Energy-saving gas burner

A technology for gas stoves and burners, applied in the direction of burners, combustion methods, combustion types, etc., can solve problems affecting safety, waste, insufficient combustion, etc., to solve the burner backfire, improve stability, and improve safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is further described below in conjunction with specific embodiments.

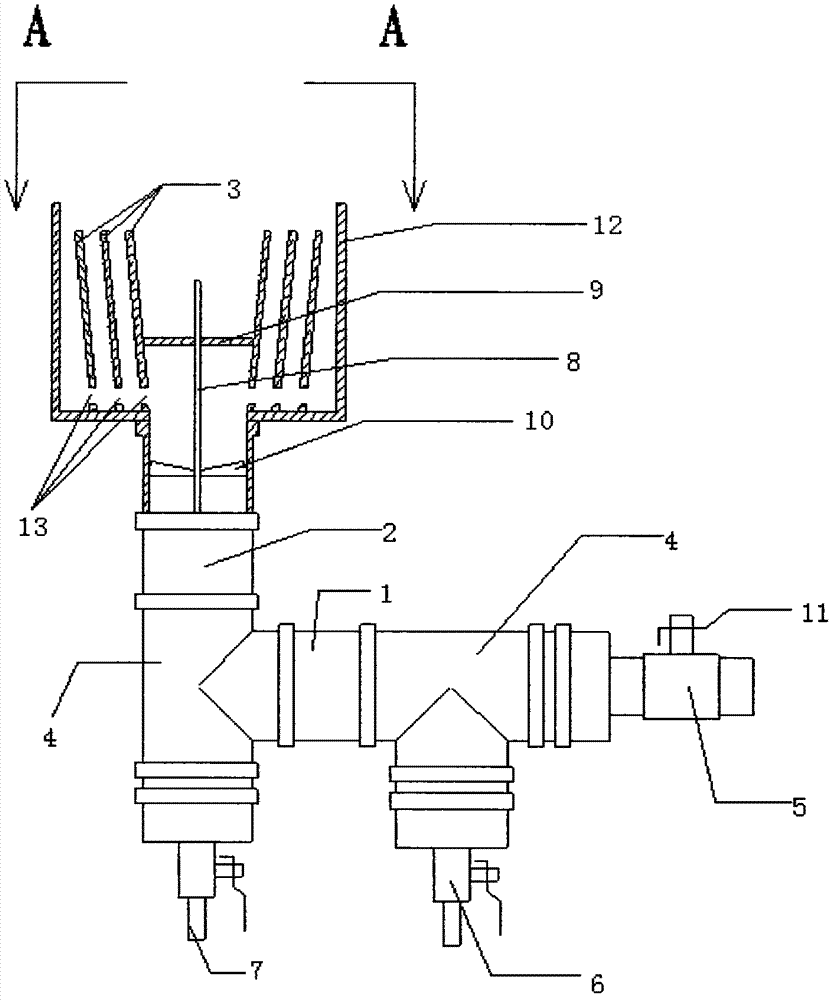

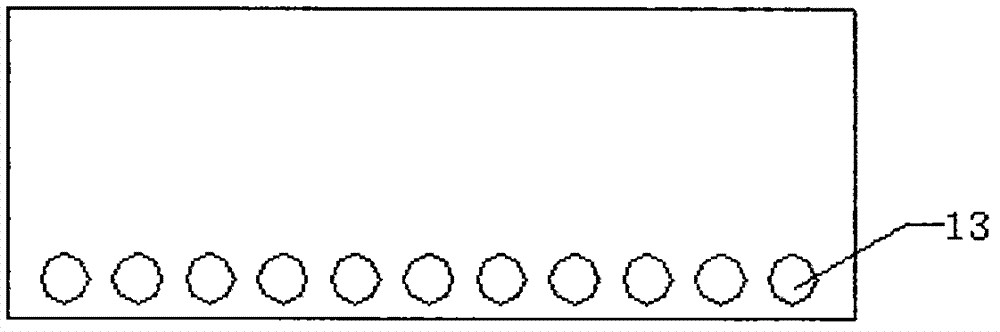

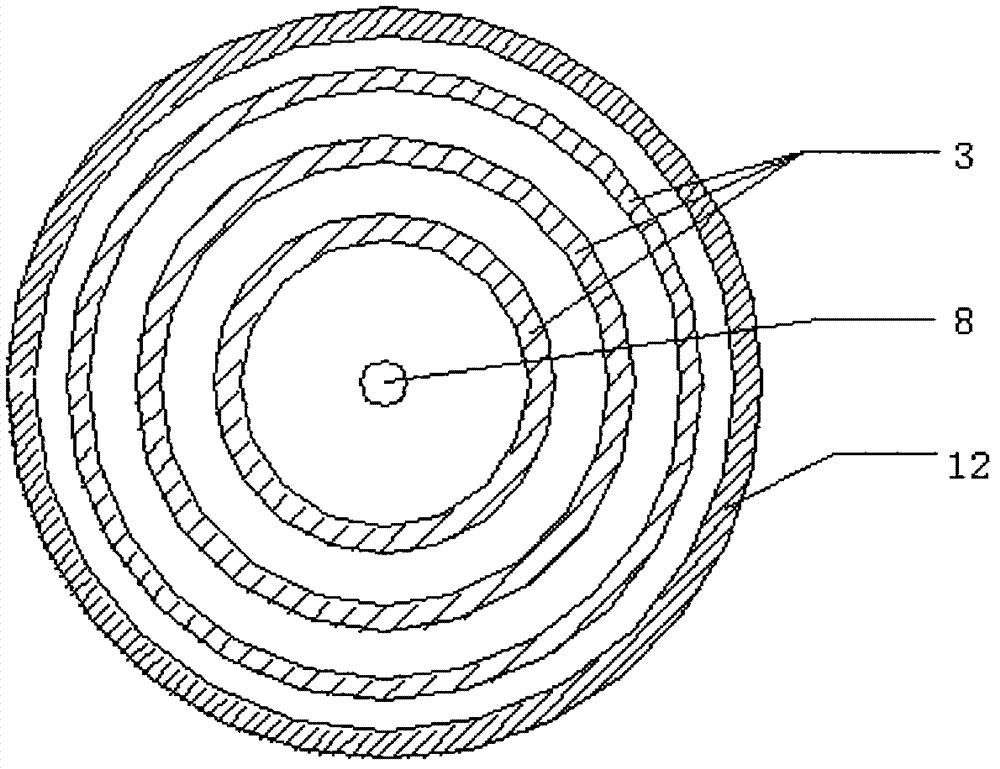

[0018] Such as Figure 1-3 Shown, 1. a kind of energy-saving gas burner head, comprises front road mixing chamber (1), back road mixing chamber (2) and burner head part, and described front road mixing chamber (1) is passed through tee joint (4) respectively It is connected with the air inlet control valve (5) and the gas inlet valve (6); one end of the rear mixing chamber (2) is respectively connected with the front mixing chamber (1) and the water discharge valve (7) through a three-way joint (4) , the other end of the rear mixing chamber (2) is connected to the burner part, and the burner part includes a burner shell (12), a gas distributor (10), a flame tube (8), and a burner sealing plate (9) And the gas guide sleeve (3), the flame tube (8) is located in the center of the furnace head part, and the lower part is connected to the subsequent mixing chamber (2) through the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com