A moving contact of an arc extinguishing chamber, an arc extinguishing chamber, and a high-voltage circuit breaker

A moving contact and interrupter technology, applied in high-voltage air circuit breakers, high-voltage/high-current switches, circuits, etc., can solve the problems of reduced sealing performance, large number of parts, and increased operating power of circuit breakers to achieve good sliding Effects of sealing performance, inner cavity volume reduction, and processing cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0023] The first specific embodiment of the high-voltage circuit breaker of the present invention includes an arc extinguishing chamber. Since other structures do not involve the improvement of the present invention, a detailed description is omitted.

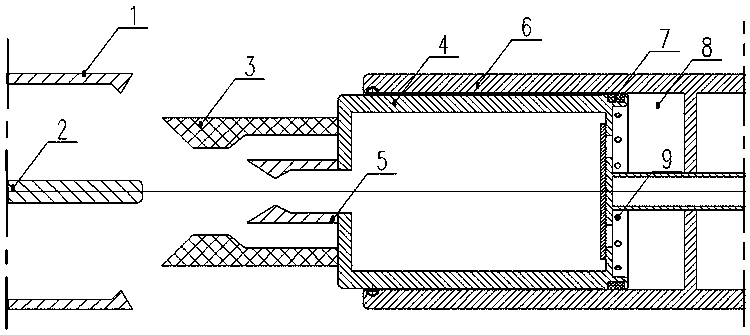

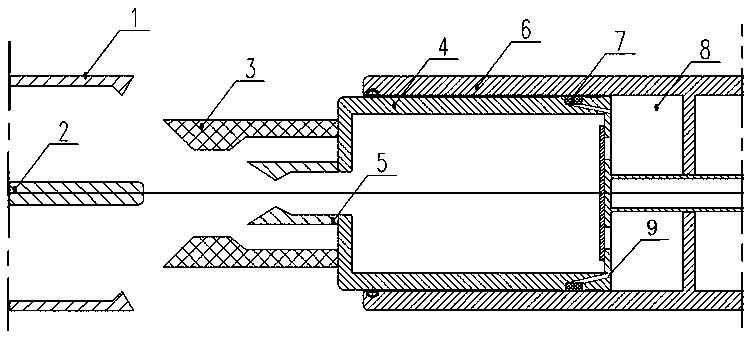

[0024] The structure of the interrupter is as figure 1 As shown, in this embodiment, the arc extinguishing chamber is a self-energizing arc extinguishing chamber, which includes moving and static contacts arranged oppositely. The static contact includes a static contact base 1 and a static contact 2. The moving contact includes a moving main contact 4 and a moving contact 5 and a nozzle 3 arranged at the front end of the moving main contact 4, that is, one end facing the static contact. The movable contact is mounted in the conductive base 6 for guiding movement, and is electrically connected to the conductive base 6 through a spring contact guide. The conductive seat 6 has a cylindrical structure, and the movable main contact 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com