Feeding system of biomass boiler

A biomass boiler and feeding system technology, applied in the direction of burning fuel in melting state, combustion type, combustion method, etc., can solve deflagration or abnormal sudden positive pressure, affecting continuous and uniform feeding requirements of the boiler feeding system, Damage to the fuel delivery system and other problems, to achieve the effect of solving the backlog of fuel tumbling, improving the problem of fuel bridging, and preventing the problem of backfire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

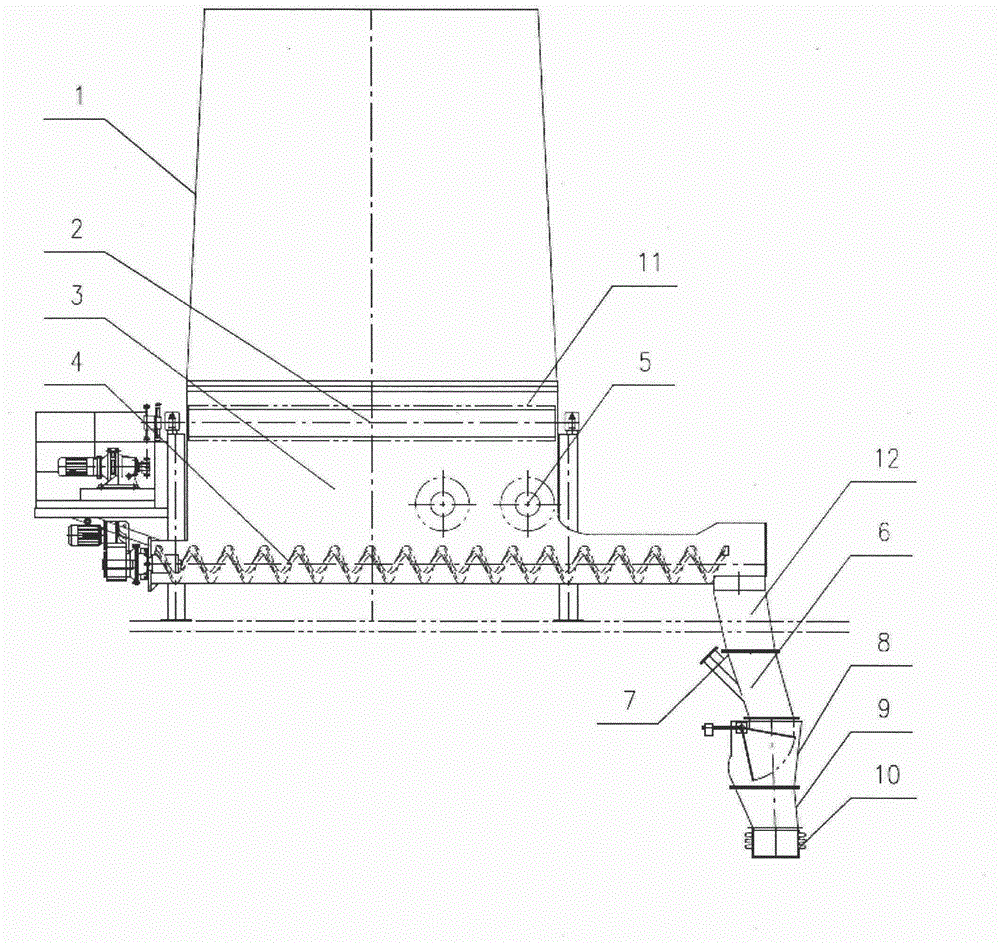

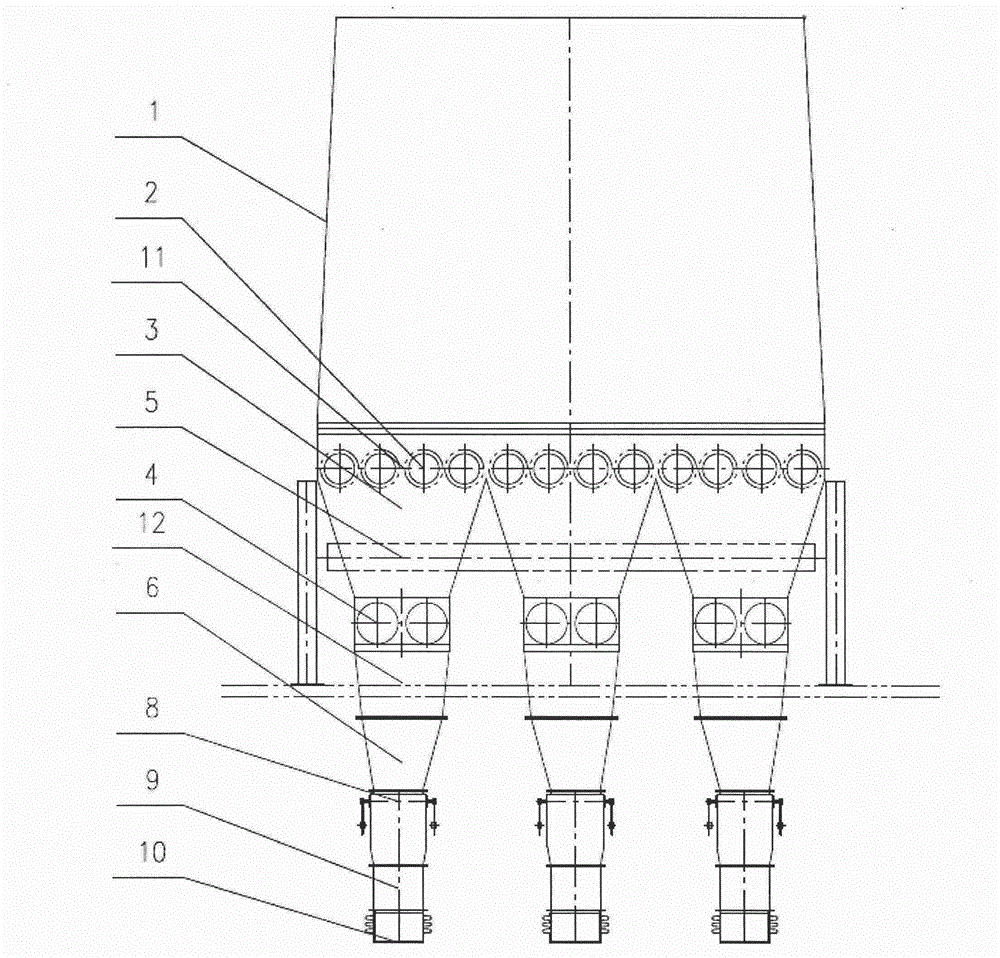

[0012] A biomass boiler feeding system, including a large silo (1), a longitudinal feeding device (2), a small silo (3), a screw conveyor (4), a slide pipe (6), and a flame arrester (8) , transition pipe (9), expansion joint (10), transition blanking pipe (12), characterized in that: it also includes a horizontal feeding device (5), air duct (7), and the air duct (7) is obliquely inserted and welded In the slide pipe (6), the lower part of the slide pipe (6) is directly connected to the flame arrester (8), and the lower part of the flame arrester (8) is directly connected to the transition pipe (9), and the transition pipe (9) passes through the expansion joint (10) Connected with the feed pipe of the boiler, two sets of horizontal feeding devices (5) are arranged in the small silo (3), and six sets of vertical feeding devices (2) are arranged in the large hopper (1). Group vertical material shifting device (2) is made of adjacent two material shifting cylinders (11). The wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com