Stove combustor assembly

A burner and total process technology, applied in the field of cookers, can solve the problems of small combustion chamber, incomplete combustion of gas, and fire of the cooker, and achieve the effect of increasing the space of the combustion chamber, fully burning the gas, and prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

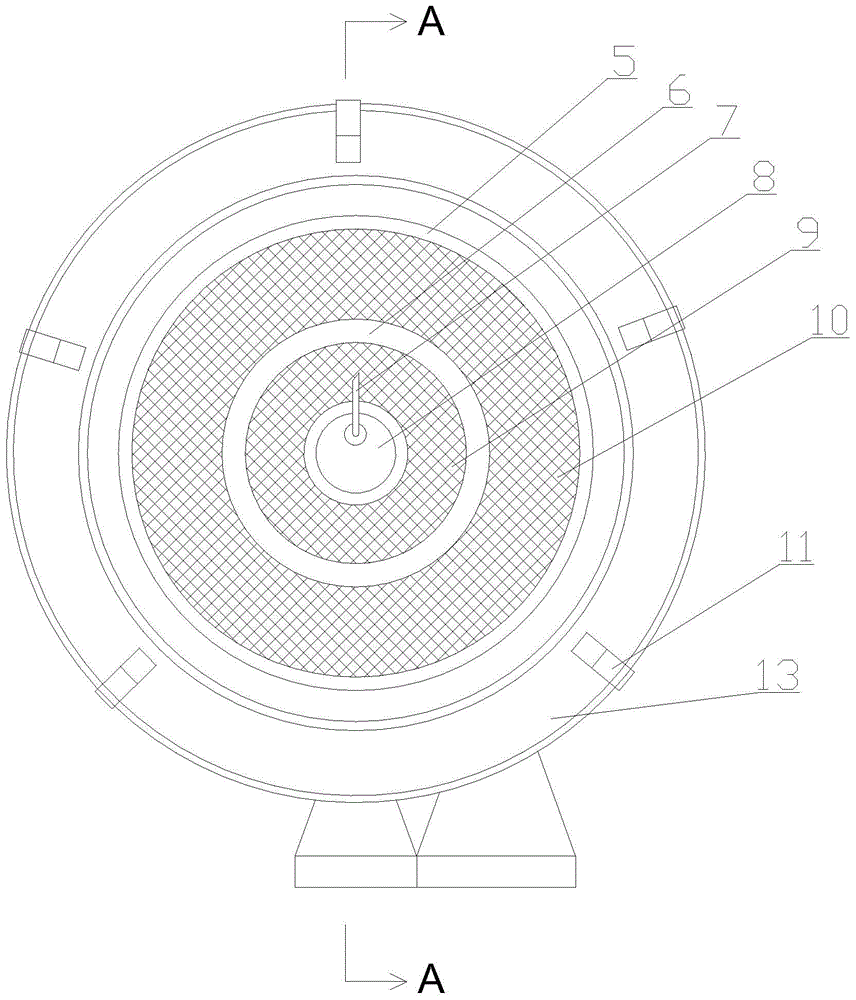

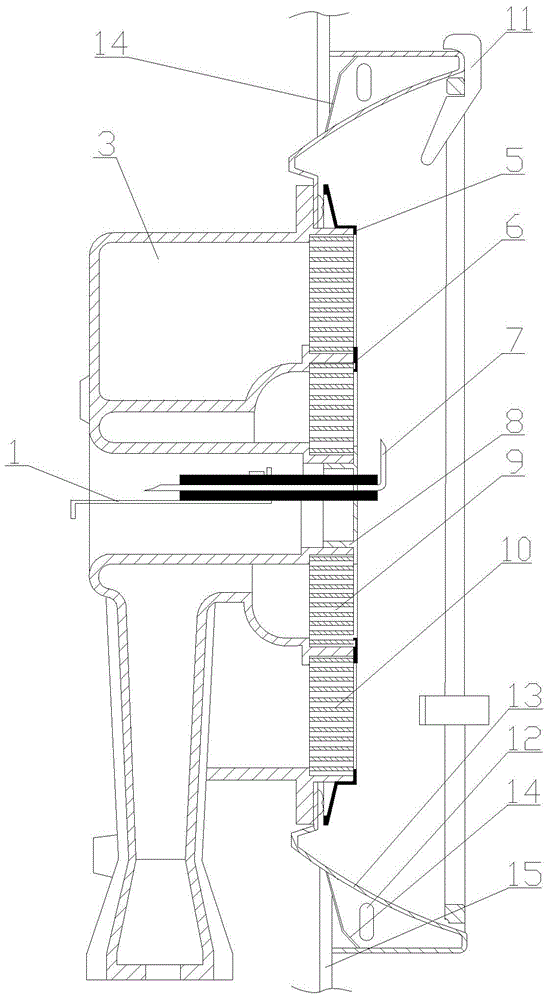

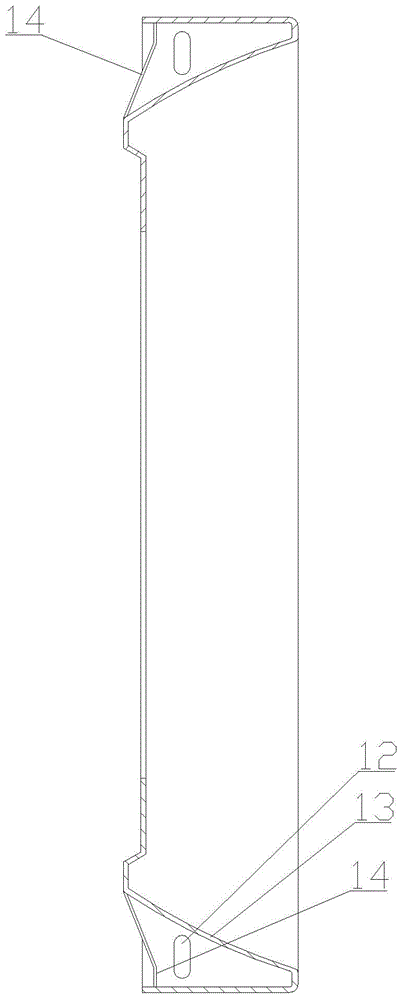

[0014] Such as figure 1 , figure 2 and image 3 As shown, the overall process of the cooker burner includes: ignition plate support 1, ignition needle, combustion chamber 3, No. Ⅰ decorative ring 5, No. Ⅱ decorative ring 6, induction needle 7, center decorative ring 8, inner ring burning plate 9, Outer ring combustion disc 10, stove frame 11, air hole 12, heat preservation disc 13, heat insulation board 14, cooker panel 15. The combustion chamber 3 of the burner is a double annular structure, and the outer ring and the inner ring are relatively isolated from the space formed by the combustion disc. The diameter range of the annular combustion chamber is 165-180 mm, and the height range of the combustion chamber is 64-90 mm.

[0015] The ignition device composed of the ignition plate bracket 1 and the ignition needle is installed at the center of the burner, so that the overall structure of the burner is more compact, and the gas ignition rate is relatively improved. The an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com