Device and method for purifying and concentrating coal bed gas and treating produced water

A processing device and coalbed methane technology, which is applied in the field of surface devices, concentration and produced water treatment devices, and the purification of coalbed methane, can solve the problems of low concentration of coalbed methane resources, difficult processing of produced water, and difficult mining, etc., to achieve reduction Auxiliary treatment equipment, initial investment reduction, water saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

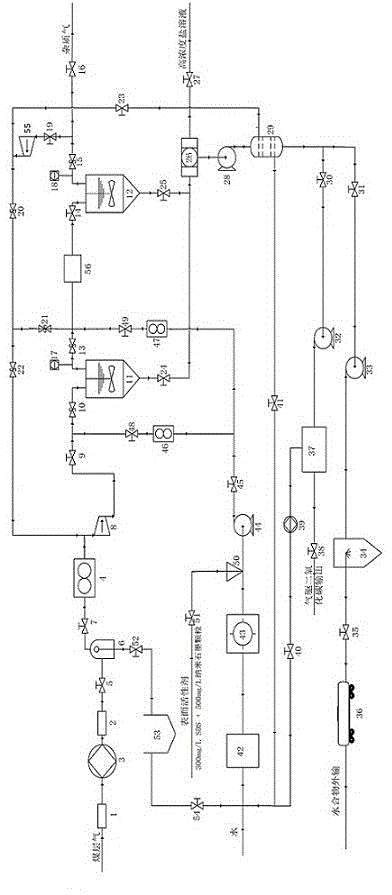

[0018] like figure 1 As shown, the present invention mainly consists of a wet flame arrester; a self-operated pressure valve; a water ring vacuum pump; a gas flow meter; a one-way valve; a separator; a fireproof and explosion-proof compressor; a safety valve; valve; gas concentration monitor; shut-off valve; filter; one-way liquid valve; slurry pump; three-phase separator; granulator; shut-off valve; transport vehicle; hydrate decomposition unit; water pump; ice making device Grinding device; liquid flow meter; Laval spray valve; clarifier. composition.

[0019] Its specific operation mode is mainly divided into the following points.

[0020](1) The produced coalbed methane passes through the wet flame arrester 1 under the action of the water ring vacuum pump 3, and enters the separator 6 through the dry flame arrester 2 through the first one-way gas valve 5 to separate and remove the produced water and solid impurities. The gas also acts as a buffer within the separator. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com