Detonating type flame arrester

A flame arrester and detonation technology, applied in the field of detonation type flame arresters, can solve the problems of low safety, obstruction and high production cost, and achieve the effects of obvious fire extinguishing effect, improved safety factor and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

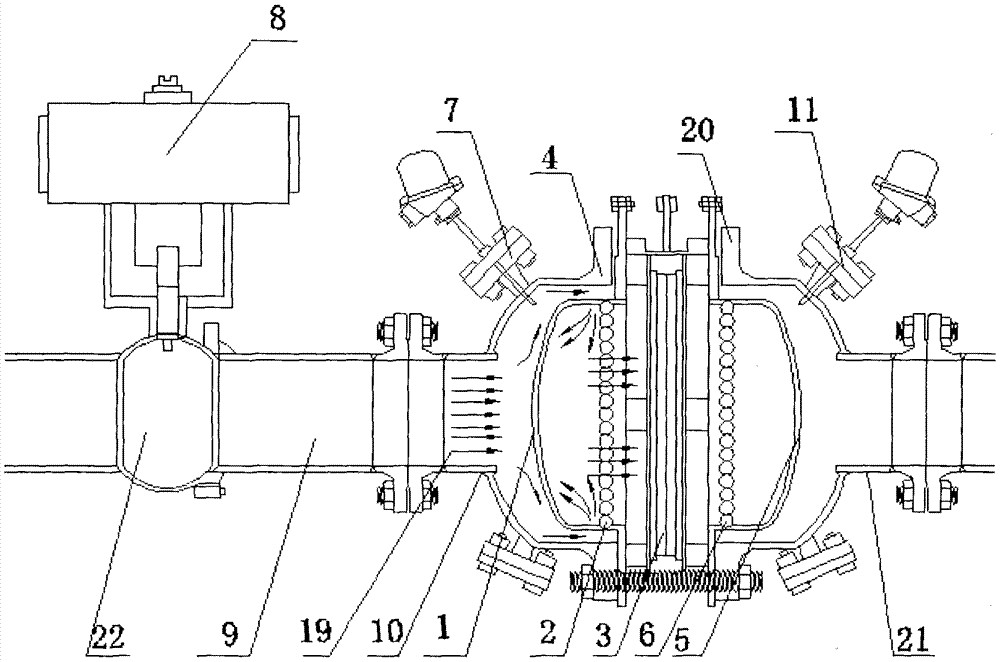

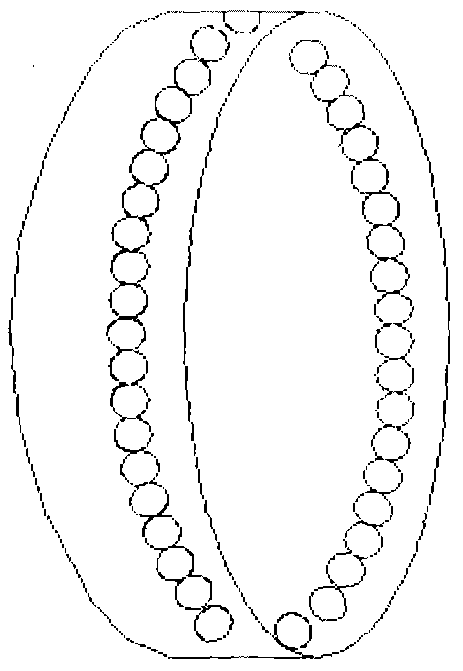

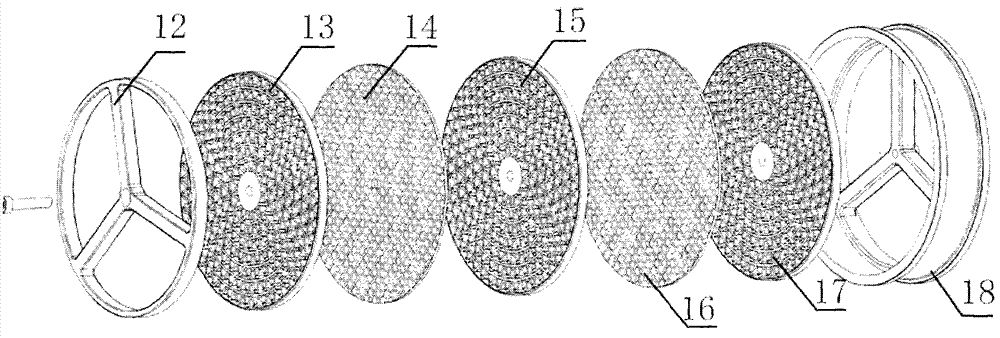

[0016] like figure 1 , 2 As shown in , 3, the detonation type flame arrester includes shells 4, 20, flame arresters 3 and pipe joints 10, 21, and the shell 4 and the shell 20 are connected together by bolts, which is characterized in that: the shell 4 and the shell 20 There is a fire stop plate 3 between them, and buffer devices 1 and 5 are arranged between the pipe joints 10 and 21 and the fire stop plate 3 respectively. The edges of the buffer devices 1 and 5 are provided with a circle of through holes 2 and 6. There are microwave temperature control detectors 7 and 11 respectively on the upper part, the pipe joint 10 is connected in series with the cut-off valve 22 through the pipeline 9, and the cut-off valve 22 is connected with the temperature control receiver 8. The shape of the buffer devices 1 and 5 is bowl-shaped, The shape of the through holes 2 and 6 is circular. When in use, the flame 19 enters the expansion space formed between the buffer device 1 and the casin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com