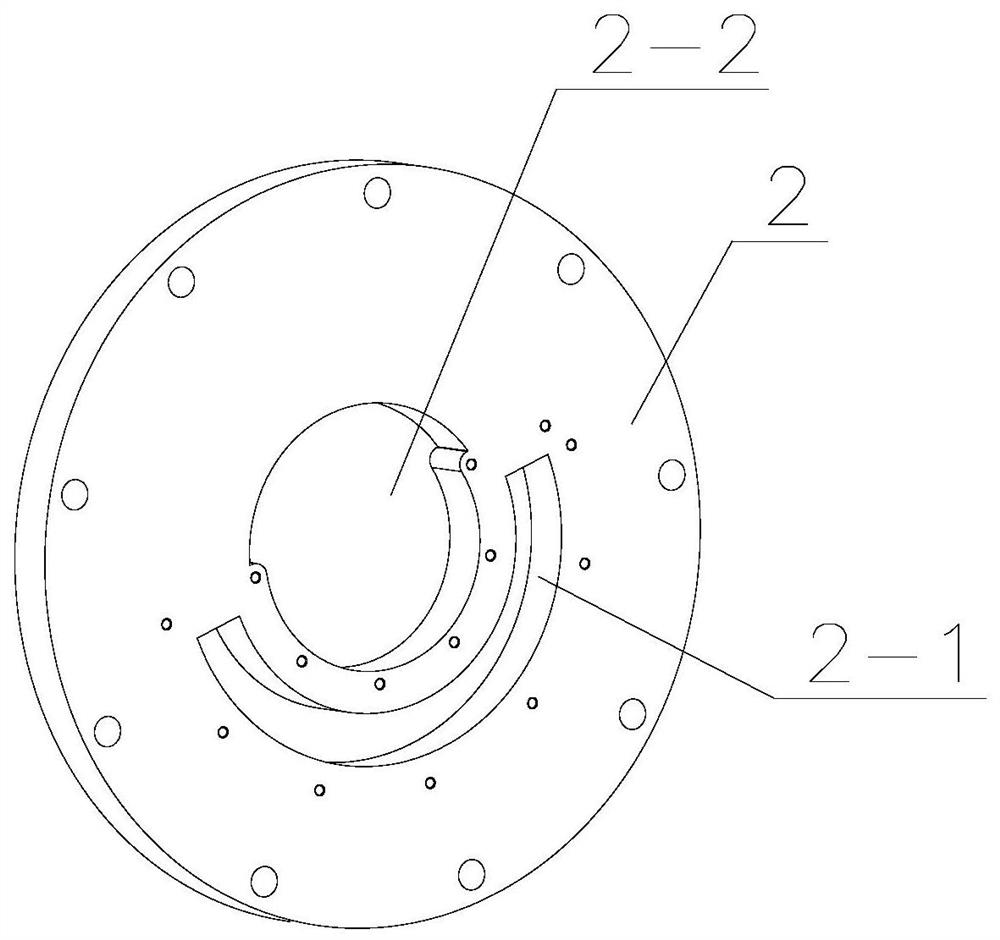

[0021] Such as Figure 1-5 As shown, an internal combustion wave rotor exhaust mixing device based on vane flow guide and pressure relief of the present invention includes a wave rotor 1, a sealing disk 2 and an exhaust port 3, and an annular cavity is arranged inside the wave rotor 1, A plurality of partitions 1-2 arranged in the radial direction are arranged at circumferential intervals in the annular cavity to divide the annular cavity into a plurality of wave rotor passages 1-1;

[0022] The wave rotor 1 is arranged on one end of the sealing plate 2 and is airtightly connected with the sealing plate 2. The end surface of the wave rotor 1 and the side surface of the outlet s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com