Dryness improving device and method for improving steam dryness of steam injection boiler

A technology for steam injection boilers and lifters, which is applied to the components of steam boilers, steam boilers, steam boiler accessories, etc., can solve the problem of poor fuel atomization effect, sealing structure that does not meet sealing requirements, and unreasonable combustion chamber structure. problem, to achieve the effect of easy disassembly and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

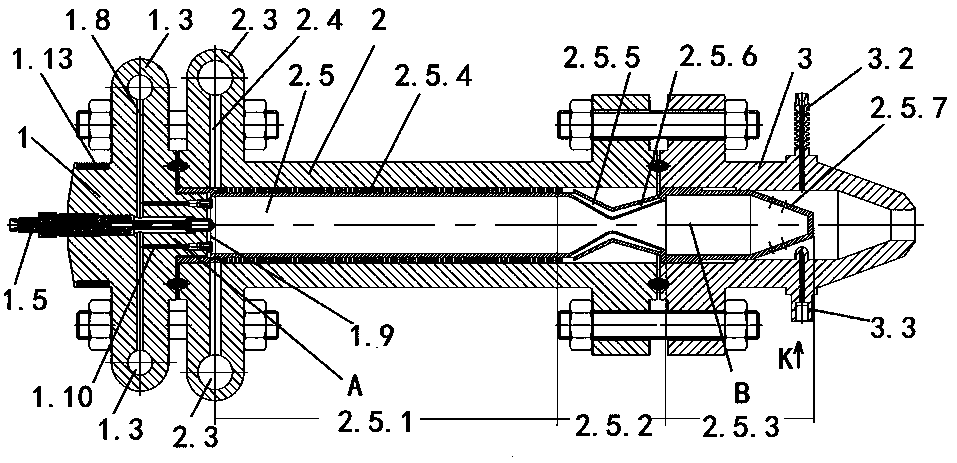

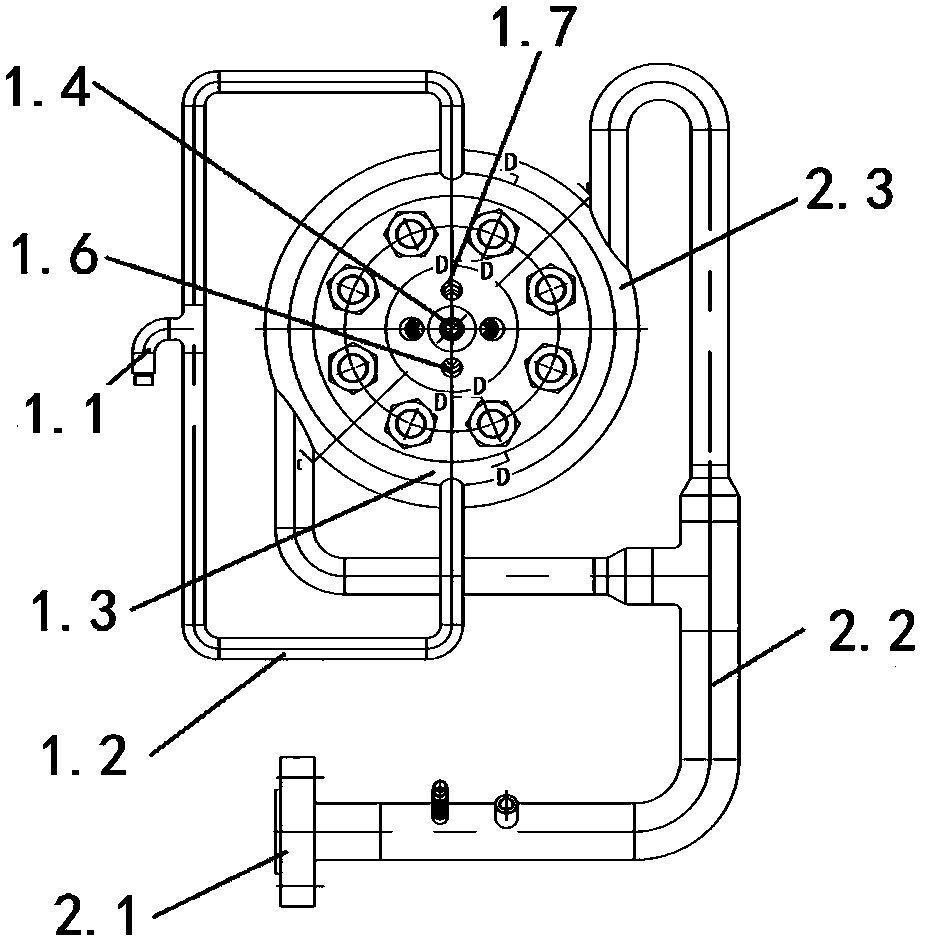

[0036] Embodiment 1, with reference to attached Figure 1-6 , a dryness lifter for improving the steam dryness of a steam injection boiler mentioned in the present invention mainly includes a front end head 1, a cylinder body 2, and a rear end head 3, wherein the front end head 1 and the cylinder body 2, the cylinder body 2 and the rear end head The ends 3 are all connected in the form of flanges.

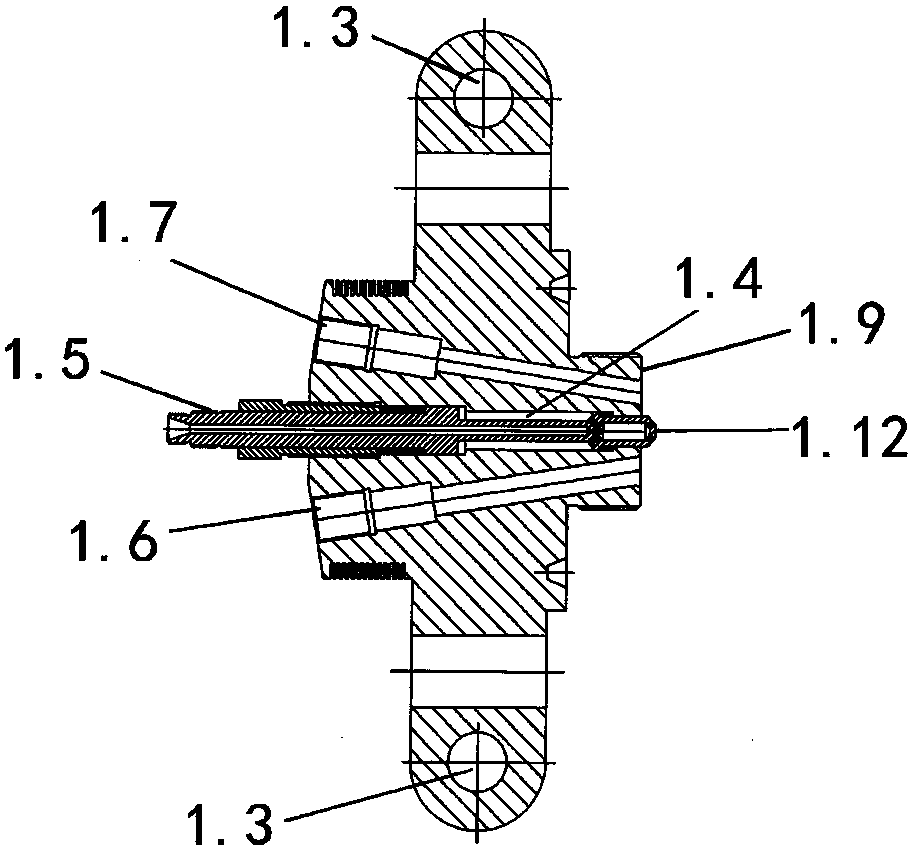

[0037] The front end head 1 is provided with a compressed air inlet 1.1, a compressed air connecting pipe 1.2, a compressed air intake passage 1.3, a fuel pipe passage 1.4, a fuel pipe 1.5, an ignition rod passage 1.6, and a flame detector passage 1.7. The compressed air intake channel 1.3, the fuel pipe channel 1.4, the ignition rod channel 1.6, and the flame detector channel 1.7 communicate with the combustion tube 2.5 respectively. The fuel pipe 1.5, the ignition rod, the flame detector and the corresponding passages are all fastened on the front end head 1 through threaded cap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com