Two-stage screw feeding anti-tempering automatic slag removing burning device

A screw feeding device and screw feeding technology are applied in the field of two-stage screw feeding anti-tempering automatic slag removal combustion device, which can solve the problems of affecting air holes, biomass particles on fire, and particle powder cannot be separated in time, so as to solve the problems of return Fire problems, the effect of improving combustion quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

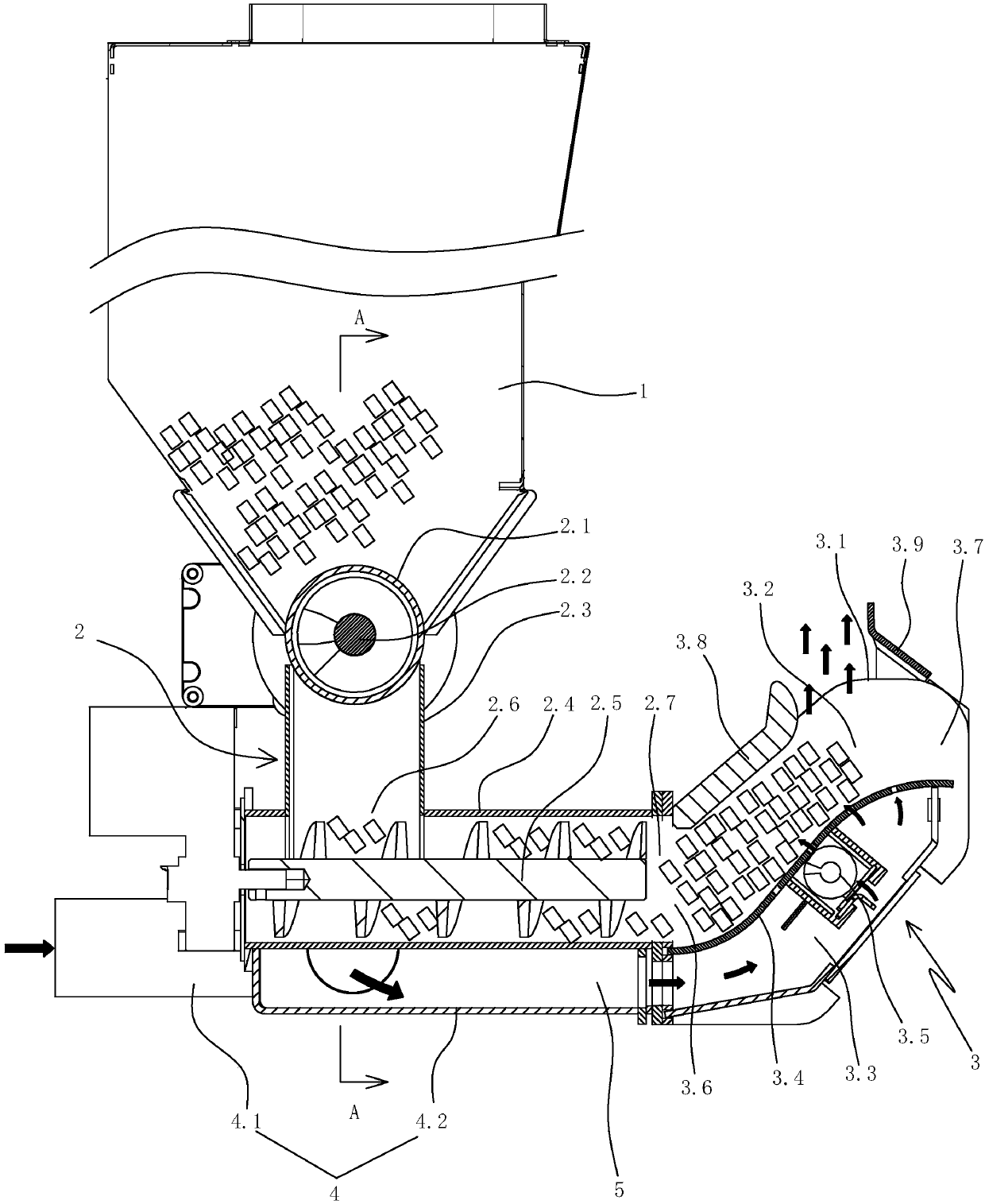

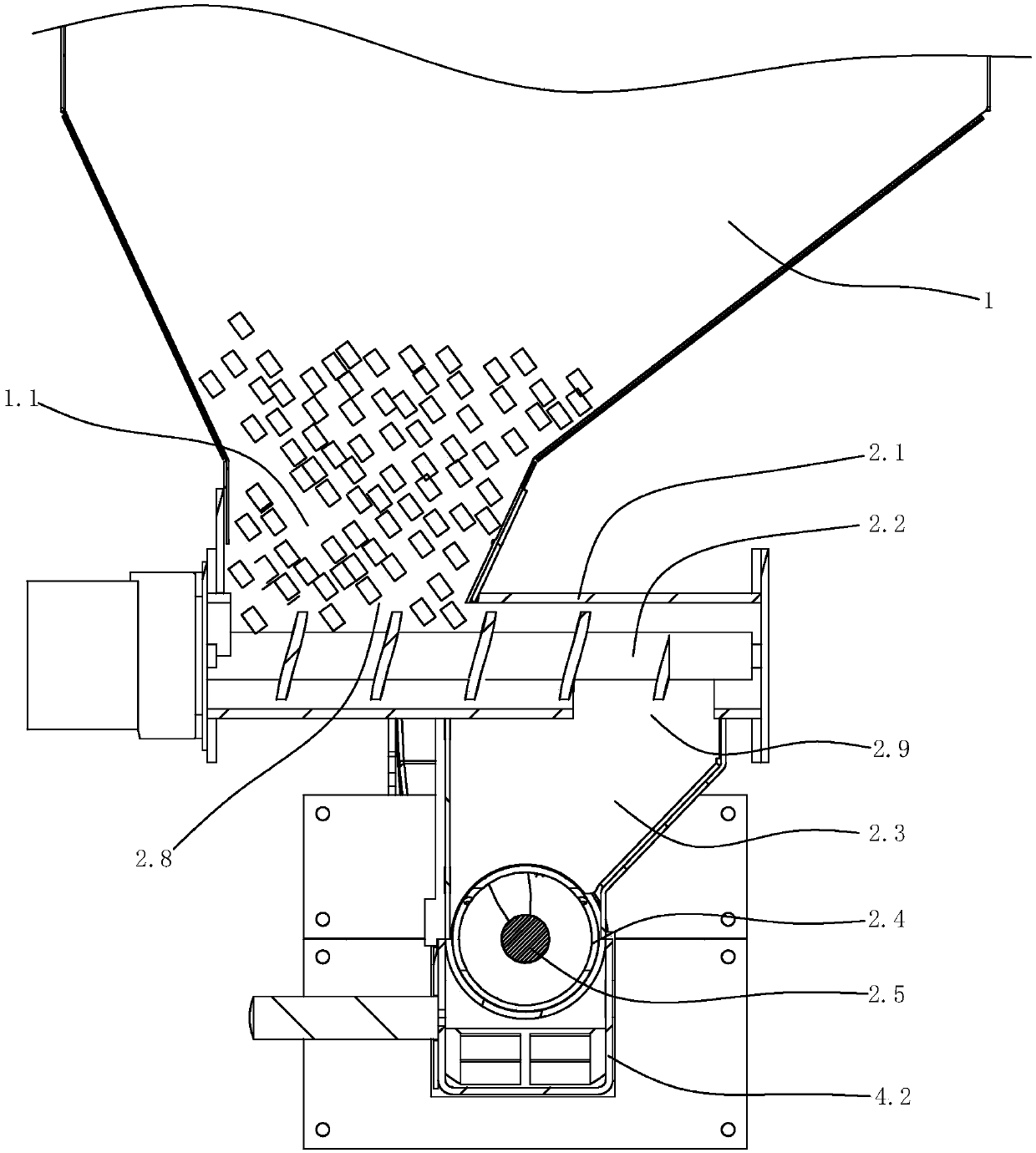

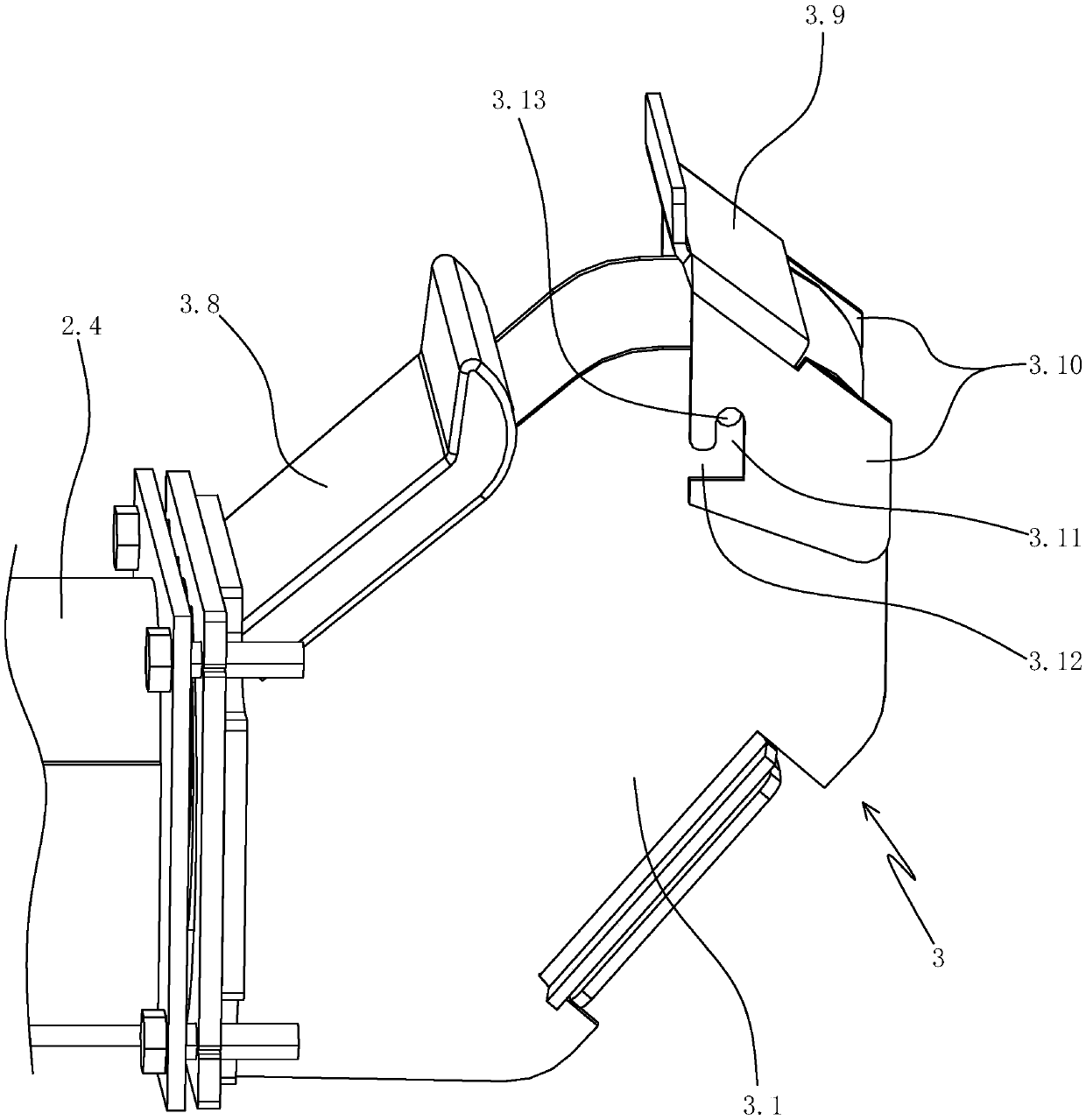

[0037] Specific embodiment one: as figure 1 , figure 2 As shown, a two-stage screw feeding anti-tempering automatic slag removal combustion device includes a material box 1, a two-stage screw feeding device 2 and a self-cleaning ash and slag combustion device 3.

[0038] The bottom of feed box 1 is funnel-shaped. The bottom of the feed box is provided with a blanking port 1.1.

[0039] The two-stage screw feeding device includes an upper feeding cylinder 2.1, an upper feeding auger 2.2 rotatingly arranged in the upper feeding cylinder, an upper driving motor for driving the upper feeding auger, and an upward opening on the outer surface of the upper feeding cylinder. Upper feeding barrel inlet 2.8, upper feeding barrel outlet 2.9 which is arranged on the outer surface of the upper feeding barrel opening downwards, lower feeding barrel 2.4 positioned below the upper feeding barrel, rotation of the lower feeding twist arranged in the lower feeding barrel Dragon 2.5, the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com