Application of hydrogen fuel and rotary engine thereof

A rotary engine and hydrogen fuel technology, applied in the direction of combustion engines, internal combustion piston engines, engine components, etc., can solve problems such as no solution, engine backfire, power shortage, etc., to reduce energy consumption, increase mileage, and save energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

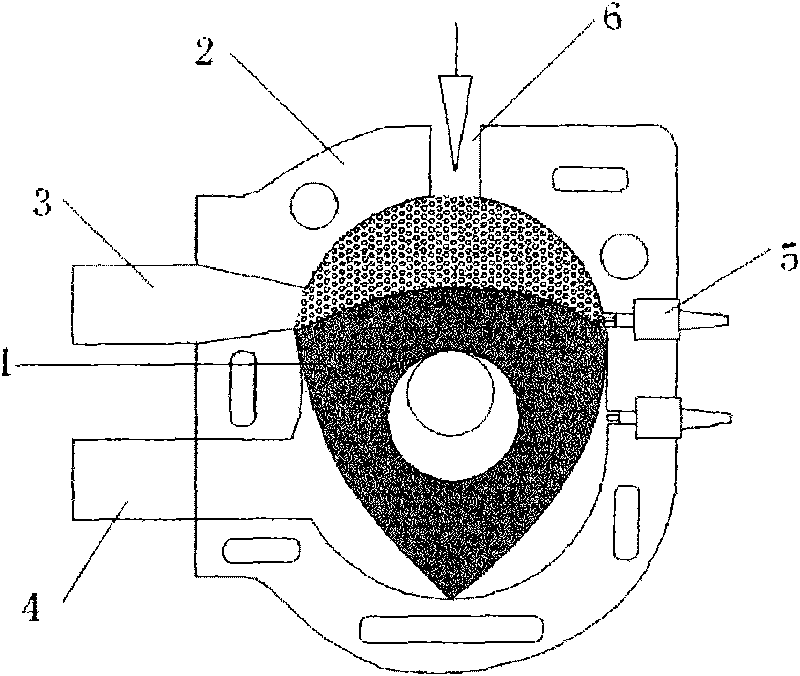

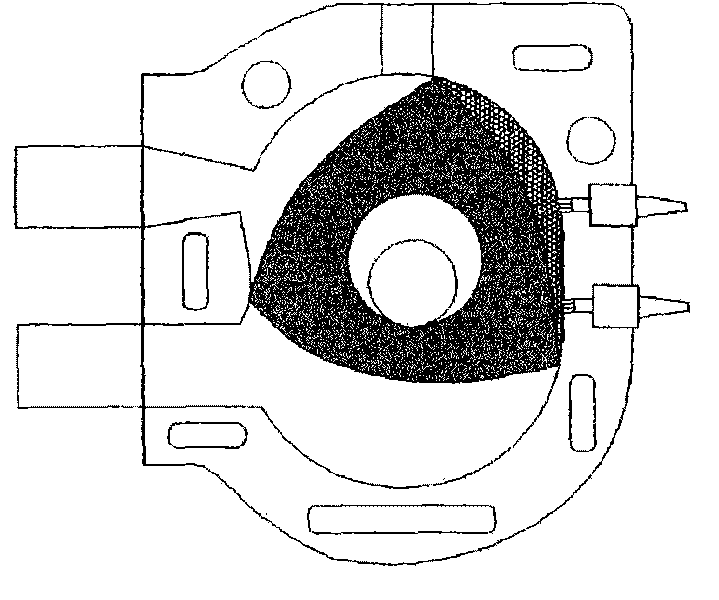

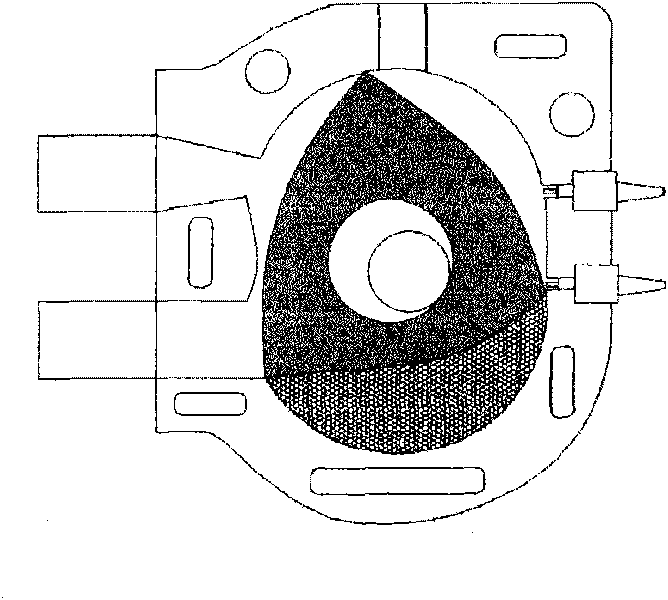

[0024] Such as figure 1 As shown, the hydrogen fuel rotary engine includes a rotor 1 and a housing 2, on which an air inlet 3 and an exhaust port 4 are opened, and two spark plugs 5 are also provided, which is the prior art. There is also a hydrogen inlet 6 on the casing, which is located on the top of the casing, and high-pressure hydrogen can be injected into the cylinder chamber formed by the rotor and the casing through the hydrogen inlet 6 at regular intervals, and the air is taken in from the casing. Port 3 is drawn into the cylinder chamber.

[0025] Such as Figure 5 As shown, the hydrogen gas injection device is connected to the hydrogen gas inlet through the pipeline. The injection device includes a hydrogen bottle 7, a hydrogen stabilized pressure rail 9, and the hydrogen cylinder 7 and the hydrogen stabilized pressure rail 9 are connected through pipelines; the hydrogen stabilized pressure rail is provided with an injection valve 10, and the injection valve is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com