Combined fluidized bed biomass boiler

A technology of biomass boiler and composite flow, which is applied in the direction of fluidized bed combustion equipment, fuel burning in a molten state, lighting and heating equipment, etc., can solve the problems of fire in the silo and reduce combustion efficiency, and achieve good ignition state and improved Thermal efficiency and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

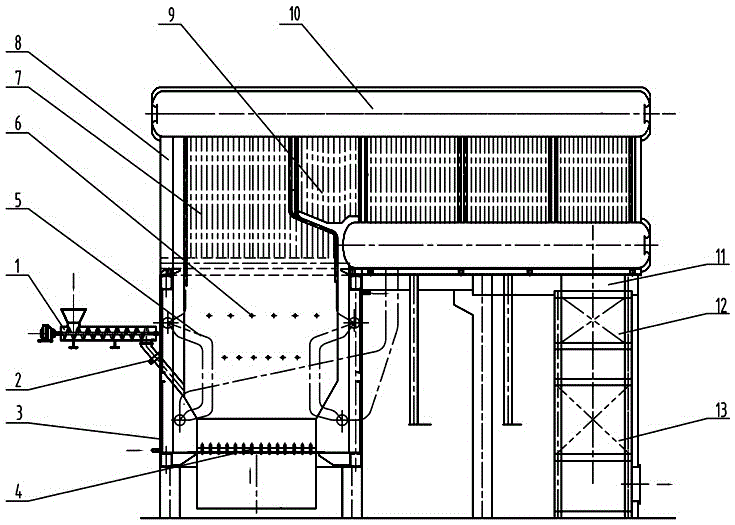

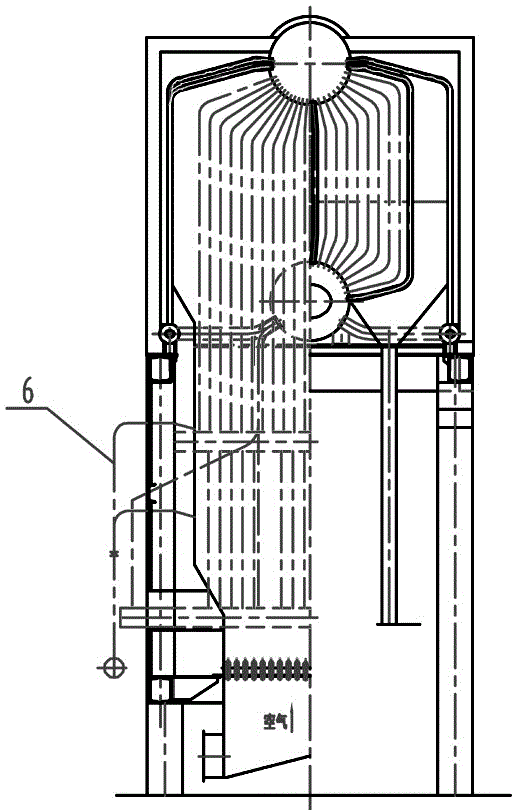

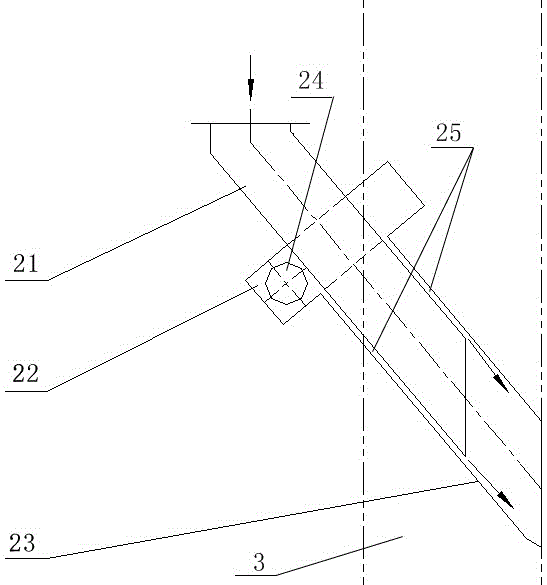

[0018] see Figure 1 to Figure 3 , the present invention comprises a feeder 1; an anti-tempering feeding device 2; a low water-cooled interlayer 3; a fluidized bed 4; a lower furnace and buried pipe 5; layer 8; internal circulation ember chamber 9; pressure body 10; connecting flue 11; economizer 12; air preheater 13. The economizer 12 and the air preheater 13 are arranged below the tail of the boiler. The anti-tempering feeding device 2 includes a feed pipe 21 and a jacket 23, an air supply interlayer 25 is formed between the jacket and the feed pipe, the jacket 23 is provided with a flanged air supply disk 22, and the air supply disk 22 is provided with Air supply hole 24.

[0019] The lower part of the furnace 15 is provided with a low-level water-cooled interlayer 3 .

[0020] A flame angle 14 is provided below the upper flue gas outlet of the furnace 15 .

[0021] The upper flue gas outlet of the furnace 15 is provided with an internal circulation ember chamber 9 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com